Method for preventing slender tubular component from burning in oil quenching of heat treatment

A technology of heat treatment oil and heat treatment furnace, which is applied in the field of heat treatment, can solve the problems of air pressure rise and danger, etc., and achieve the effect of eliminating fire, ensuring the quenching effect, and eliminating the danger of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The material of the cap-shaped plug in the implementation can be selected from any steel material without affecting the normal quenching of the parts, but generally speaking, it is best to choose the same material as the parts.

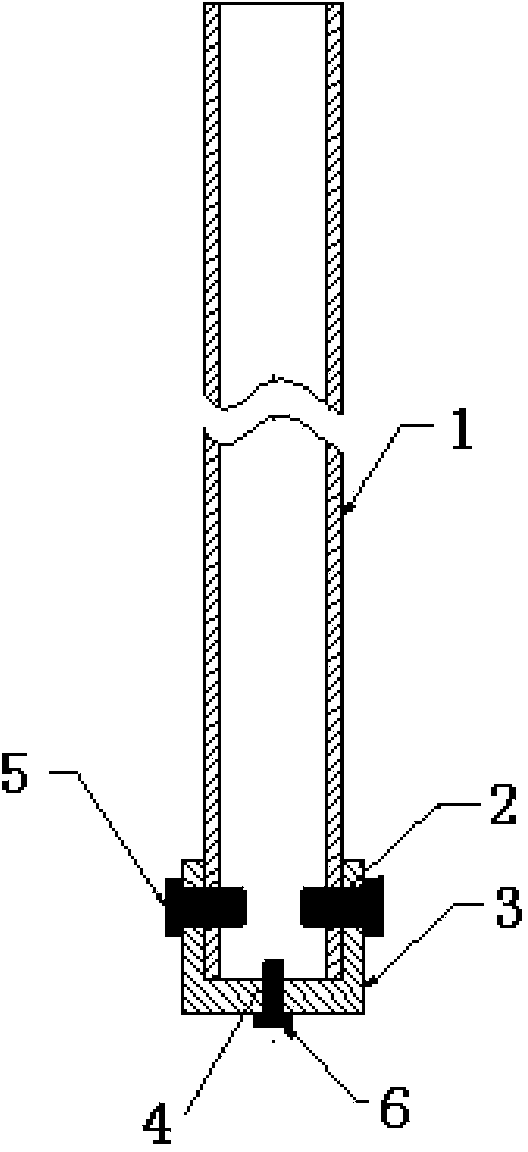

[0010] Referring to the accompanying drawings, there is a cap-shaped plug 3 matching the nozzle diameter of the elongated tubular part 1, the side wall of the plug is provided with a connecting hole 2, and the bottom of the plug is provided with an oil leakage hole 4; Before heat treatment and oil quenching, fasten the cap-shaped plug 3 to the nozzle at one end of the part, the side wall of the plug is fixed on the side wall of the nozzle of the part 1 with the connecting piece 5, and the drain at the bottom of the plug is connected with the bolt 6 On the oil hole 4, block the oil leakage hole 4; hang the part 1 vertically in the heat treatment furnace with the nozzle end of the cap-shaped plug 3 facing down; after the quenching is completed, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com