Precast rod handling system and control method thereof

A loading and unloading system and technology for preforms, which are applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of broken preforms, potential safety hazards in the loading and unloading process, and difficulty in manually loading and unloading rods, so as to reduce the risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

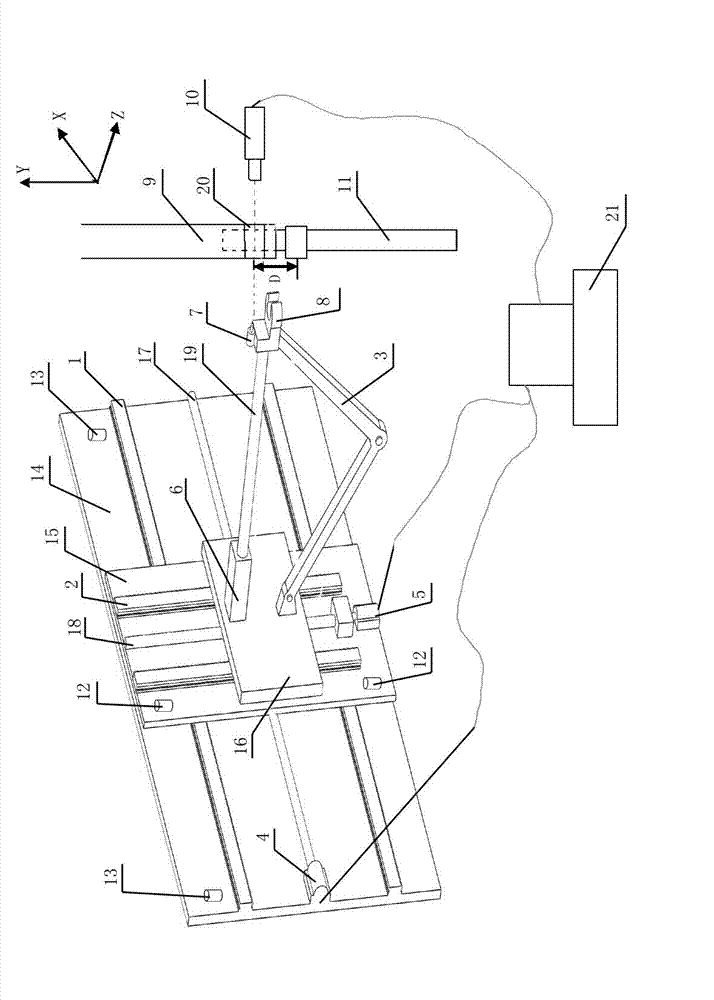

[0029] Refer to attached figure 1 , a preform loading and unloading system includes a three-way moving device, a control center and a preform lifting device; the three-way moving device includes an X-axis plate 14, an X-axis moving guide rail 1, an X-axis screw rod 17, and an X-axis Moving servo motor 4, Y-axis plate 15, Y-axis moving guide rail 2, Y-axis screw 18, Y-axis moving servo motor 5, Z-axis plate 16, Z-axis drive cylinder 6, Z-axis arm 3. Support bar bracket 8, transmitter 7 and receiver 10; two symmetrical X-axis moving guide rails 1 are installed on the X-axis plate 14, and an X-axis is installed between the two X-axis moving guide rails 1 To the screw rod 17, an X-axis moving servo motor 4 is installed at one end of the X-axis screw rod 17; the Y-axis plate 15 is vertically installed on the X-axis moving guide rail 1, and two Symmetrical Y-axis moving guide rails 2, a Y-axis screw rod 18 is installed between two Y-axis moving guide rails 2, and a Y-axis moving se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com