Method and device for applying waste heat of solid waste incineration system to treatment of waste paint buckets

A technology for solid waste and waste paint buckets, applied in the direction of combustion methods, incinerators, combustion types, etc., can solve the problems of incomplete treatment of waste paint buckets, and achieve the goal of eliminating environmental pollution and waste of various resources, with obvious effects and purification The effect of the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

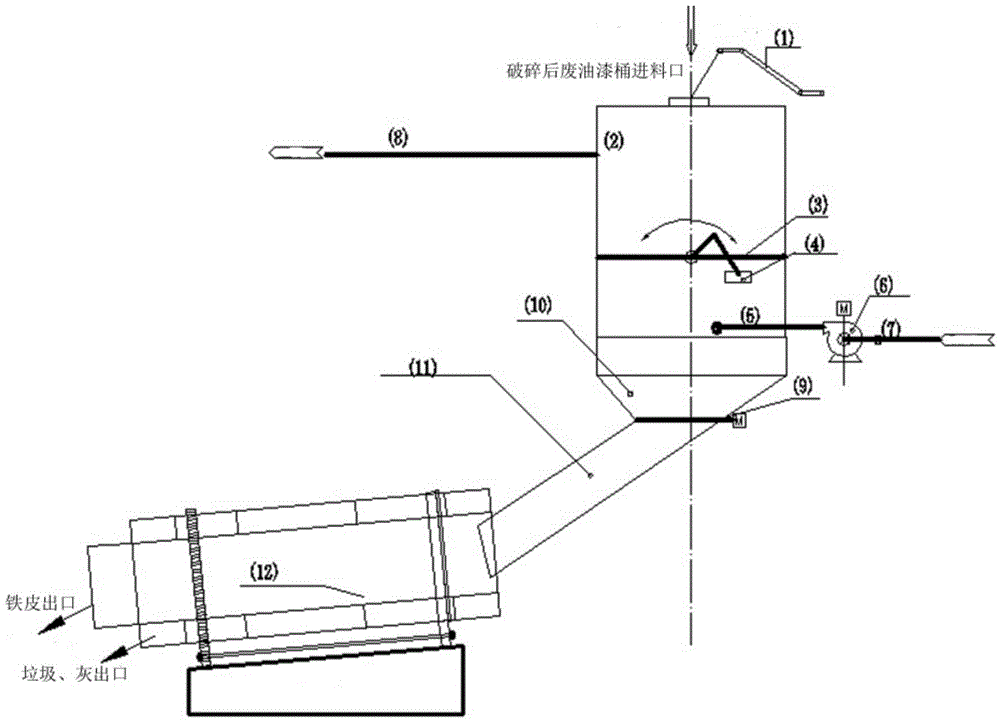

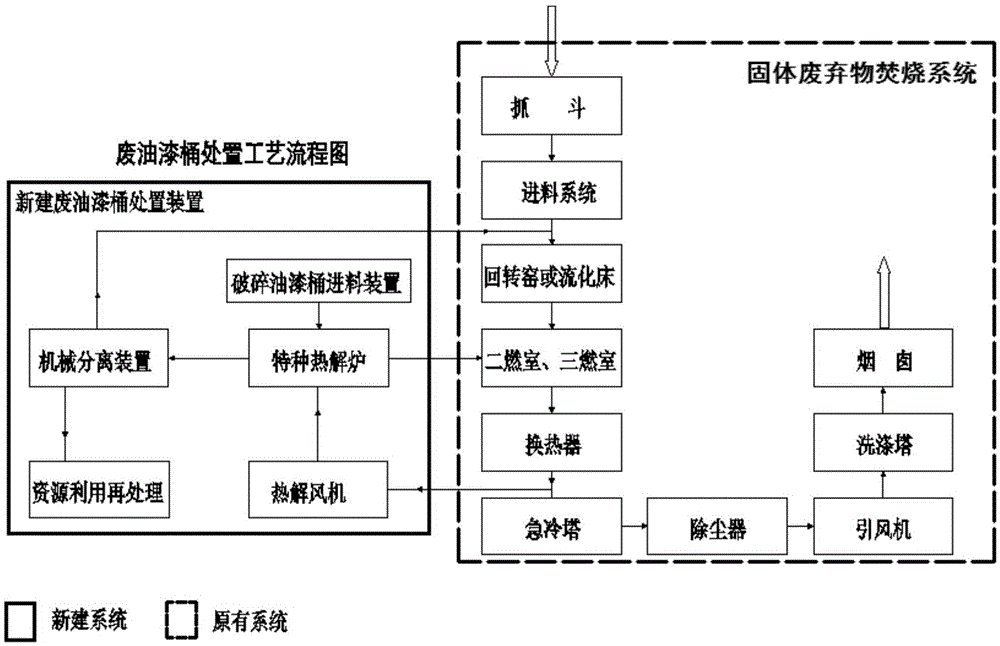

[0025] as attached figure 1 As shown, the present invention mainly includes feeding device 1, pyrolysis furnace 2, turning grate 3, hydraulic device 4; Feed chute 11 and separation device 12.

[0026] Under the action of the high-temperature pyrolysis fan 6, the high-temperature flue gas enters from the hot air pipe 7, enters the pyrolysis furnace 2 through the pipe 5, and heats the broken paint bucket at a high temperature, and the heated flue gas is sent to the incinerator again through the pipe 8 to burn. Under the toasting of the continuously entering high-temperature hot air, the paint bucket fragment iron sheet in the pyrolysis furnace 2 is separated from the iron sheet after high-temperature carbonization. After being heated at a high temperature, the fire grate 3 is rotated and turned over. Simultaneously, the flap valve 9 is opened, and the processed paint bucket iron sheet enters the separation device 12 through the discharge chute 11. In this way, the iron sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com