Method for disassembling flexible screen and TP and clamp

A flexible screen and protective film technology, which is applied in hand-held devices, manufacturing tools, transportation and packaging, etc., can solve problems such as burns of operators, and achieve the effects of preventing energy waste, saving energy, and occupying less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In an embodiment of the present invention, a method for disassembling a foldable flexible screen and a TP includes the following steps:

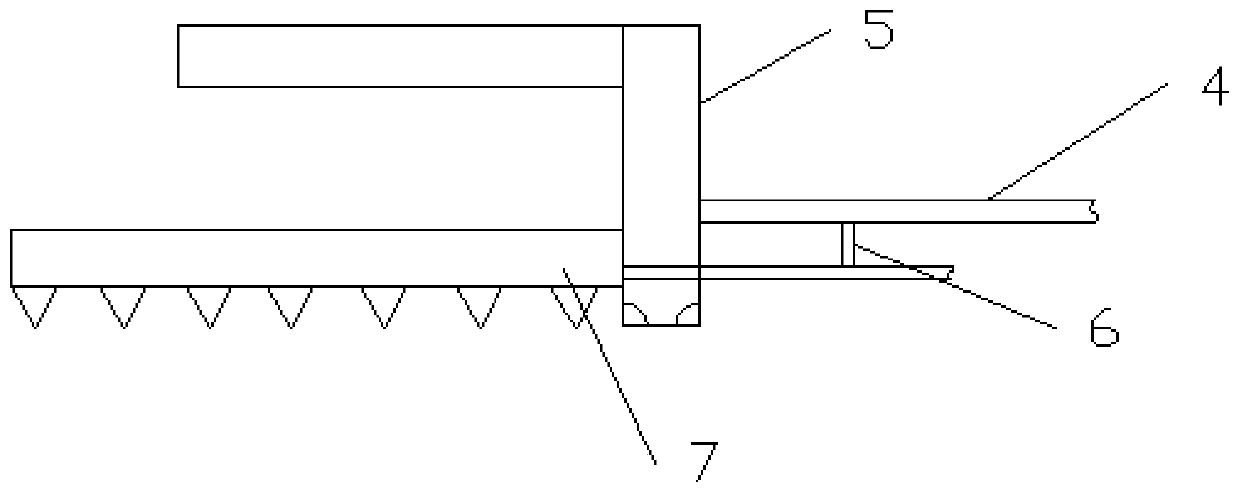

[0041] Figure 4 It is a schematic diagram of the front view structure of the heating equipment, TP, and flexible screen in the dismantling method of the flexible screen and TP, as shown in Figure 4 , S1. Place TP2 facing down on the heating platform, stick a hard protective film with a thickness of 0.5mm on the flexible screen 3, and ensure that the bonding is smooth and free of air bubbles;

[0042] S2, then use the heating device 1 to heat to 50 degrees, and keep the heating time for 2 minutes;

[0043]S3. Use a diamond wire with a diameter of 0.04mm to cut apart the flexible screen 3 and TP2, use the flexible screen and TP dismantling jig to support the flexible screen 3, remove the flexible screen 3, and turn it over so that the hard protective film faces Adsorb it on the heating platform, clean the residual glue, and then pro...

Embodiment 2

[0047] Figure 4 It is a schematic diagram of the front view structure of the heating equipment, TP, and flexible screen in the dismantling method of the flexible screen and TP, as shown in Figure 4 , S1. Put TP2 facing downwards on the heating platform, stick a hard protective film with a thickness of 1mm on the flexible screen 3, and ensure that the bonding is smooth and free of air bubbles;

[0048] S2, then use the heating device 1 to heat to 65 degrees, and keep the heating time for 3 minutes;

[0049] S3. Use a diamond wire with a diameter of 0.06mm to separate the flexible screen 3 from the mobile phone screen T, use the flexible screen and TP dismantling jig to support the flexible screen 3, remove the flexible screen 3, and turn it over to make the hard protective film Adsorb it face down on the heating platform, clean the residual glue, and then apply the protective film to TP2 to protect it. When applying the protective film, it is required to be flat and free of ...

Embodiment 3

[0054] Figure 4 It is a schematic diagram of the front view structure of the heating equipment, TP, and flexible screen in the dismantling method of the flexible screen and TP, as shown in Figure 4 , S1. Place TP2 facing down on the heating platform, and stick a hard protective film with a thickness of .5mm on the flexible screen 3, and ensure that the bonding is smooth and free of air bubbles;

[0055] S2, then use the heating device 1 to heat the heating platform, the heating temperature is 70 degrees, and the heating time is kept for 4 minutes;

[0056] S3. Use a diamond wire with a diameter of 0.07mm to separate the flexible screen 3 from the TP, use the flexible screen and TP dismantling jig to support the flexible screen 3, remove the flexible screen 3, and turn it over so that the hard protective film faces Adsorb it on the heating platform, clean the residual glue, and then protect the TP2 with a protective film. When applying the protective film, it is required to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com