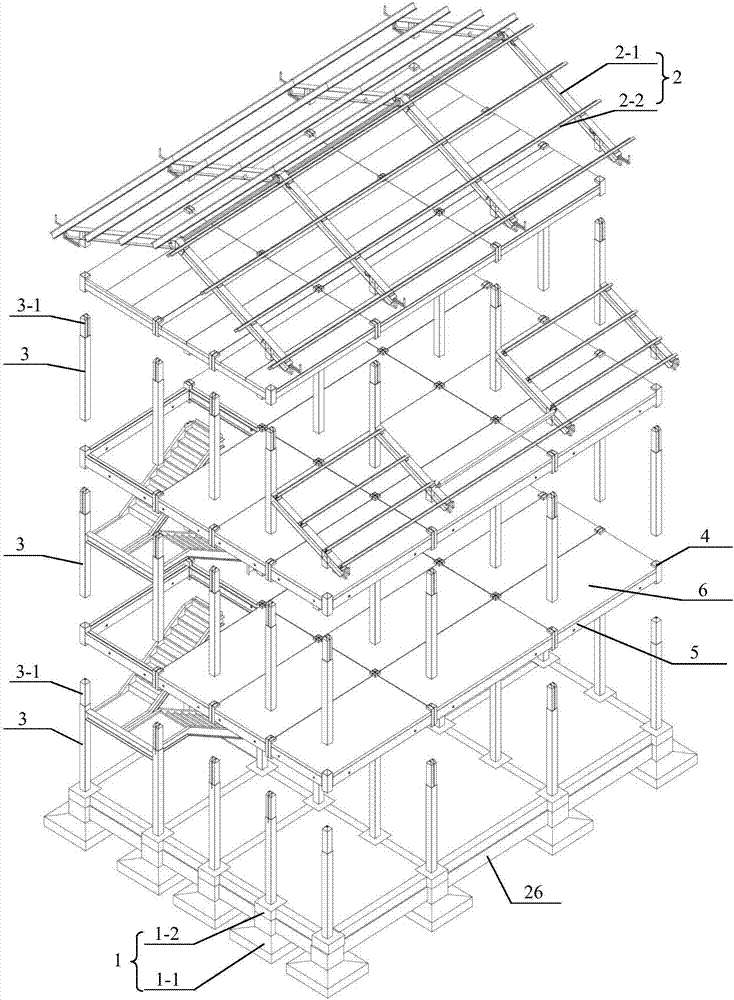

Prefabricated building main body structure

A building main body and prefabricated technology, applied in the direction of building structure, construction, etc., can solve the problems of difficult standardized management, single installation method, and low degree of assembly, so as to improve on-site work efficiency, reduce environmental pollution, and reduce labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

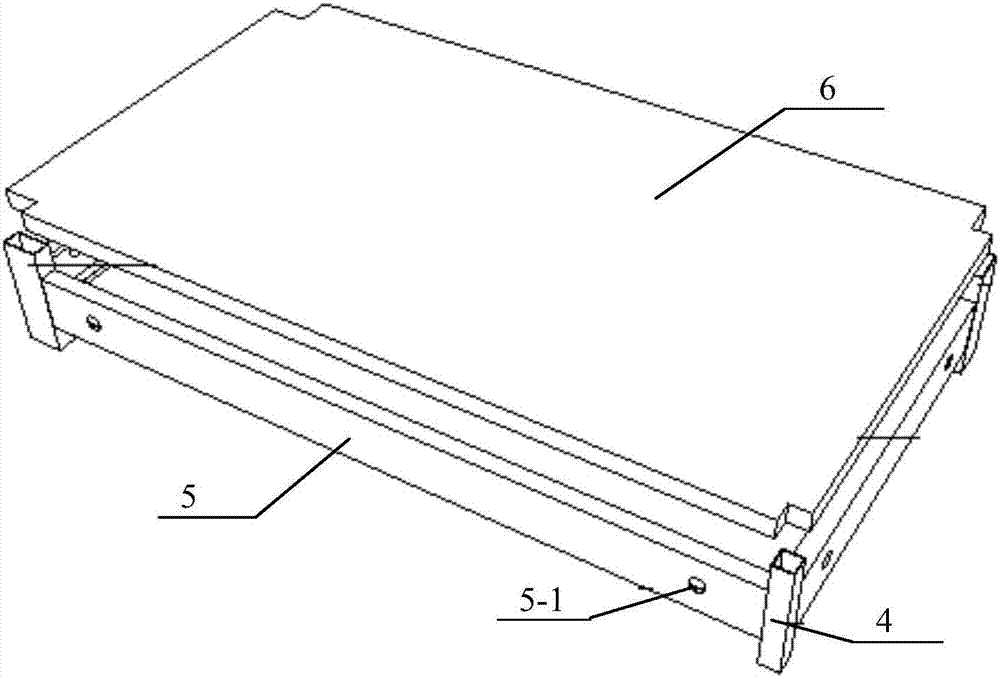

Method used

Image

Examples

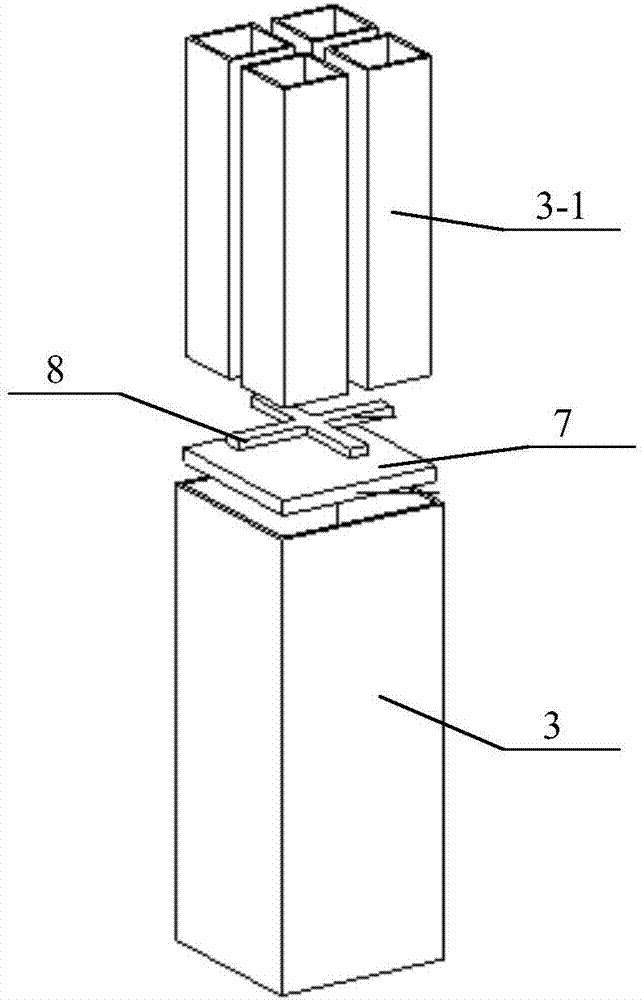

Embodiment 1

[0059] Such as Figure 5 As shown in (b), the upper part between the four mortise tubes 3-1 is provided with a partition 9 for convenient sleeve insertion, the partition 9 is a cross partition, and the width L of the cross partition is equal to the width of the cross steel plate 8 a is the same as Figure 5 As shown in (a), the material of the cross partition can be rubber, which has a certain degree of elasticity. In this way, the cross partition is placed on the upper part of the gap between the four tenon tubes 3-1 to ensure that it does not slip to the bottom of the tenon tube. After the sleeve is put on the mortise tube, the cross partition is moved to the bottom, which does not affect the insertion and has a certain buffering effect on vibration.

Embodiment 2

[0061] Such as Figure 5 As shown in (c), the two mortise tubes 3-1 that are arranged oppositely are provided with a rectangular spacer ring 10 for convenient sleeve insertion, such as a rectangular rubber ring, etc., which have certain elasticity, and the two rectangular spacer rings 10 The corners are connected as an integral structure, and two rectangular spacer rings 10 are sleeved on the opposite tenon tubes 3-1 respectively. The width a is consistent, and the width of each rectangular spacer ring 10 outside the four tenons can be set a little smaller, as long as it does not affect the implementation of the present invention.

Embodiment 3

[0063] Such as Figure 5 As shown in (d), the upper parts of the four mortise tubes 3 are provided with rectangular spacer rings 10, such as rubber rectangular rings, etc., which have certain elasticity. The width D between the two tenon tubes is the same as the width a of the cross steel plate. This can ensure that the gaps between the top and the bottom of the four tenon tubes are consistent, which is convenient for inserting the sleeve, and the width of the rectangular spacer ring outside the four tenons can be set a little smaller, as long as it does not affect the implementation of the present invention.

[0064] In Embodiment 1 to Embodiment 3, before the sleeve is inserted into the tenon tube, the separator 9 and the rectangular spacer rings 10 and 11 are all arranged on the upper part of the gap between the tenon tube 3-1 to ensure that they do not slip to the bottom of the tenon tube , when the sleeve is placed on the tenon tube, the partition 9 and the rectangular s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com