Pre-crosslinked black high-adhesion flame-retardant packaging adhesive film and preparation method thereof

An encapsulating film, high-bond technology, applied in the direction of non-polymer adhesive additives, adhesives, film/sheet adhesives, etc. Affect the appearance of components and other issues, to reduce the risk of combustion, increase adhesion, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

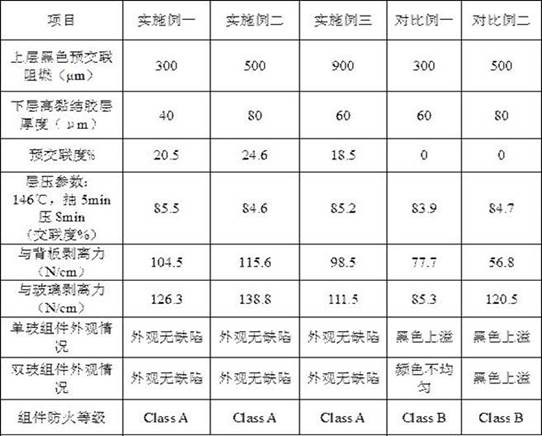

Examples

preparation example Construction

[0037] A method for preparing a pre-crosslinked black high-adhesion flame-retardant packaging film, characterized in that: the specific steps are as follows:

[0038] The first step: Acidify the expanded graphite to be used. The method is: in a three-necked flask, add expanded graphite with a liquid mass of 3%~5% to a 1mol / L acetic acid solution under stirring, and heat up to 80°C. After reacting for about 12 hours, wash with deionized water repeatedly until the pH value is neutral, and then dry at room temperature for at least 48 hours to constant weight to obtain acidified expanded graphite.

[0039] The second step: carry out surface modification treatment on molybdenum disulfide. The method is: in a three-necked flask, first heat ethanol to 60°C, then add water and coupling agent in turn according to the mass ratio under stirring, and add Add molybdenum disulfide after 1 minute, continue stirring at 60°C for 60 minutes, then distill ethanol at 70°C, and finally dry at 120°...

Embodiment 1

[0048] The first step is the formula design of the black flame retardant film layer:

[0049] Main material: ethylene-vinyl acetate copolymer (EVA), which is made by mixing EVA resin with 18% VA content and EVA resin with 26% VA content according to the weight ratio of 1:1.

[0050] Antioxidant: the main antioxidant is β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate, and the auxiliary antioxidant is triphenyl phosphite according to the weight ratio of 1: 2 ratio mix.

[0051] Cross-linking agent: the cross-linking curing agent is a compound of 2-ethylhexyl peroxide tert-butyl carbonate and ethyl 3,3-di(tert-butyl peroxy)butyrate; the auxiliary cross-linking agent is triallyl Hydroxyl isocyanurate, triallyl cyanurate and trimethylolpropane trimethacrylate are mixed in any proportion.

[0052] Silane coupling agent: Vinyl tris(β-methoxyethoxy) silane and vinyl triacetoxy silane are compounded at a molar ratio of 1:1.

[0053] Light stabilizer: bis(2,2,6,6-tetrameth...

Embodiment 2

[0067] The first step is the formula design of the black flame retardant film layer:

[0068] Main material: Ethylene-vinyl acetate copolymer (EVA), which is made by mixing EVA resin with 14% VA content and EVA resin with 26% VA content according to the weight ratio of 1:2.

[0069] Antioxidant: The main antioxidant is β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate, and the secondary antioxidant is tris(4-nonylphenol) phosphorous acid ester and tris(2,4-di-tert-butylphenyl)phosphite are mixed in any proportion.

[0070] Cross-linking agent: the cross-linking curing agent is a compound of tert-amyl peroxide 2-ethylhexyl carbonate and ethyl 3,3-di(tert-butylperoxy)butyrate; the auxiliary cross-linking agent is propoxylated pentaerythritol Tetraacrylate, triallyl cyanurate and trimethylolpropane trimethacrylate are mixed in any proportion.

[0071] Silane coupling agent: Vinyl tri(β-methoxyethoxy) silane and vinyl triacetoxy silane are compounded at a molar ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com