Flexible circuit board welding device

A technology of flexible circuit boards and welding devices, which is applied to welding positions, auxiliary devices, printed circuits, etc., can solve problems such as high temperature and easy burns to workers, and achieve the effects of shortening the interval time, avoiding burns, and improving processing efficiency

Inactive Publication Date: 2018-06-05

宁波隆锐机械制造有限公司

View PDF0 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Secondly, the temperature of the support plate is high after use, and it is easy to burn the workers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

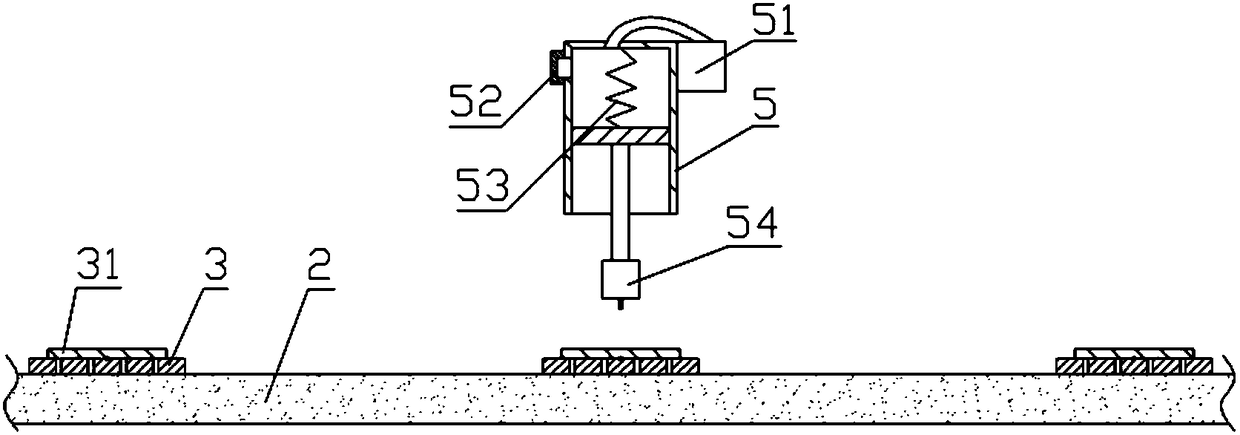

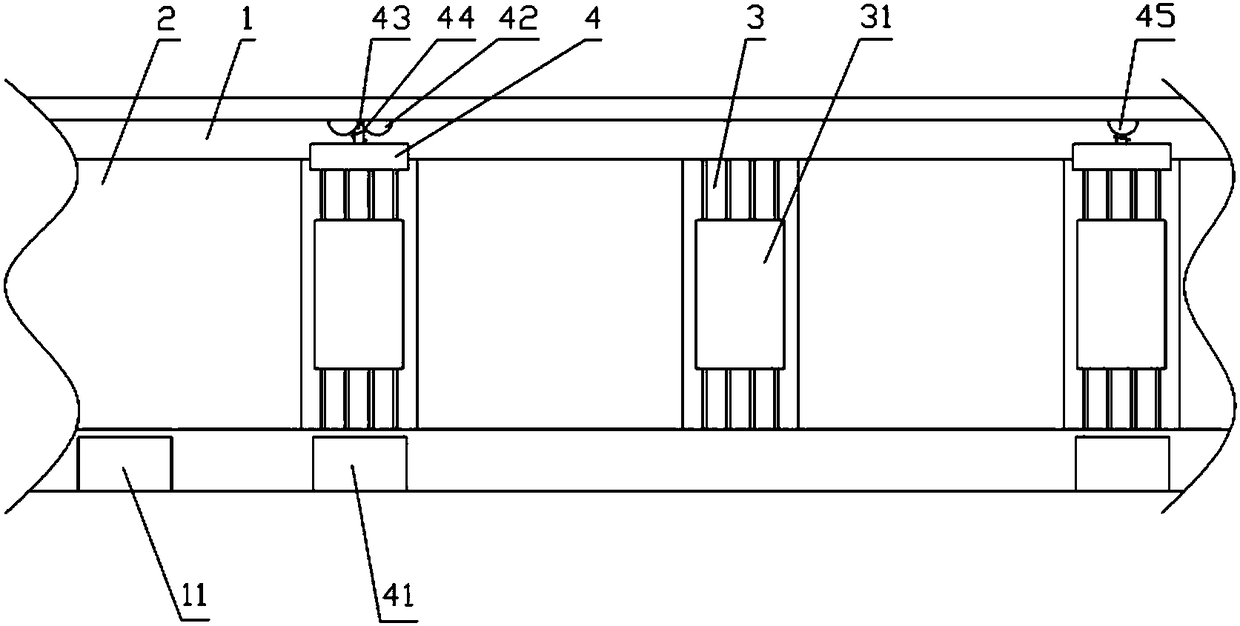

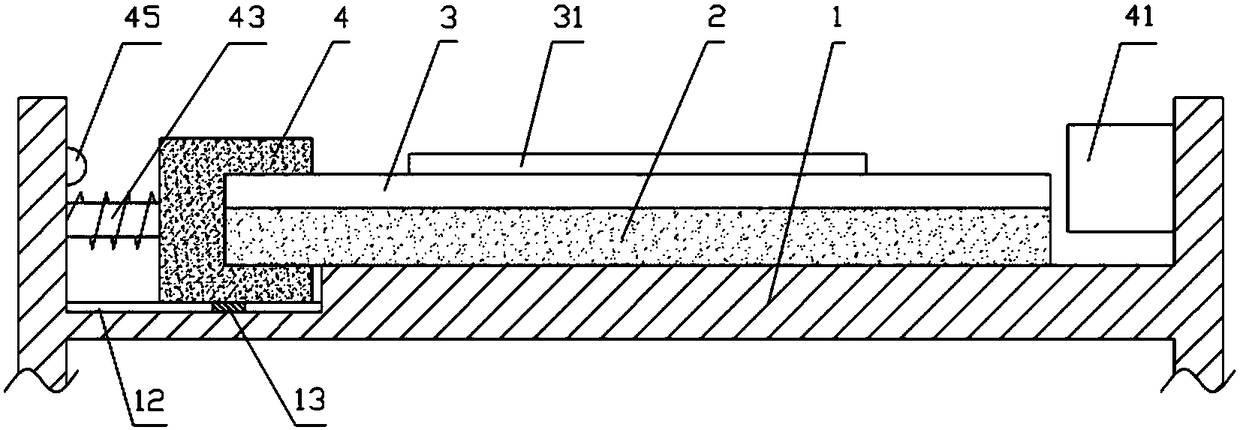

The invention relates to the field of circuit board production, and particularly discloses a flexible circuit board welding device comprising a machine frame, a cooling fan, a conveyor belt, a weldingmechanism and a control mechanism, wherein a supporting plate is fixed on the conveyor belt; the welding mechanism comprises an electric soldering iron, a cylinder and a welding fan; the cylinder isprovided with an exhaust port, and a returning spring is arranged in the cylinder; the control mechanism includes a stopping mechanism and a cooling mechanism, and the stopping mechanism and the cooling mechanism each include a cooling fan and an air bag, the air bag and the cooling fan are located on both sides of the conveyor belt respectively, the cooling fan is fixed on the machine frame, andthe air bag can slide relative to the machine frame. A first heated expansive substance is stored in the air bag of the stopping mechanism, a second heated expansive substance is stored in the air bagof the cooling mechanism, a closing switch is fixed on the machine frame, and the closing switch can shut down the conveyor belt and the welding fan, and the machine frame is provided with a compression spring. According to the scheme, the supporting plate can be cooled while a circuit board is welded.

Description

technical field [0001] The invention relates to the field of circuit board production, in particular to the field of flexible circuit board production. Background technique [0002] Circuit board, also known as printed circuit board, can gather a large number of electrical components together and provide them with electrical connections, and is an essential part of electronic components. The flexible circuit board is a kind of circuit board, which is a highly reliable and excellent flexible circuit board made of polyimide or polyester film as the base material. It is mainly used in many products such as mobile phones, notebook computers, PDAs, digital cameras, and LCMs. [0003] During the production process of the flexible circuit board, the circuit board needs to be soldered. When welding, a support plate needs to be installed under the circuit board. The support plate supports the circuit board and the electric soldering iron to prevent the electric soldering iron from e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K3/02B23K3/08B23K37/047B23K101/42

CPCB23K3/087B23K3/026B23K3/085B23K37/047

Inventor 王健

Owner 宁波隆锐机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com