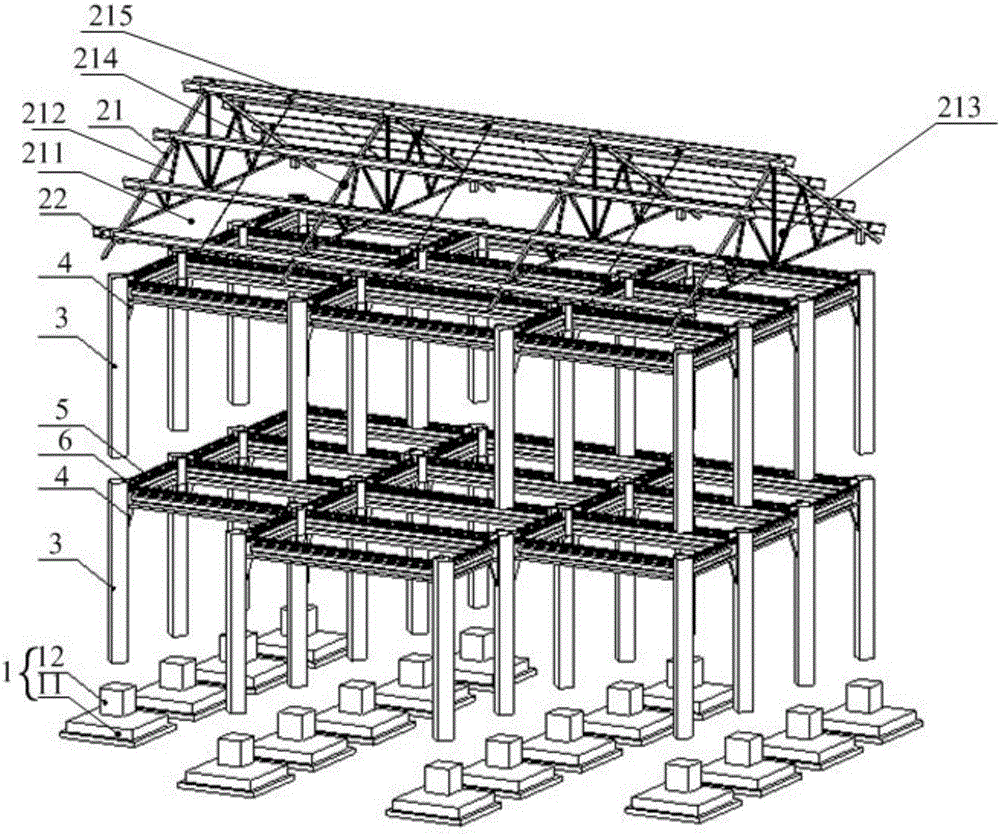

Assembly type main structure of building

A kind of building main body and assembly technology, which is applied in the direction of building components, building structure, construction, etc., can solve the problems of difficult standardized management, complicated installation process, single installation method, etc., and achieve high construction efficiency, simple and convenient operation, and reduce environmental pollution. pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

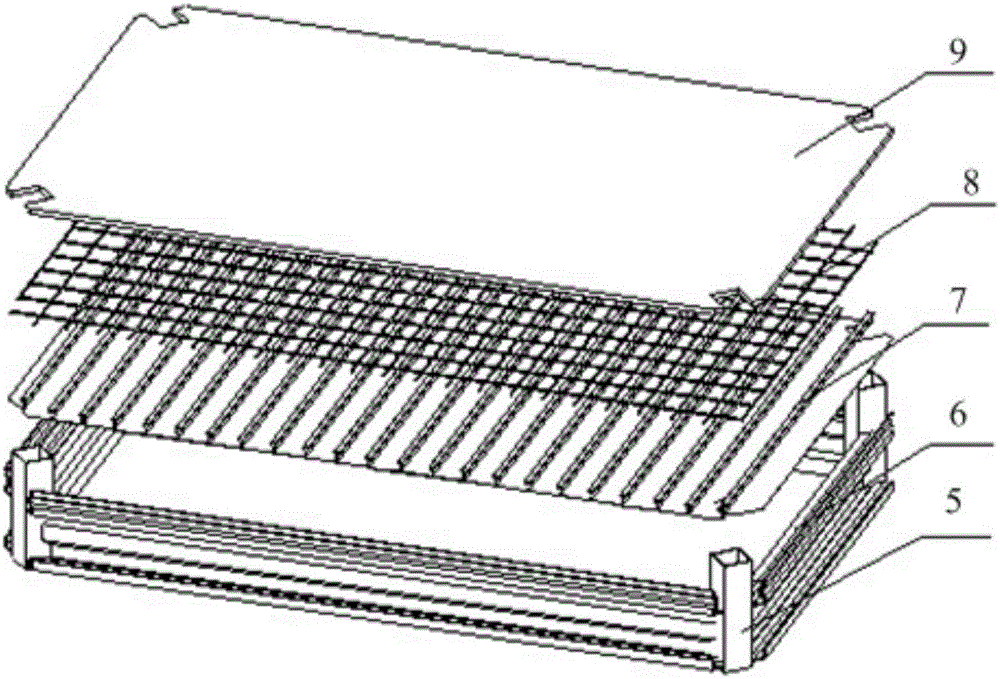

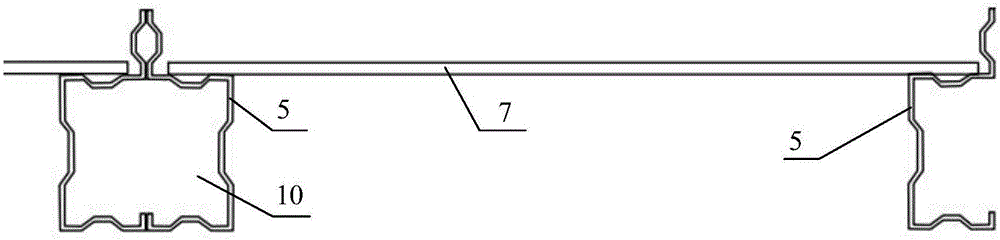

[0057] Such as Figure 7 As shown in (a), the beam support 4 is fixedly provided with a protrusion, and the sleeve 6 is plugged on the protrusion. The insertion between the protrusion and the sleeve 6 realizes the connection between the composite beam slab and the square pipe column 3 .

Embodiment 2

[0059] Such as Figure 7 As shown in (b), the girder 4 is welded by several metal plates, the cross section of the girder 4 is a right triangle, the cross section of the sleeve 6 is a square, and the socket of the lower part of the sleeve 6 and the girder 4 is provided with a The hypotenuse of the corbel 4 matches the inclined surface, and the lower part of the sleeve 6 is inserted into the corbel 4 . There is no metal plate on the top of the corbel with a right-angled triangle cross section, and the lower part of the sleeve 6 is inserted into the corbel 4, and the slope of the sleeve 6 cooperates with the hypotenuse of the corbel 4, which is more stable.

Embodiment 3

[0061] Such as Figure 7 As shown in (c), the girder 4 is welded by several metal plates, the cross section of the girder 4 is a right-angled trapezoid, the cross section of the sleeve 6 is square, and the lower part of the sleeve 6 is inserted into the girder 4 . There is no metal plate on the top of the corbel 4 with a right-angled trapezoidal cross section, and the lower part of the sleeve 6 is inserted into the upper part of the corbel 4. The insertion is stable and the sleeve 6 can be prevented from sliding down.

[0062] The order of the above implementations is for convenience of description only, and does not represent the advantages or disadvantages of the implementations. In Embodiment 1-3, in order to increase the firmness of the connection between the sleeve 6 and the square pipe column 3, the contact surface between the sleeve 6 and the square pipe column 3 can be welded.

[0063] In order to improve the practicability of the present invention, the materials of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com