Flat iron including evaporation chamber connected with scale recycle chamber of scale-removing hole

A recovery cavity and evaporation chamber technology, which is applied to hand irons, household utensils, washing devices, etc., can solve the problems of not being able to ensure the convenience of plug placement at the same time, the risk of large burns from the plug, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

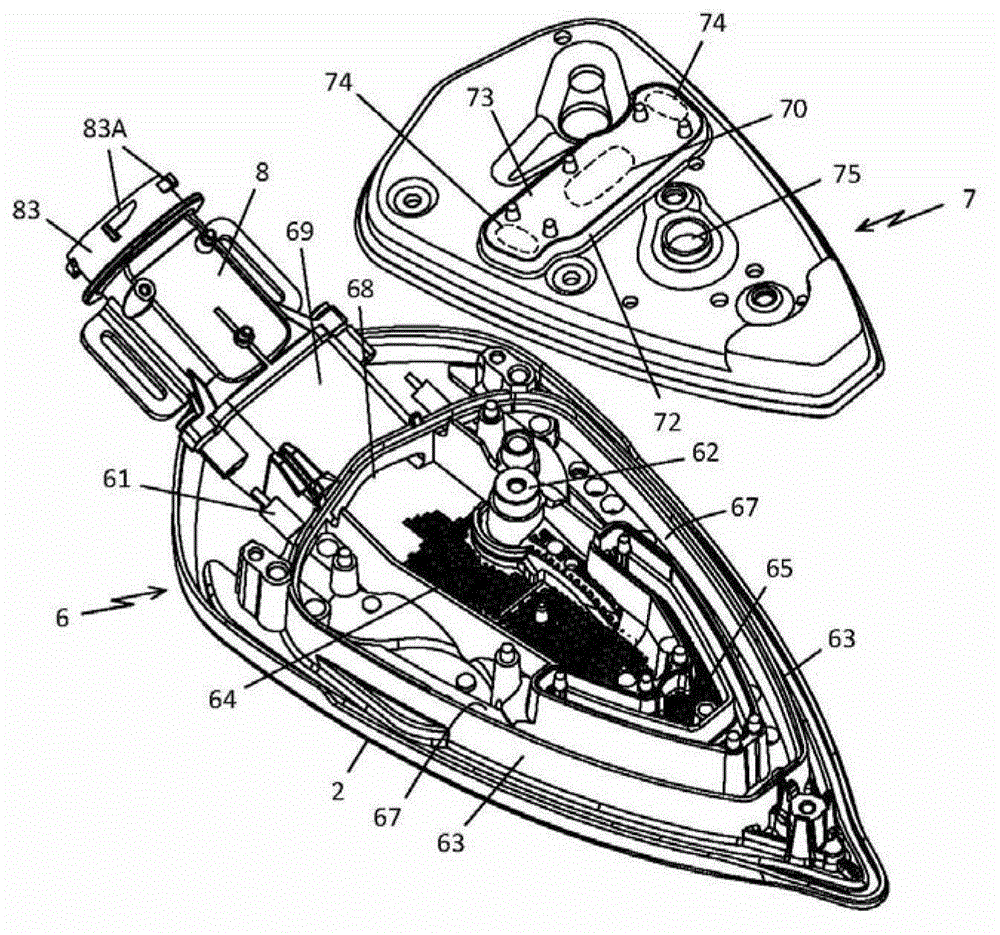

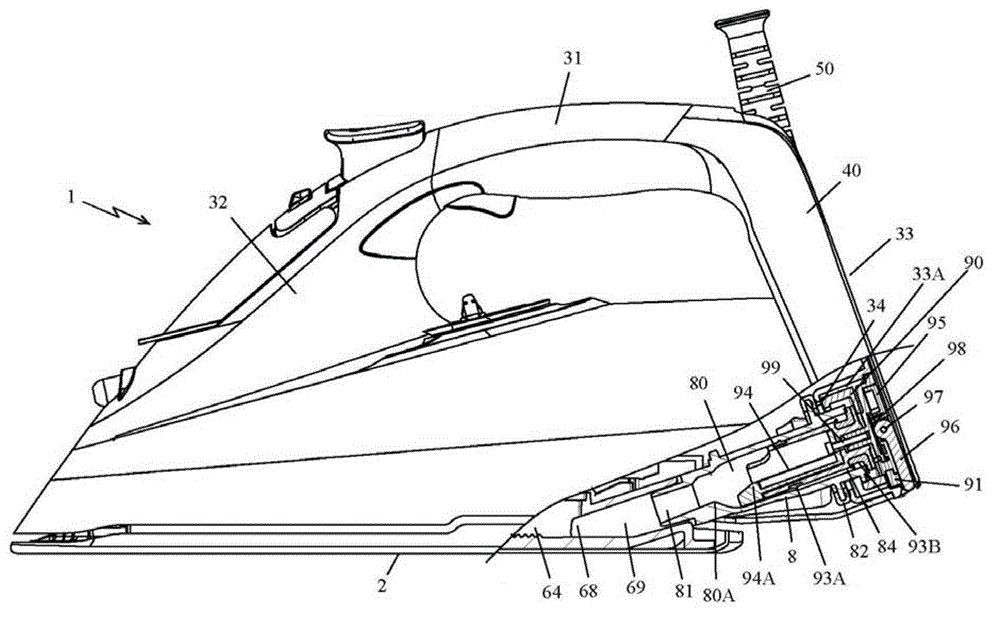

[0033] Only the components required to understand the invention are shown. In order to facilitate the reading of the drawings, the same components are given the same reference numerals in each figure.

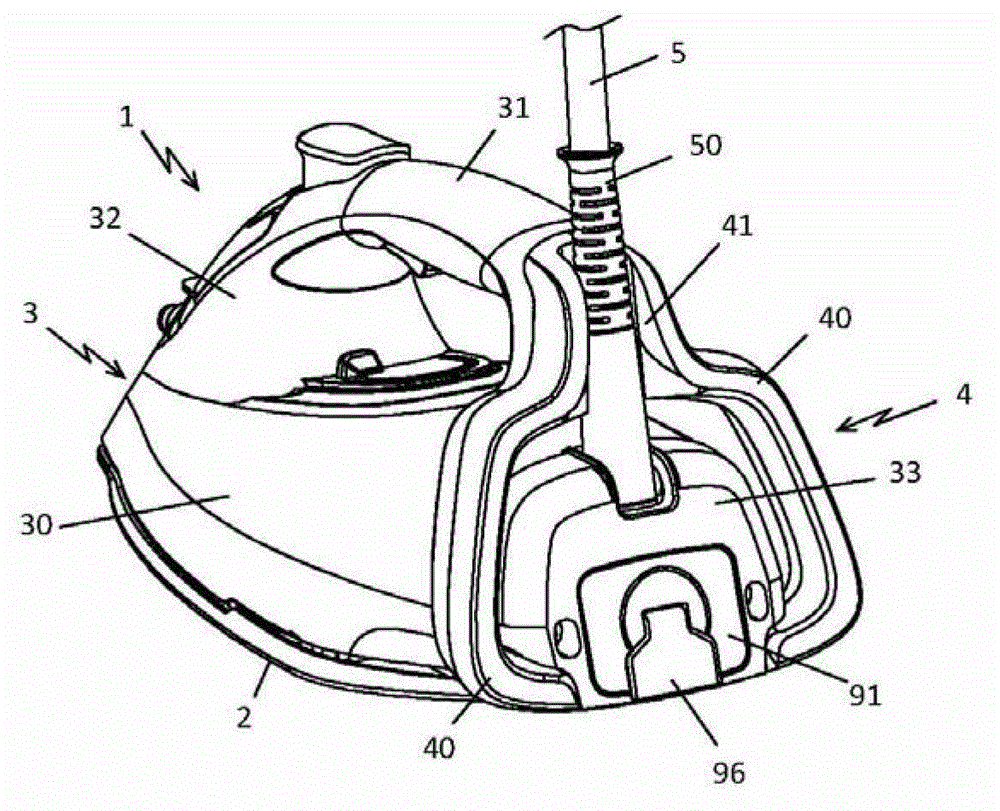

[0034] figure 1 A steam iron 1 is shown. The iron 1 includes a flat ironing soleplate 2. The soleplate 2 is equipped with a set of steam outlets (not shown). The soleplate 2 is equipped with a BMC hybrid plastic shell 3 and shell 3 There is a water container 30 inside, and the housing includes a gripping handle 31, which is connected to the front of the iron through feet 32 in a known manner, and the feet 32 extend the front end of the handle.

[0035] Preferably, the foot 32 at the front of the handle 31 is hollow so as to contain the parts of the iron, and the housing 3 includes a rear surface 33 which is connected to the inside of the base 4 in the non-working phase of ironing. , The iron can be placed approximately vertically using the base 4, which includes two arms 40 tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com