Automatic quenching oil groove and quenching method by utilizing automatic quenching oil groove

A quenching oil tank and quenching oil technology, applied in quenching devices, heat treatment equipment, manufacturing tools, etc., can solve problems such as failure to meet quenching quality requirements, operator burns, low quenching hardness, etc., to achieve high work efficiency, simple operation, Good quenching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

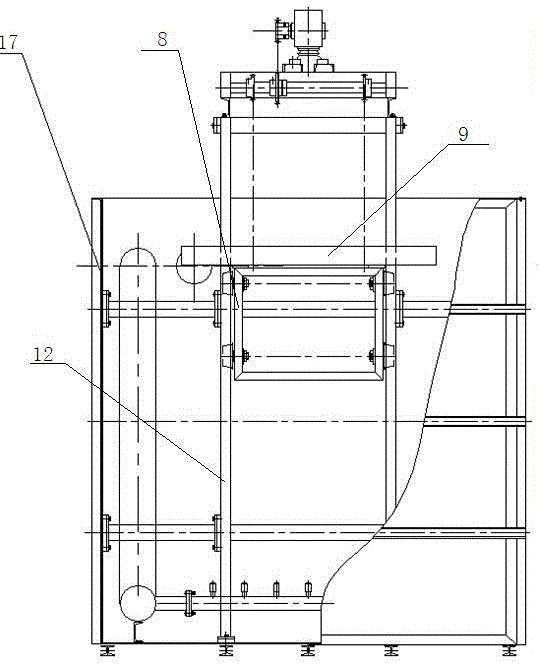

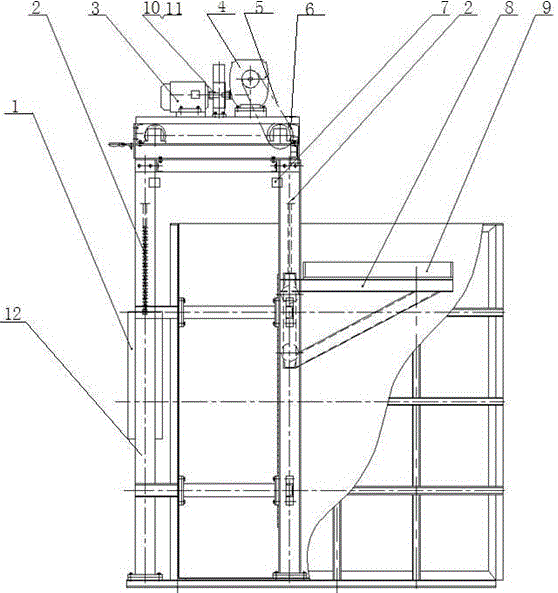

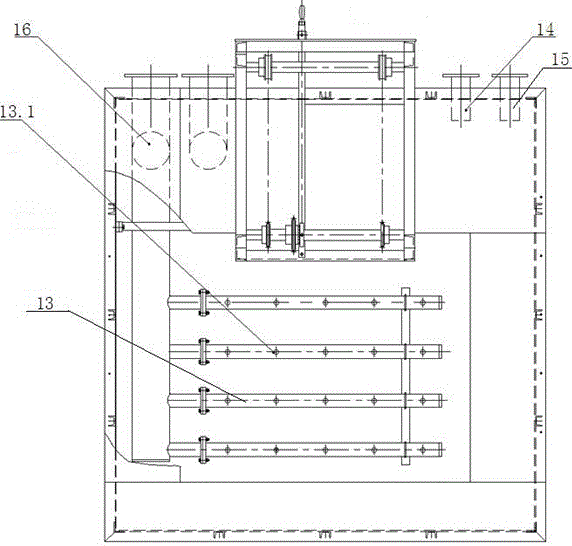

[0029] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0030] An automatic quenching oil tank, including the tank body 17. The overall structure of the tank body 17 is square, which is welded and fixed by Q235 steel plate and channel steel. It has high structural strength and long service life. When in use, the tank body 17 is half placed Below the ground, it is convenient to operate and saves operating space.

[0031] The lifting mechanism includes a motor 3 and a reducer 4 positioned at the top of the bracket 12, the reducer 4 drives the first output shaft to rotate through the first chain transmission mechanism 4, and the second sprocket 6 is arranged on the first output shaft , the second sprocket 6 meshes with the second chain 2 surrounding the bracket 12 . The material holding mechanism includes a material tray 9 for placing workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com