Automatic welding machine for welding of phase shifter

A technology of automatic welding machine and phase shifter, which is applied in the direction of welding/welding/cutting items, welding positions, welding equipment, etc., which can solve the problems of uneven technical level of welding personnel, slow assembly speed, and decreased work efficiency, and achieve Good use and promotion effect, good product consistency and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

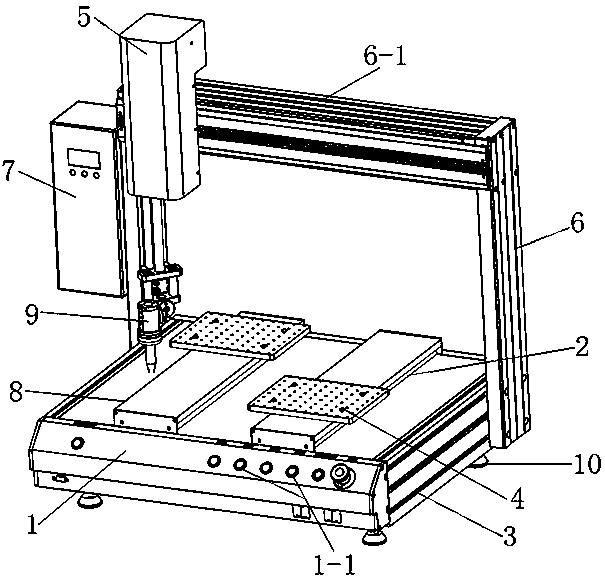

[0033] Refer to attached Figure 1-2 An automatic welding machine for phase shifter welding includes a base 1, an upper track 2 on the base, a side track 3 on the base, a welding tool 4, a welding arm 5, a welding arm bracket 6 and a control box 7; the base 1 is cube-shaped, The upper surface of the base 1 is provided with two equal-sized frock positioning bosses 8 parallel to the sides, and the base upper track 2 is arranged on both sides of the frock locating boss 8, above each frock locating boss 8. The welding tool 4 is provided, and the welding tool 4 is fixed on the tool positioning boss 8 by screws, or is movably installed on the tool positioning boss 8 by buckling the track 2 on the base, and can realize different size products by replacing the welding tool 4 Welding: base side rails 3 are arranged on both sides of base 1, and welding arm bracket 5 is slidably connected to base side rail 3. Rail 6-1 is slidably connected with welding arm 5 on welding arm slide rail 6-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com