Tin soldering method for aluminum enameled wire

An aluminum enameled wire and enameled wire technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve problems such as potential safety hazards, equipment burnout service life, etc., achieve stable quality, solve solder surface virtual welding, guarantee Effect on service life and safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

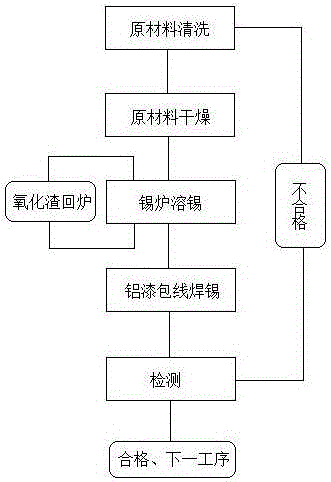

[0022] Such as figure 1 The shown method for soldering aluminum enameled wire includes the following steps. Step 1) Cleaning the enameled wire raw material once to remove dust and impurities on the material, so as to facilitate accurate, efficient and high-quality soldering. Step 2) Dry the enameled wire raw materials after cleaning in step 1 to remove the moisture on the enameled wire raw materials, so as to facilitate accurate, efficient and high-quality soldering operations. Step 3) Firstly, melt the tin bar in a tin furnace, and then pass the dried enameled wire raw material in step 2 through the tin bar solution in the tin furnace for soldering operation. Step 4) First inspect the finished solder in step 3 to check whether there are missing soldering, virtual soldering, false soldering, multiple tin or tin holes on the solder surface, if there are no such missing soldering, virtual soldering, false soldering, multiple tin or tin holes , then proceed to the next productio...

Embodiment 2

[0025] Such as figure 1 The shown method for soldering aluminum enameled wire includes the following steps. Step 1) Cleaning the enameled wire raw material once to remove dust and impurities on the material, so as to facilitate accurate, efficient and high-quality soldering. Step 2) Dry the enameled wire raw materials after cleaning in step 1 to remove the moisture on the enameled wire raw materials, so as to facilitate accurate, efficient and high-quality soldering operations. Step 3) Firstly, melt the tin bar in a tin furnace, and then pass the dried enameled wire raw material in step 2 through the tin bar solution in the tin furnace for soldering operation. Step 4) First inspect the finished solder in step 3 to check whether there are missing soldering, virtual soldering, false soldering, multiple tin or tin holes on the solder surface, if there are no such missing soldering, virtual soldering, false soldering, multiple tin or tin holes , then proceed to the next productio...

Embodiment 3

[0028] Such as figure 1The shown method for soldering aluminum enameled wire includes the following steps. Step 1) Cleaning the enameled wire raw material once to remove dust and impurities on the material, so as to facilitate accurate, efficient and high-quality soldering. Step 2) Dry the enameled wire raw materials after cleaning in step 1 to remove the moisture on the enameled wire raw materials, so as to facilitate accurate, efficient and high-quality soldering operations. Step 3) Firstly, melt the tin bar in a tin furnace, and then pass the dried enameled wire raw material in step 2 through the tin bar solution in the tin furnace for soldering operation. Step 4) First inspect the finished solder in step 3 to check whether there are missing soldering, virtual soldering, false soldering, multiple tin or tin holes on the solder surface, if there are no such missing soldering, virtual soldering, false soldering, multiple tin or tin holes , then proceed to the next production...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

| solidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com