Pipe arrangement machine with function of distinguishing colors of bobbins

A management machine and yarn tube technology, applied in the field of management machine, can solve the problems of high processing cost and complex structure, and achieve the effect of low manufacturing and processing cost and simple structure of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

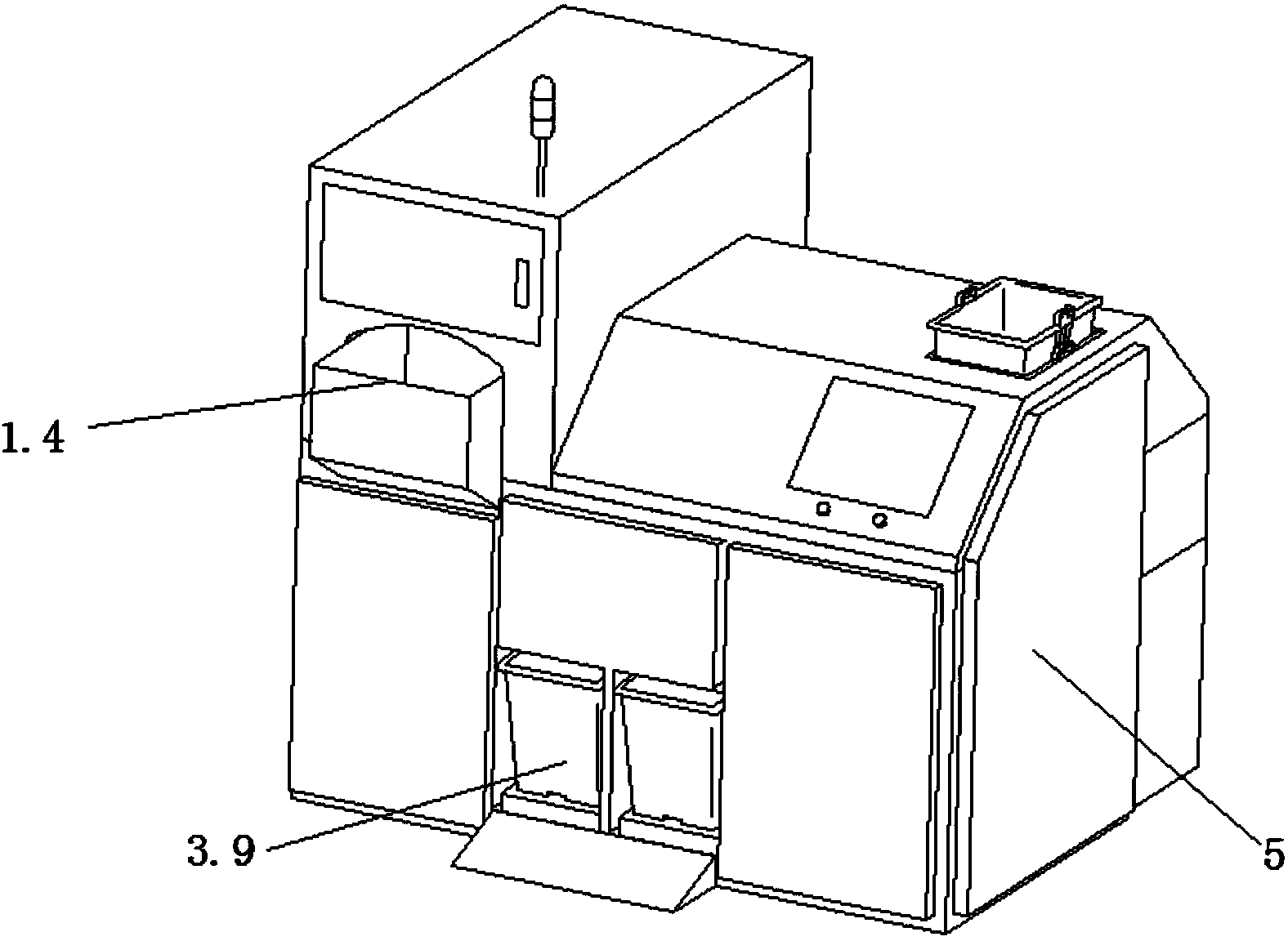

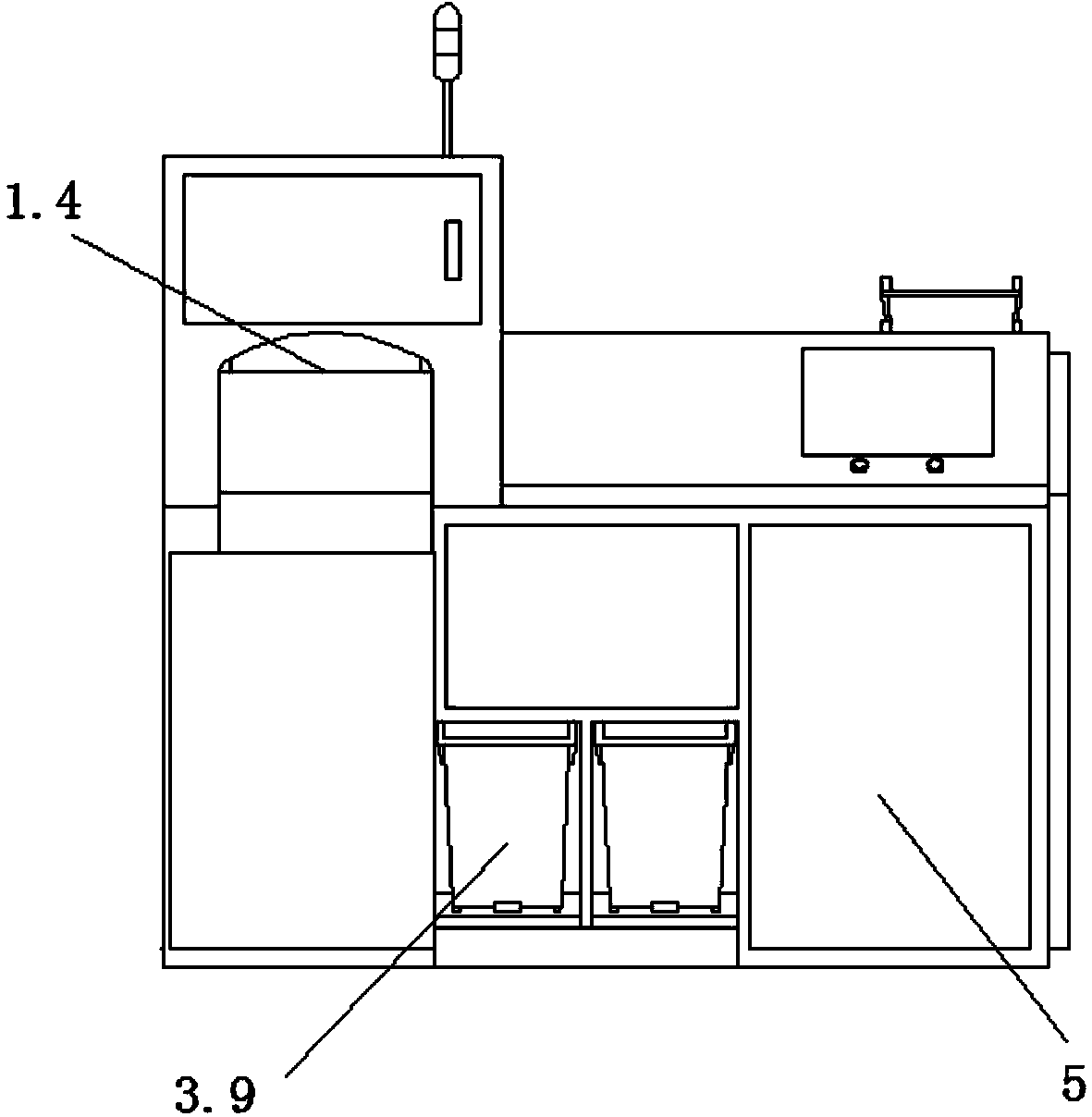

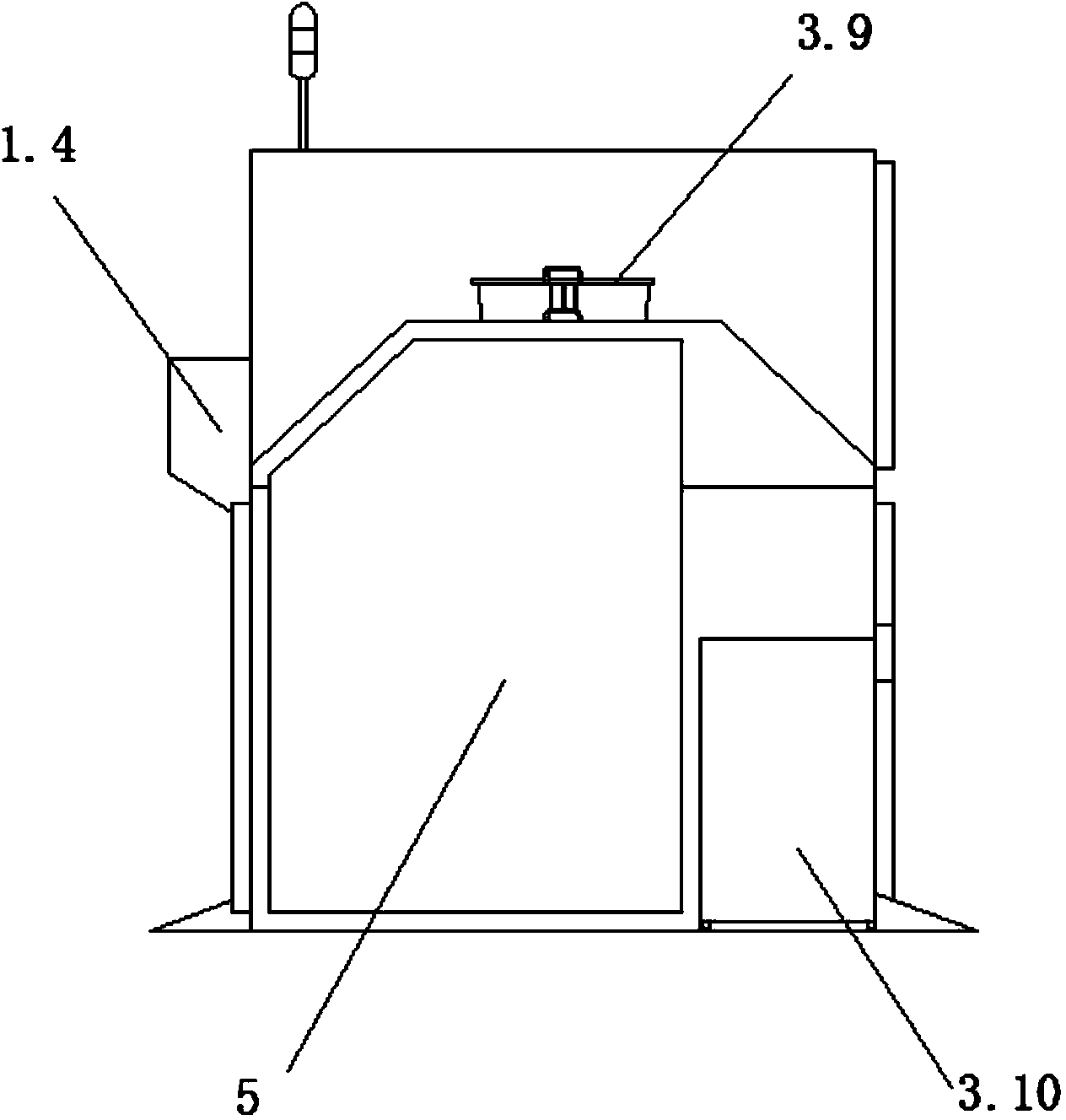

[0074] Such as Figure 1-11 As shown, a management machine with the function of distinguishing the color of bobbins according to the present invention includes a pipe storage mechanism 1 , a sorting and turning mechanism 2 , a frame 4 and a casing 5 .

[0075] Such as Figure 12-14 As shown, the storage tube mechanism 1 includes a hoist 1.1, a lifting block group 1.2, a management baffle 1.3 and a connection box 1.4, the hoist 1.1 is a belt conveyor, the driving roller of the hoist 1.1 and the slave The moving drum is set up and down and the axis is parallel to the horizontal plane. The side wall of the connection box 1.4 has an opening, which is blocked by the conveyor belt of the elevator 1.1, and the conveyor belt of the elevator 1.1 facing the opening of the side wall of the connection box 1.4 is directed to the connection box. 1.4 Tilt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com