Press-welding type electric soldering iron

A technology of electric soldering iron and soldering iron tip, applied in soldering iron, welding position, welding equipment and other directions, can solve the problems of inconvenient welding, low welding efficiency, and difficulty in grasping the flow of solder to the welding point, etc., to achieve strip edge welding, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment the present invention is further described:

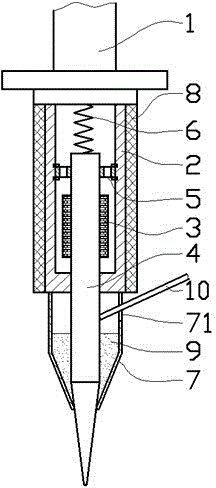

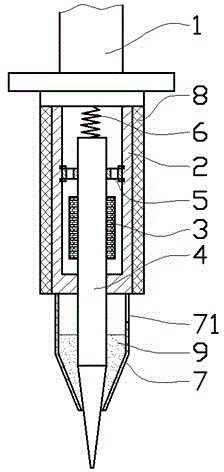

[0018] Such as figure 1 As shown in the embodiment, the pressure-welding electric soldering iron includes a handle 1, a shell 2, a soldering iron core 3, and a soldering iron tip 4; the shell 2 is cylindrical in shape and is assembled on the lower part of the handle 1; It is in the shape of a straight rod with a conical front end. A guide ring 5 is installed inside the housing 2. The soldering iron tip 4 can slide through the guide ring 5 and the lower part of the housing 2. The soldering iron core 3 is fixedly wrapped in the The outside of the soldering iron tip 4 uses the heating structure of an externally heated electric soldering iron. The soldering iron core 3 is formed by winding electric heating wires in parallel on a hollow porcelain tube. The mica sheet in the middle is insulated and leads to two The wire is connected with 220V AC power supply. The soldering iron core 3 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com