Patents

Literature

245results about How to "Reasonable connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

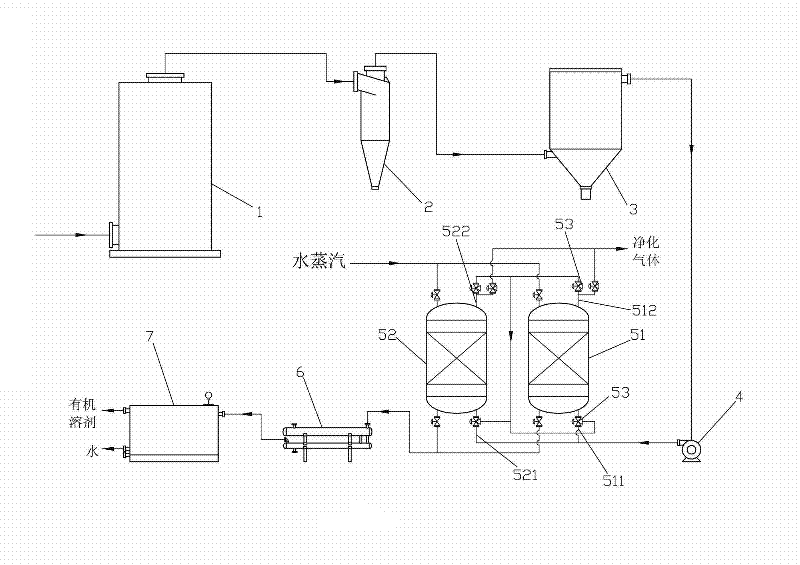

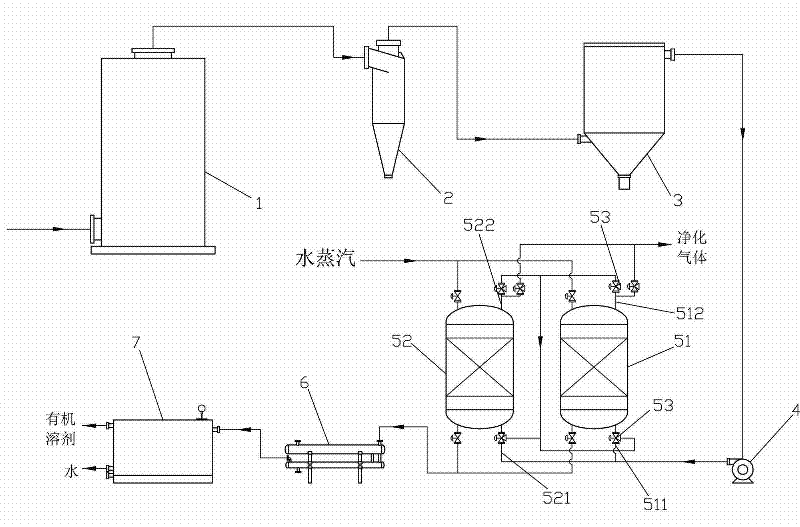

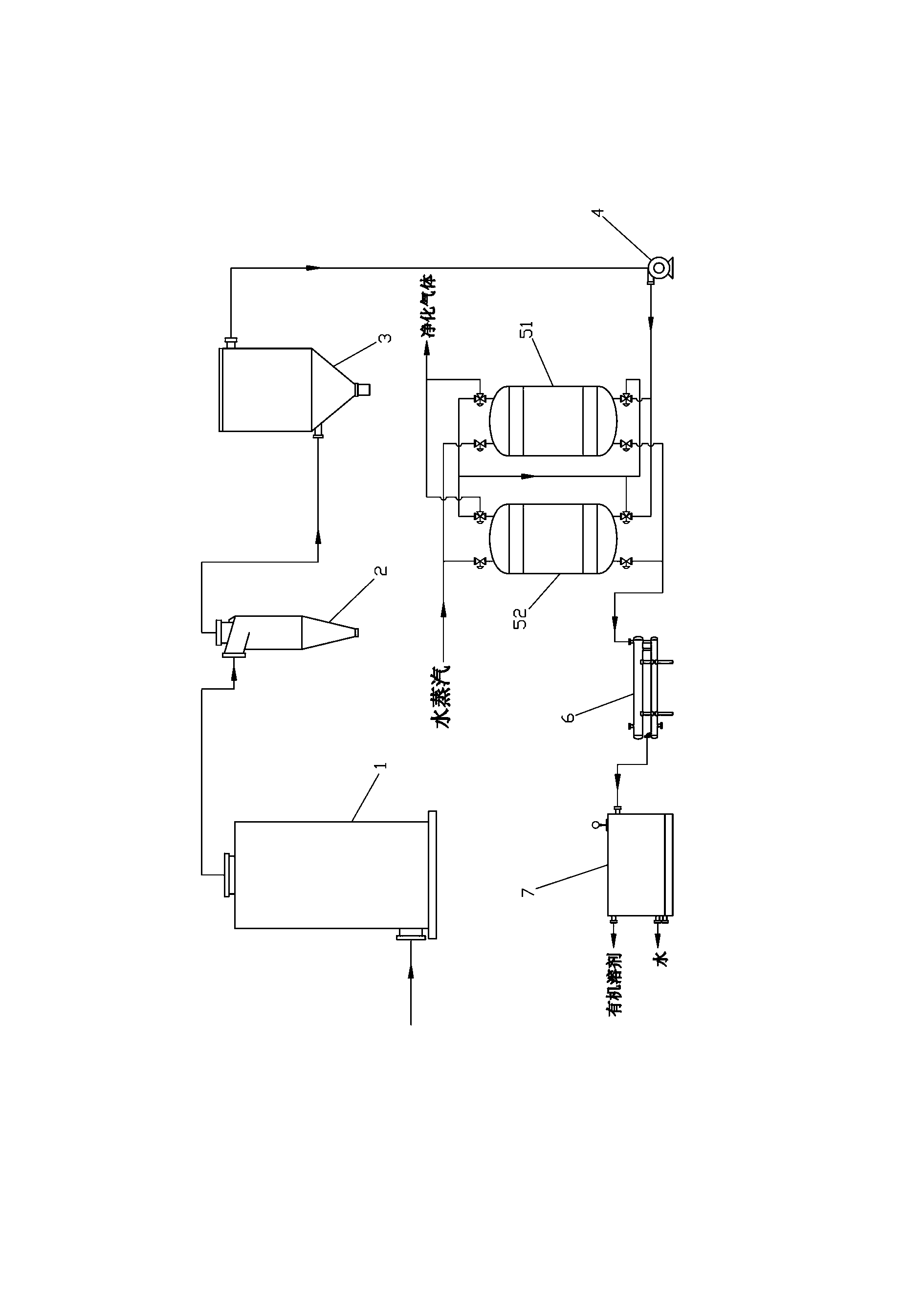

Recycling device for exhaust gas of painted organic solvent and method for recycling organic solvent

The invention discloses a recycling device for an exhaust gas of a painted organic solvent. The recycling device comprises a painting fog removing device, a fan, an absorbing jar, a condenser and an oil-water separator which are connected in turn, wherein the painting fog removing device comprises a gas collecting tank, a cyclone dust collector and a bag type dust collector; the gas collecting tank is used for temporarily storing the exhaust gas of the organic solvent; and the gas collecting tank, the cyclone dust collector and the bag type dust collector are connected in turn. All componentsof the recycling device are reasonably and compactly jointed; collection efficiency is high; and the painting fog is efficiently removed while a trouble in frequently exchanging filter cotton is avoided. The invention also discloses a method for utilizing the recycling device for the exhaust gas of the painted organic solvent to recycle the organic solvent. The method comprises the following steps: removing the painting fog; absorbing; desorbing steam; condensing; and separating oil from water, wherein the step of removing the painting fog is carried out by changing the painting fog into painting powder and then efficiently removing the painting fog. Compared with a traditional process, the method is more reasonable, compact and labor-saving.

Owner:中科天龙(厦门)环保股份有限公司

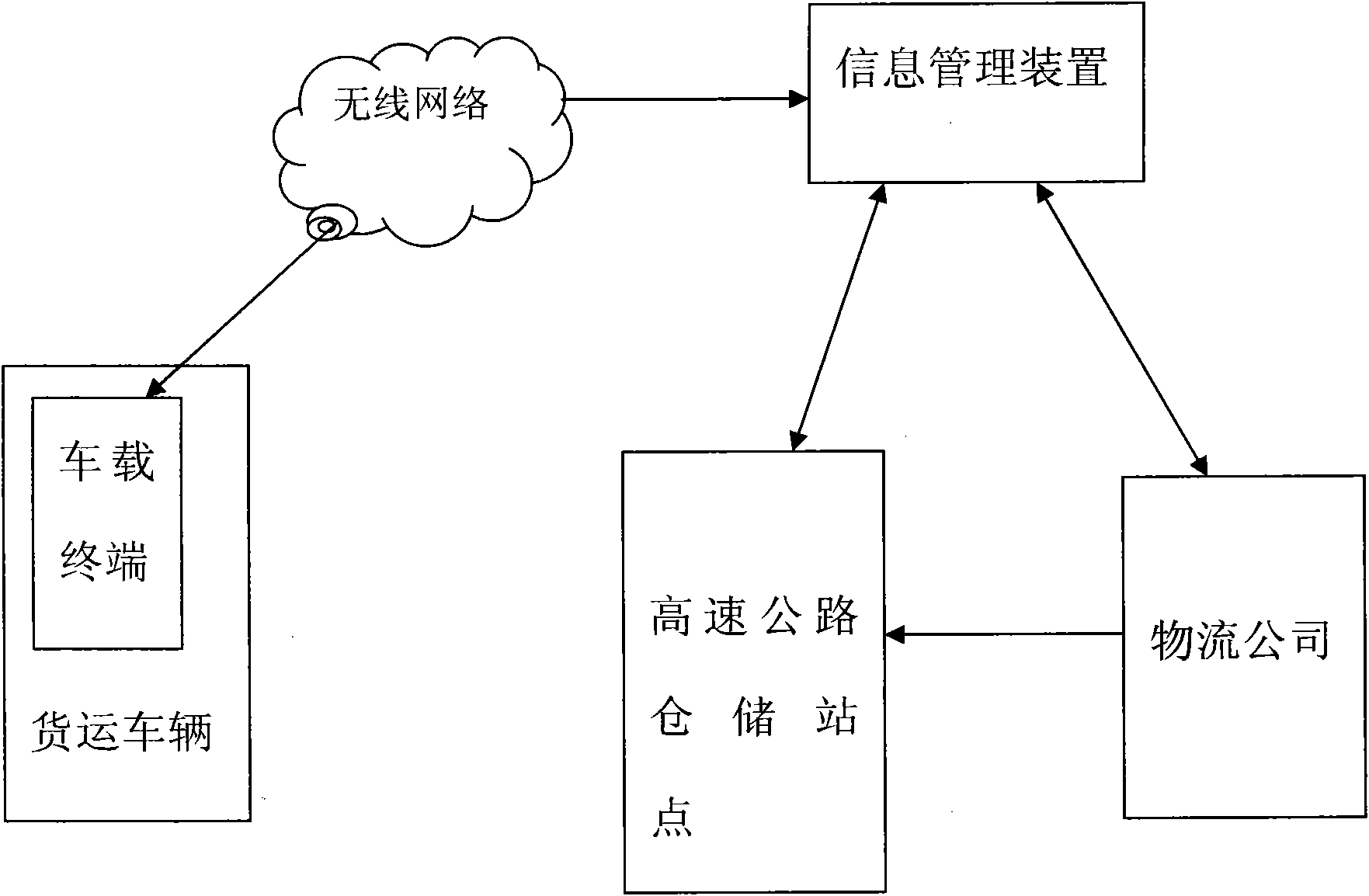

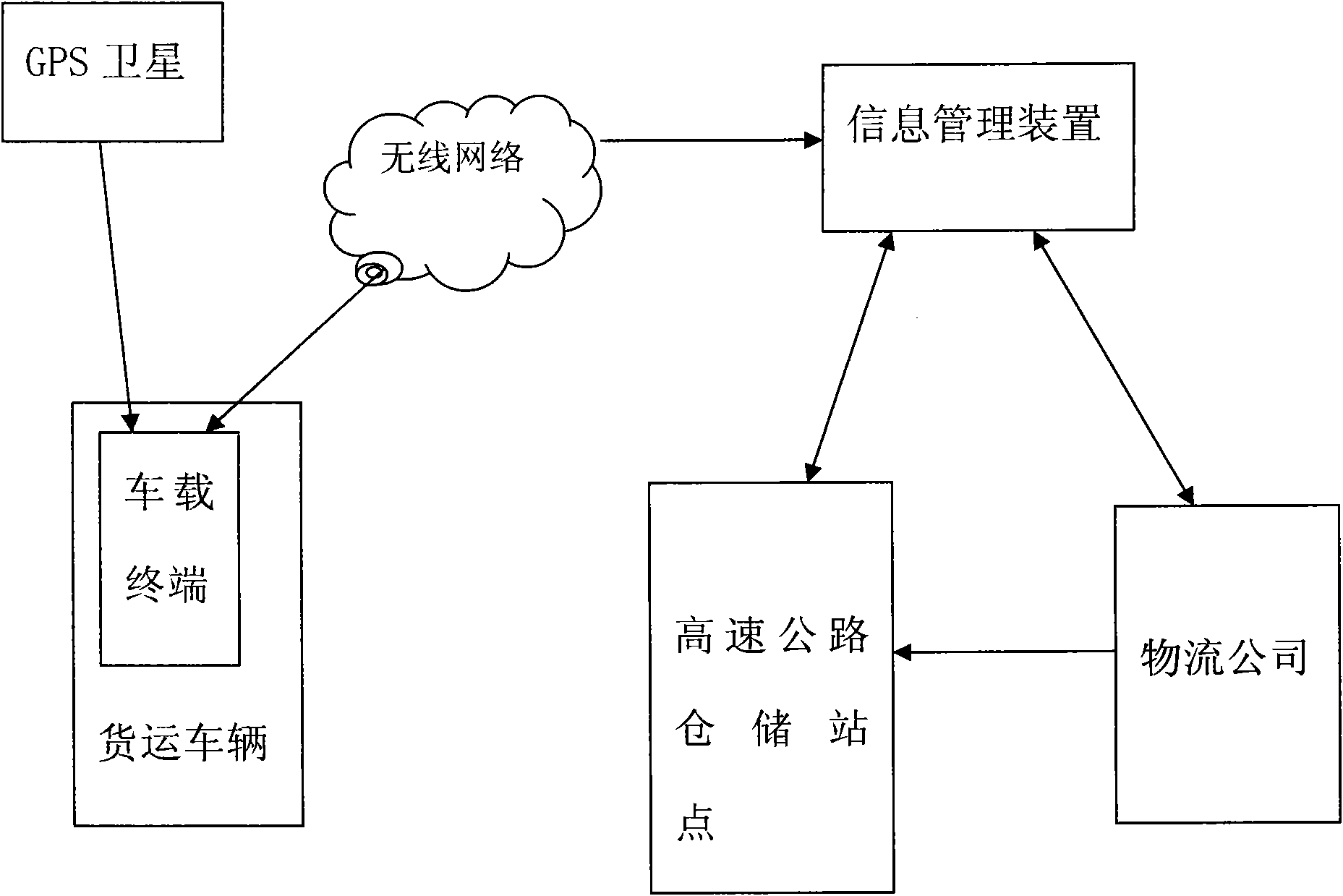

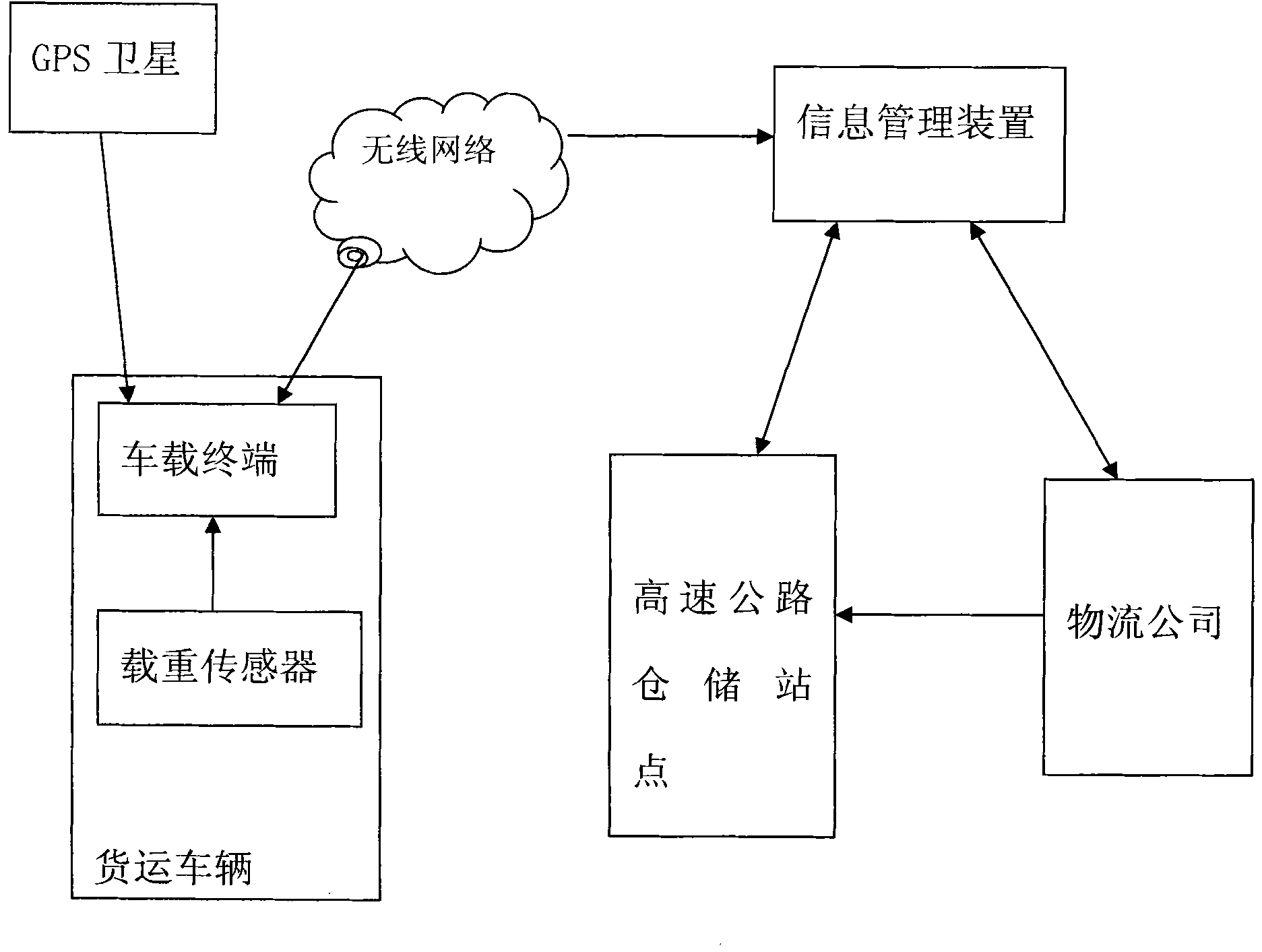

Integrated dispatch stowage system of freight logistics

InactiveCN101840536AImprove the level ofScientific schedulingLogisticsLogistics managementComputer terminal

The invention discloses an integrated dispatch stowage system system, which manages and dispatches freight vehicles by utilizing storage stations built on a highway and a computer network information platform and distributes goods at the storage station on the highway directly. The system comprises vehicle-mounted terminals arranged on the freight vehicles, a plurality of goods storage stations built on the highway and an information management device, wherein computer terminals of the freight storage stations send information of the goods needing to be carried to the information management device; and the information management device carries out wireless communication with the vehicle-mounted terminals to know whether the freight vehicles are in no load, carries out matching with the information of the carried goods, and then sends the distribution loading information to the vehicle-mounted terminals so as to carry out dispatch of the freight vehicles. The system not only realizes fast distribution and transportation, effectively reduces empty-loaded rate of transport vehicles and reduces the cost, but also avoids large transport vehicles from entering urban distribution, and reduces the pollution of urban traffic pressure and automobile exhaust on the urban environment.

Owner:童超

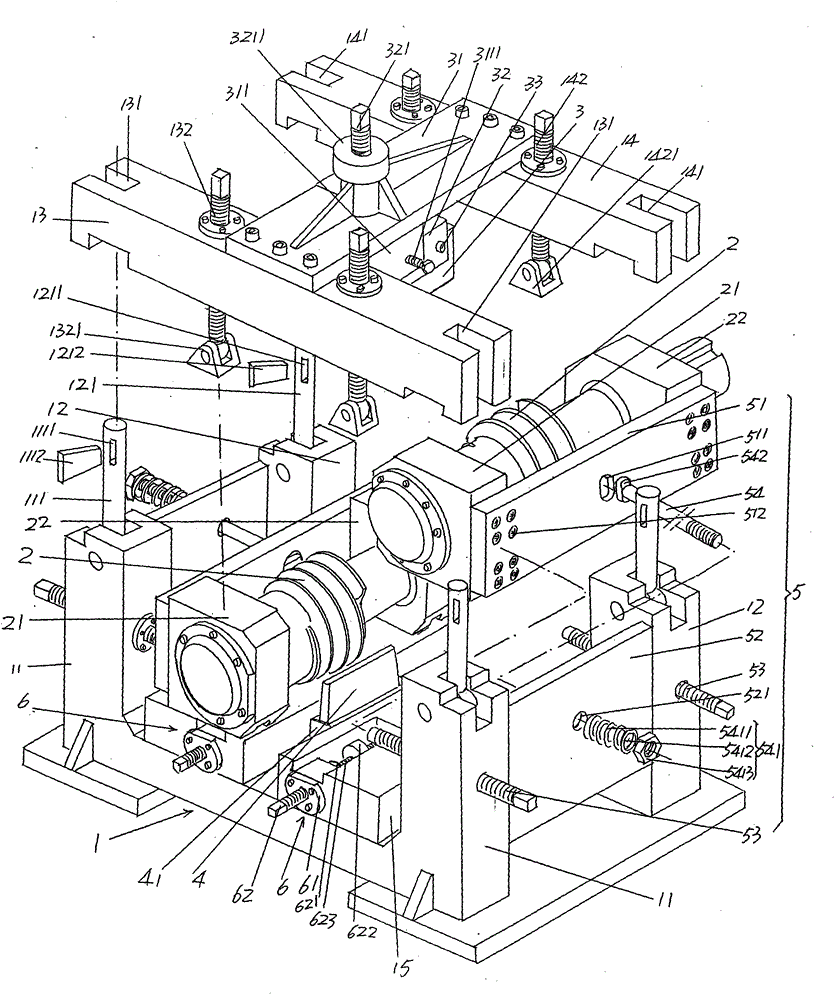

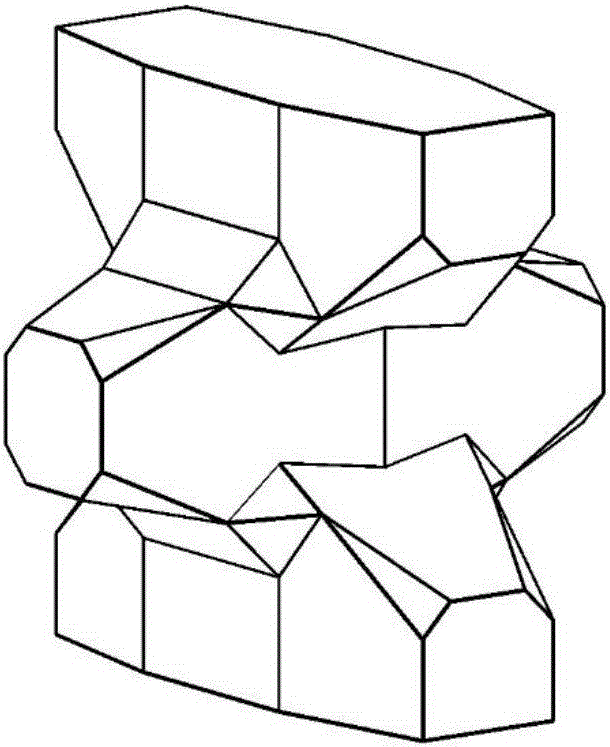

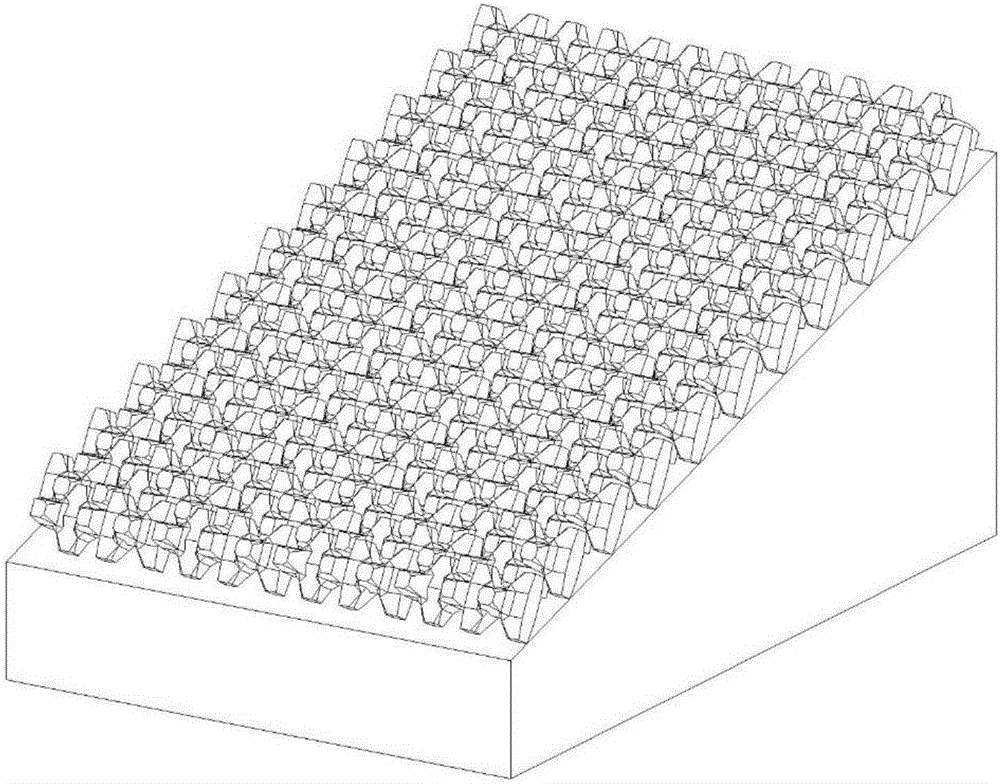

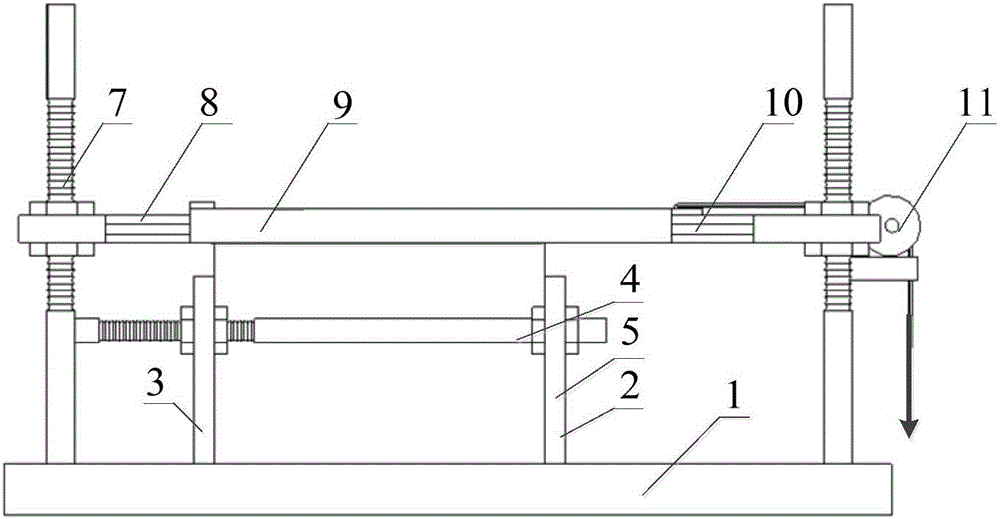

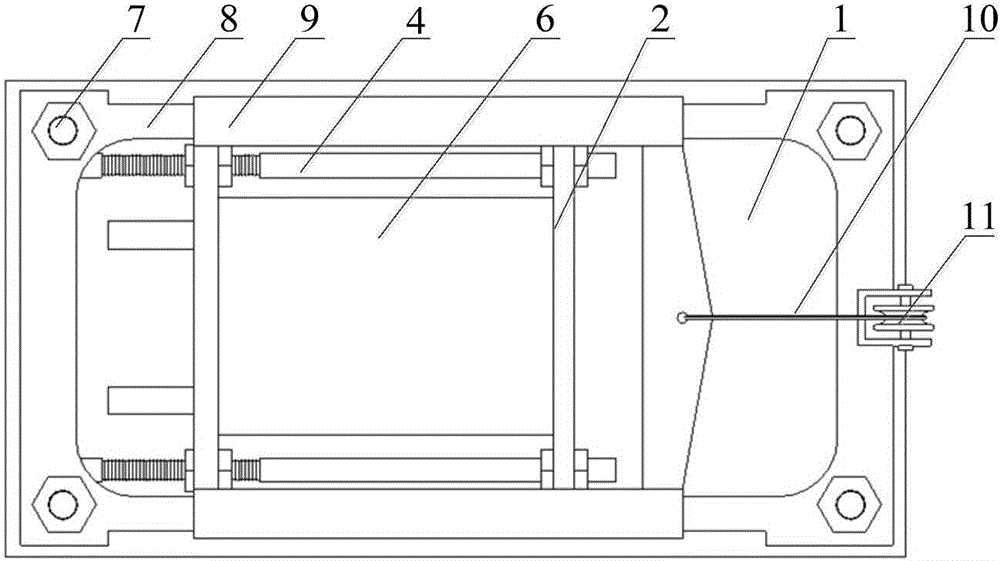

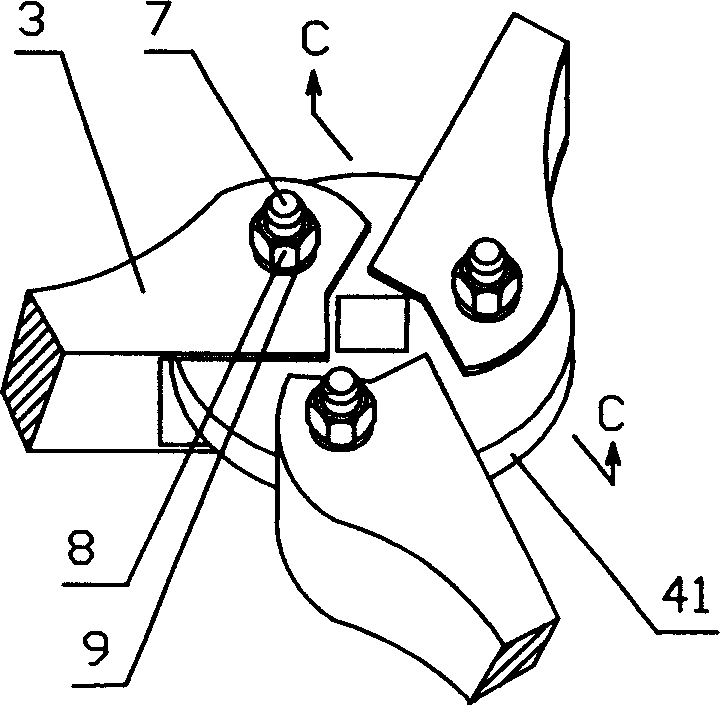

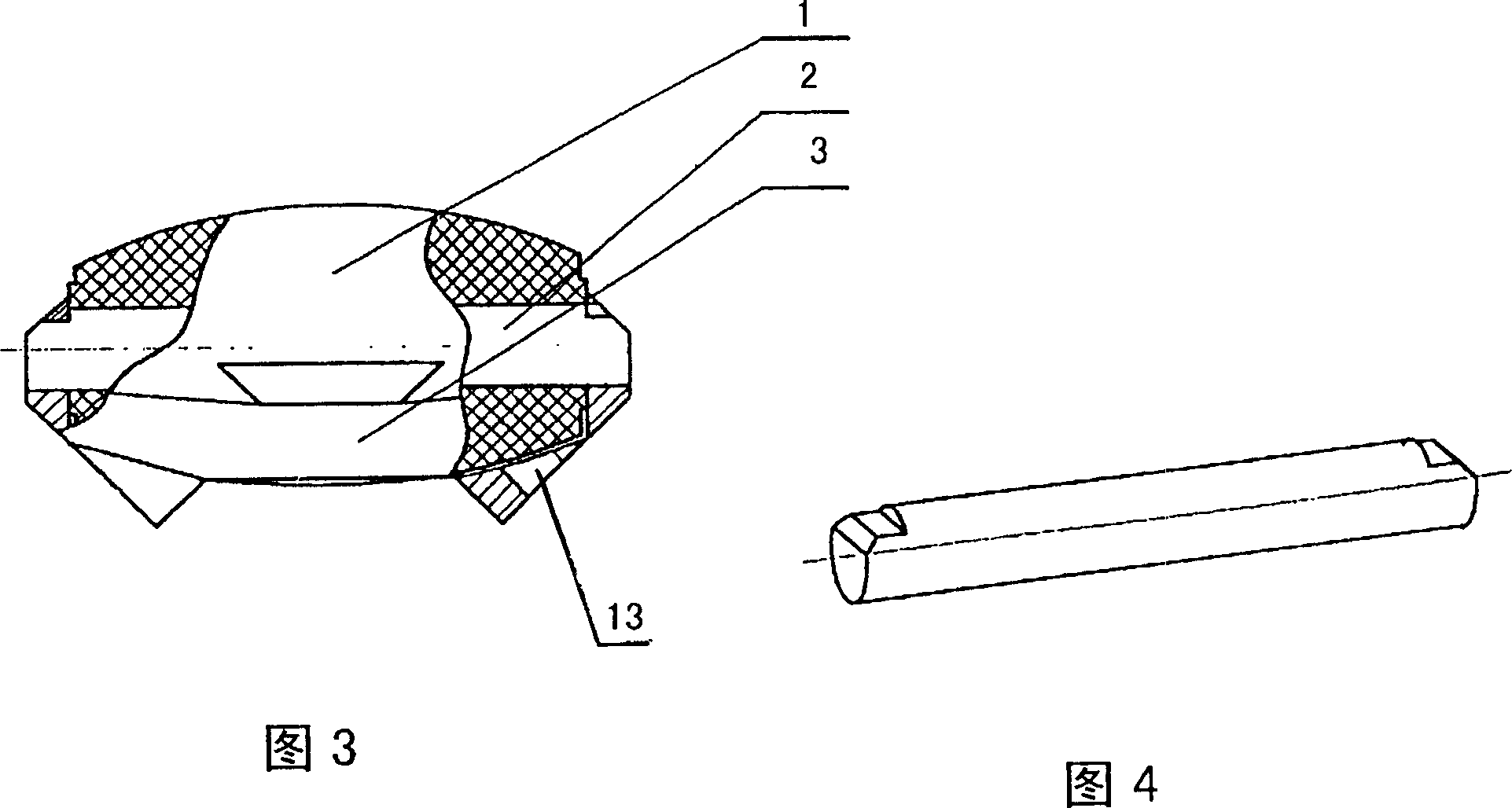

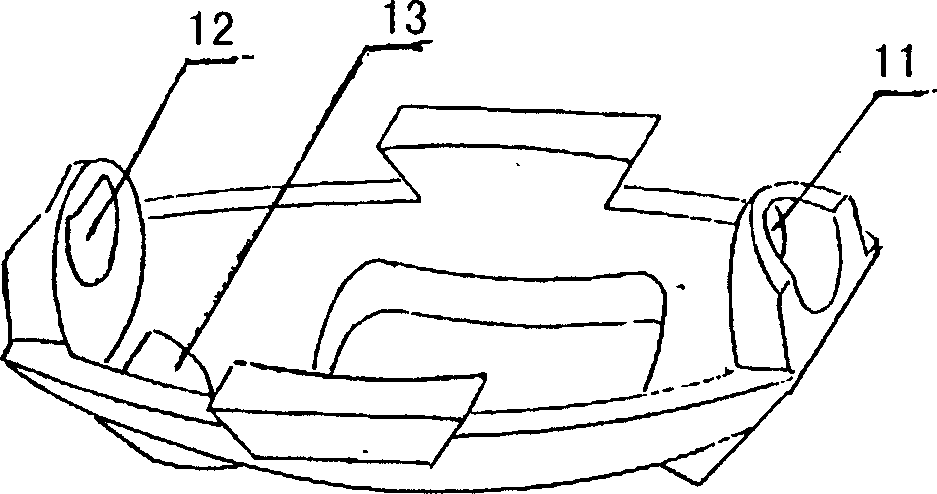

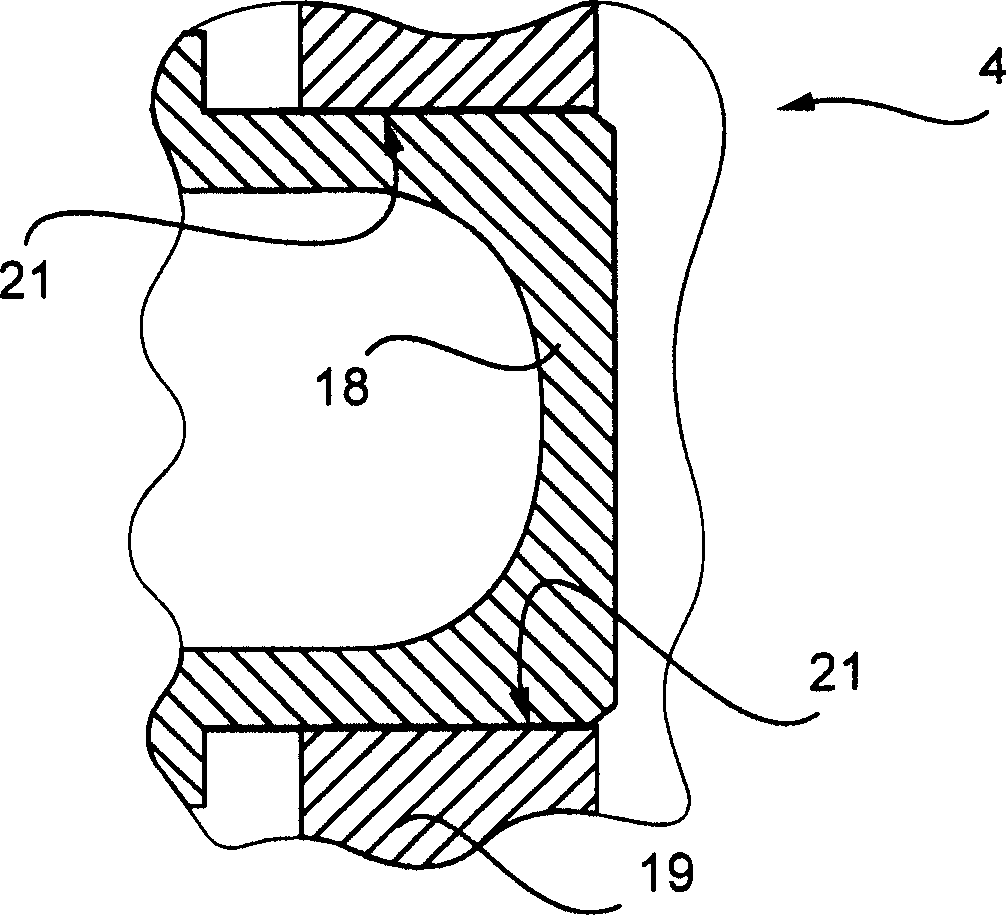

Ball forming mechanism of steel ball rolling mill with quickly assembled ball rolling rollers

The invention discloses a ball forming mechanism of a steel ball rolling mill with quickly assembled ball rolling rollers, and belongs to a steel ball processing machine. The ball forming mechanism comprises a bracket, a pair of ball forming rollers, upper and lower ball stop plates and a pair of ball forming roller parallel distance adjusting device. The ball forming mechanism is characterized in that: two ends of a first upper cross beam are provided with first locking rod grooves, the upper ends of a pair of first bracket upright posts are hinged with first locking rods, and one end of thefirst locking rod is provided with a first mortise; two ends of a second upper cross beam are provided with second locking rod grooves, the upper ends of a pair of second bracket upright posts are hinged with second locking rods, and one end of the second locking rod is provided with a second mortise; a connecting plate is provided with a pull rod head hole, a pull rod head is formed at one end of a pull rod, and the end faces of a pair of adjusting screws are propped against the surface of a connecting block; and the first upper cross beam is provided with a first compaction screw, the lowerend of the screw is hinged with a first pressure pin, the second upper cross beam is provided with a second compaction screw, and the lower end of the screw is hinged with a second pressure pin. The ball forming mechanism is convenient and quick to assemble or disassemble, and can ensure the parallel distance of a pair of ball forming rollers and prevent a shaft seat from carrying the ball forming rollers to cause shake and jump.

Owner:CHANGSHU FEIFAN METALWORK

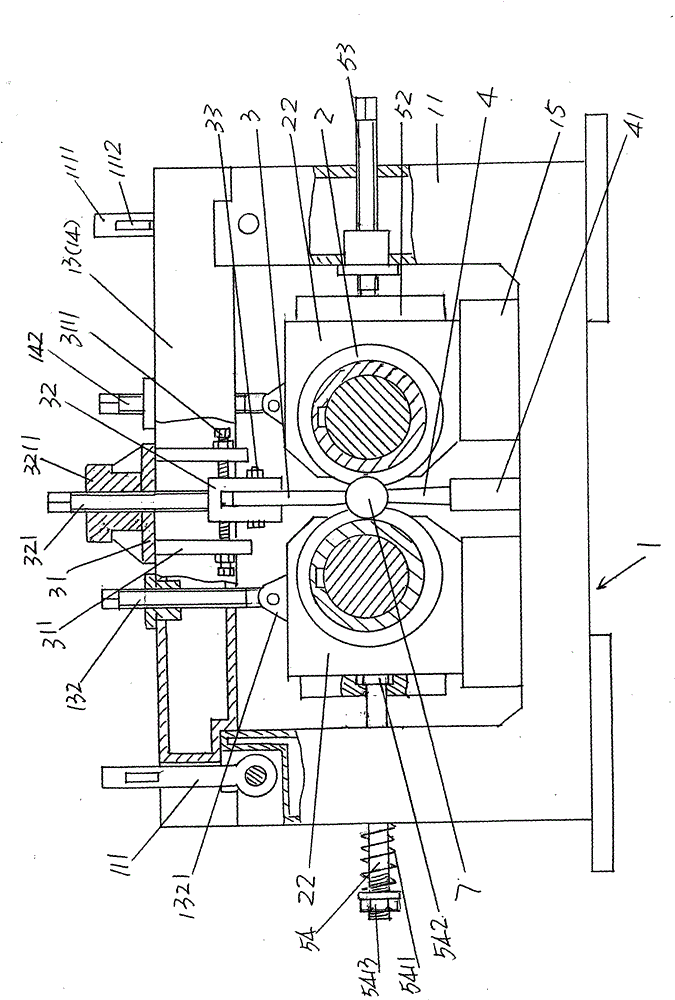

Sludge drying burning treatment method and integrated apparatus

ActiveCN101117261AComprehensive treatment effectReasonable connectionSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationHot blastCombustion chamber

The invention relates to a disposal method and integrated gear of anhydration and incineration of sewage sludge. The technical problems that the invention has solved are that the anhydration of incineration of sewage sludge are integrated, the heat utilization of incineration and the comprehensive processing effect are good. The methods of the invention are that: 1) pretreatment of wet sewage sludge; 2) access to a spray head on the top of a spray drying tower (8) of the sewage sludge for spray drying after which drying particles are obtained; exhaustion of offgases from an offgas outlet at the bottom of a tower drier (8); 3) access of the drying particles to a rotary burning kiln (10) for incineration, with the high temperature gases needed by the startup and operation of the rotary burning kiln (10) supplied by a hot-blast stove; exhaustion of the slag particles from a slag outlet; 4) access of the high temperature gases from the rotary burning kiln (10) to a second combustion chamber (9) for sufficient combustion; delivery of the high temperature gases after combustion to the spray drying tower (8).

Owner:ZHEJIANG HUANXING MACHINERY

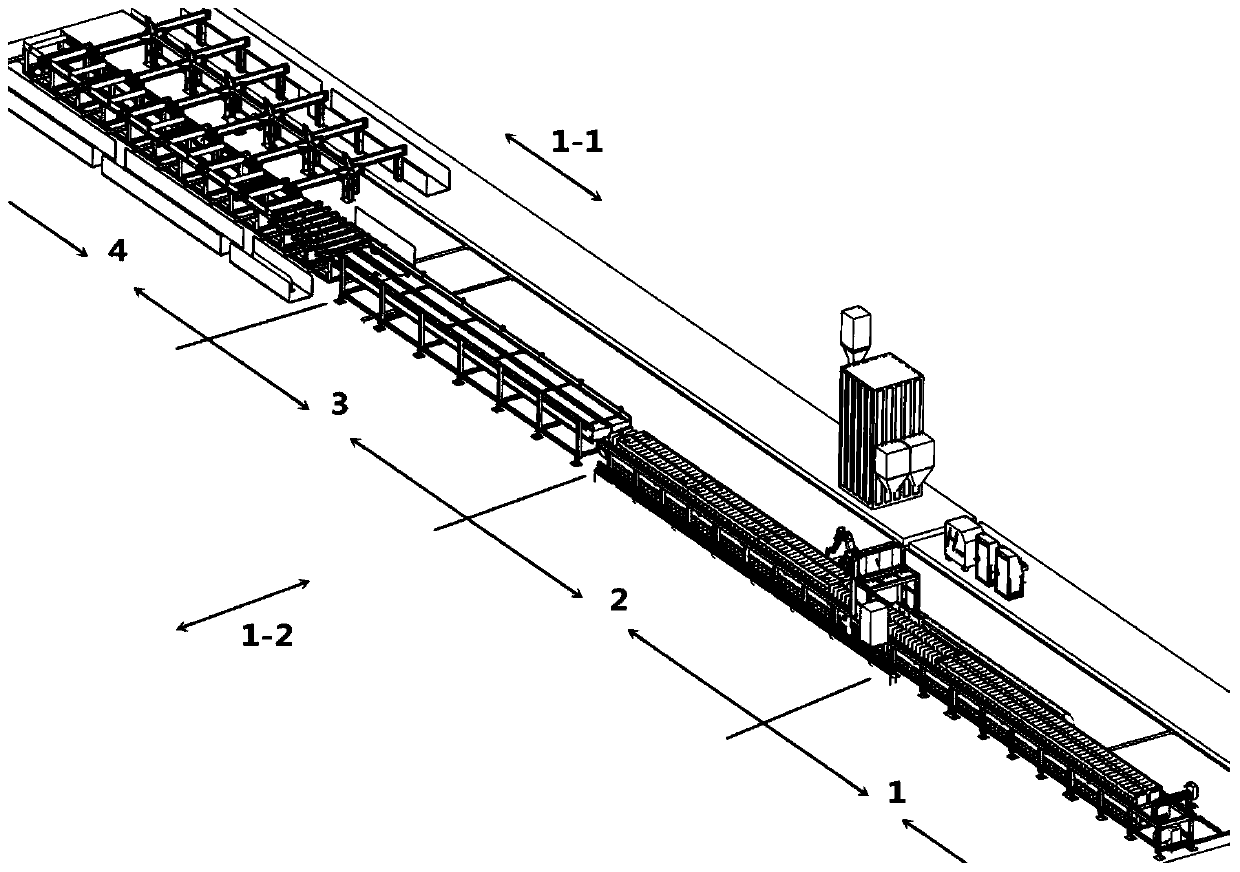

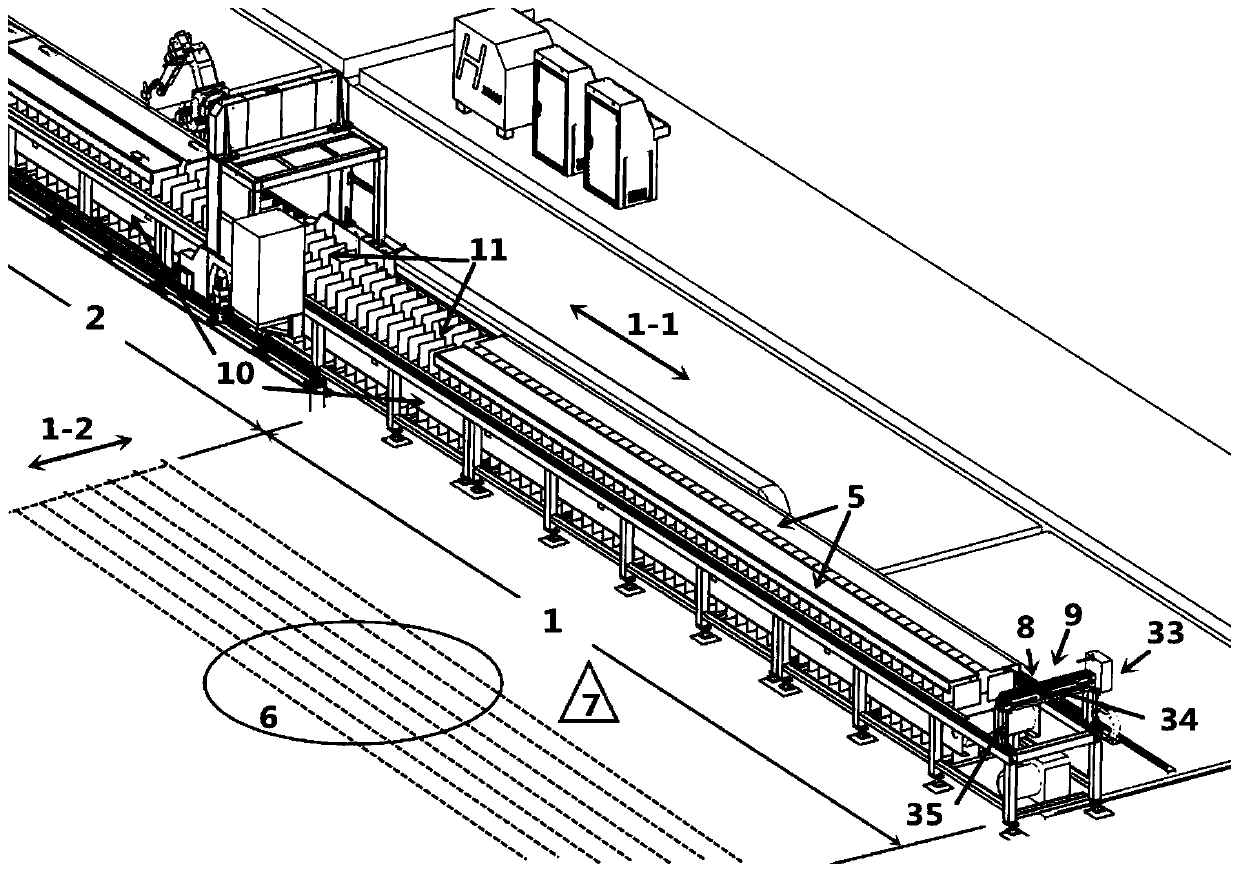

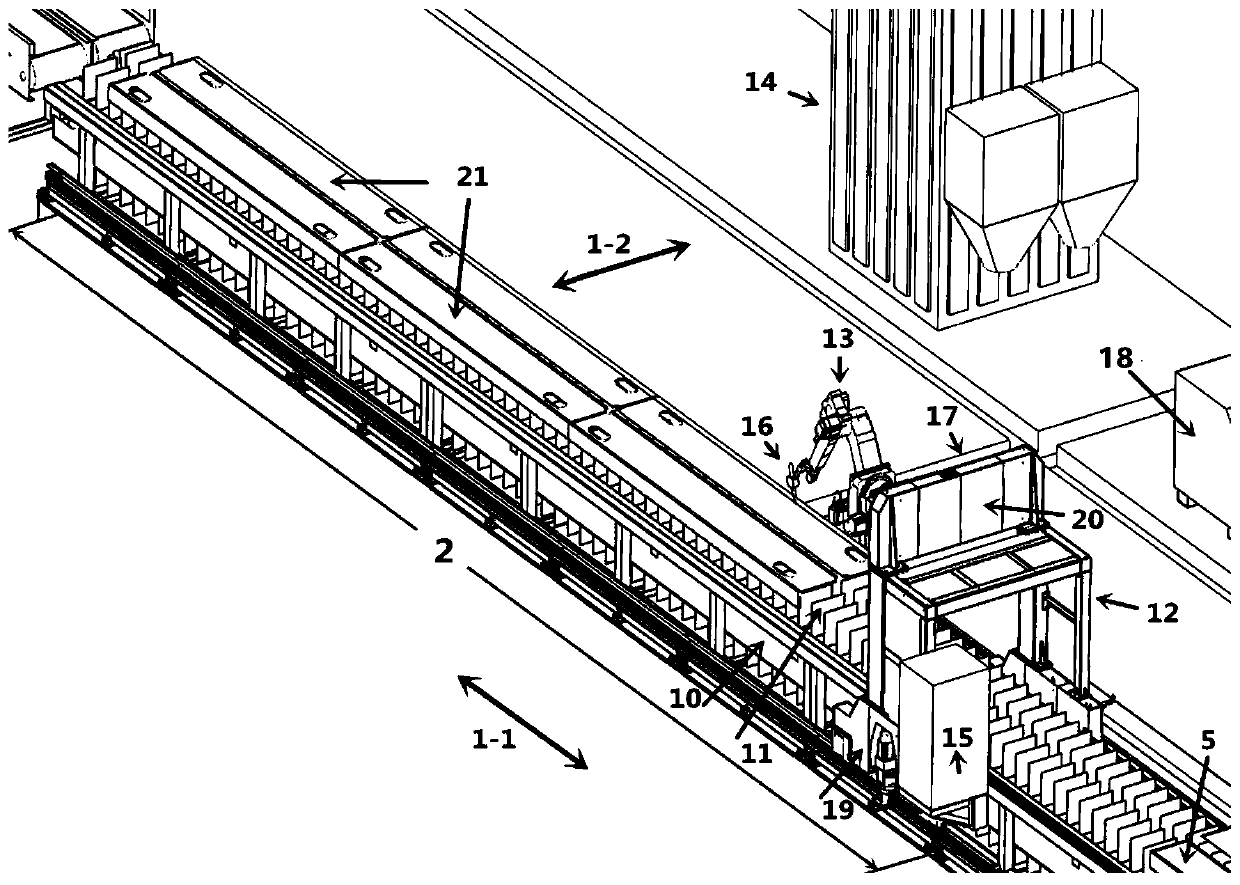

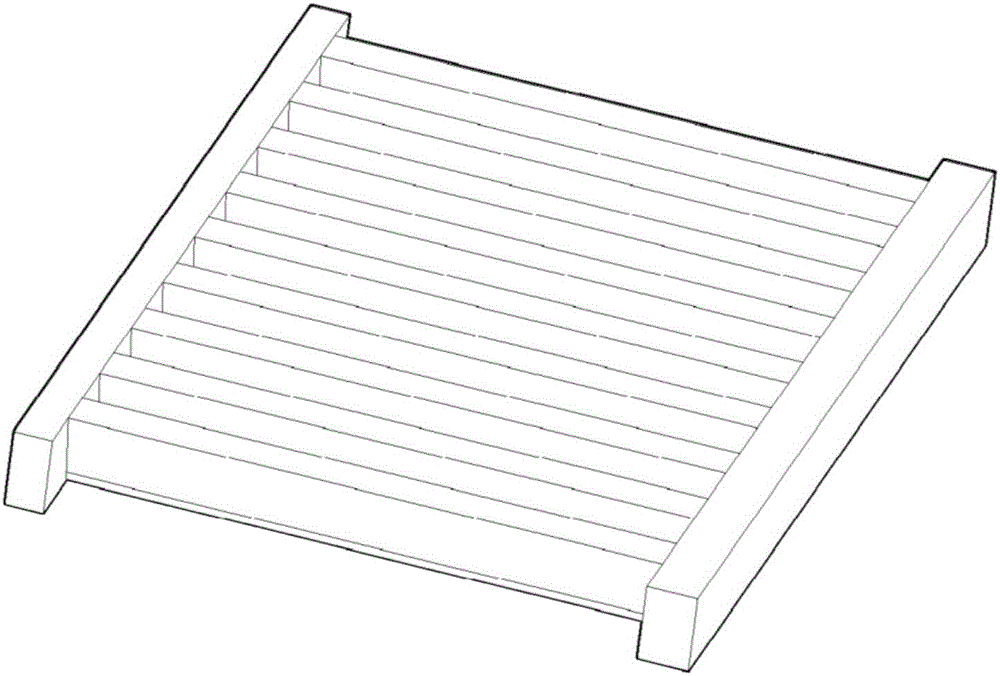

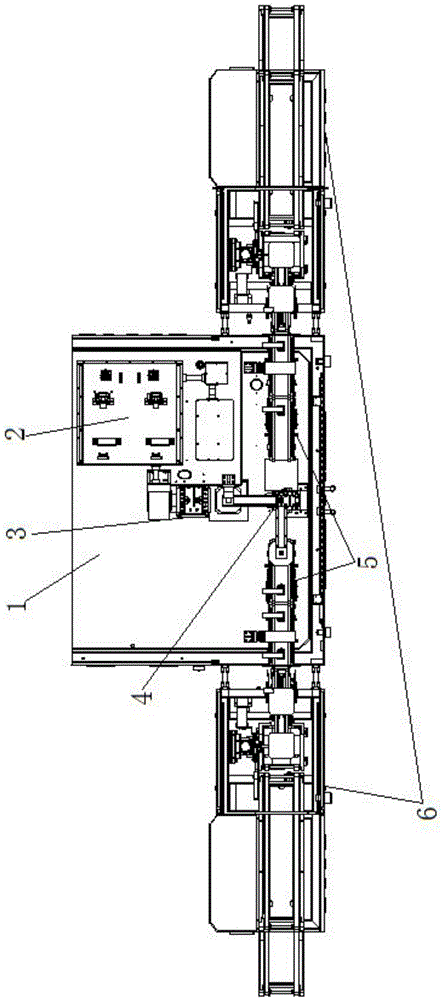

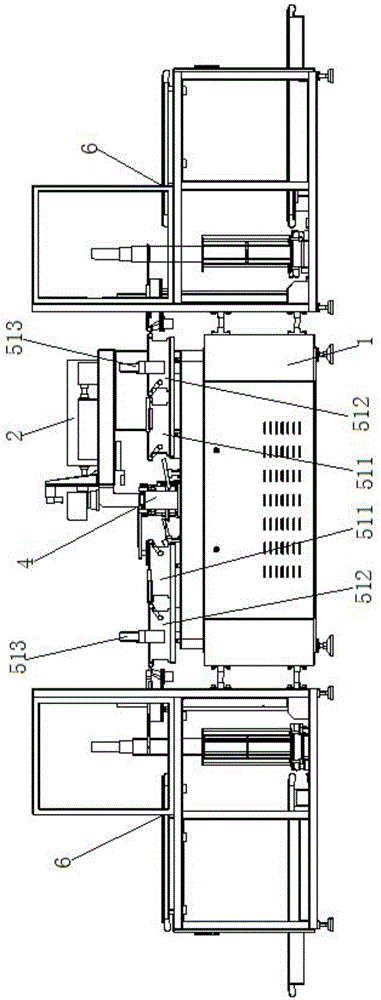

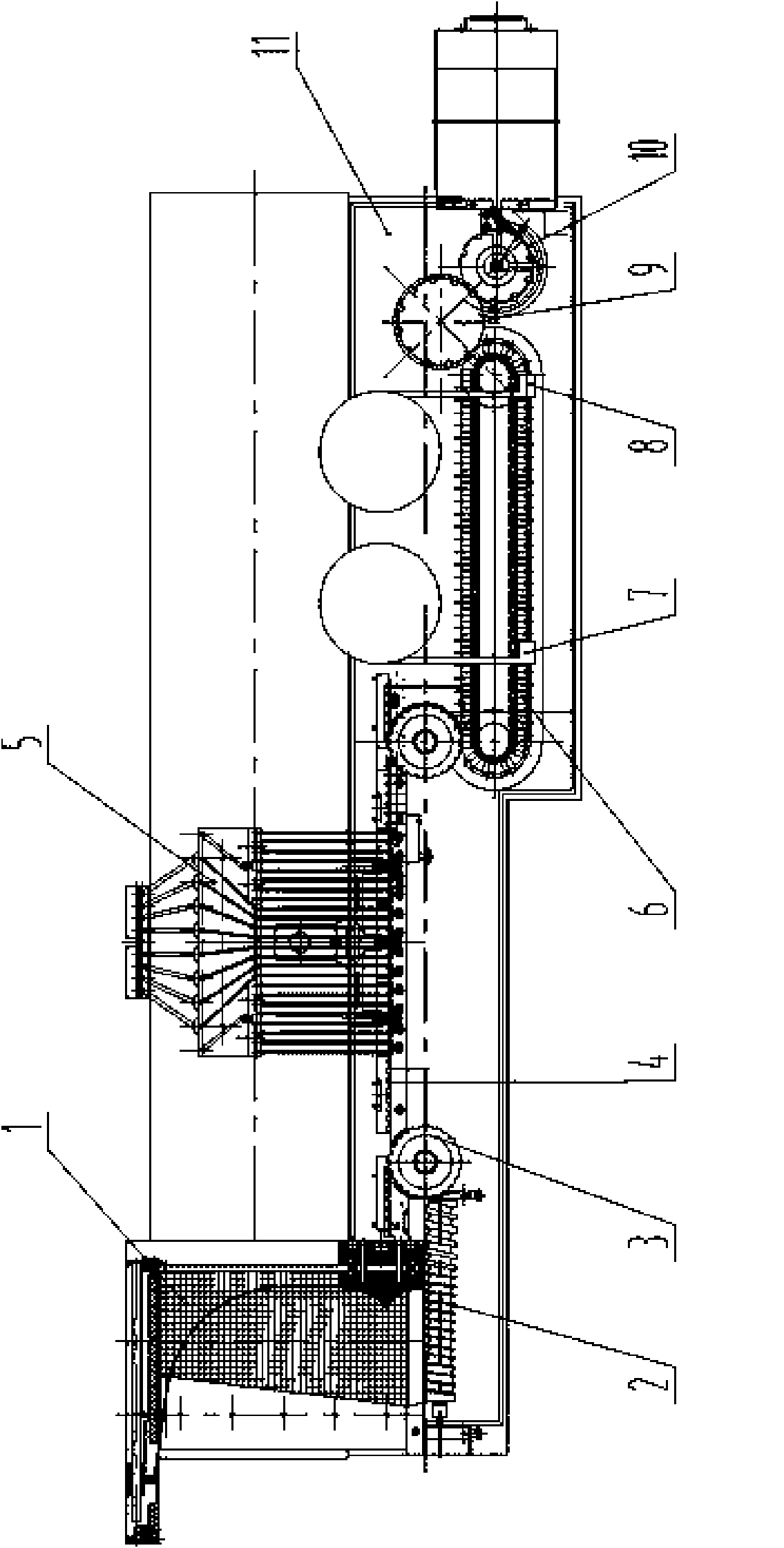

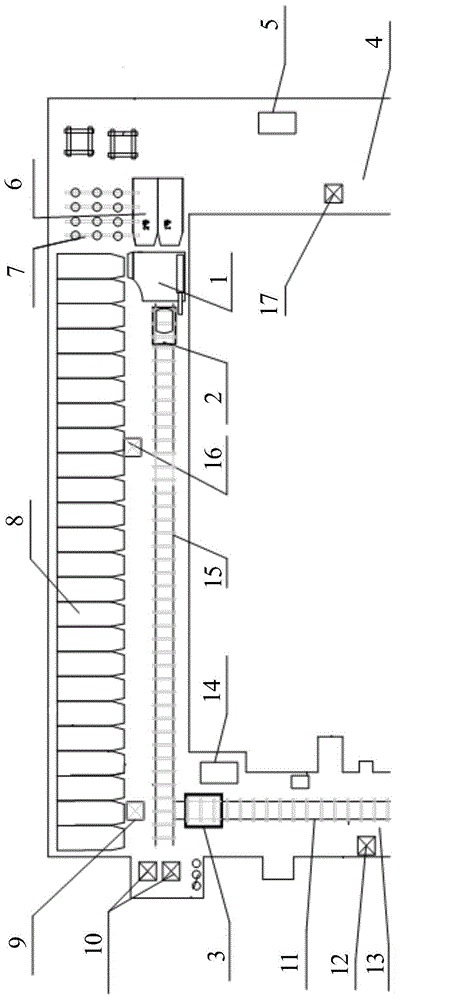

Automatic sectional material cutting production equipment and method

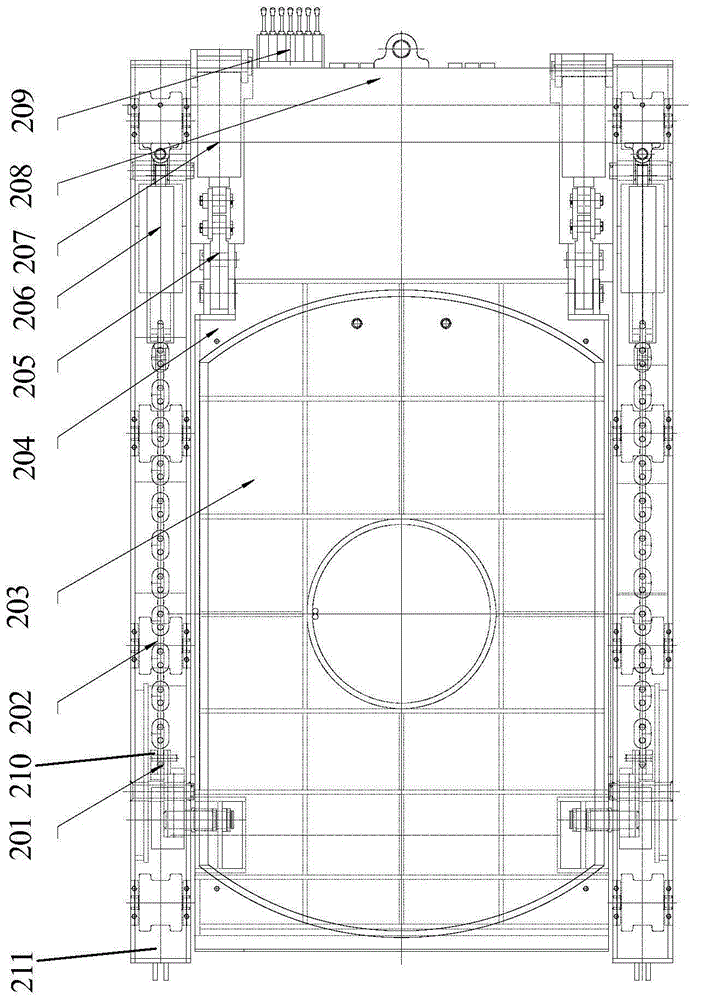

ActiveCN110153730AReasonable transmissionReasonable connectionMeasurement/indication equipmentsOther manufacturing equipments/toolsMachiningInkjet printing

The invention discloses automatic sectional material cutting production equipment and a method. The equipment solves the problem that the efficiency is low, the quality is poor, the maintenance and machining cost is high, the machining difficulty of a complex wedge-head workpiece is high when cutting workpieces in the prior art. The production equipment comprises a feeding and code inkjet printingarea (1), a cutting area (2), a to-be-sorted area (3) and a discharging area (4), the feeding and code inkjet printing area (1), the cutting area (2), the to-be-sorted area (3) and the discharging area (4) are arranged in sequence, the the feeding and code inkjet printing area (1) and the cutting area (2) are provided and a first rotary type chain plate conveying mechanism (10) and a material table (11), the to-be-sorted area (3) is provided with two sets of second rotary type chain plate conveying mechanisms (22) which are arranged in parallel, and the discharging area (4) is provided with adischarging mechanism longitudinal conveying roller set device (24) and a discharging mechanism transverse rotating chain moving device (25). According to the equipment and the method, the efficiencyof cutting the workpiece is greatly improved.

Owner:北京林克曼数控技术股份有限公司

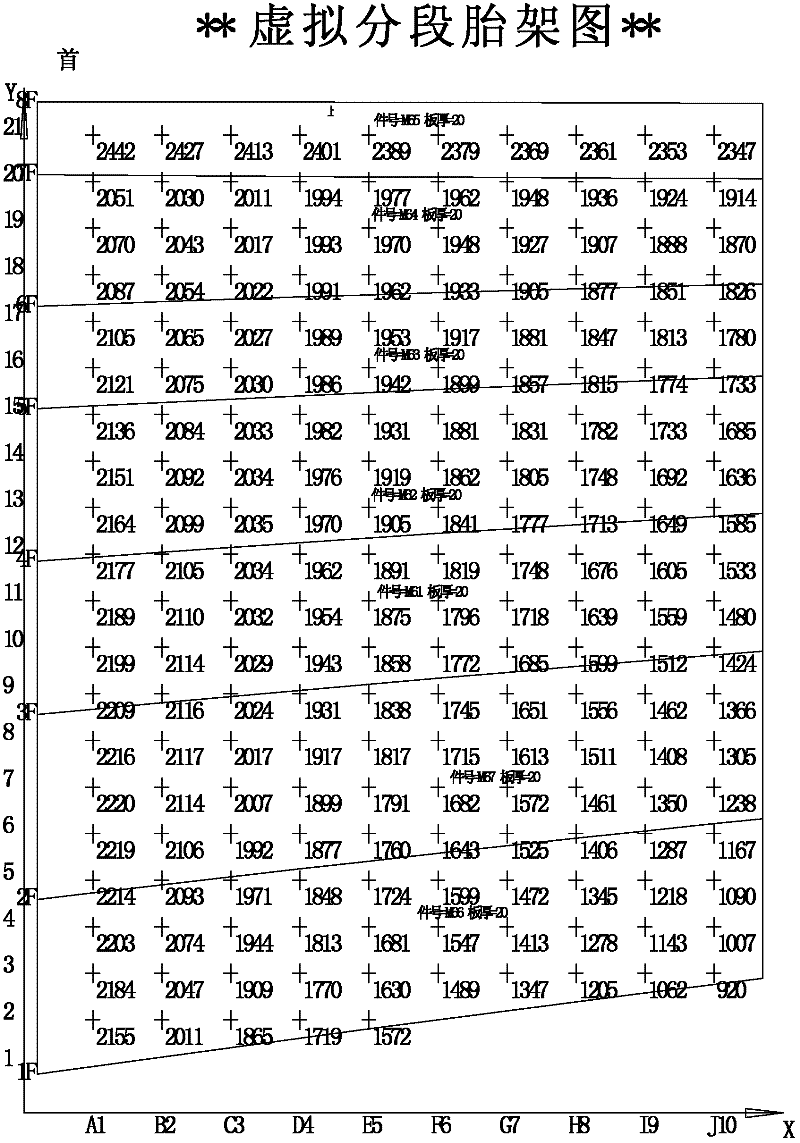

Standardized construction method for hydraulic prefabricated member based on BIM (Building Information Modeling)

InactiveCN106326536APrecise layoutFast, accurate and reasonable arrangementDesign optimisation/simulationSpecial data processing applicationsEngineeringControl parameters

The invention provides a standardized construction method for a hydraulic prefabricated member based on BIM (Building Information Modeling). The standardized construction method comprises the following steps: S1, modeling a three-dimensional parameterization model by using a BIM modeling tool, and further implementing the design of three-dimension drawing according to the model; S2, dividing and classifying project units according to different members; S3, deploying corresponding members in a three-dimensional model of a specific project; S4, exporting to obtain an arrangement drawing, a detail table and control parameters of the members, and counting the project quantity of the members; S5, performing BIM on a prefabricated field, and guiding capital construction of the prefabricated field based on the BIM; S6, exporting the three-dimensional parameterization model, thereby performing specific three-dimension design and structure operation on the members; S7, simulating all stages of field operation for prefabricating the members; S8, implementing field prefabrication of the members; S9, prefabricating the members and implanting chips containing traceable prefabrication quality information of the members into the members; S10, after prefabrication of the members is finished, performing hanging safe construction on the members.

Owner:上海交通建设总承包有限公司

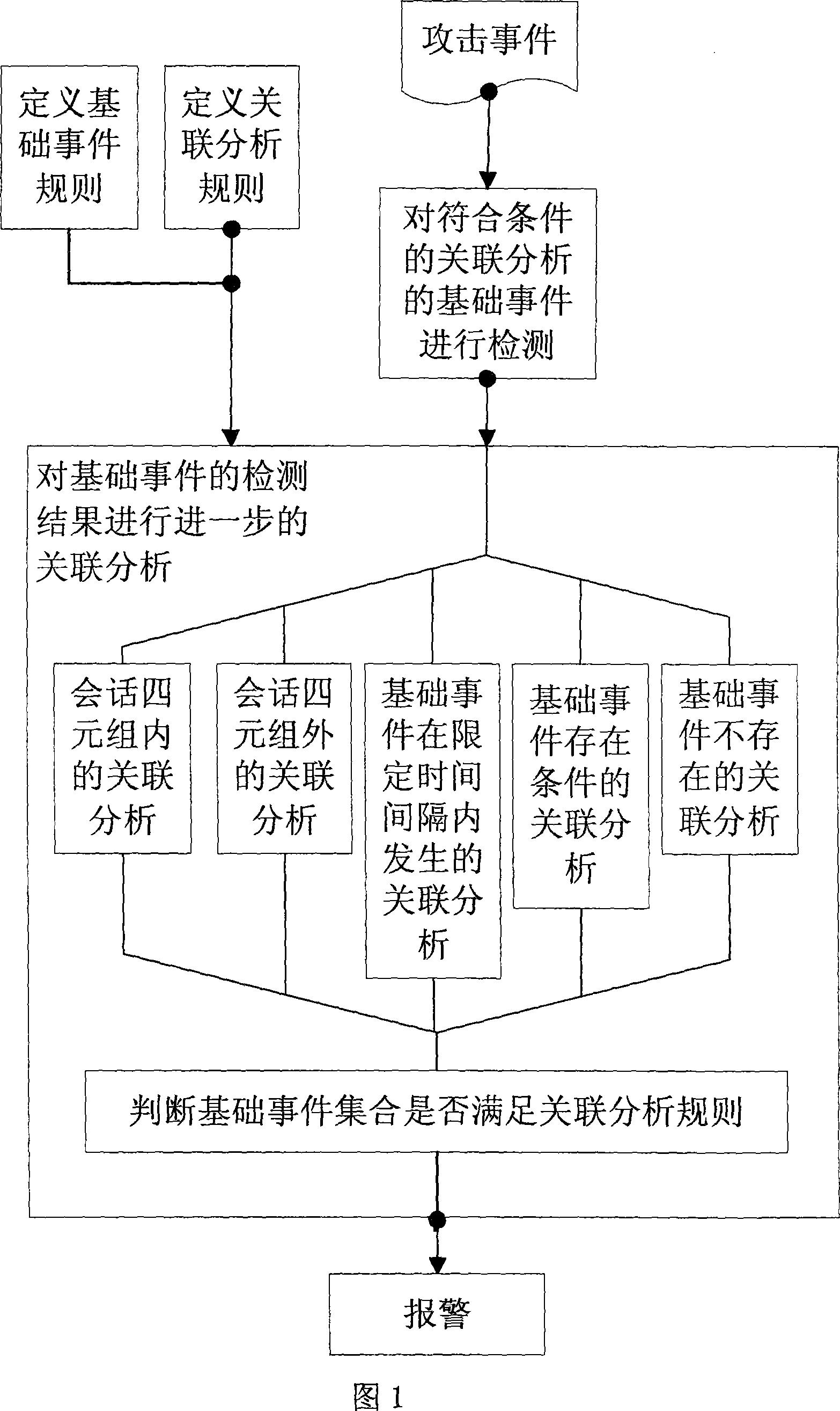

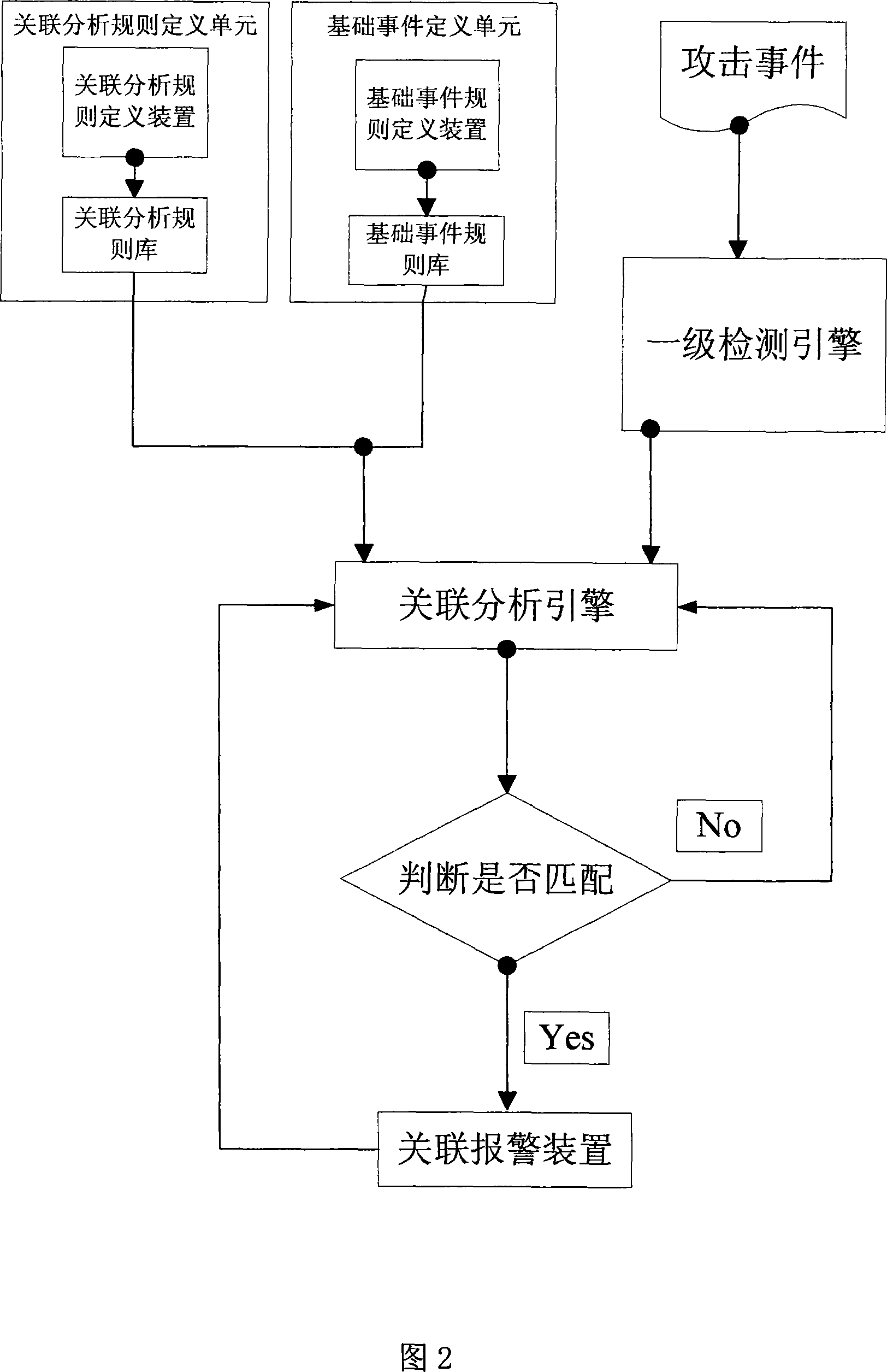

Associative attack analysis and detection method and device based on the time sequence and event sequence

InactiveCN101034974AAccurate detectionComprehensive descriptionData switching networksSecuring communicationCorrelation analysisAttack analysis

This invention is based on the time and events sequence to analysis attacking detection methods and devices involved in exchange for the function of the network. It is a methods and devices to prevent removing data from the data transmission channel without permission .The method provides a complex text-based attack description language to make the user can amend the built-related characteristics, and add new features of related events. The present invention include: basic rules of the incident, the rules of the association, first level detection engine, correlation analysis engine. The whole process of attacking are described more comprehensive and reasonable taking into account the time factor and the order of events Such description and testing which distinct the basic incidents more carefully are more in line with the requirements of detecting attacks. The invention also describes the relation between alarm incident and not alarm incident.

Owner:BEIJING VENUS INFORMATION TECH

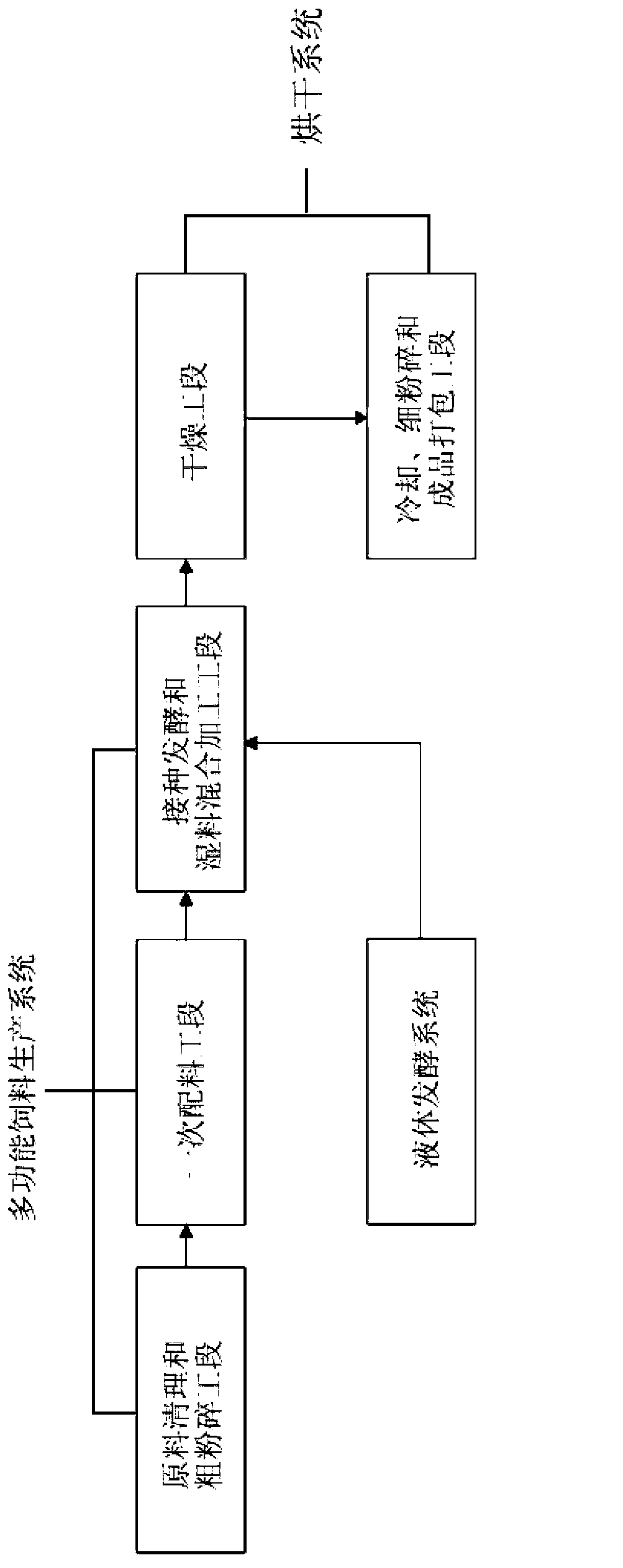

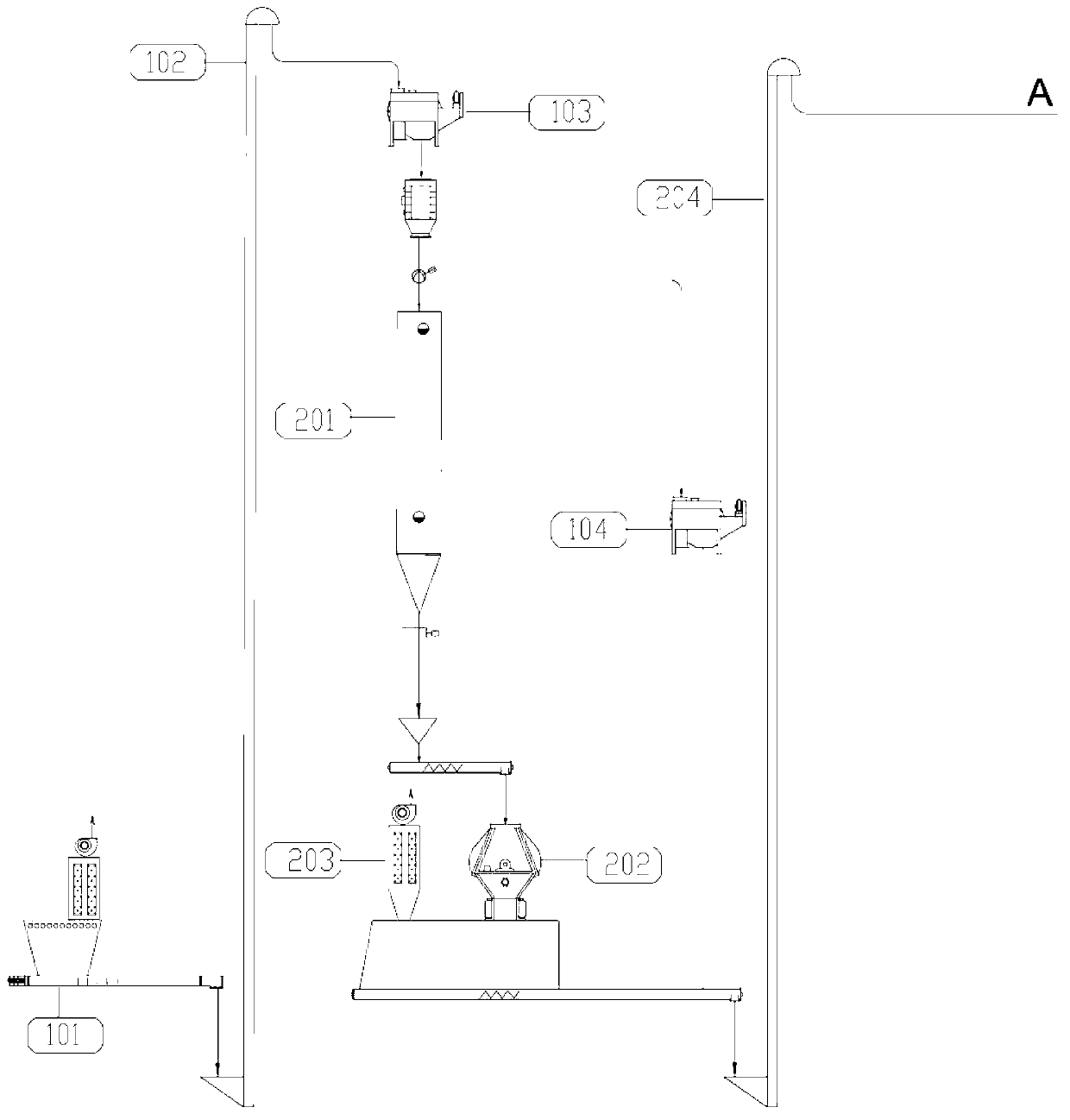

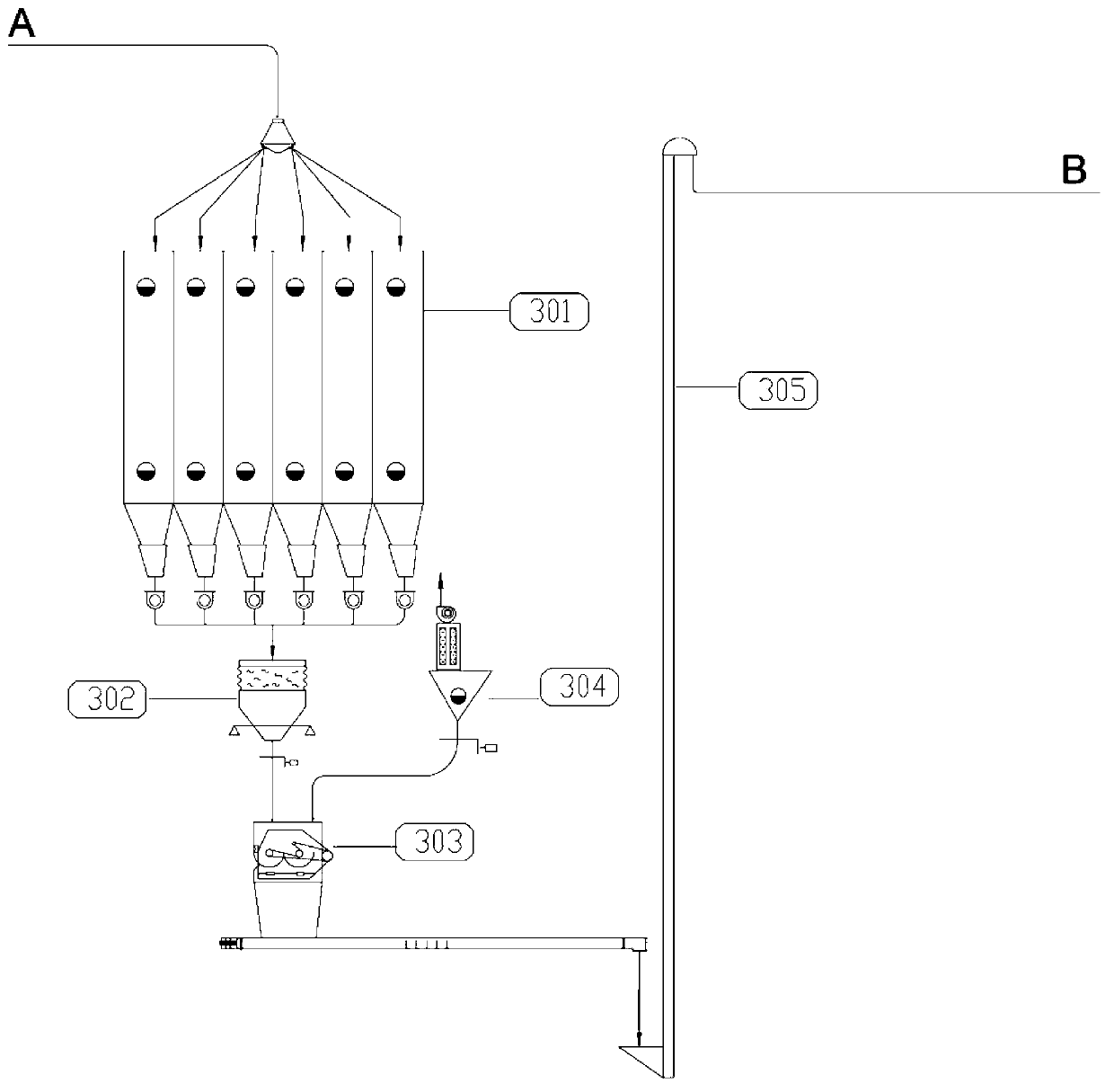

Production device and method of biological feeds

ActiveCN103126042ARealize continuous mass productionPrevent rustFeeding-stuffWork performanceAutomation

The invention provides a production device of biological feeds. The production device is composed of a multifunctional feed production system, a liquid fermentation system and a drying system, the multifunctional feed production system further comprises a raw material clearing and coarse grinding working section, a primary burdening working section and an inoculation fermentation and wet material mixing production working section, and the drying system further comprises a drying working section and a cooling, refine smashing and end product packing working section. The feed production device and a method are high in automation and mechanization degree, stable in working performance, high in work efficiency and simple and convenient to operate and achieve industrialization and large-scale production of probiotic fermented feeds.

Owner:张有聪

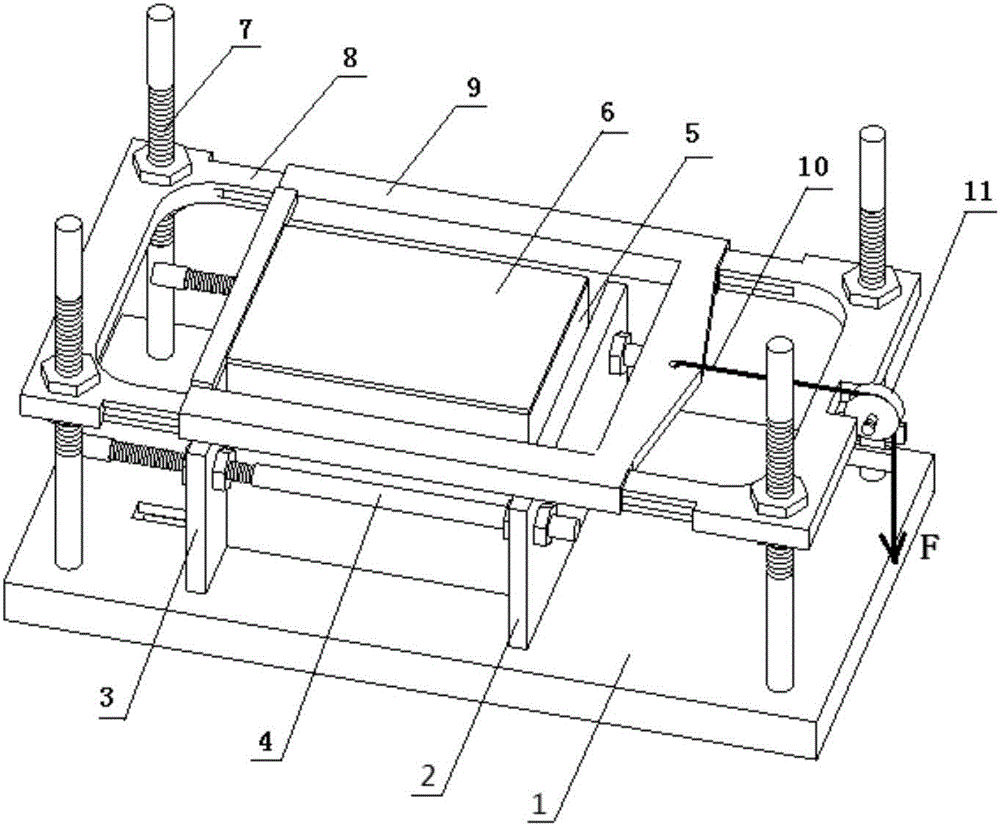

Cement-based composite material reinforced concrete interface shearing test device and test method

ActiveCN106680110AThe interface adhesion is fully reflectedEffective interface adhesionClimate change adaptationUsing mechanical meansReinforced concreteEngineering

The invention discloses a cement-based composite material reinforced concrete interface shearing test device. The device comprises reinforced old concrete, a cement-based composite material reinforcing layer sample, a base, a fixing mechanism, a loading mechanism and a supporting threaded rod, wherein the fixing mechanism comprises a movable front baffle plate and a fixed back baffle plate which are connected through a connecting threaded rod, and the old concrete is partially fixed on the base; the loading mechanism comprises a lifting type sliding rail, an orbit type sliding frame, a tension steel cable and a fixed pulley; the bottom of the orbit type sliding frame is level to the combining surface of the cement-based composite material reinforcing layer; the lifting type sliding rail is fixed on the supporting threaded rod in a free lifting way; the orbit type sliding frame can be fixed on the lifting type sliding rail in a sliding manner; the fixed pulley is fixed on one end of the lifting type sliding rail and is integrated with the orbit type sliding frame through the tension steel cable. The device disclosed by the invention is simple and easy to operate, convenient to assemble and test; the testing method based on the device can effectively determine the interface adhesive property of the cement-based composite material reinforced concrete structure.

Owner:HOHAI UNIV

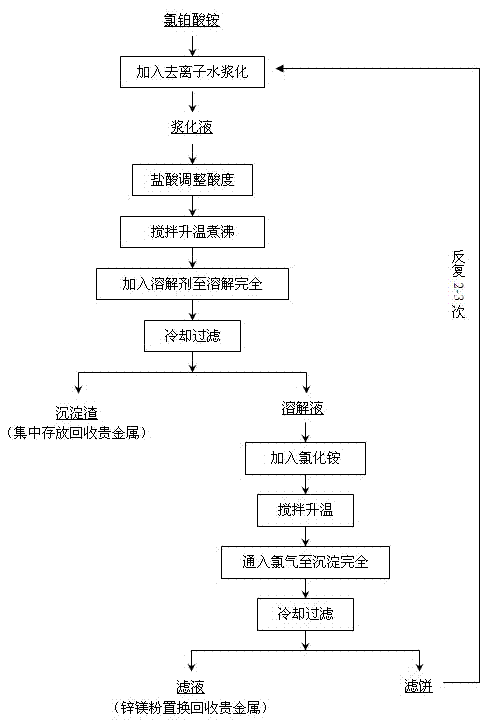

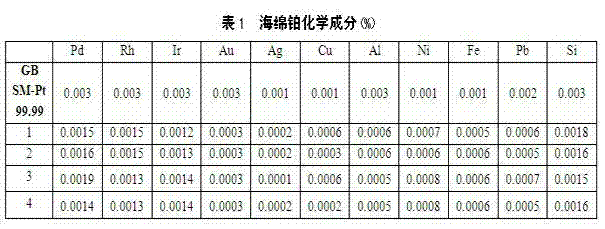

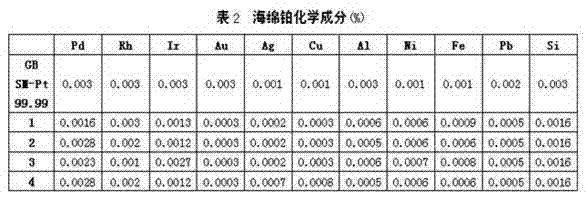

Platinum refining technology

A platinum refining technology comprises the steps of platinum family metal contained concentrate (slag, secondary resources and the like) chlorination dissolving, dissolved solution acidity adjustment, organic reducing agent ammonium oxalate precipitation, and precious metal filtering separation. The technology has the characteristics of wide material adaptability and simple operation, allows ammonium chloroplatinate of a platinum family metal contained material containing ammonium chloroplatinate to be efficiently and rapidly dissolved and precipitated, and allows the dissolving efficiency, the precipitation rate and the refining recovery efficiency to reach 95-99%, 99% and 90-95% respectively in the whole refining process; and compared with a traditional ammonium chloride repeated-precipitation method, the technology effectively solves a problem that nitrogen oxide cannot be discharged in a standard reaching mode, and eliminates the problems of large labor intensity of a aqua regia dissolved solution nitrate removing process and low production efficiency. The reducing agent ammonium oxalate is an organic reagent, and reacts to generate a pollution-free gas which can be directly discharged in the reaction process, so a solution system is not changed, thereby no influences on subsequent platinum precipitation by ammonium chloride are caused, and the yield and the quality of platinum family metal products are substantially improved.

Owner:JINCHUAN GROUP LIMITED

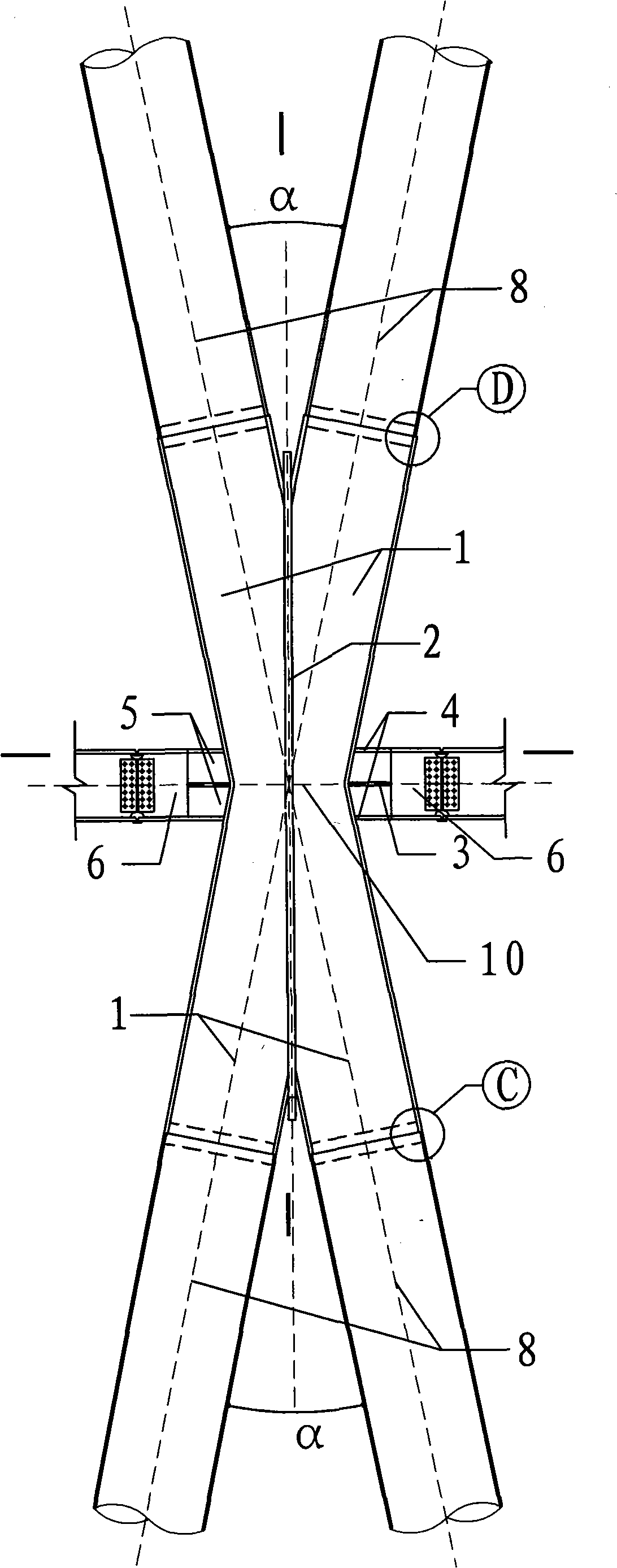

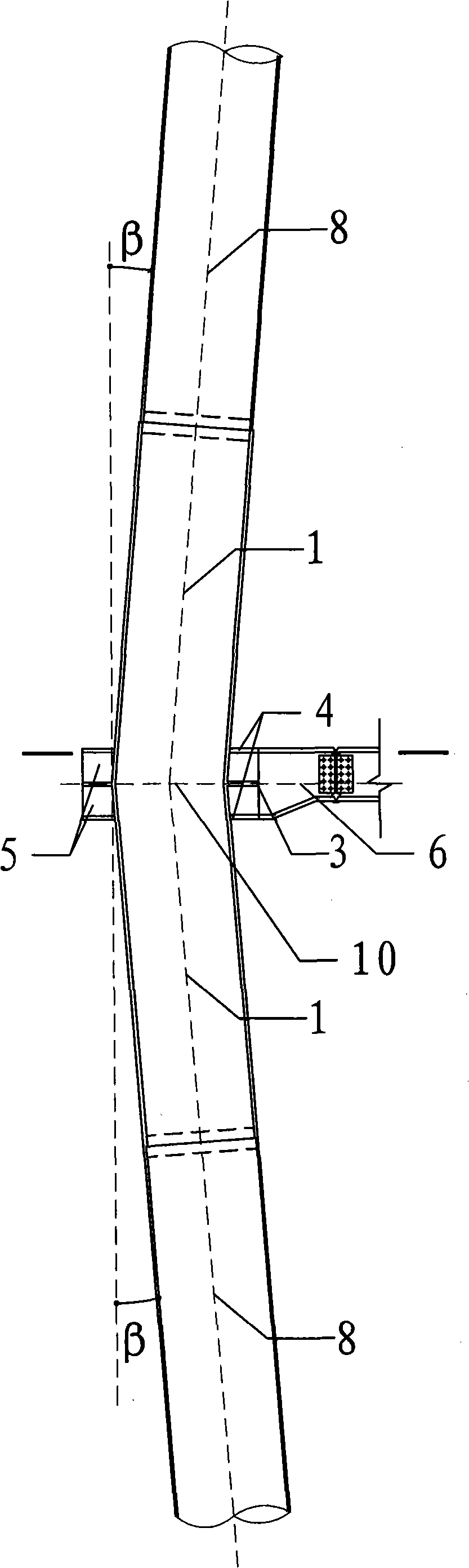

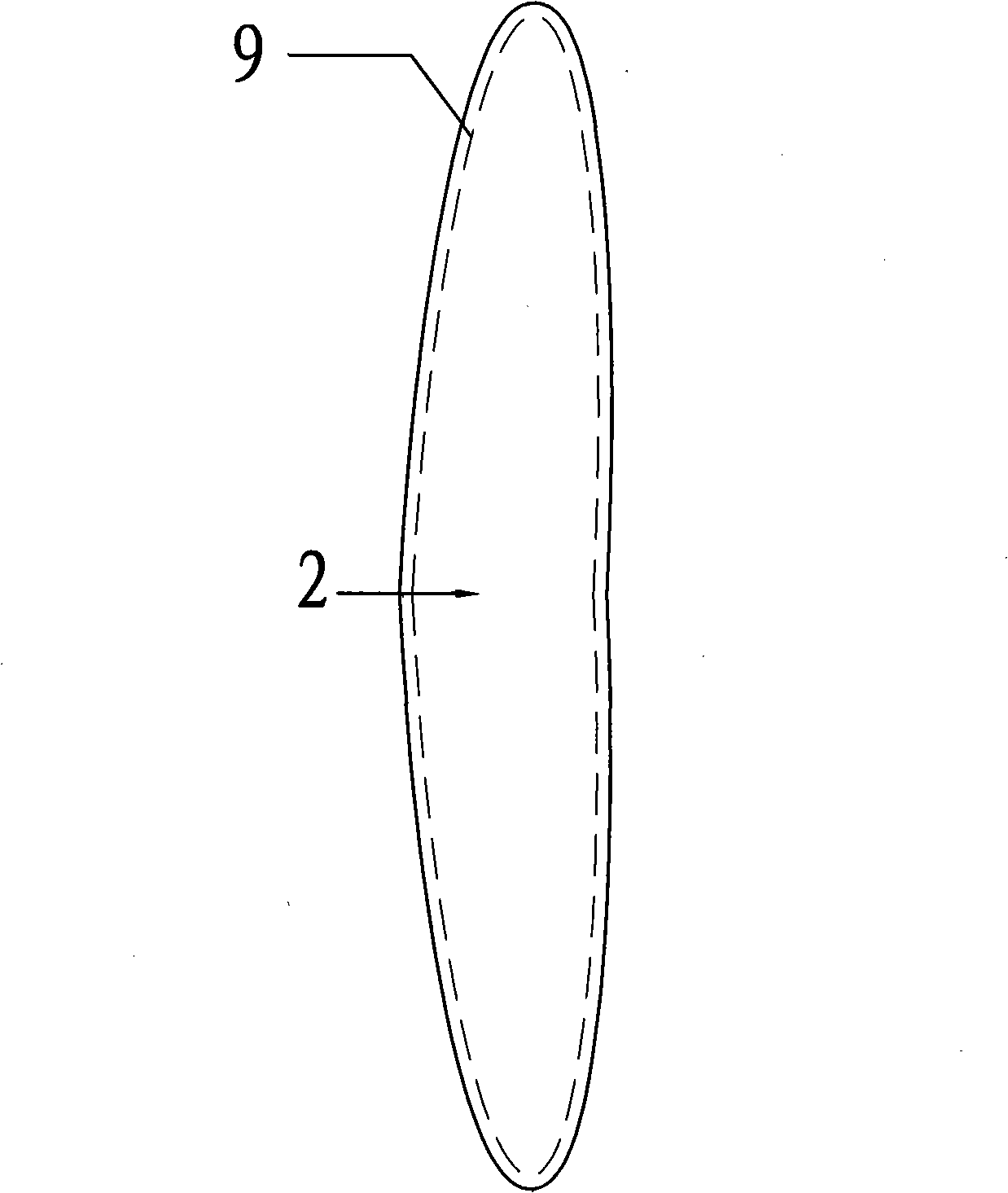

Steel tube concrete diagonal frame column spatial tubular joint and its manufacture method

InactiveCN101260689APower transmission is clearActive connectionBuilding constructionsSteel tubeMaterials science

The invention provides an oblique grid column spatial joint for a concrete-filled steel tube and a manufacture method thereof, wherein, four round steel tubes of the joint are crossed at the position of an oval connecting plate, and welding connections are adopted among the four round steel tubes and between the round steel tubes and the oval connecting plate; a circumferential reinforcing plate consists of at least two annular steel plates, is welded on the four round steel tubes on the welded joint of a central plane; two annular plates parallel to the circumferential reinforcing plate are respectively welded on round steel tubes above and under the circumferential reinforcing plate; stiffener plates are welded between the circumferential reinforcing plate and the annular plates in uniform distribution; and joint extending brackets are welded on the annular plates. The manufacture method of the joint comprises the welding among the round steel tubes and the connecting plate, and the welding of the circumferential reinforcing plate, the annular plates and the stiffener plates. The joint has the advantages of clear force transfer, high bearing capacity, light weight, good performance and convenient construction, can effectively connect an upper oblique grid column and a lower oblique grid column so as to realize the spatial intersection of the joint of the concrete-filled steel tube column, and have excellent engineering application foreground.

Owner:SOUTH CHINA UNIV OF TECH

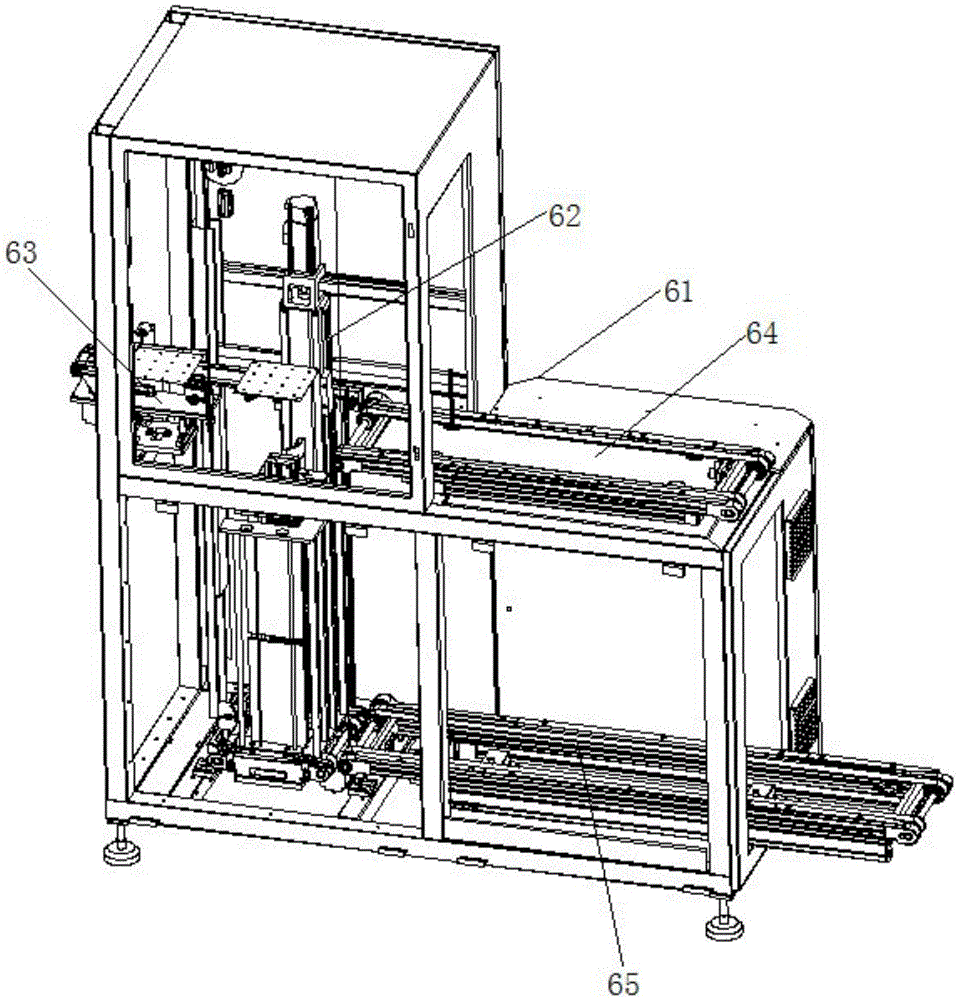

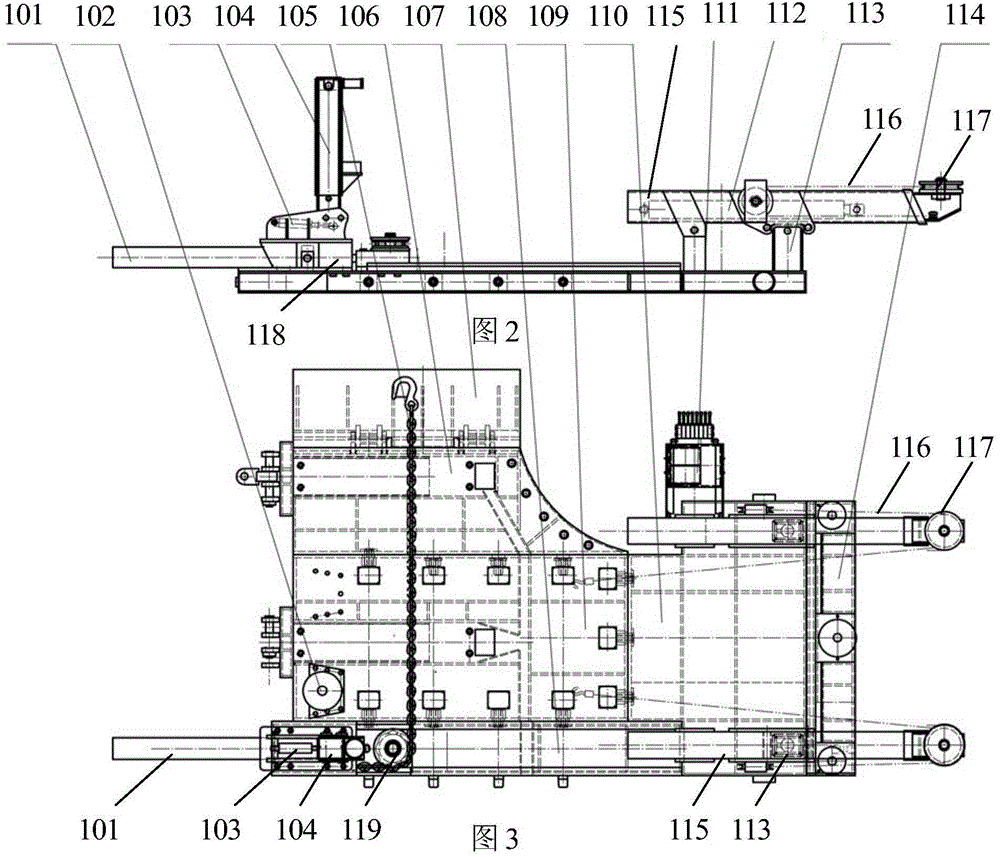

Laser processing equipment for full-automatic solar battery piece

ActiveCN105618934ASimple structureEasy to useManipulatorLaser beam welding apparatusLaser processingEngineering

The invention relates to laser processing equipment for a full-automatic solar battery piece. The laser processing equipment comprises a workbench, a laser processing host, a battery piece processing table, a rotary mechanical arm assembly, left and right battery piece caching and transferring components and left and right battery piece connection assemblies, wherein the laser processing host and the battery piece processing table are both installed on the workbench; the battery piece processing table is arranged below a laser processing head of the laser processing host; the rotary mechanical arm assembly is installed on the workbench on one side of the battery piece processing table; the left and right battery piece caching and transferring components are installed on the workbench on the two sides of the rotary mechanical arm assembly; in the rotation process of the rotary mechanical arm assembly, the free end of the rotary mechanical arm assembly can rotate to the positions above the battery piece processing table and above the left and right battery piece caching and transferring components on the two sides of the rotary mechanical arm assembly respectively; and the left and right battery piece connection assemblies are installed on the two sides of the workbench. The laser processing equipment has the advantages of simple structure, convenience in use, high production efficiency and strong processing stability.

Owner:WUHAN DR LASER TECH CORP LTD

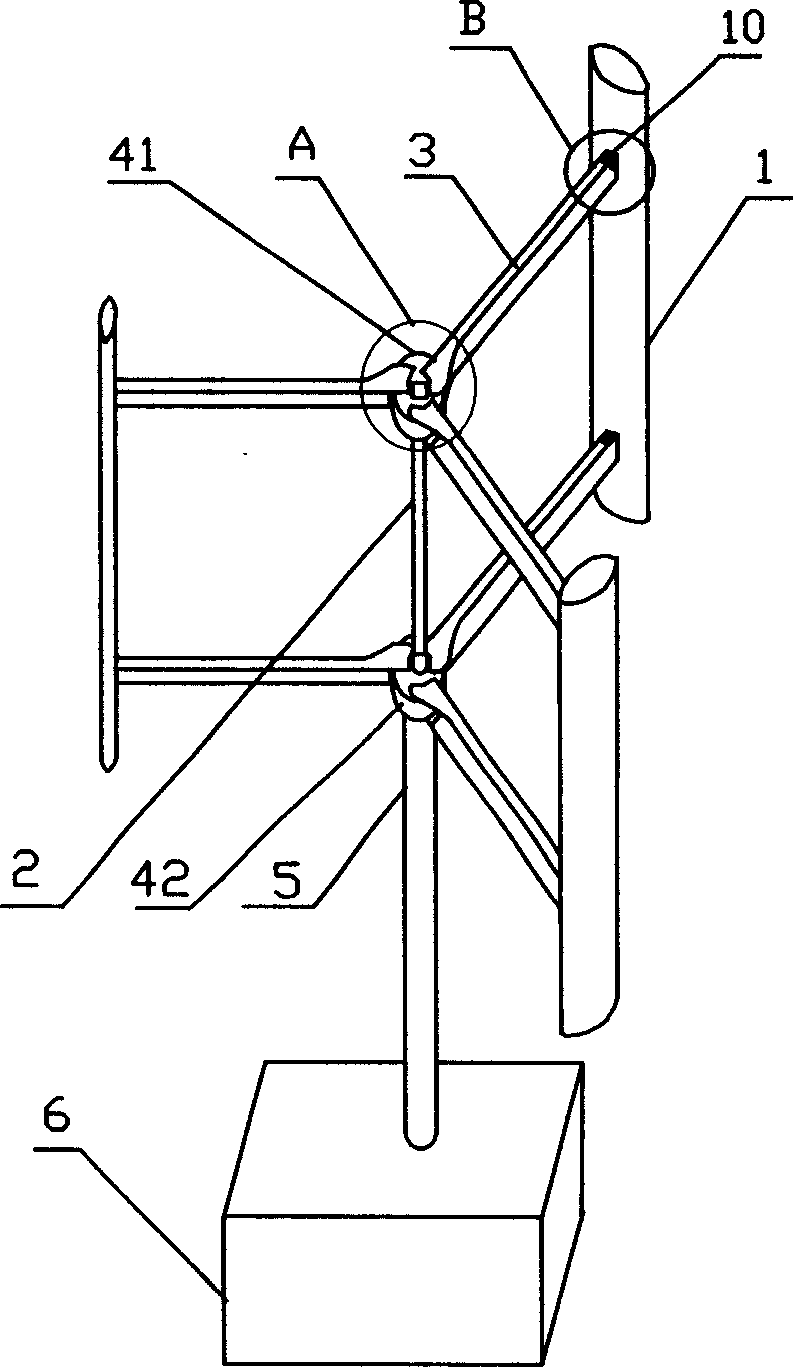

Wind blade device for wind generating system

InactiveCN1641214AReduce resistanceReasonable connectionFinal product manufactureWind motor assemblyAlloyEngineering

The breeze leaf device of the wind power system that the invention provide, includes the breeze leaf, rotate shaft, cannula, generator and adopt the perpendicular axis type, the breeze leaf presents a long form, the cross section adopt the NACA0009 wing type, breeze leaf is parallel with the shaft axis line in its length, the string perpendicularity toward the shaft axis line by the length direction, through the conjunction of horizontal beam and shafts, need not to change the windmill direction according to the direction of wind, the space take up is small, the noise is small; the Breeze leaf is solid to become the type adoption the macromolecule compound material, the shaft adoption carbon steel material to manufacture, the contact installation adopt the aluminum metal alloy material, which have good and enduring, anti-causticity, safety, applicably to the temperature changing from minus 55 deg.C to plus 70 deg.C in land, deserts, follow various bad environment of the region of etc. of sea, such as sand dust, salt fog, damp weather etc., enduring time is 20 years long.

Owner:泉州凯丽化工有限公司

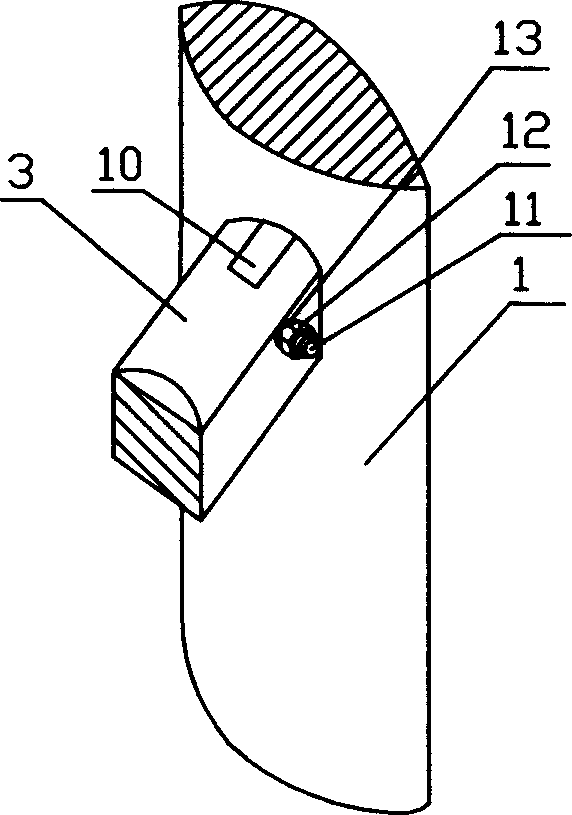

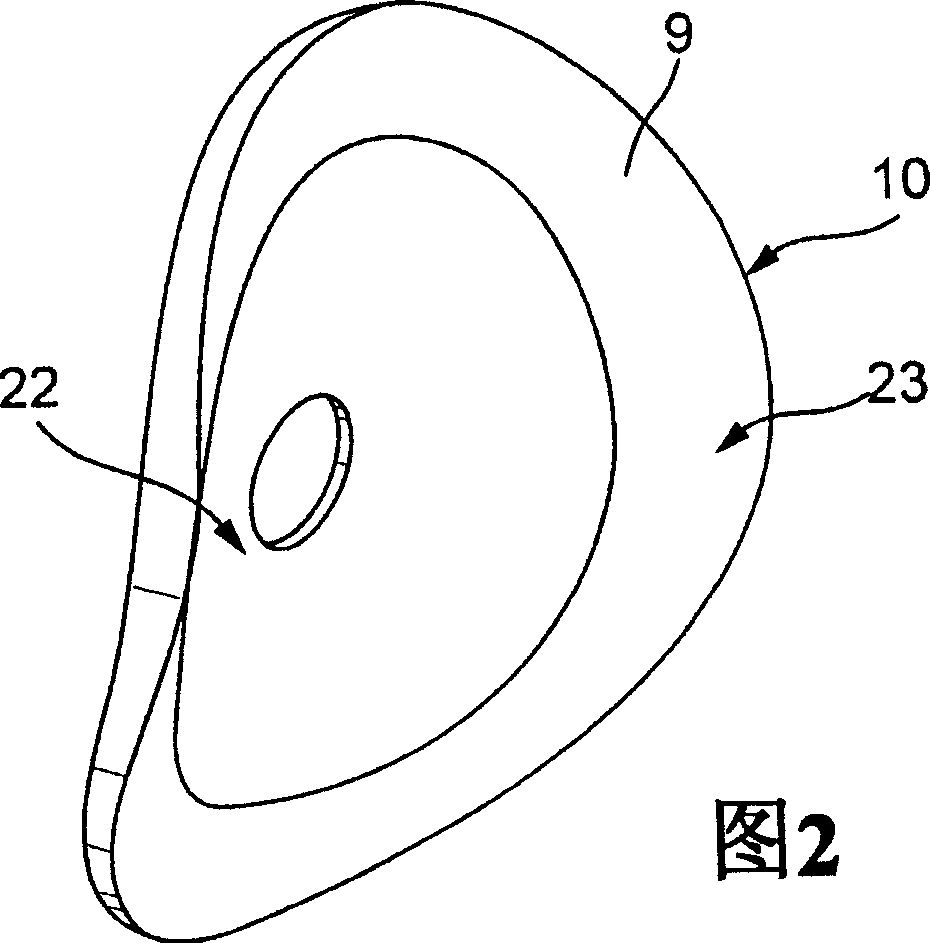

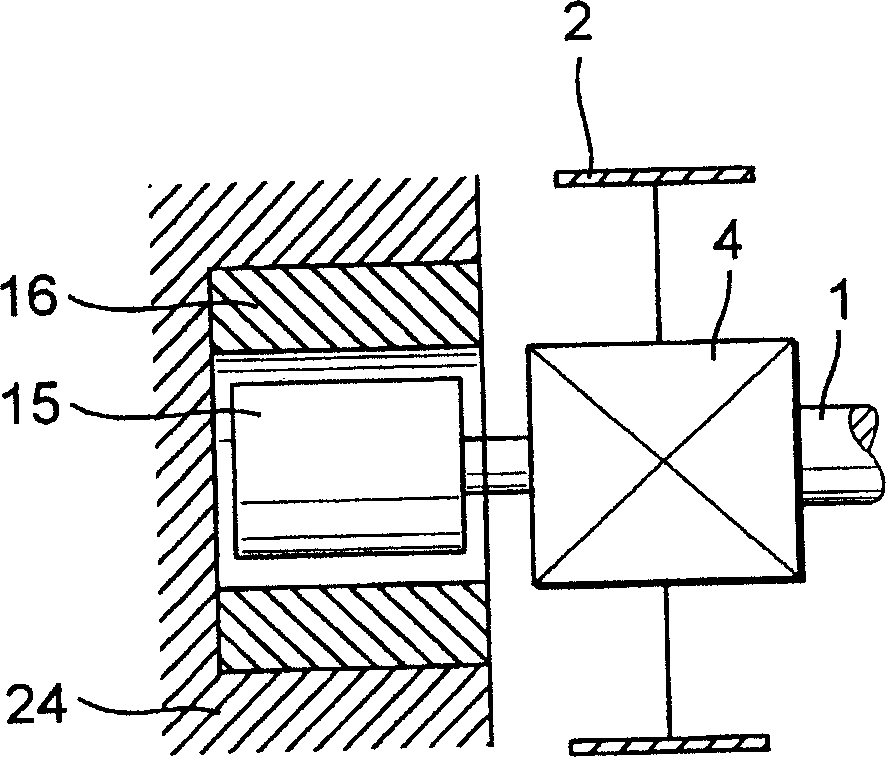

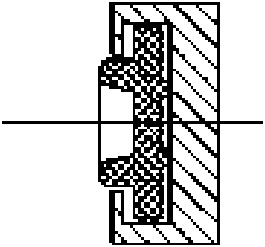

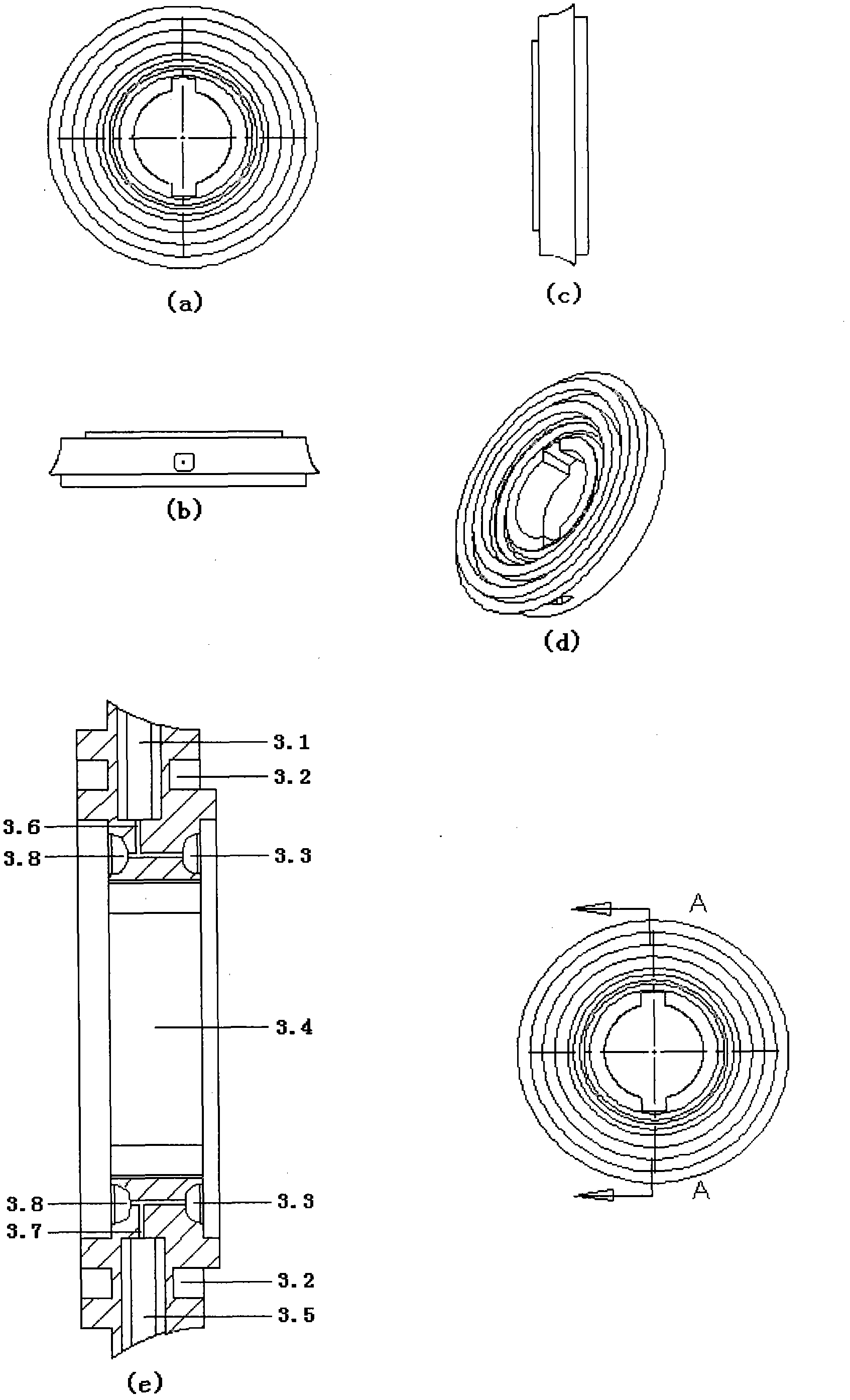

Device for varying valve timing in an internal combustion engine

InactiveCN1671950ACompact structureMoment of inertia down toValve arrangementsGearingCircular discInternal combustion engine

A device for varying valve timing in an internal combustion engine comprises an adjusting mechanism for varying an angle of rotation between a drive pinion ( 2 ) and a camshaft (end portion of the camshaft , said adjusting mechanism being configured as a wobble transmission. The drive pinion ( 2 ) comprises a first front-end gearing ( 9 ) and a disk ( 10 ) comprises a second front-end gearing ( 11 ), which first and second front-end gearings mesh partially with each other, and the number of teeth of said front-end gearings differ from each other by at least one tooth. To reduce the overall dimensions of the device and avoid gearing lash, it is proposed, on the one hand, to connect the disk ( 10 ) rotationally fast to the camshaft ( 1 ) and on the other hand, to configure the disk ( 10 ) in axial direction of the camshaft ( 1 ) as a flexible element that can be deformed in axial direction by an adjusting device (thrust plate 17 ).

Owner:INA SCHAEFFLER KG

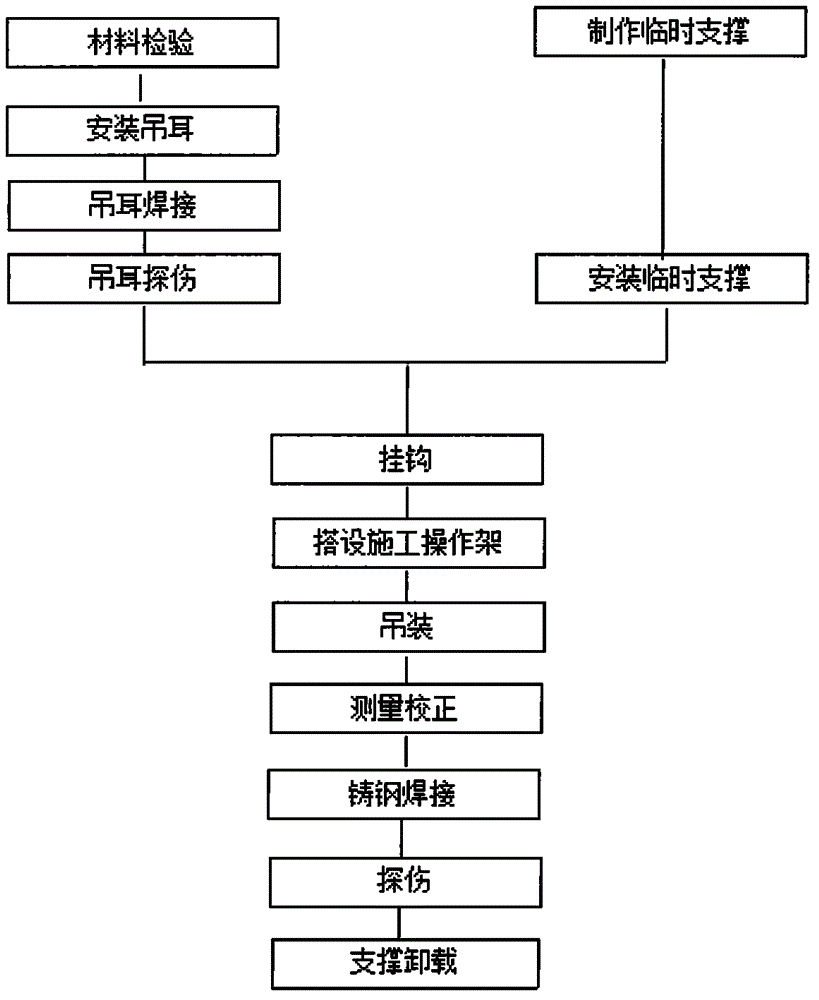

Method for installing and constructing special-shaped large-tonnage steel castings

InactiveCN104631837AGuarantee the construction qualityThe connection is reasonable and validWelding/cutting auxillary devicesAuxillary welding devicesVertical displacementWelding joint

The invention discloses a method for installing and constructing special-shaped large-tonnage steel castings. The large-tonnage steel castings are complex in shape and are hoisted through a heavy crawler crane. Before the steel castings are hoisted, a symmetric method is adopted to analyze and determine the installing positions of lifting lugs of the steel castings, and a welding work platform is arranged on the welding portions of the steel castings in advance. In the installing and constructing process, a sling of the crawler crane is used for controlling the vertical displacement of the steel castings, a wind cable is used for adjusting the horizontal displacement of the steel castings, and the installation accuracy and construction safety of the steel castings are guaranteed by means of temporary support and other measures; after the steel castings are installed in place, the quality of weld joints is guaranteed through a series of processes such as weld preheating, in-process heat preservation and postweld heat treatment according to the material characteristics of the steel castings and up-down welding structures. By means of the method, the standard requirements for joints of the special-shaped large-tonnage steel castings are met, the construction quality is ensured, connection is more reasonable and effective, the consumption of steel is reduced, and meanwhile the appearance quality of a building is improved.

Owner:YONGSHENG CONSTR GRP +1

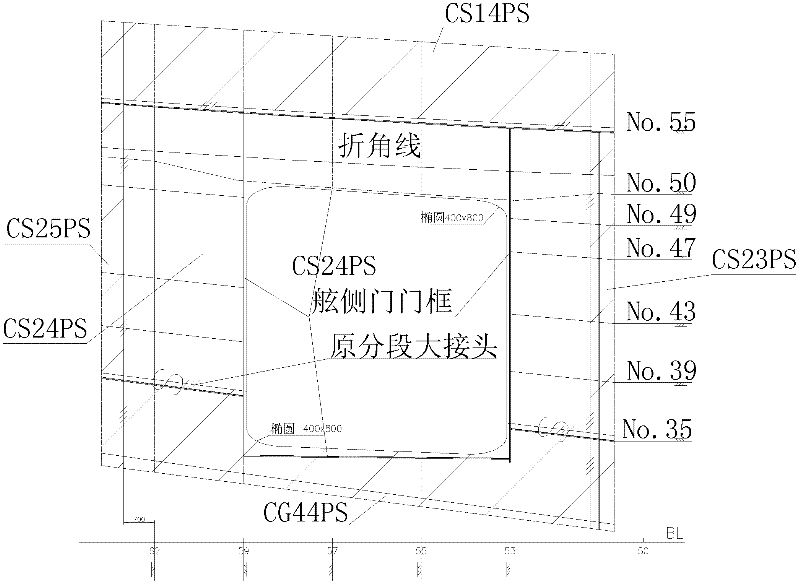

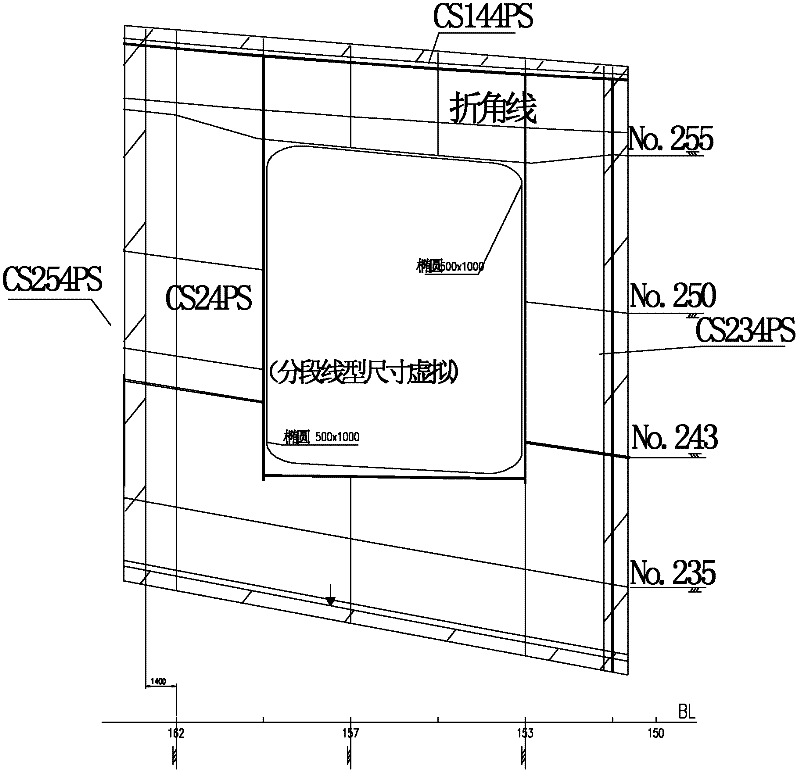

Method for manufacturing and installing inclined curved side port

The invention relates to a method for manufacturing and installing an inclined curved side port, which comprises the following steps: according to the practical situation of the linear curvature of the side port manufactured and installed in a hull side area, performing subsection division again to enable a new subsection to contain the whole side port, and enabling the new subsection to be named a CS24APS subsection; implementing bodiless manufacturing and integral welding on the structure of the side port and the CS24APS subsection at a time; positioning a hinge and performing preassembly on the side port; after the CS24APS subsection is assembled and unbodied, performing the preassembly on the side port in the CS24APS subsection; when docking final assembly is performed, firstly, installing a locating backer when the side port and the block of the subsection are folded; performing final fine adjustment to determine the position of the hinge by utilizing a large crane and an auxiliary assembly tool when a dock is formally provided with the side port; and then welding. The method for manufacturing and installing the inclined curved side port is capable of ensuring the operation of the dock to be safe and one-time hoisting to be successful, thereby, the production efficiency of assembly is improved, and the production cycle of the dock is shortened.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

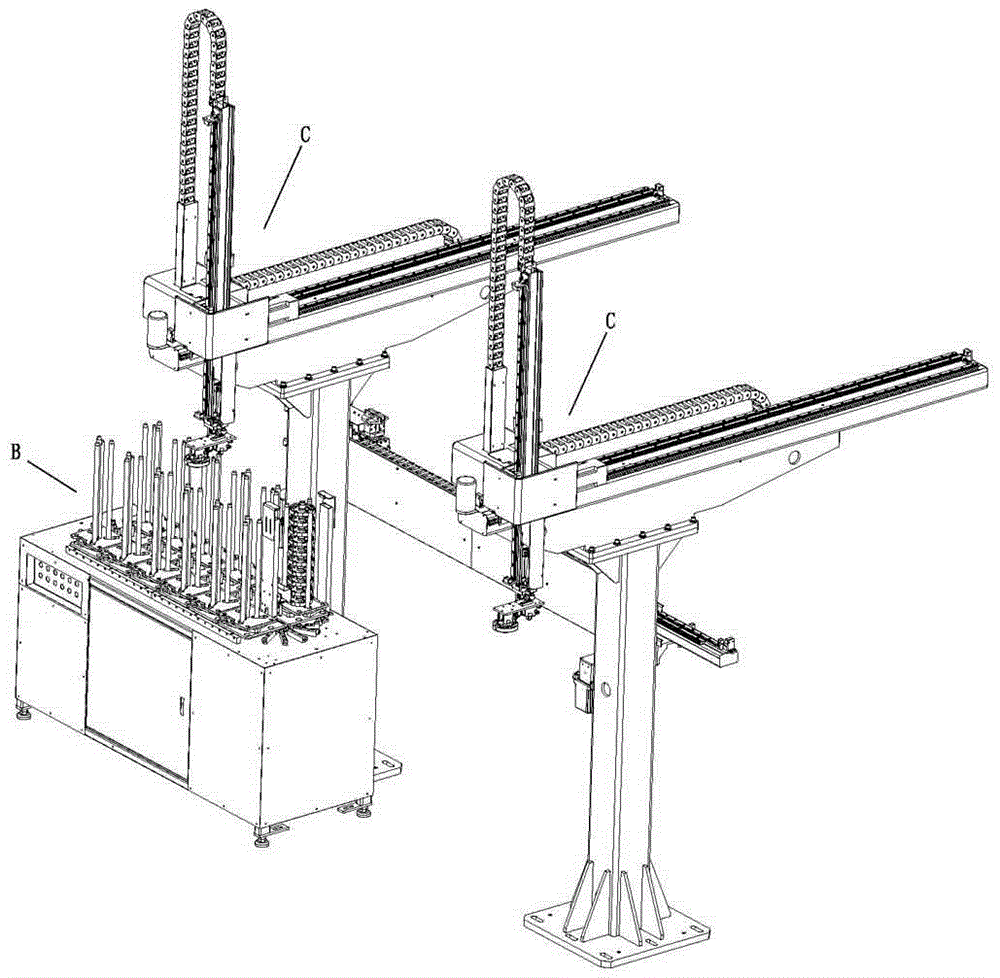

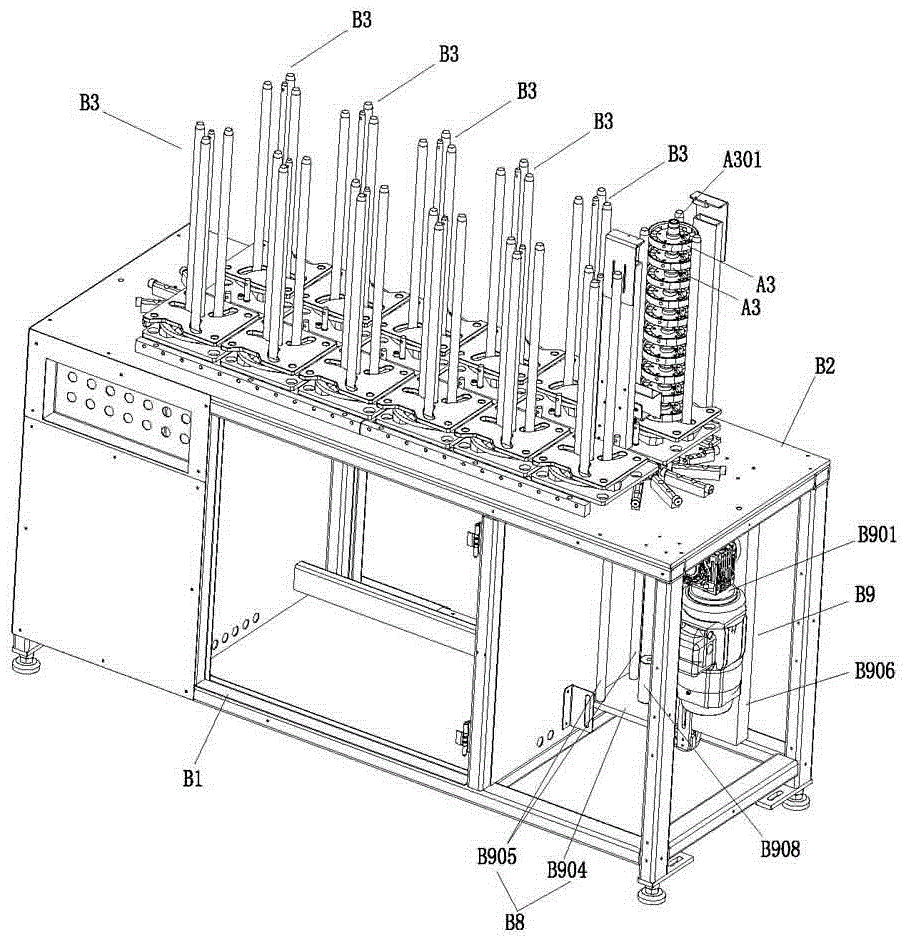

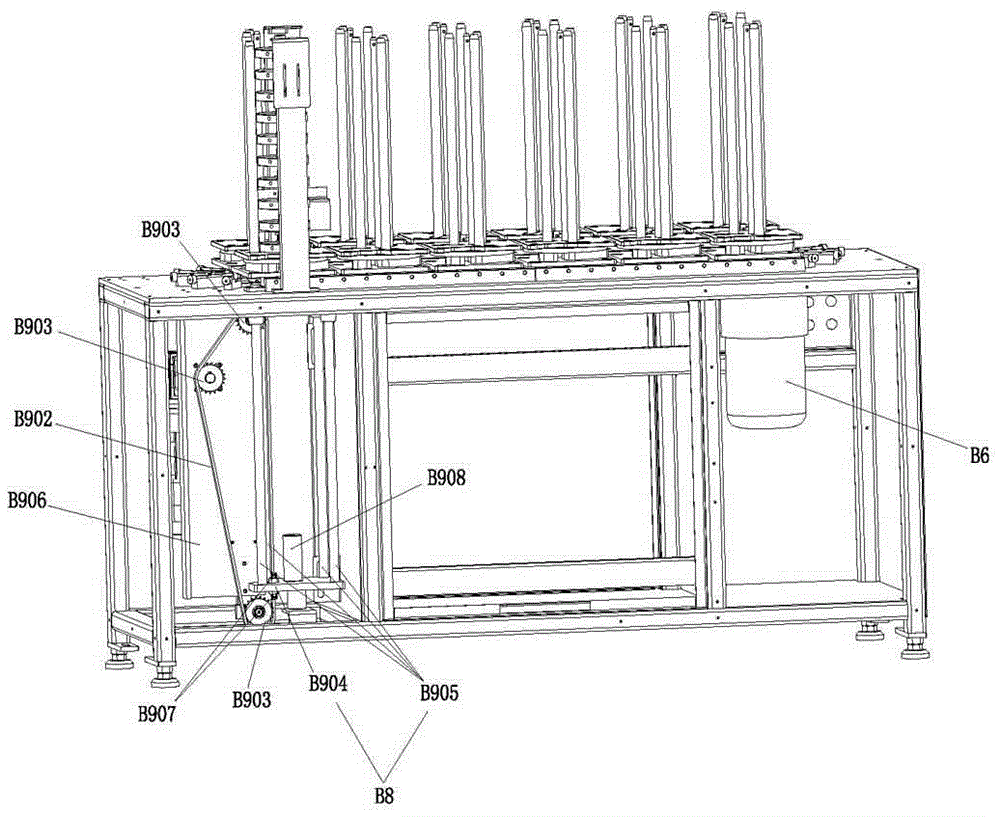

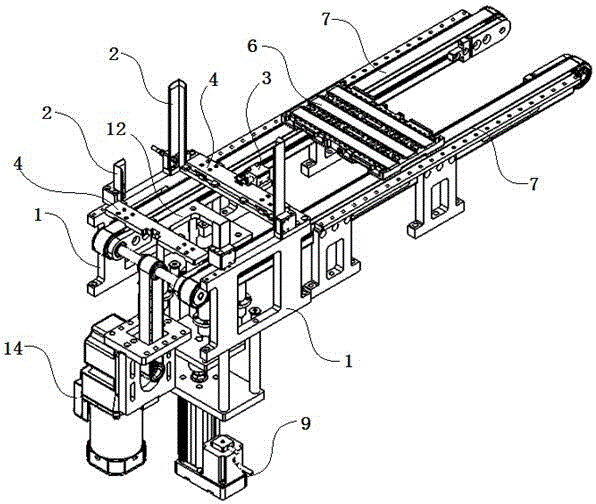

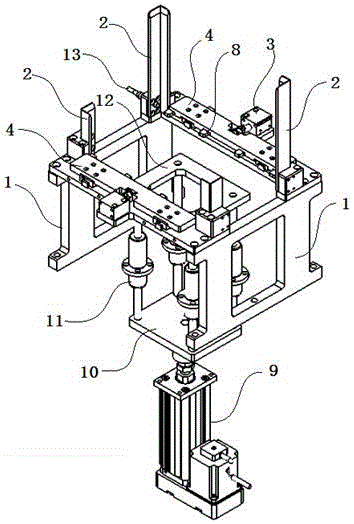

Automatic feeding and taking equipment with u-turning device

The invention relates to automatic feeding and taking equipment with a u-turning device. The automatic feeding and taking equipment comprises a rotary type material bin and two two-shaft mechanical arms and a u-turning transferring device; the rotary type material bin comprises a material bin base, a working table is arranged at the top of the material bin base, a plurality of material storage frames are installed on the working table, and a plurality of workpieces are stacked on each material storage frame; two transmission chain wheels are arranged on the two sides of the working table correspondingly, the two transmission chain wheels are connected through a transmission chain, and one of the transmission chain wheels is driven by a transmission chain wheel motor; the multiple material storage frames are arranged in the layout extending direction of the transmission chain, each material storage frame is in connected fit with the transmission chain through a connecting assembly, and each material storage frame achieves movement along with transmission of the transmission chain; a lifting frame is installed in the material bin base and is driven by a lifting assembly, so that the lifting frame penetrates the working table to upwards lift the workpieces; and the multiple material storage frames are all arranged to be capable of moving along with the transmission chain, rotary workpiece conveying is formed, the storage capacity of the workpieces is effectively increased, and the machining efficiency is effectively improved.

Owner:广东圣特斯数控设备有限公司

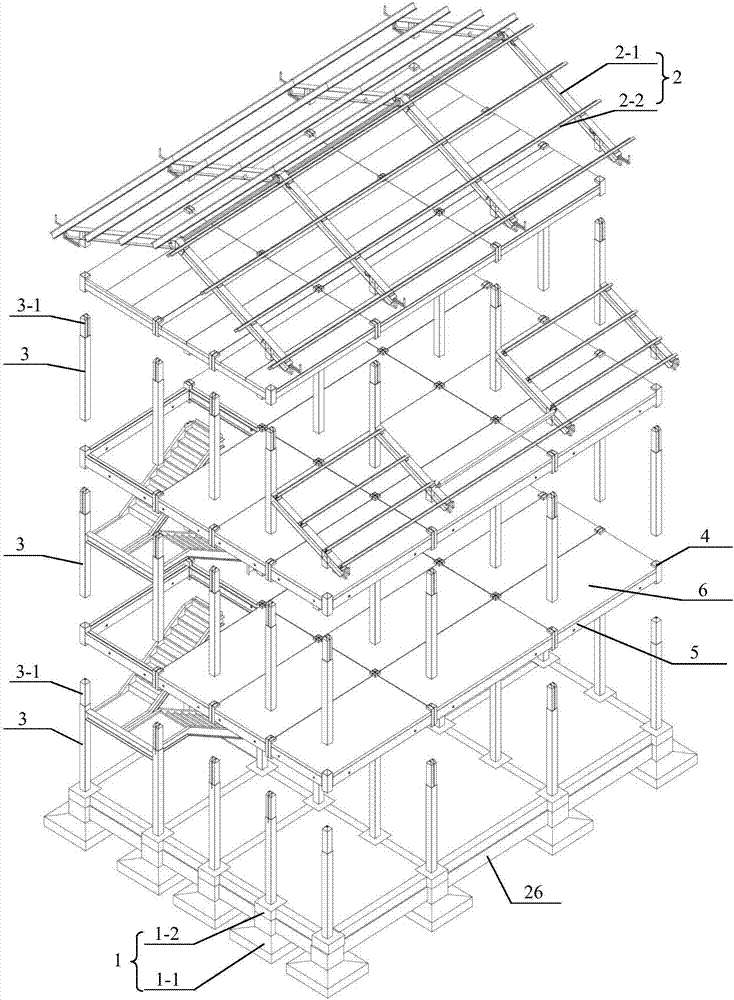

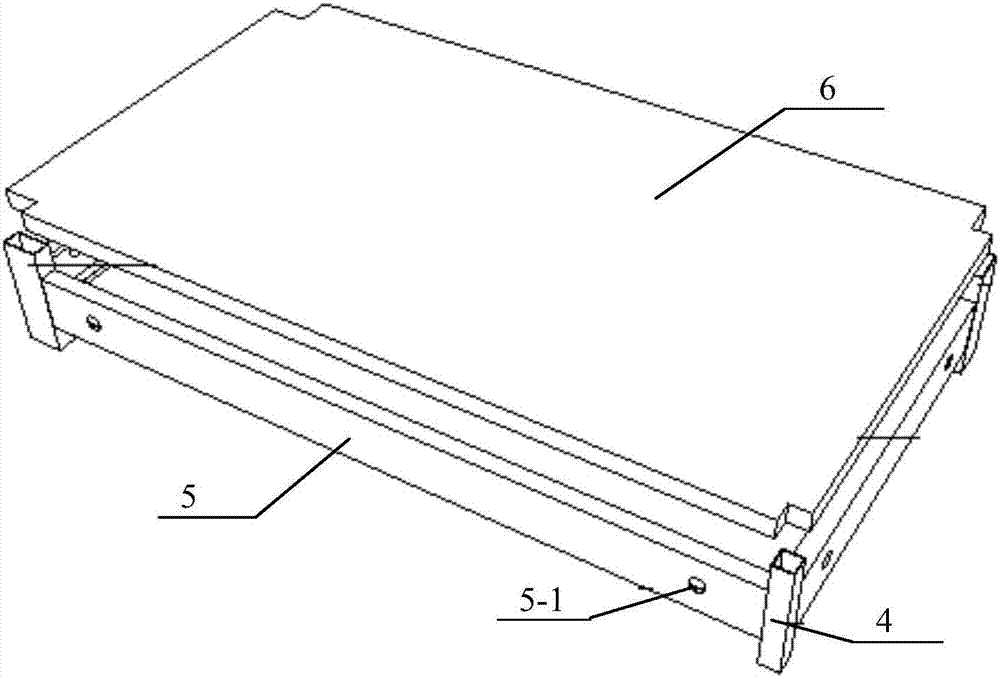

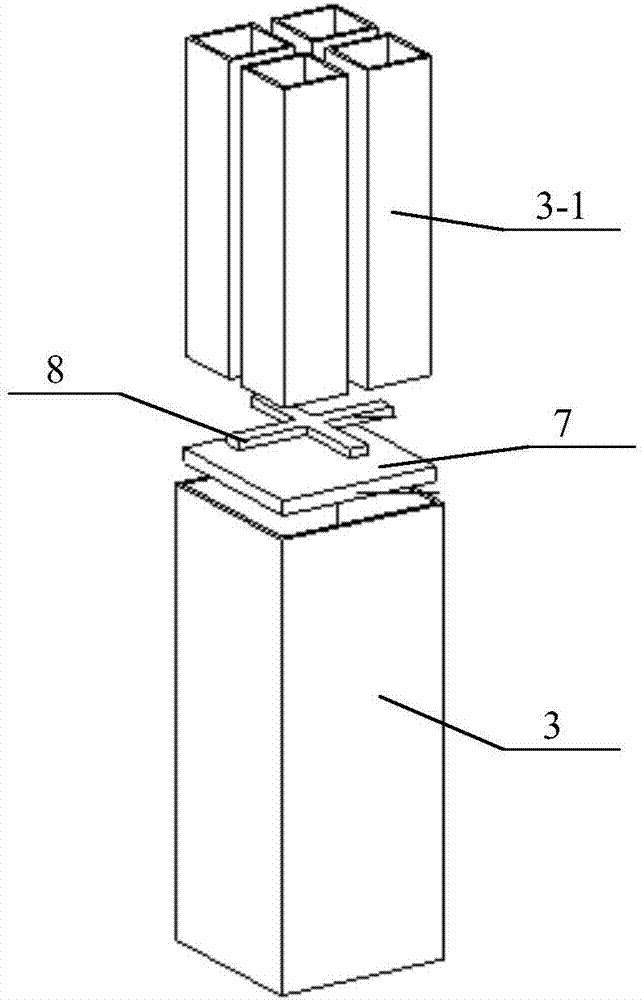

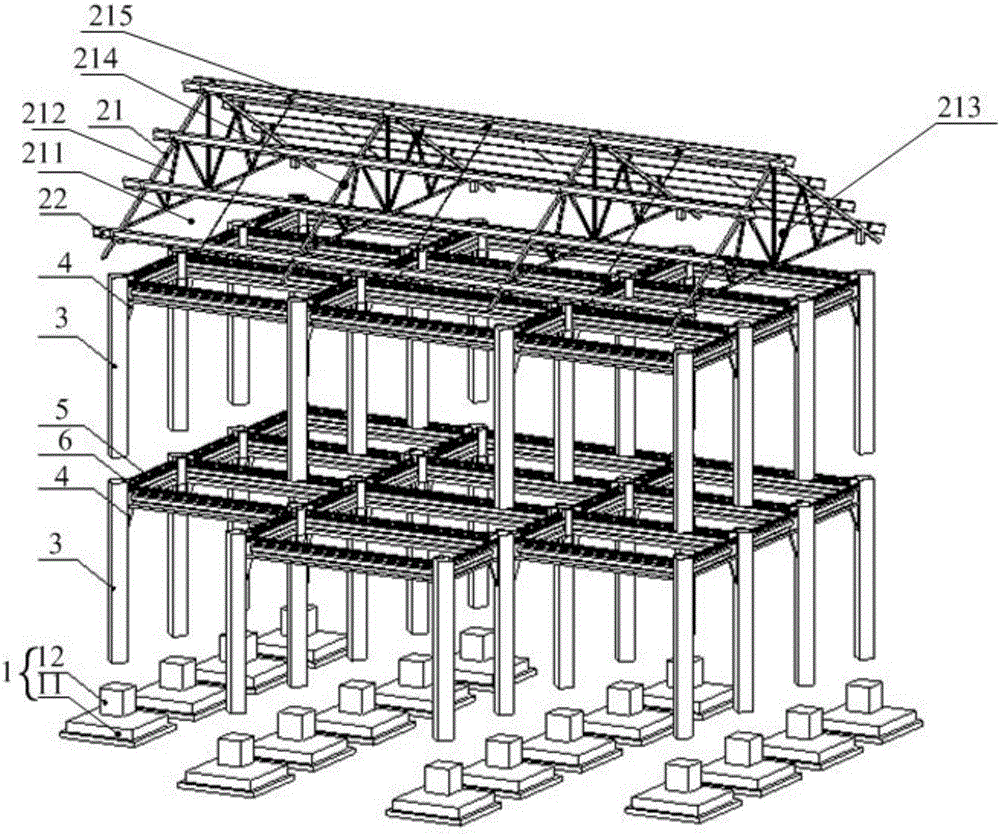

Prefabricated building main body structure

PendingCN107366356AReasonable connectionEasy to installBuilding constructionsFloor slabArchitectural engineering

The invention discloses a prefabricated building main body structure, and relates to the technical field of constructional engineering structures. The prefabricated building main body structure comprises an independent foundation; at least one layer of floor slabs is fixedly arranged above the independent foundation; a supporting structure is arranged under each layer of the floor slabs; a roof frame structure is fixedly arranged above the top layer of the floor slabs; the floor slabs comprise a plurality of combination beam plates; the supporting structure of each layer comprises a plurality of square pipe columns; tenon pipes connected with the combination beam plates in an inserting manner are arranged on the square pipe columns; a stairway is arranged between every two vertically adjacent layers of floor slabs; the combination beam plates comprise four-corner components; steel beams are fixedly connected between the adjacent four-corner components; the upper edges of the steel beams are spaced from the top ends of the four-corner components by a certain distance; concrete slabs are poured on the steel beams; reinforcement meshes are arranged in the concrete slabs; reserved pipeline holes are formed in the side surfaces of the steel beams; and the four-corner components are sleeves matched with the tenon pipes in an inserting manner. The beam and column connection is reasonable, the mounting is convenient and the flexural capacity is high.

Owner:北京善筑科技股份有限公司

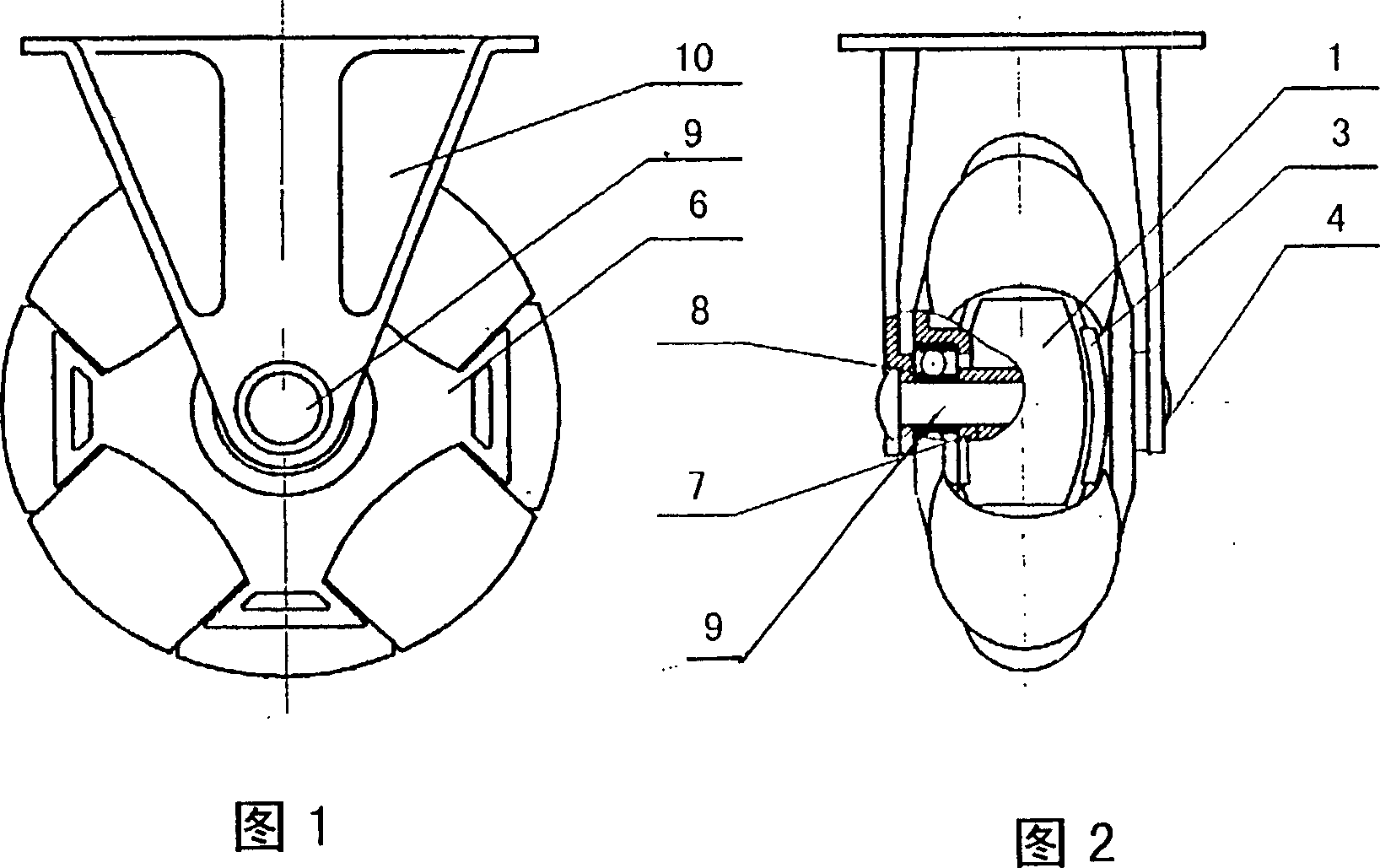

Universal wheel

The invention relates to the structure and shape of a universal wheel, disclosing a new universal wheel, composed of big and small waist drum rollers, batwing bracket, long and short mandrels, side cover plate, bearing, sleeve, central shaft, wheel frame and so on. Its character: the two rollers and the two mandrels fixed on the batwing bracket compose the wheel edge, the batwing bracket is linked with the side cover plate, and the bearing, the central shaft and the wheel frame are installed in the center of the side cover plate, thus composing it. It uses the two rollers to compose double-freedom mechanism, thus able to be pushed in an arbitrary direction to move without rotating the direction of the wheel when used, saving the rotary space. In addition, it has not only better stopping property to prevent the sand from intruding into the inner cavity of the rollers, but also has advantages of reasonable structure, good technique, etc.

Owner:黄善钧 +1

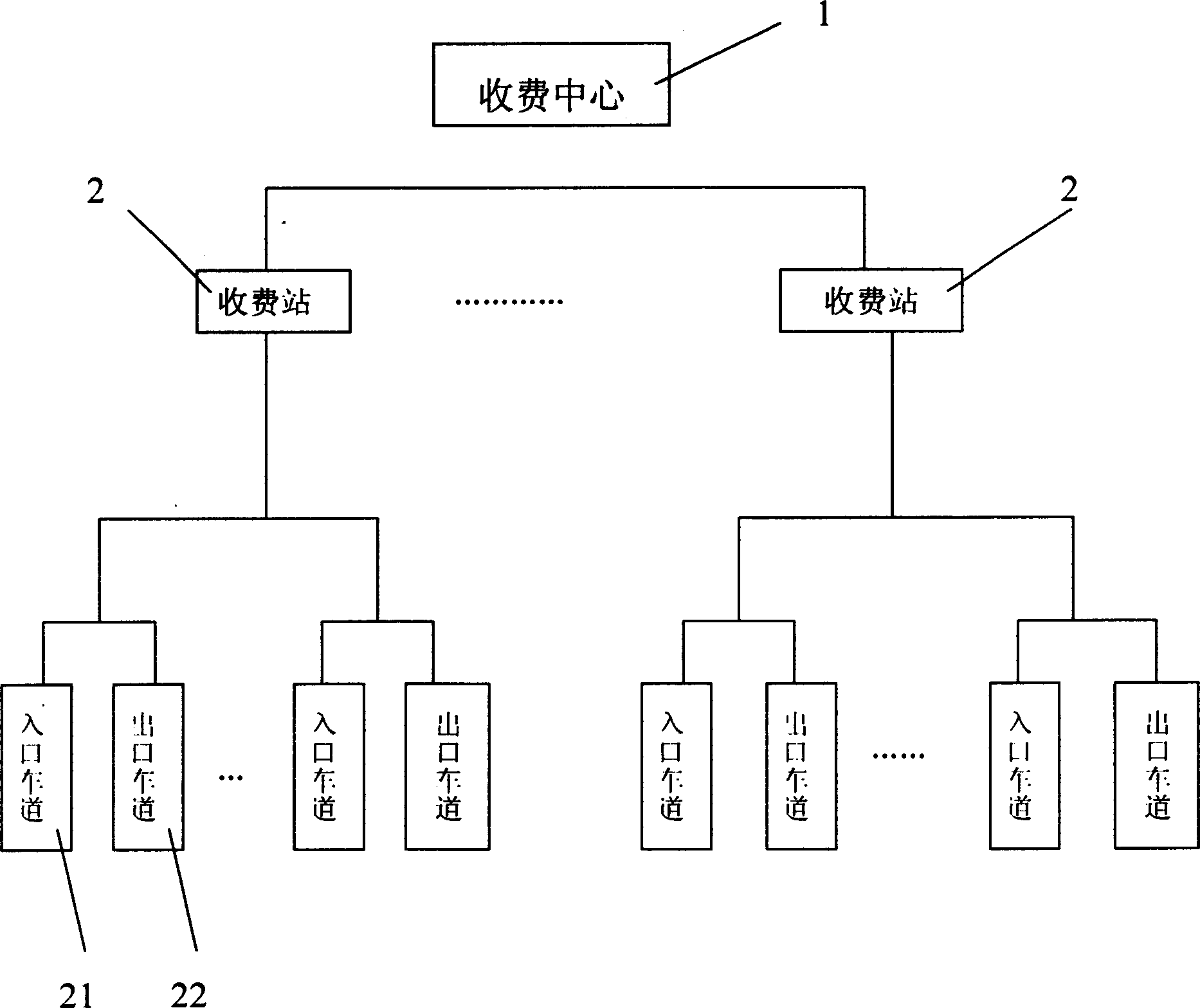

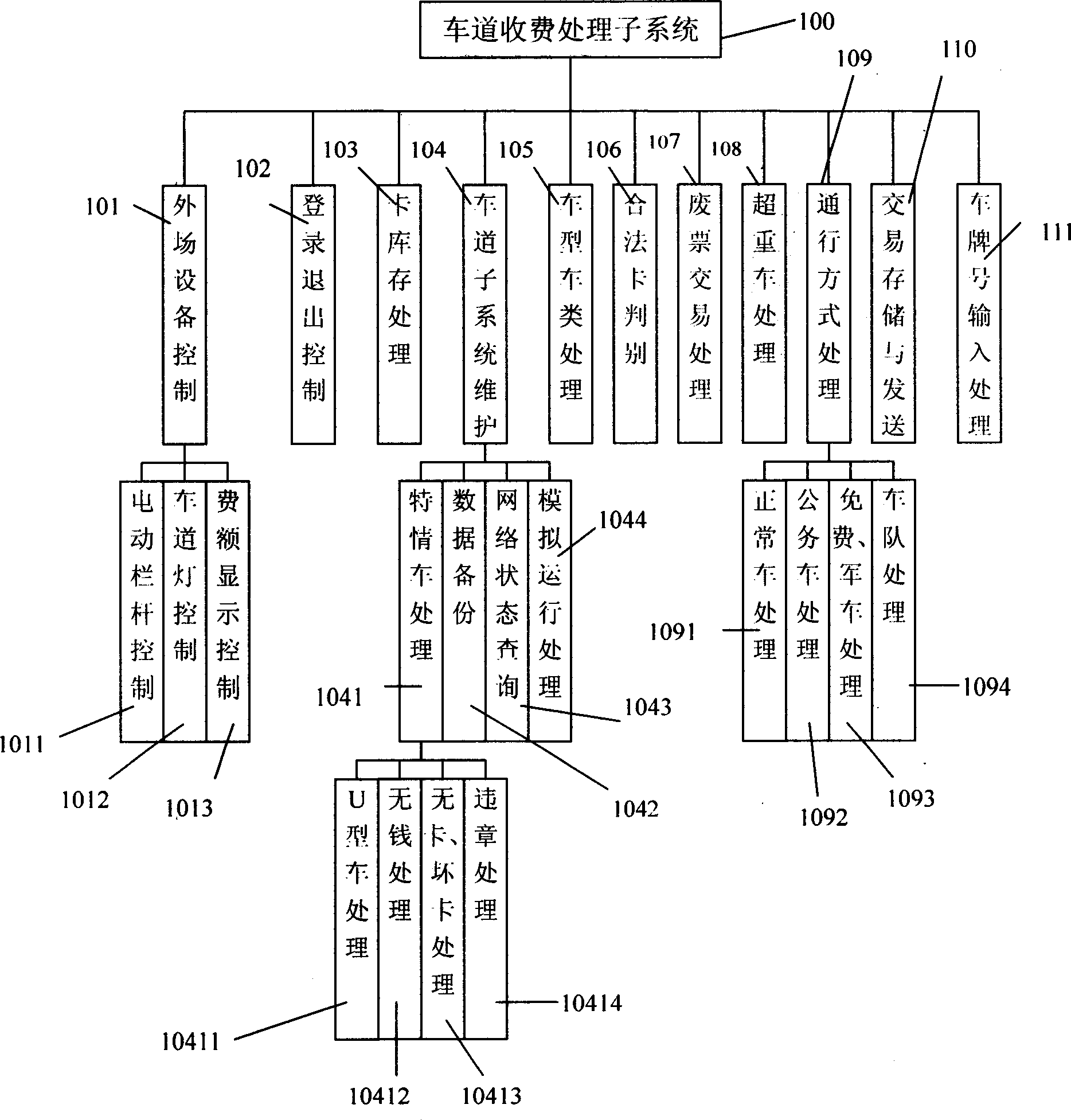

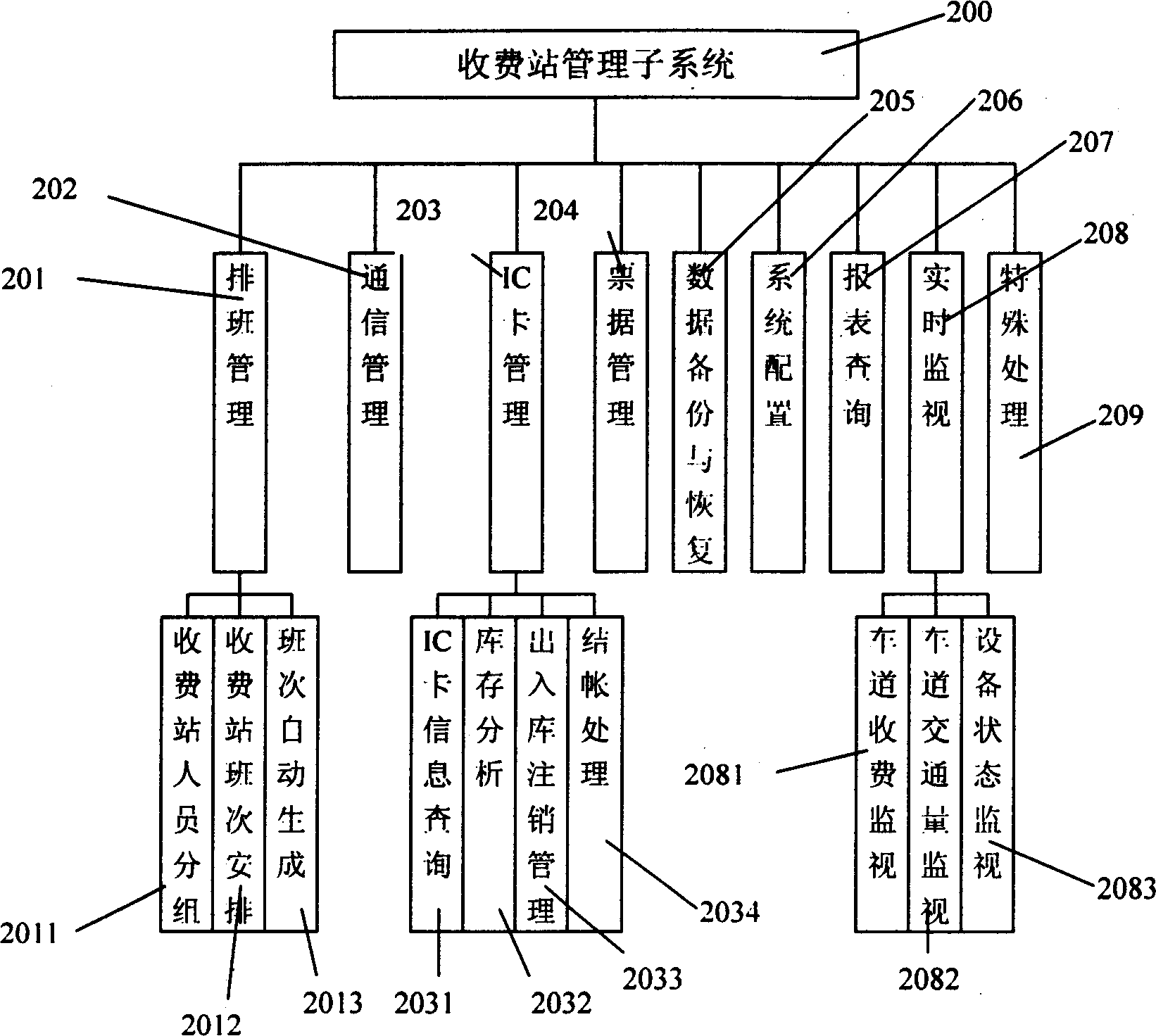

Universal road toll collecting system

InactiveCN1399231ASolve Rate CalculationsImprove versatilityTicket-issuing apparatusData switching by path configurationEngineeringWide area network

The universal road tool system includes a tool centre at least a toll gate and at least two entrance and exit lane subsystems. The said toll center is connected with toll gate via WAN while the toll gate is connected to the entrance and exit lane subsystems via LAN. The toll collecting center has resident toll data definition creating program based on vehicle type, distance, unit price, tunnel and bridge number and vehicle tonnage. The present invention solves the problem of calculating toll with several tunnels and bridges and has two automatically changed rates, is universal and can reduce the labor strength of the managers.

Owner:上海经达信息科技股份有限公司

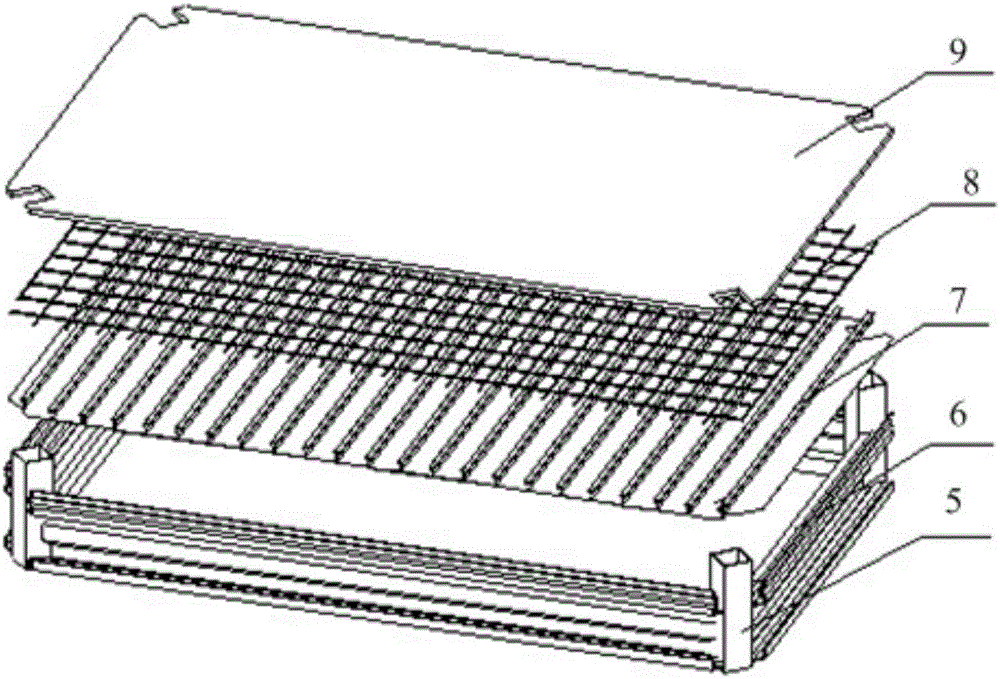

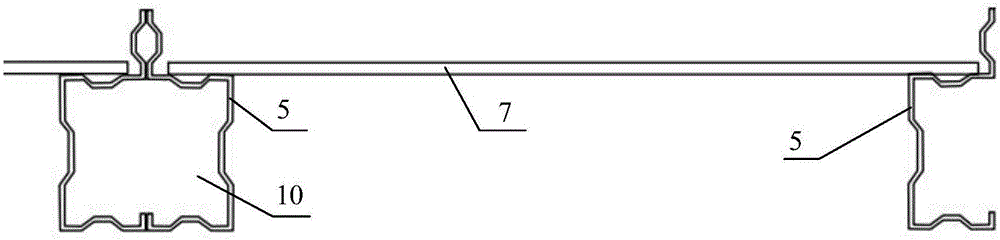

Assembly type main structure of building

InactiveCN106759900AReasonable connectionEasy to installFloorsFoundation engineeringCold formedEngineering

The invention discloses an assembly type main structure of a building, and relates to the technical field of building engineering structures. The assembly type main structure of the building comprises isolated foundations, at least one layer of supporting beam group and at least one layer of cold-formed thin-walled steel composite beam plates are arranged on the isolated foundations, and a roof frame structure is arranged on the top supporting beam group, wherein each layer of supporting beam group comprises a plurality of square tubular columns, and the upper portion of each square tubular column is provided with a beam support; each cold-formed thin-walled steel composite beam plate comprises a lipped channel stiffened structural beam, a profiled steel sheet, a reinforcing mesh and a concrete plate, and the end of each lipped channel stiffened structural beam is provided with a sleeve; each lipped channel stiffened structural beam comprises a vertical plate, a first transverse plate and a second transverse plate, a vertical baffle is arranged above each first transverse plate, and stiffened structures are arranged on the first transverse plates, the second transverse plates, the vertical plates and the vertical baffles respectively. The assembly type main structure is reasonable in beam-column connection, convenient to install, high in flexural capacity and suitable for large-span commercial complex buildings.

Owner:北京善筑科技股份有限公司

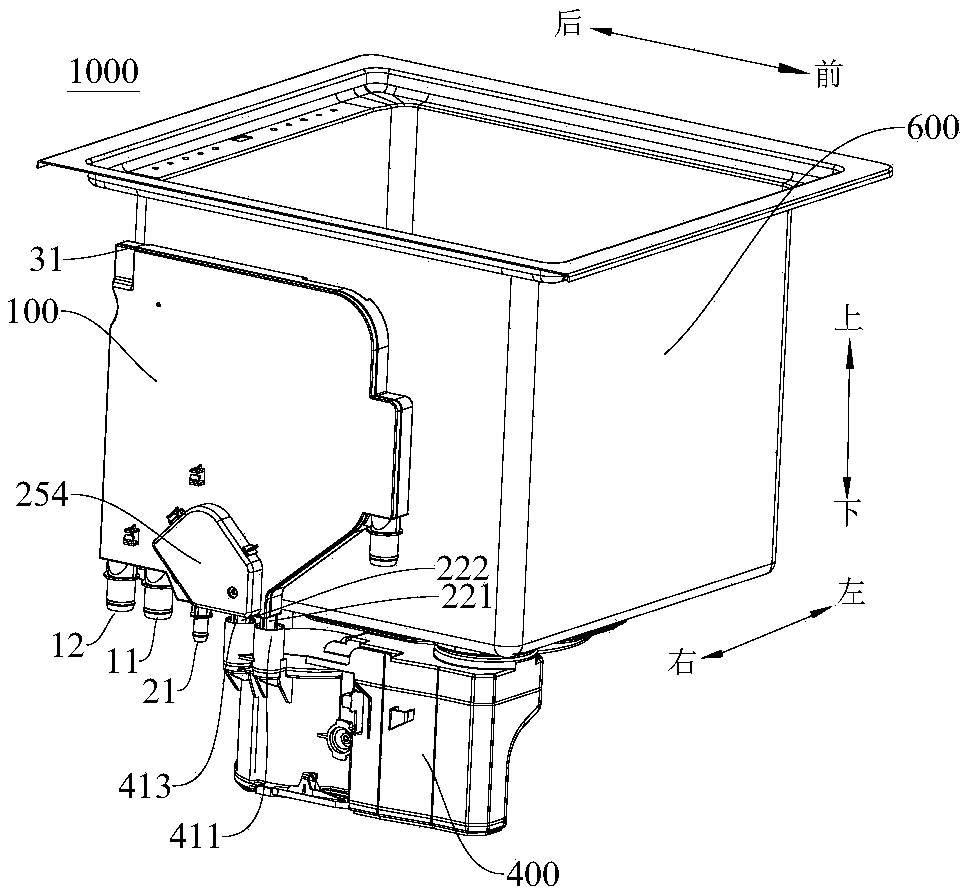

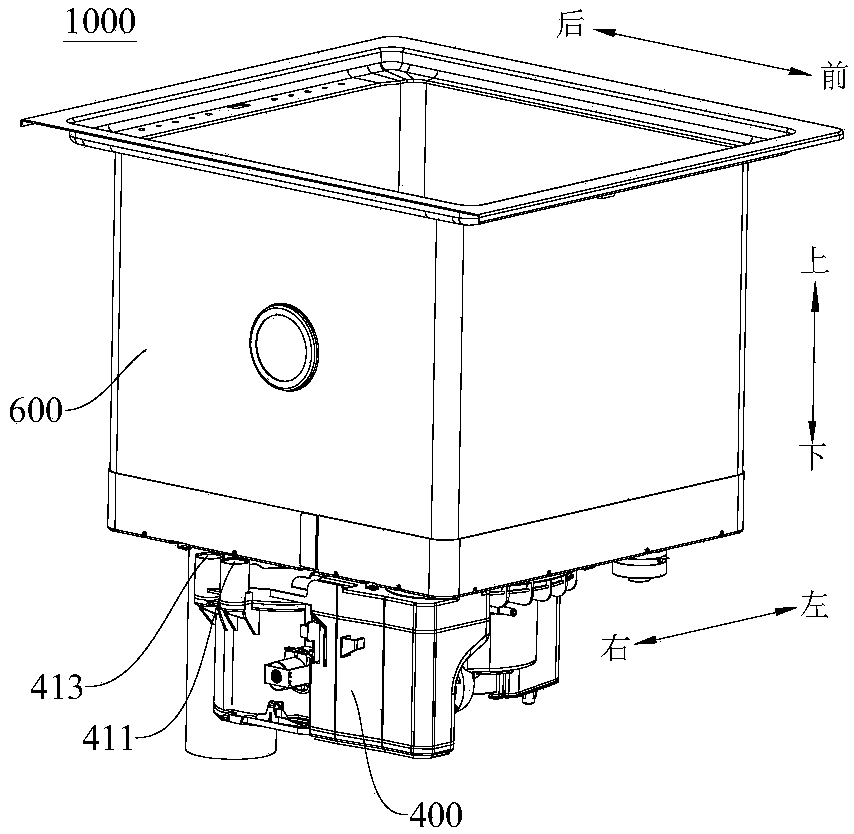

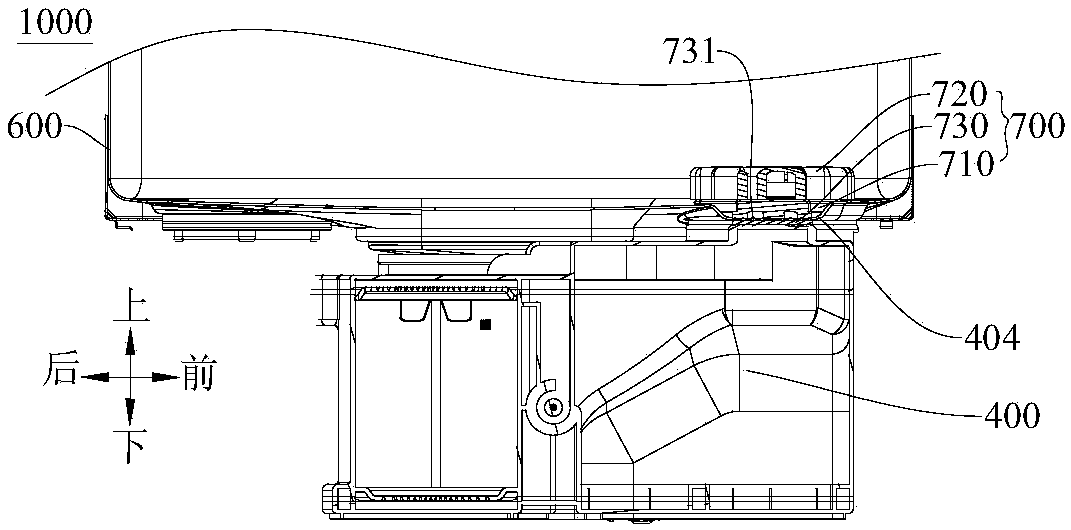

Water tank-type dish washer

ActiveCN107713937ASet compactReasonable layingTableware washing/rinsing machine detailsReclaimed waterProcess engineering

The invention discloses a water tank-type dish washer. The dish washer comprises a washing tank body and a water softener. A mounting hole is formed in the bottom wall of the washing tank body, the water softener is located on the bottom wall outside the dishing tank body and comprises a water softener body, a regeneration control part and a salt lacking detection device. A soft water cavity and asoftening regeneration cavity are limited in the water softener body, the regeneration control part is used for controlling communication and disconnection between the soft water cavity and the softening regeneration cavity, and the salt lacking detection device is used for detecting whether or not salt is lacked in the softening regeneration cavity; a soft water inlet and a soft water outlet which are communicated with two sides of the soft water cavity respectively are formed in the water softener body, a regeneration water adding port and a salt adding port which are communicated with thesoftening regeneration cavity are further formed in the water softener body, the salt adding port is formed in the top of the water softener body, right opposite to the mounting hole, and the soft water outlet is communicated with the washing tank body. According to the water tank-type dish washer, the control part and the detection part are arranged compactly on the water softener, and all passages in the water softener are laid reasonably, so that pipes on a dish washer are connected reasonably, and the cost is low.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD +1

Linear filling plug-hanging and cover-hanging cover pressing machine

InactiveCN101643191ASafe and reliable workReasonable connectionCap application using vaccuumClosure using stoppersBottle

The invention relates to a linear filling plug-hanging and cover-hanging cover pressing machine which is used for providing a plug and a cover for a bottle type packing container used for the pharmaceuticals and food industry and is especially suitable for packing oral liquid. The linear filling plug-hanging and cover-hanging cover pressing machine of the invention comprises a bottle feeding-arranging component, a filling component, a cover-pressing component, a bottle discharge thumb wheel component and a machine stand, wherein a plug-hanging component and a cover-hanging component are arranged between the filling component and the cover-pressing component. The invention divides the traditional plug-cover combined type cover hanging component into two separated components, namely the plug-hanging component and the cover-hanging component, thereby putting an end to pollution possibly generated by the traditional hanging cover and preventing the normal running of the machine from beinginfluenced by the malposition of the plug and the cover. The invention has the advantages of reasonable design, novel structure, high degree of standardization and universalization and low productioncost.

Owner:TRUKING TECH LTD

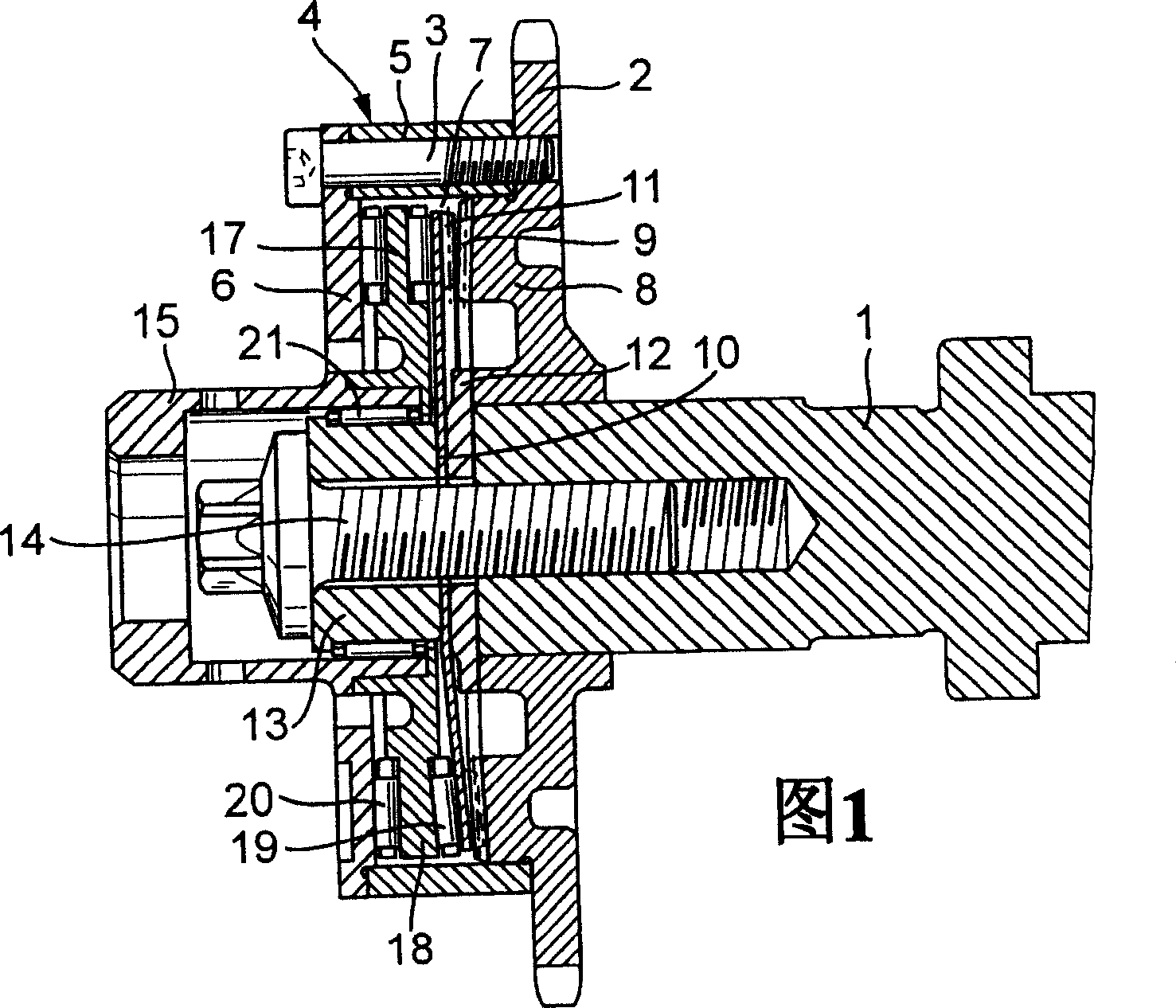

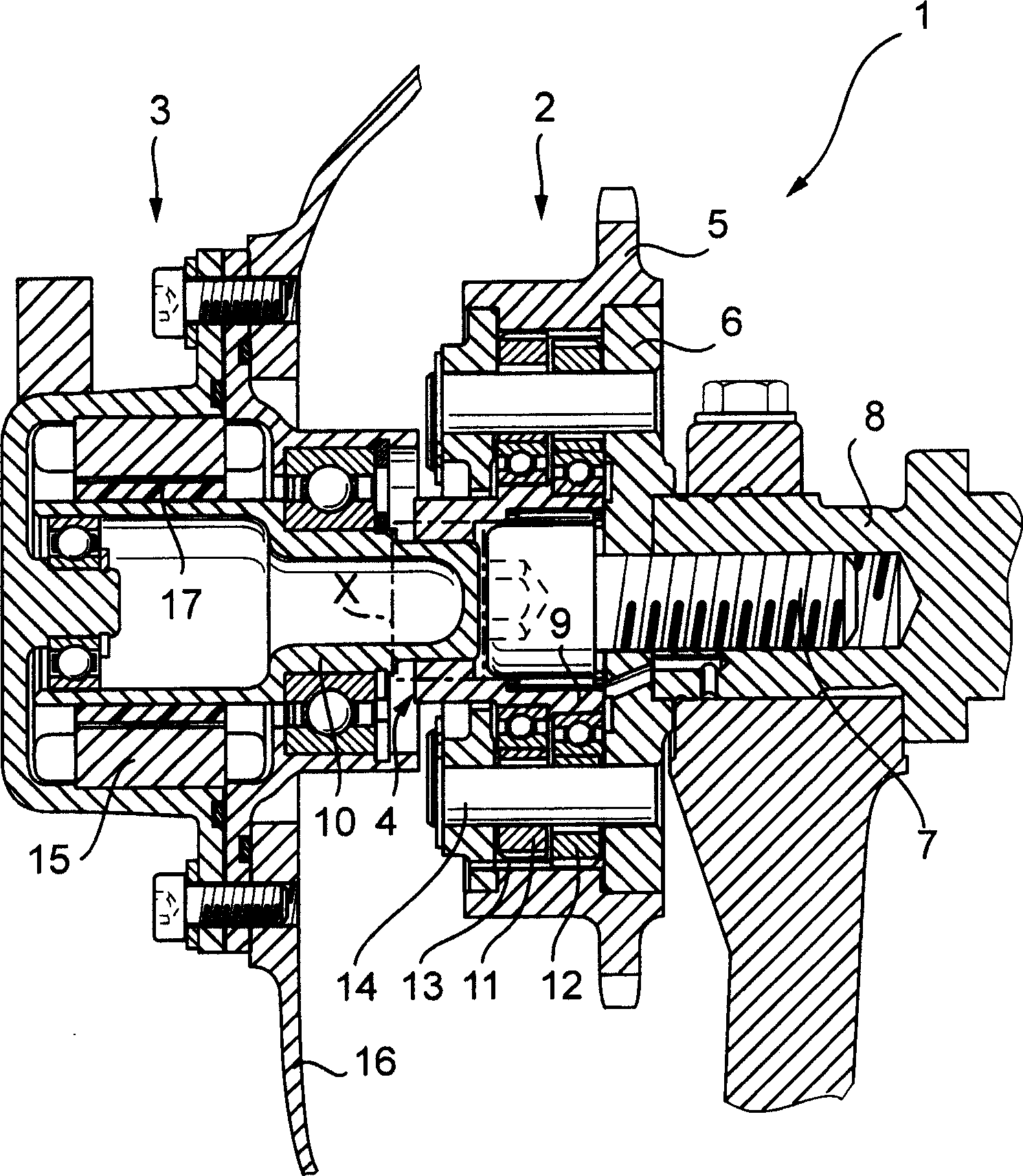

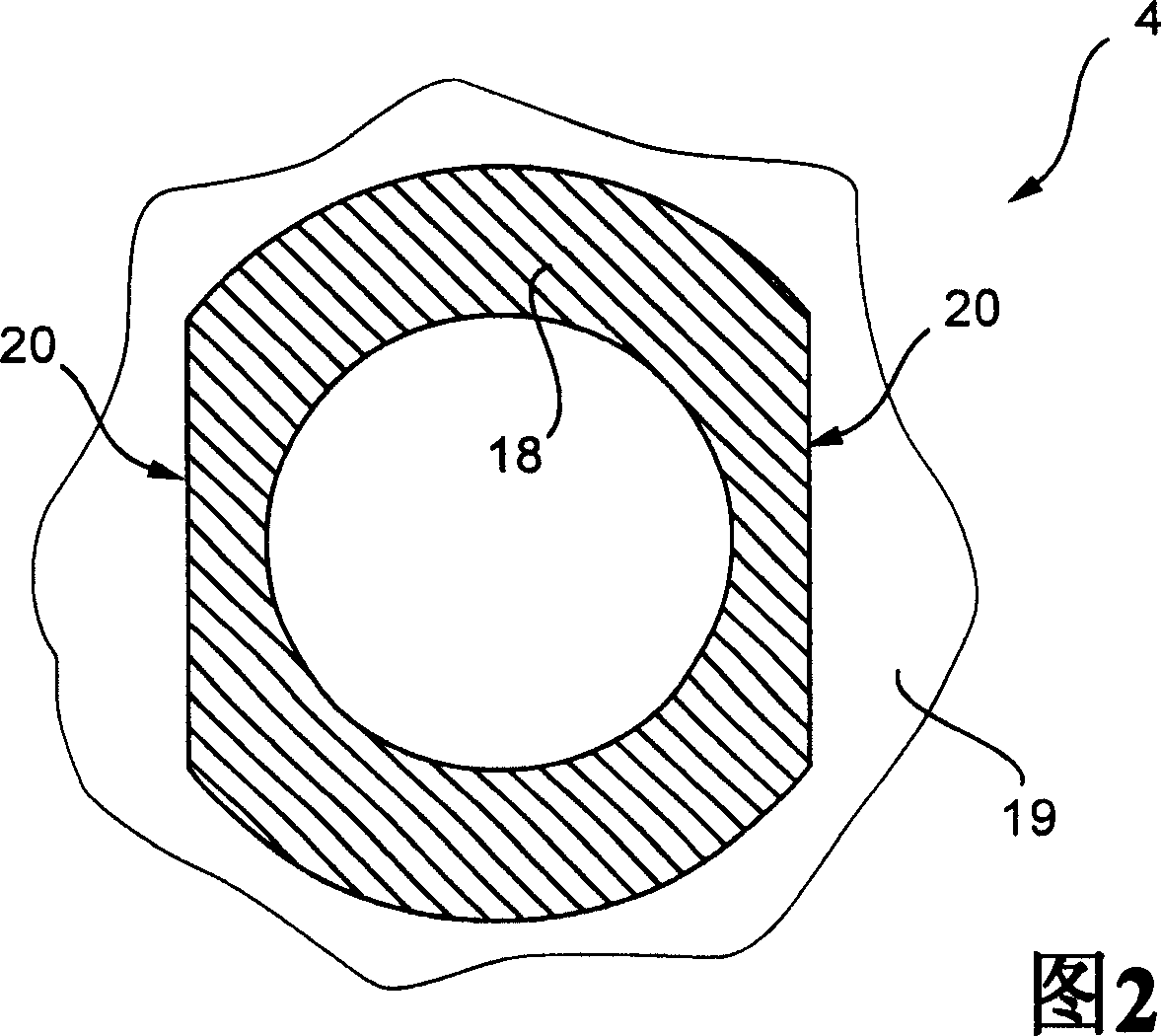

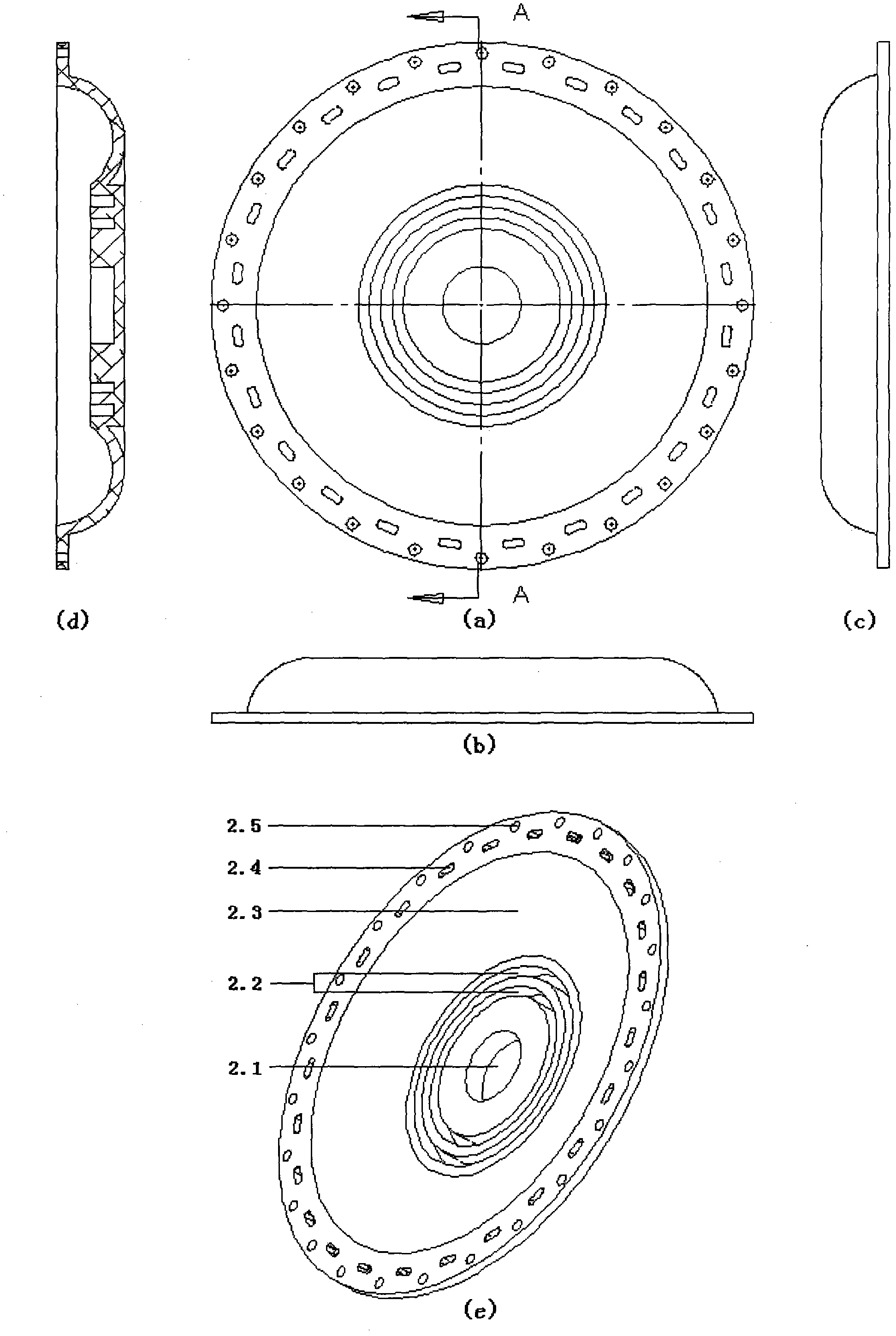

Electrically driven camshaft adjuster

InactiveCN1694999AEliminate gapsReduce manufacturing costYielding couplingCouplings for rigid shaftsExternal combustion engineEngineering

The invention relates to a camshaft adjuster (1) for adjusting and fixing the relative position of the angle of rotation of a camshaft (8) in relation to the crankshaft of a reciprocating piston internal combustion engine. Said adjusting device comprises a high transmission and friction-reduced adjusting gear mechanism (2), comprising a drive shaft which is rotationally fixed to the crankshaft, a driven shaft which is rotationally fixed to a camshaft (8) and an adjusting shaft (9) which is connected to an adjusting motor shaft (10) of an adjusting motor. A camshaft adjuster (1), which is economical to run, can be produced such that the adjusting gear mechanism (2) and the adjusting motor (3) are embodied as separate units and are connected together by a rotational backlash-free, disengaging clutch (4).

Owner:SCHAEFFLER TECH AG & CO KG

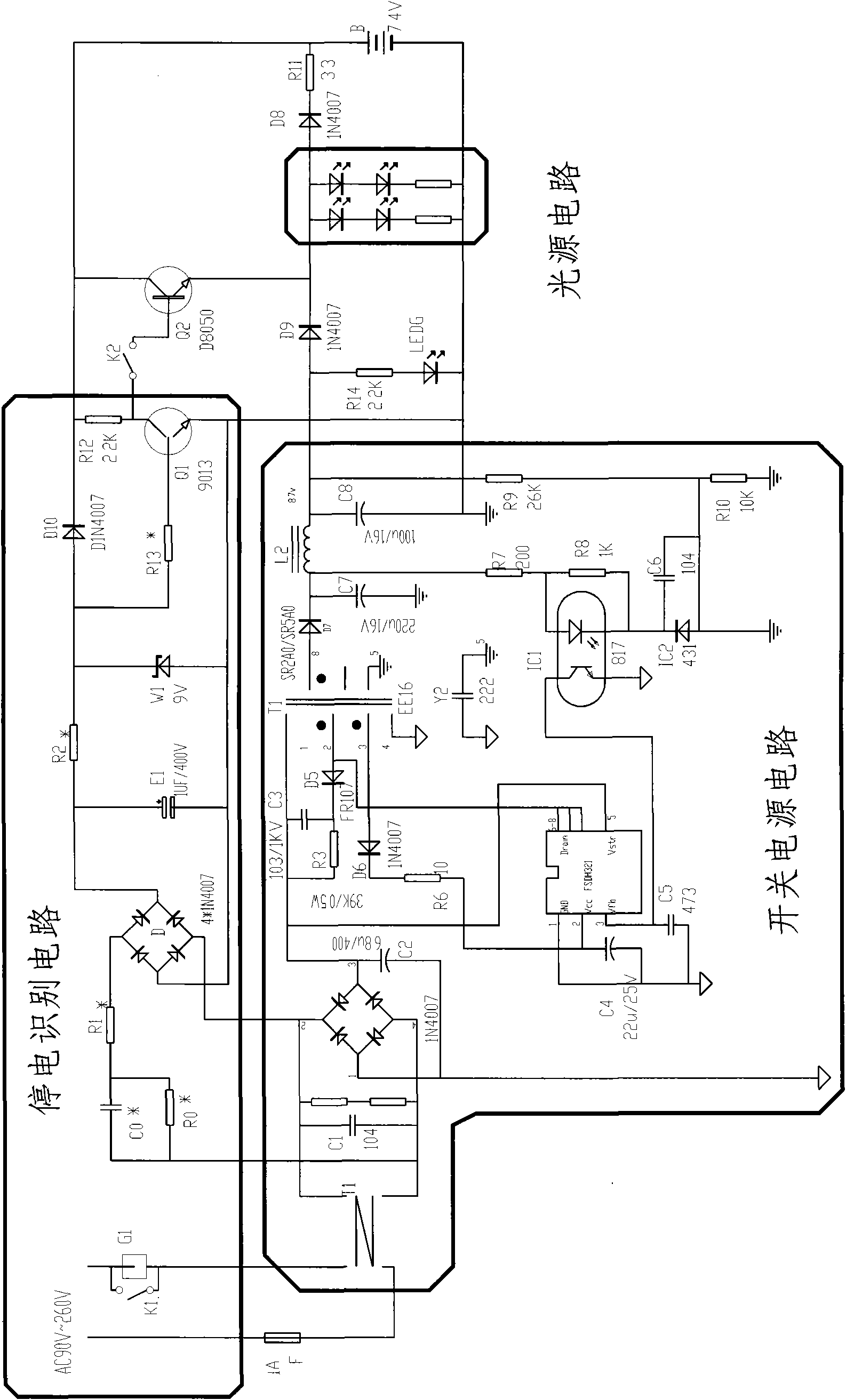

LED illumination emergency lamp circuit and LED lamp using circuit

InactiveCN101541125AReasonable connectionCompact structureBatteries circuit arrangementsPoint-like light sourceEngineeringLight source

The invention provides an LED illumination emergency lamp circuit and an LED lamp using the circuit. Through the LED illumination emergency lamp circuit with a power failure identification circuit and the LED illumination emergency lamp using the circuit, the invention realizes the integration of an illumination circuit and an emergency circuit into the same lamp circuit. Therefore, the function can be realized without double lamp bases. Under the condition of the same light source and a single knife switch, the lamp not only can be turned on and off through the switch like a common illuminating lamp, but also can be automatically started for emergency illumination when a power failure occurs. The invention solves the problems of emergency lamp integration and miniaturization, easy installation, long service life for a rechargeable battery, long emergency time, energy conservation and environmental protection, and the like. In addition, the circuit has reasonable connection, a handy product and a compact structure, and is applied to the environmental illumination, household illumination and industrial production.

Owner:高伟林

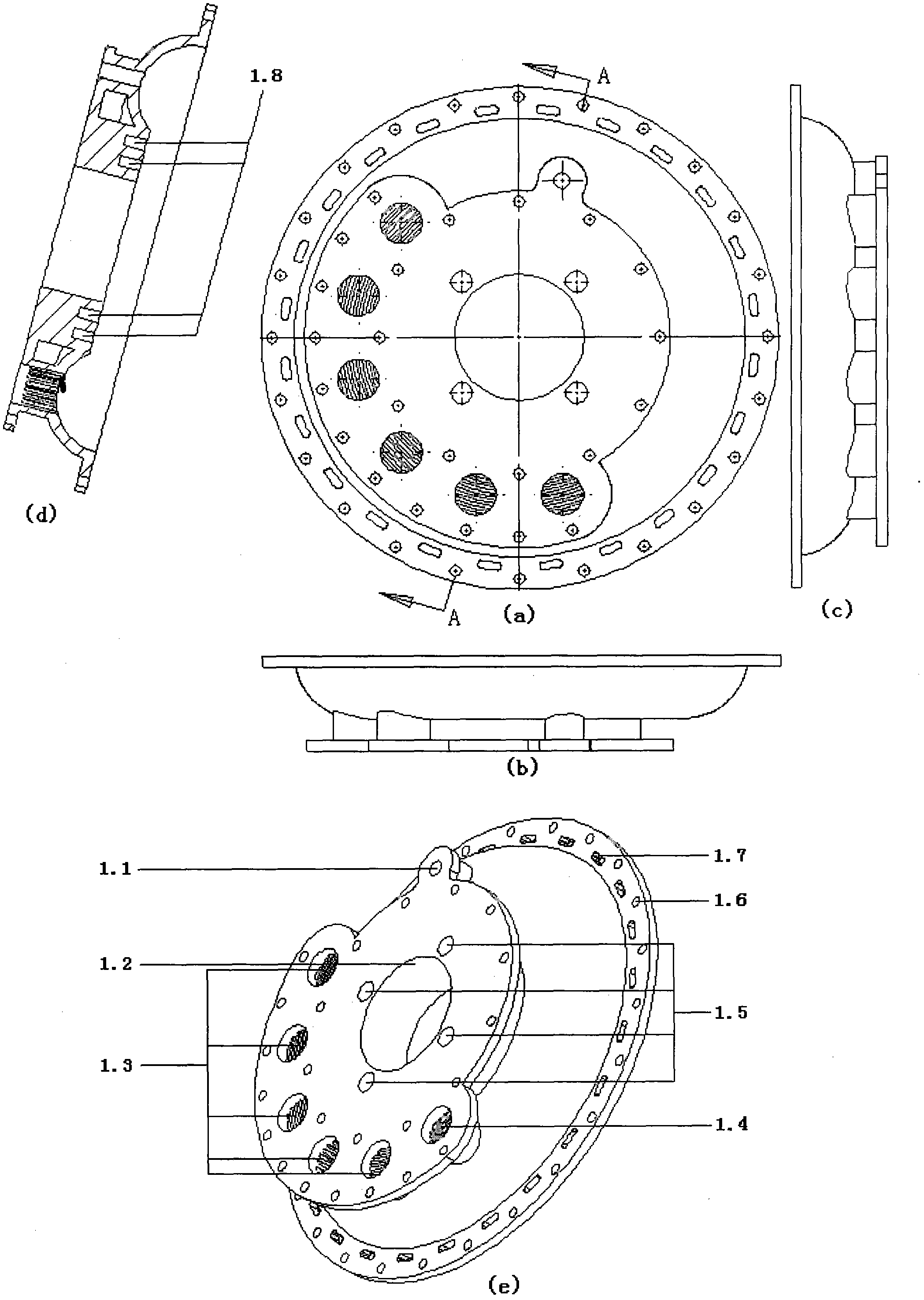

Double-rotor rotary piston engine

ActiveCN102322338ANo torque dead pointReduce power consumptionInternal combustion piston enginesCombustionStress point

The invention relates to a double-rotor rotary piston engine, belonging to internal-combustion engines. A cylinder is of an annular cylinder. A double-rotor mechanism formed by a rotor a and a rotor b rotates in the same direction in a left and right changeable manner in the annular cylinder. The left and right changeable rotate can be converted into continuous rotation and then output through a power output module. Each rotor of the engine comprises a rotor disc and two fan-shaped pistons. The annular cylinder is dynamically divided into four closed spaces through the four pistons. Each rotor rotates in 180 DEG so that four strokes of sucking, compressing, acting and exhausting can be completed. The left and right changeable rotation is realized through a left and right changeable system. Combustible gas is sucked through a normally opened gas inlet. A plurality of gas inlets are arranged on the wall of the annular cylinder. The gas inflow amount can be controlled in real time according to requirements. Waste gas is discharged through a normally opened exhaust hole. Rotation force is directly generated through the regular circle rotor disc. The acting stress point is along the direction of the tangent line of the rotor disc. The double-rotor rotary piston engine is high in power, steady for operation and low in vibration.

Owner:王尚锋

Spray paint organic solvent exhaust gas recovery device and organic solvent recovery method

InactiveCN103316560AReasonable connectionClosely connectedCombination devicesOrganic solventDust control

The invention discloses a spray paint organic solvent exhaust gas recovery device and a method for recovering an organic solvent by the use of the device. The device provided by the invention comprises a paint mist removal device, a blower fan, an adsorption pot, a condenser and an oil-water separator which are connected in order. The paint mist removal device comprises an air collector which is used for temporary storage of organic solvent exhaust gas, a cyclone dust collector and a cloth bag deduster. The air collector, the cyclone dust collector and the cloth bag deduster are connected in order. According to the recovery device, parts are connected reasonably and compactly, dedusting efficiency is high, paint mist is efficiently removed, and the trouble of frequently replacing filter cotton is saved. The invention also discloses a method for recovering the organic solvent by the use of the device. The method successively comprises steps of: removal of the paint mist, adsorption, water vapour desorption, condensation and oil-water separation, wherein the paint mist removal step is to change the paint mist into a paint powder and effectively remove the paint powder. In comparison with the present technologies, the method provided by the invention is more reasonable and compact and is labor-saving.

Owner:QUANZHOU TIANLONG ENVIRONMENTAL ENG

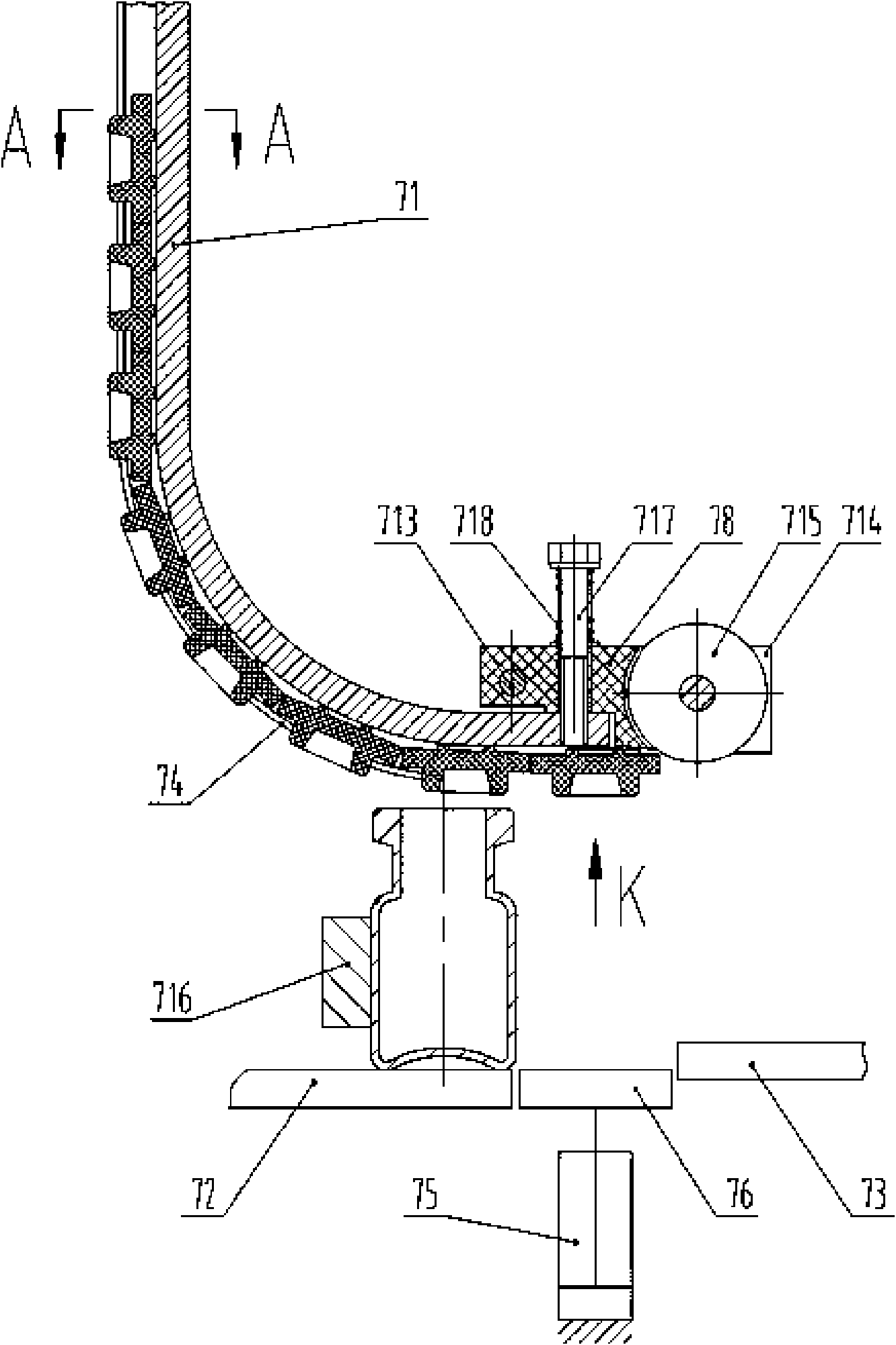

Hydraulic support drawing, turning, transporting and retracting device

InactiveCN104453972AImprove working environmentReduce labor costsMine roof supportsEngineeringMechanical engineering

The invention relates to the field of hydraulic supports for comprehensive mechanized coal mining, in particular to a hydraulic support drawing, turning, transporting and retracting device which is suitable for drawing, turning, transporting and retracting when a comprehensive mechanized coal mining face retracts a hydraulic support. A hydraulic support turning platform is arranged above the hydraulic support to be retracted, the to-be-retracted hydraulic support forms two shield supports and is connected with the hydraulic support turning platform, a hydraulic support retracting cart after being assembled is arranged on a rail II in front of the hydraulic support turning platform which is connected with the hydraulic support retracting cart, a retracting and loading mechanism is arranged at the end of a rail I of a two-smooth-groove triangular point, the rail I extends onto the retracting and loading mechanism, a rail pressing plate on the retracting and loading mechanism fixes the rails, the hydraulic support retracting cart runs to the end of the rail I along the rail II and is connected with the retracting and loading mechanism, a jacking device of the retracting and loading mechanism jacks the hydraulic support retracting cart, and the retracting and loading mechanism is connected with the hydraulic support retracting cart.

Owner:辽宁威跃集团机械制造有限公司

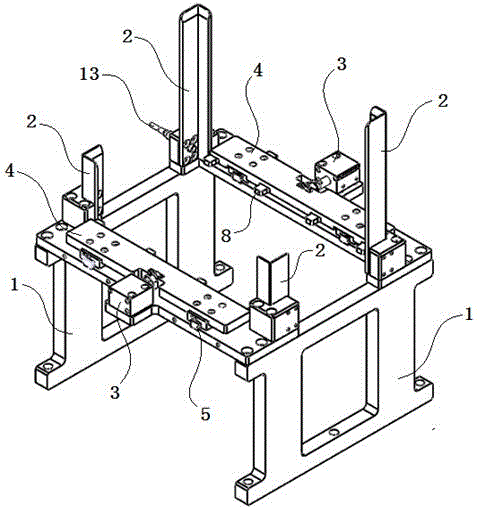

Automatic magnet assembly tray supply mechanism

InactiveCN106081643AHigh repeat positioning accuracyEasy to operateDe-stacking articlesElectric machineryMagnet

The invention discloses an automatic magnet assembly tray supply mechanism. The automatic magnet assembly tray supply mechanism comprises a storage mechanism, clamping mechanisms, a supporting mechanism and a transmission mechanism. The storage mechanism comprises a supporting frame and four retaining sides, and the four retaining sides are arranged on the upper end face of the supporting frame. The clamping mechanisms are arranged at left and right ends of the upper end face of the supporting frame respectively, clamping plates are arranged on the upper end face of the supporting frame through slide rails, and horizontal pushing air cylinders are arranged on outer sides of the clamping plates and connected with the clamping plates. The transmission mechanism is arranged below the supporting frame and comprises two conveying belts driven by a motor. The supporting mechanism is arranged below the supporting frame, a supporting air cylinder is connected with a supporting plate, four connecting rods are arranged on the upper end face of the supporting plate, and the supporting plate is fixed to the four connecting rods. The automatic magnet assembly tray supply mechanism has advantages of high repeated positioning accuracy, simplicity in operation, short maintenance period, high adaptability and the like, labor saving is achieved, action fusion with magnet assembly equipment can be realized, high reasonability in joint with the equipment is achieved, automation level is raised, and integral efficiency is improved.

Owner:苏州茂特斯自动化设备有限公司

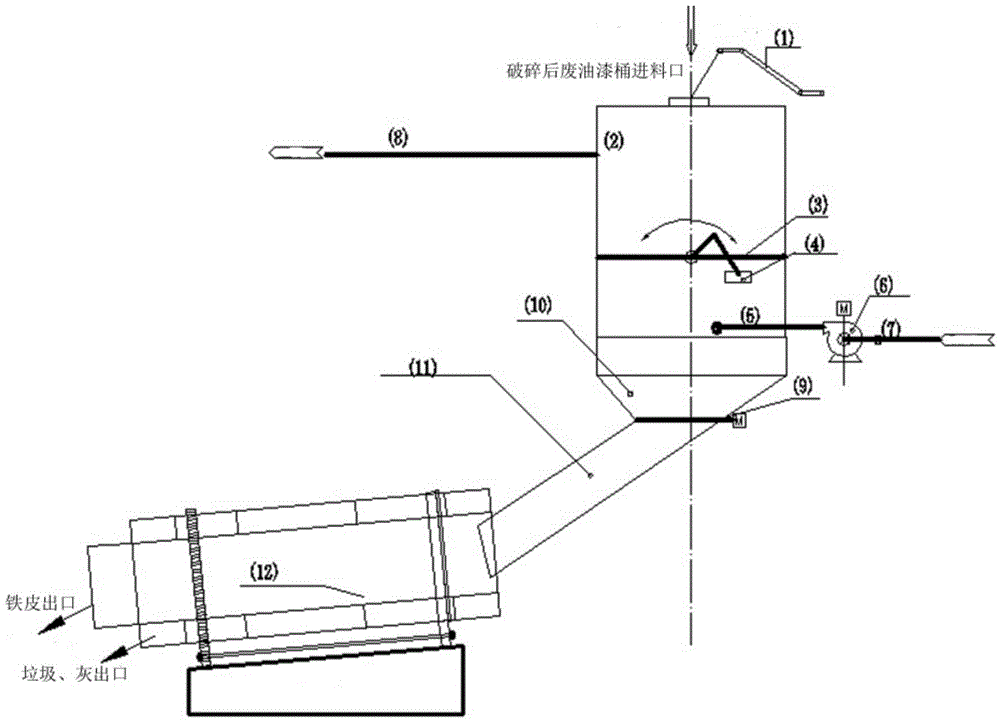

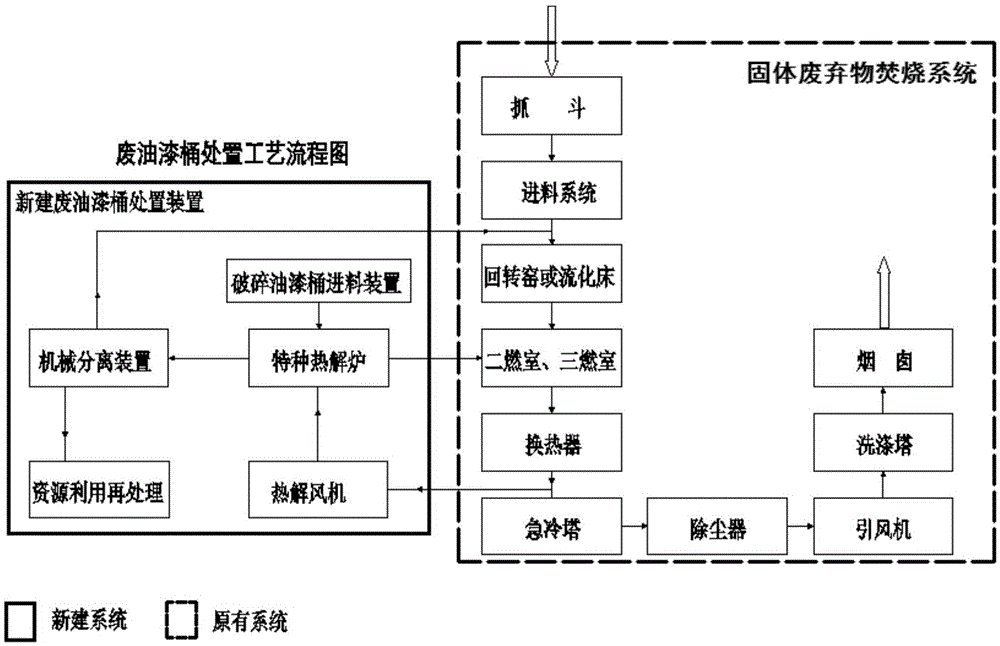

Method and device for applying waste heat of solid waste incineration system to treatment of waste paint buckets

InactiveCN105605580AReduce consumptionImprove securityIncinerator apparatusCombustion chamberIntegrated devices

The invention discloses a method and a device for applying waste heat of a solid waste incineration system to treatment of waste paint buckets. By application of the method and the device, high-temperature flue gas generated in an original rotary kiln (or fluidized bed) and secondary combustion chamber integrated incineration system is fed into a pyrolyzing furnace through a pyrolyzing fan to realize pyrolysis of the waste paint buckets, products obtained by pyrolyzing are sent into a mechanical separation device, generated pyrolysis tail gas is sent into the original rotary kiln (or fluidized bed) and secondary combustion chamber integrated incineration system to realize further treatment, tail gas generated after treatment passes through an original flue gas purification system, and purified flue gas is directly discharged into a chimney. The products obtained by pyrolyzing are separated in the mechanical separation device to recover waste metals, and residues are sent to the original rotary kiln (or fluidized bed) and secondary combustion chamber integrated incineration system to realize retreatment. Due to systematic combined design, reasonability and compactness in connection of integrated devices are realized, structural maturity of adopted equipment is realized as well, and high economy and social benefits are achieved.

Owner:史林芳 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com