Device and method for removing oil stain in high-frequency quenching liquid for steering gear

A technology of high-frequency quenching and steering gear, which is applied in the direction of quenching devices, chemical instruments and methods, and separation methods, which can solve the problems of wasting labor resources, increasing production costs, and failing to achieve results, and achieve labor cost savings and production efficiency High, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

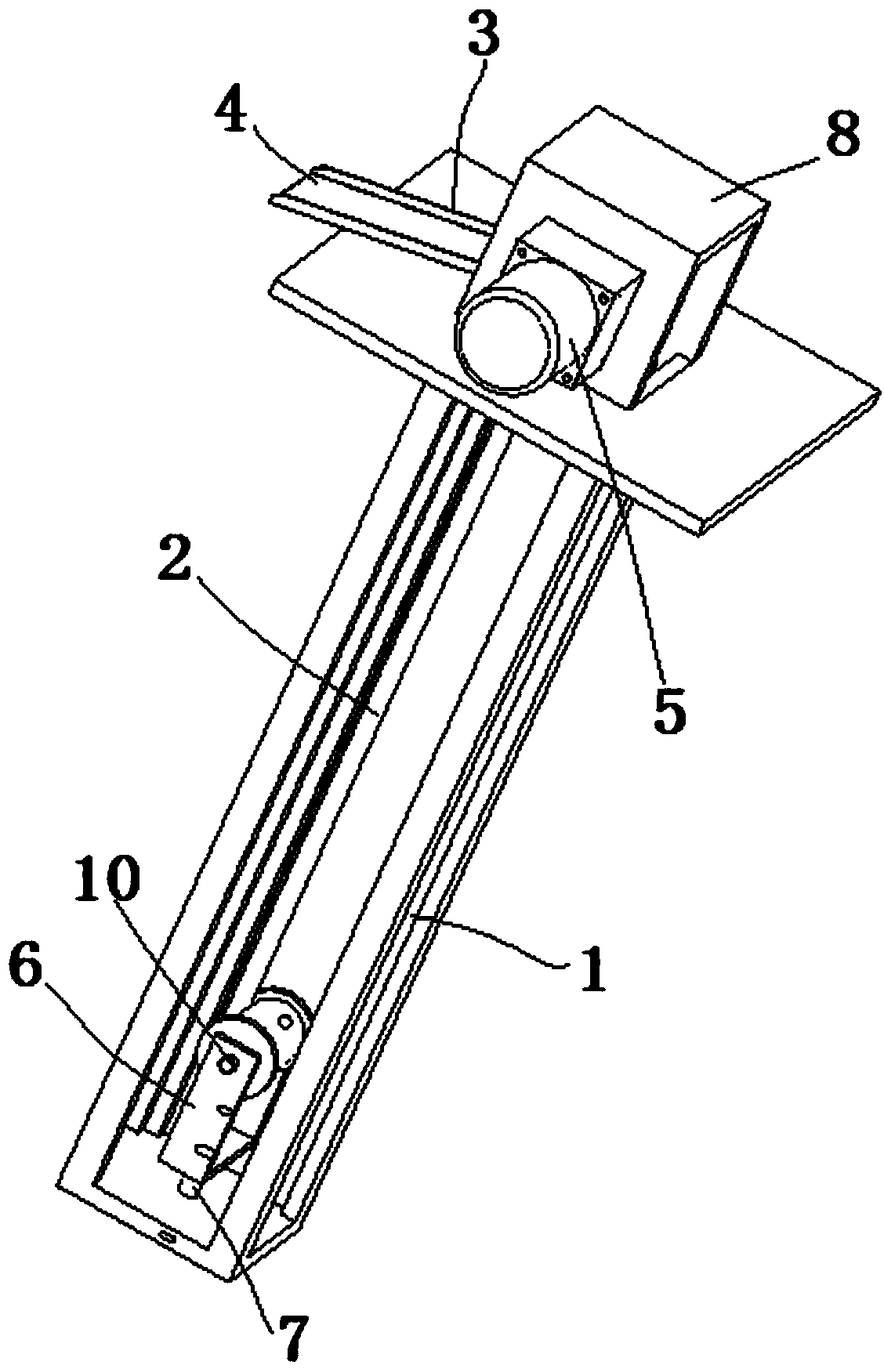

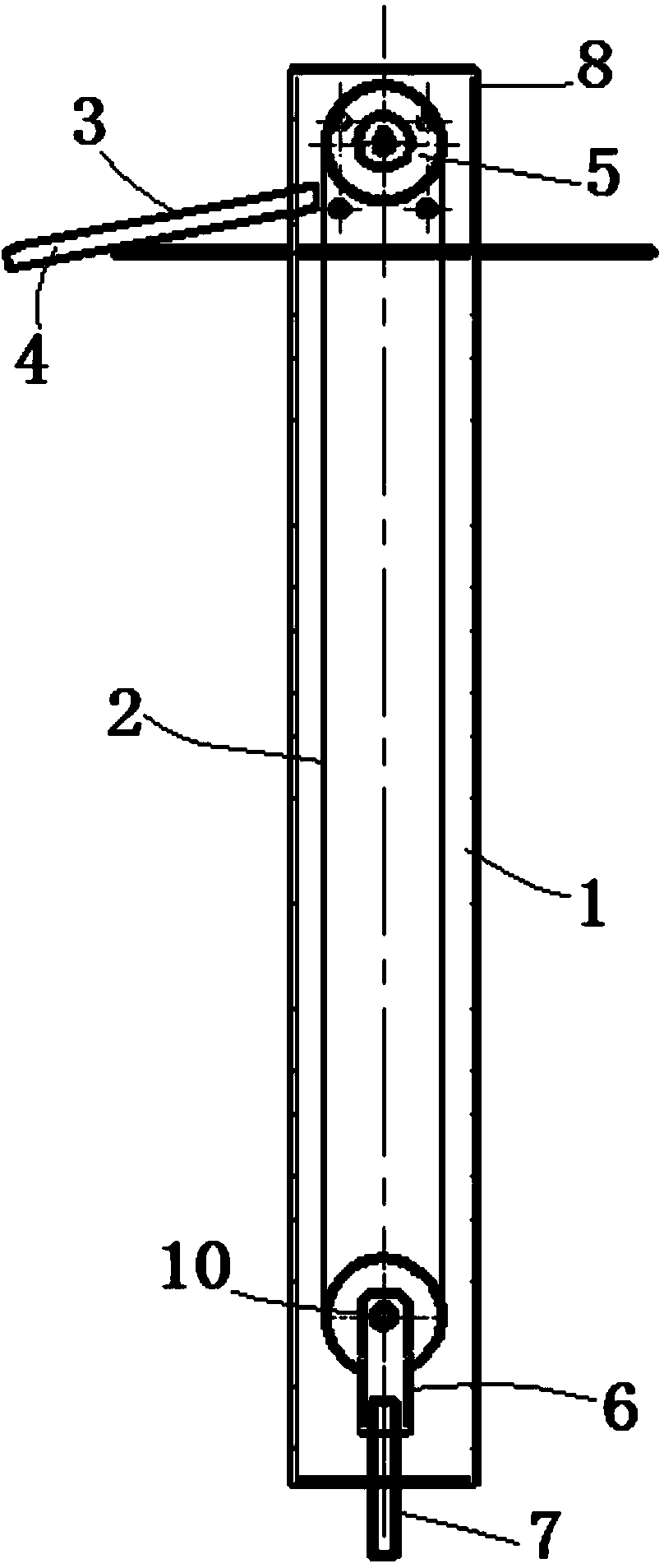

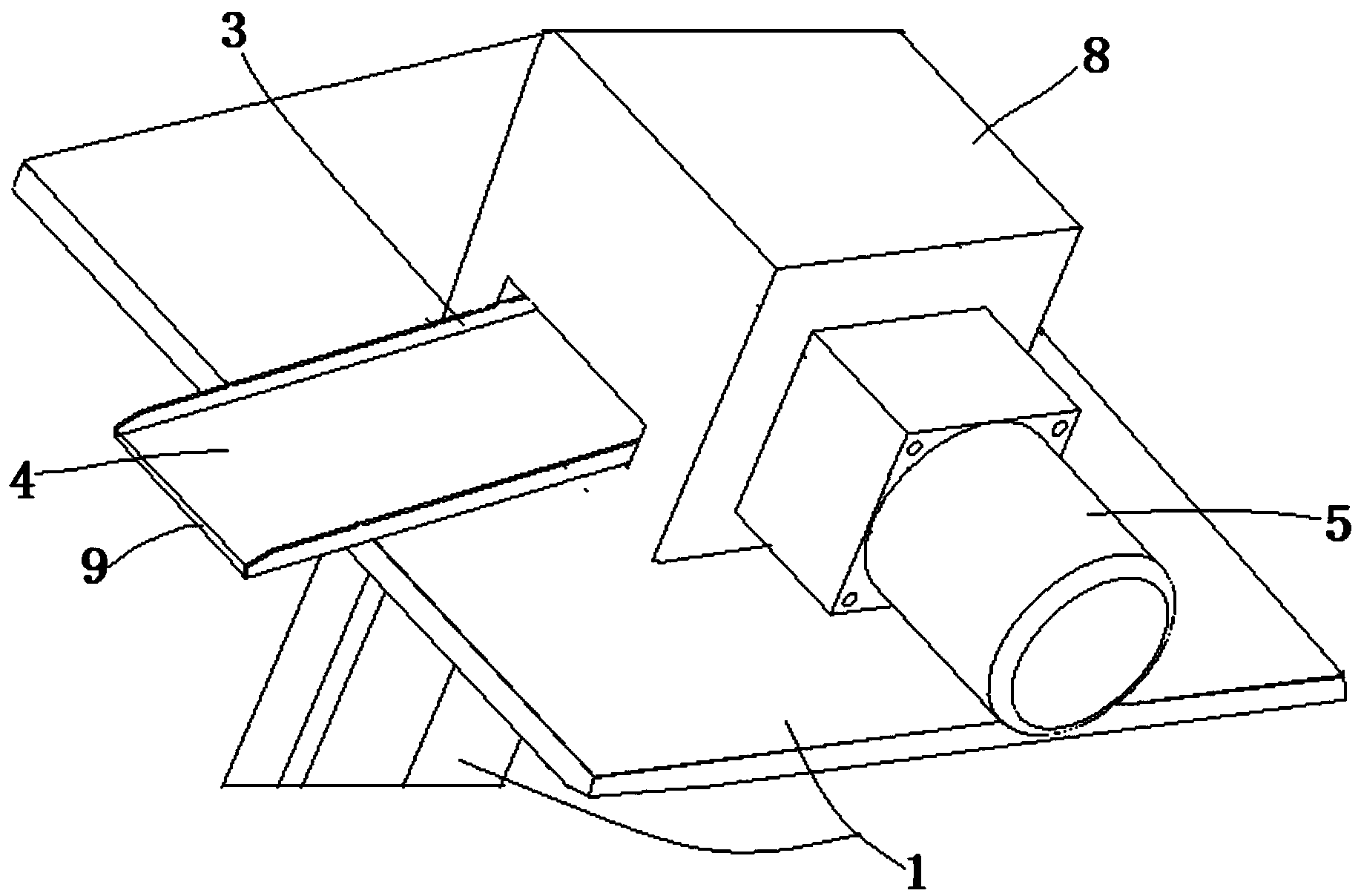

[0024] Such as Figure 1 to Figure 3 As shown, the high-frequency quenching liquid oil removal device for the steering gear includes a fixed frame 1 and a conveyor belt 2 immersed in the quenching liquid. The fixed frame 1 plays a role of fixed support. Preferably, the fixed frame 1 is made of stainless steel; the fixed frame 1 is provided with a scraper 3 for scraping off the oil on the conveyor belt 2. One end of the scraper 3 for scraping oil is located outside the conveyor belt 2, and the other end of the scraper 3 is the oil output end 4; during the movement of the conveyor belt 2, the scraper After the plate 3 scrapes off the oil stain on the surface of the conveyor belt 2, the oil stain is output through the oil stain output port 4; the pulley on one end of the conveyor belt 2 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com