Double-rotor rotary piston engine

A rotary piston and double rotor technology, applied to internal combustion piston engines, combustion engines, machines/engines, etc., can solve problems such as high power consumption, small horsepower volume ratio, and large vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] 1. Introduction of main components

[0084] 1. A cylinder head (1)

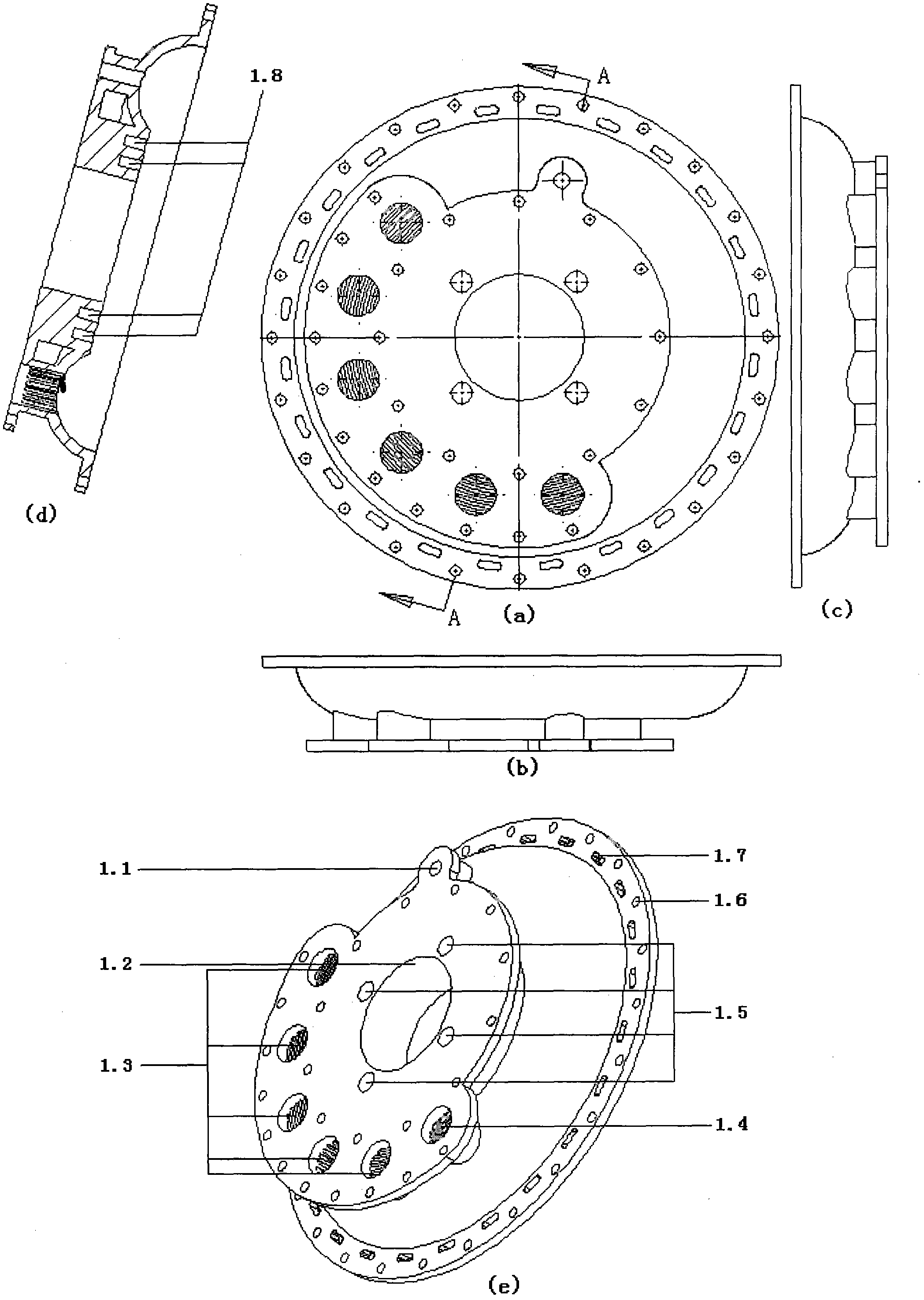

[0085] Figure 1 is a different view of the cylinder head (1). It can be seen from "e figure" that the outermost circular hole on the cylinder head (1) of a is the bolt hole (1.6); there is a circle of rounded arc-shaped holes close to the bolt hole, and these holes are coolant passage holes (1.7) ; There is also a spark plug installation hole (1.1); an exhaust hole (1.4); 5 air intake holes (1.3); 4 circular blind holes for fan wheel shaft installation (1.5); the largest hole in the middle is The a-axis passes through the hole (1.2), and the a-axis (9) bearing or bushing is installed at this position; from "d figure", we can see that there are two circular grooves near the inner wall of the cylinder. The grooves are two sealing ring mounting grooves (1.8). It can be seen from the figure that both the air intake hole (1.3) and the exhaust hole (1.4) are designed in a grid pattern to avoid uneven fric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com