Quenching process and device for low-impurity ultra-low-carbon stainless steel

A quenching device and ultra-low carbon technology, applied in the direction of quenching device, quenching agent, manufacturing tools, etc., can solve the problems that the rigidity and hardness of the product cannot reach the expected situation, the quenching method is not good enough, and the quenching efficiency is low, etc. Short contact time, improve quenching effect, improve quenching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

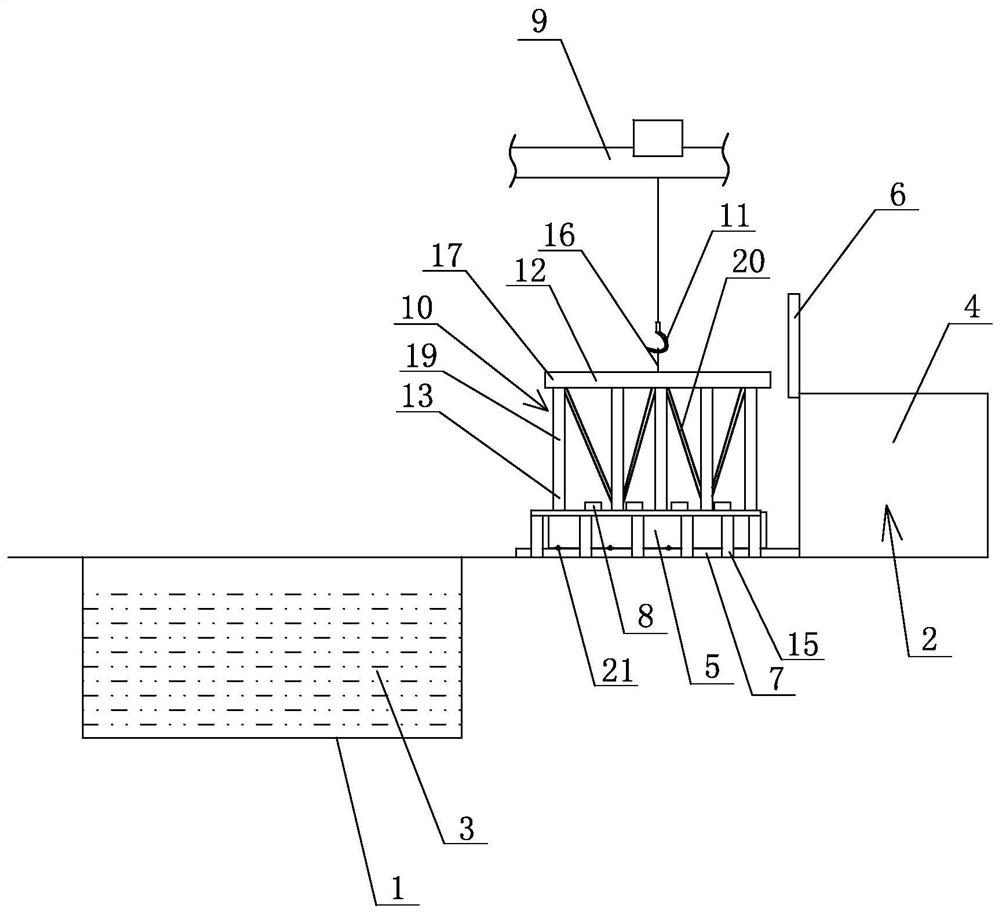

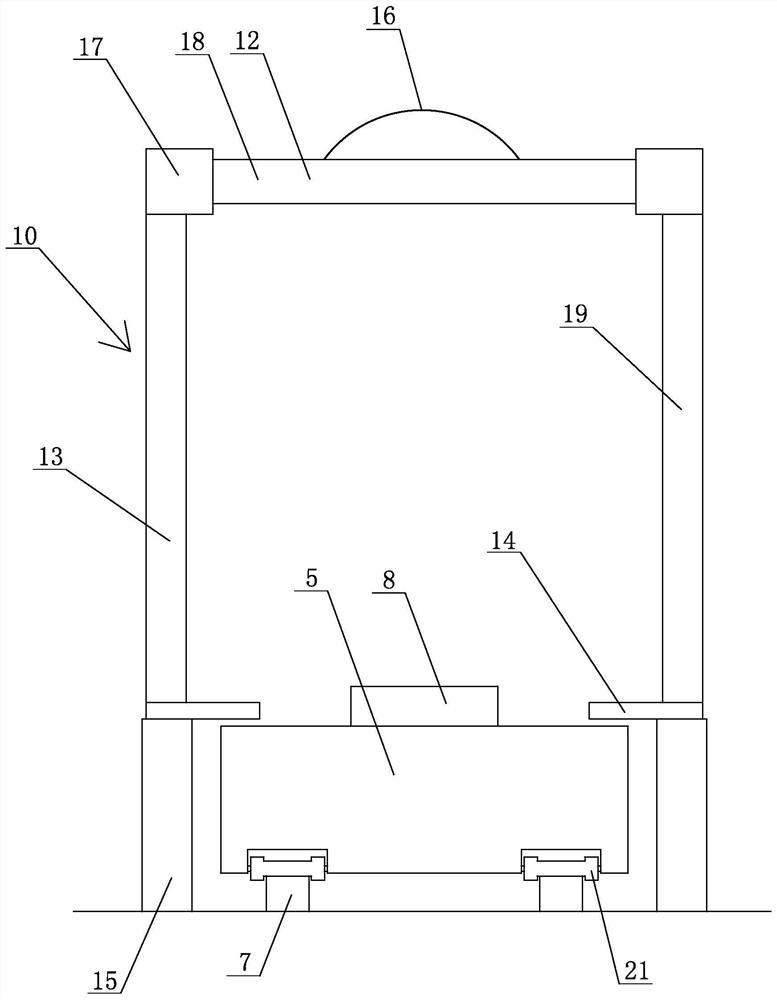

[0029] Embodiment one: see figure 1 , 2 As shown, a low-impurity ultra-low carbon stainless steel quenching process, the steps are:

[0030] ① Put the billet into the heating furnace and heat it to 1060℃~1200℃;

[0031] ② Then pull out the sliding seat at the bottom of the heating furnace. During the process of pulling out the sliding seat, the two sides of the bottom of the blank will slide to the two sides of the hanging basket, so that the hanging basket can lift the blank;

[0032] ③ Use the crane to lift the hanging basket. During the lifting process of the hanging basket, the hanging basket can be used to lift the billet and make it out of the sliding seat of the heating furnace;

[0033] ④ Drop to move the billet to the top of the quenching pool, and then lower the billet, so that the high-temperature billet is put into the quenching oil in the quenching pool, and the billet is completely sunk in the quenching oil for quenching work;

[0034] ⑤The initial temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com