Binding method of rotary target material

A technology of rotating target and target material, which is applied in metal material coating process, ion implantation plating, coating, etc., which can solve the problem of high employee proficiency requirements, poor control of binding uniformity and binding quality, labor High strength and other problems, to reduce the risk of burns, reduce the labor intensity of workers, and achieve the effect of high automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

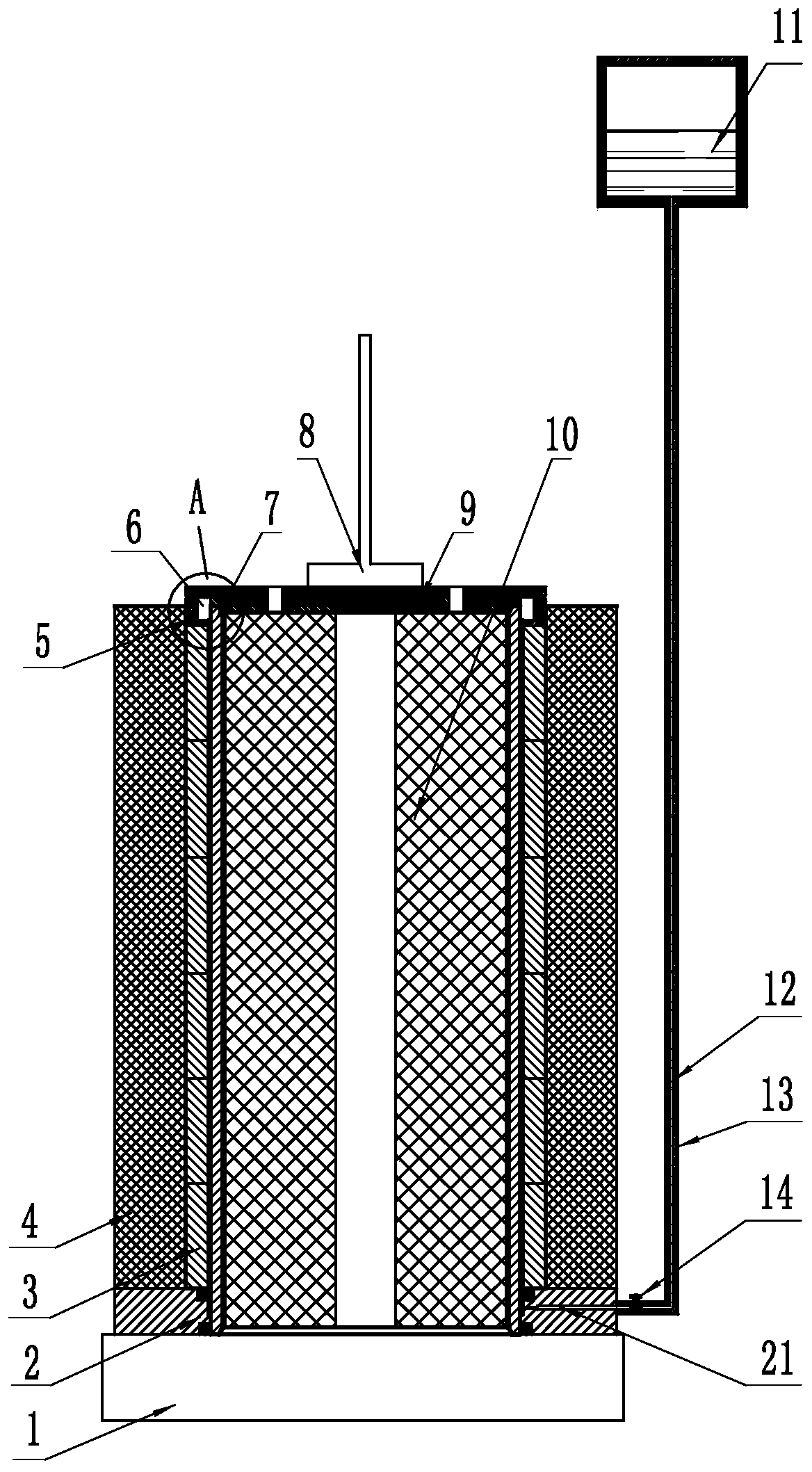

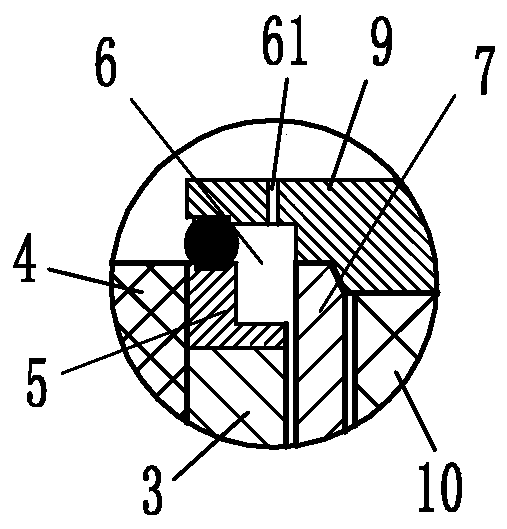

[0027] A method for binding a rotating target, the back tube is a metal tube titanium tube, the target is an ITO ceramic tube target, and the binding device used includes a heating platform 1, a mold base 2, an external heating device 4, an internal heating device 10, The upper end cover 9, the target pressing block 5, the pressure rod 8, the indium tank 11 and the indium tank heating device, the base of the mold is ring-shaped, and an indium inlet channel 21 is opened on it, and the indium tank and the indium inlet channel are connected through an indium pipe 12 A pipeline heating device 13 is arranged outside the indium pipeline, that is, a flexible heating belt is wrapped outside the indium pipeline, and a valve 14 is arranged on the indium pipeline. The external heating device is a heating jacket with segmental heating function.

[0028] The steps of the method are as follows: respectively roughen the surface of the metal tube and the ceramic tube; then heat the target mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com