System for filling a vessel

A beverage container, filling height technology, applied in control/regulation systems, instruments, liquid distribution, etc., can solve problems such as insufficiency, achieve automatic filling improvement, achieve cost savings, and avoid garbage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

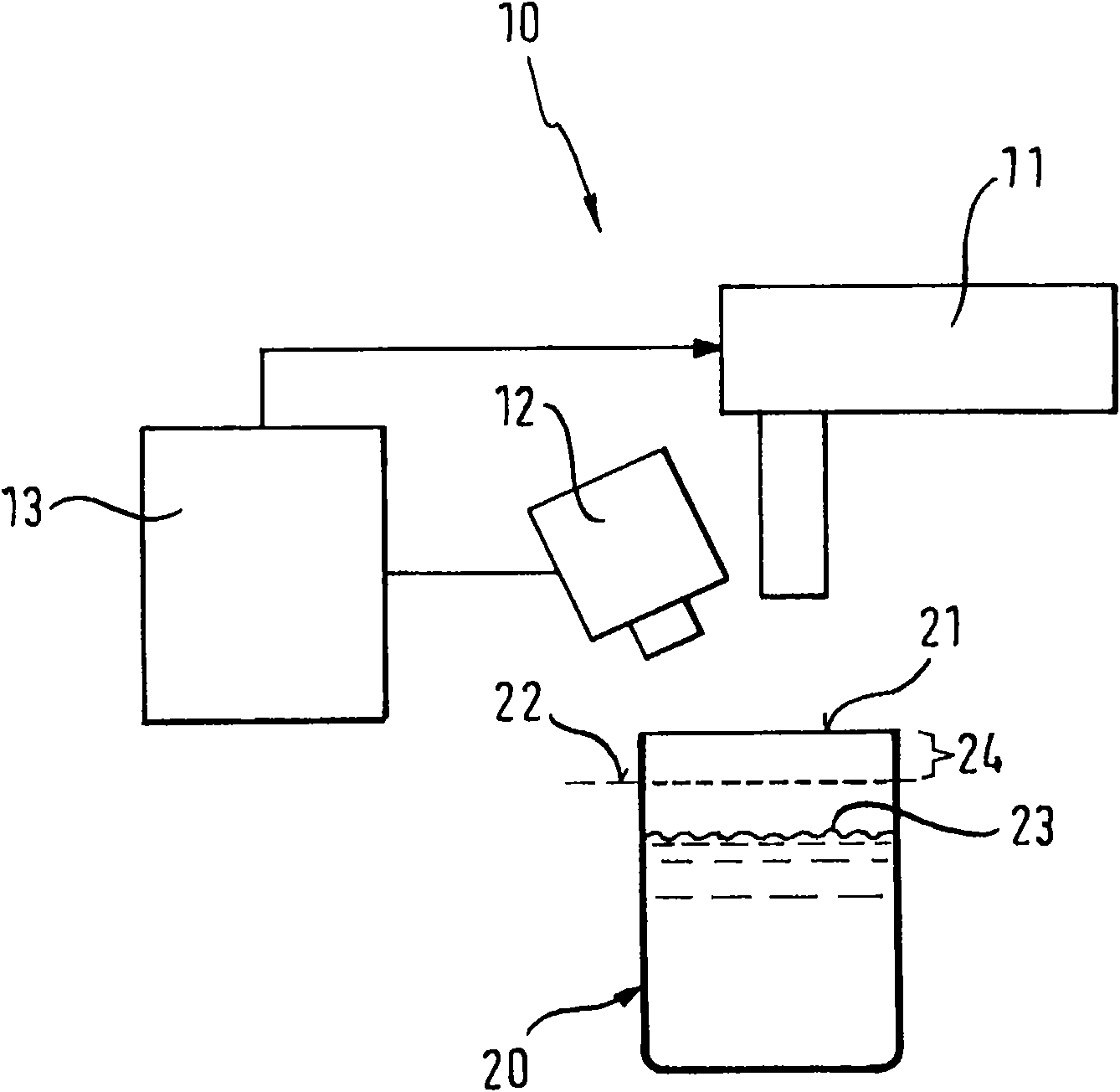

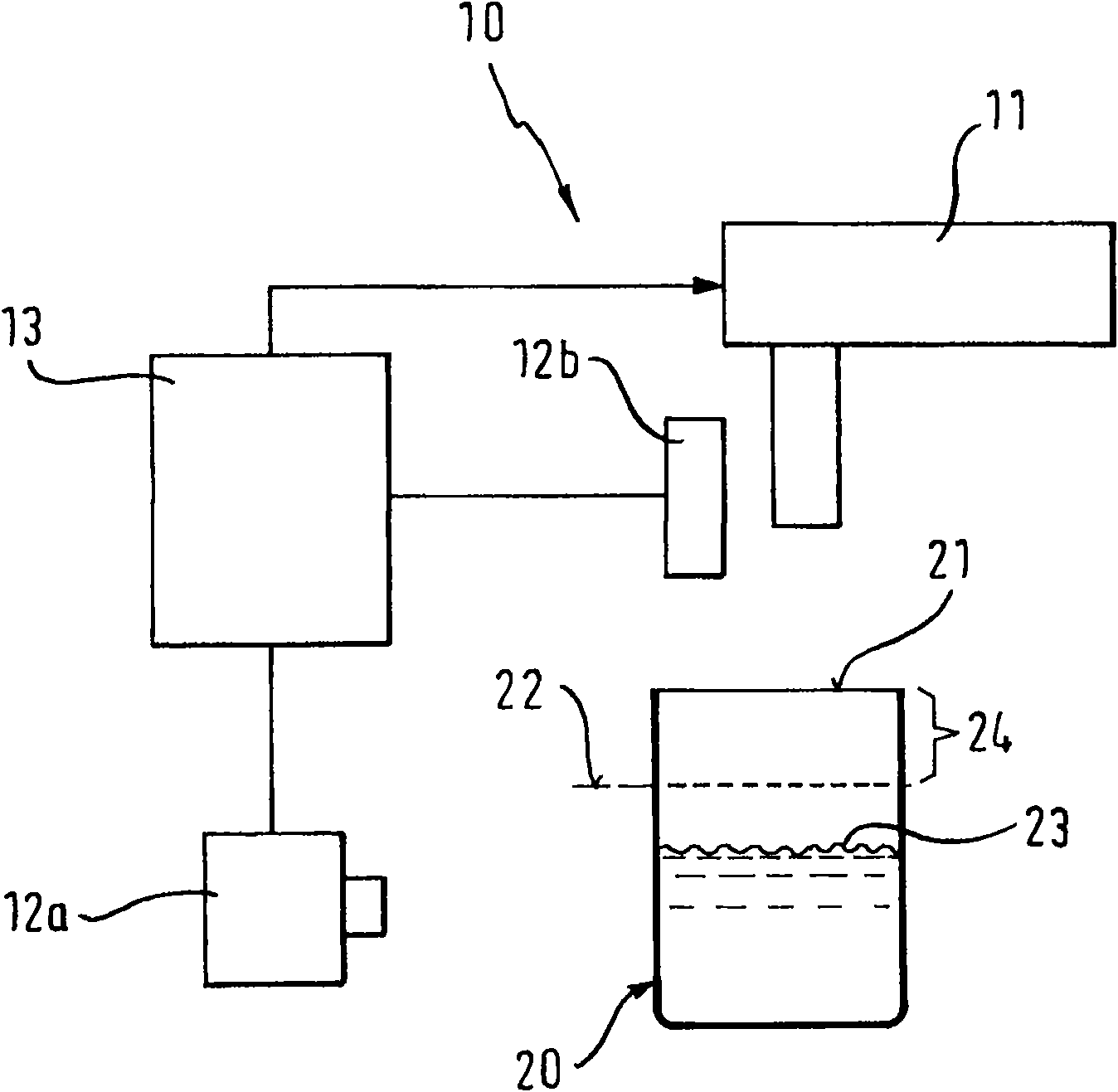

[0022] figure 1 One embodiment of a system 10 for filling beverage containers 20 is shown schematically. The system 10 has a measuring device 12 which detects a maximum filling level 21 of the beverage container 20 to be filled, which is defined by an upper edge 21 of the beverage container 20 , as well as a current actual filling level 23 . The measuring device 12 is a camera with an image recognition circuit, which stands obliquely above the beverage container 20 . The filling module 11 stands vertically above the beverage container 20 to be filled, whereas the measuring device 12 stands obliquely above the beverage container 20 . Furthermore, the system 10 has a control device 13 . The control device 13 automatically interrupts the filling process as soon as the current actual filling level 23 approximately coincides with a given theoretical filling level 22, wherein the theoretical filling level 22 is defined by a predetermined or individually definable distance from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com