Electrically driven camshaft adjuster

A technology of camshaft adjustment and wheel shaft, which is applied in the direction of valve devices, couplings, valve details, etc., can solve the problems of troublesome installation and pre-installation of servo motors, etc., and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

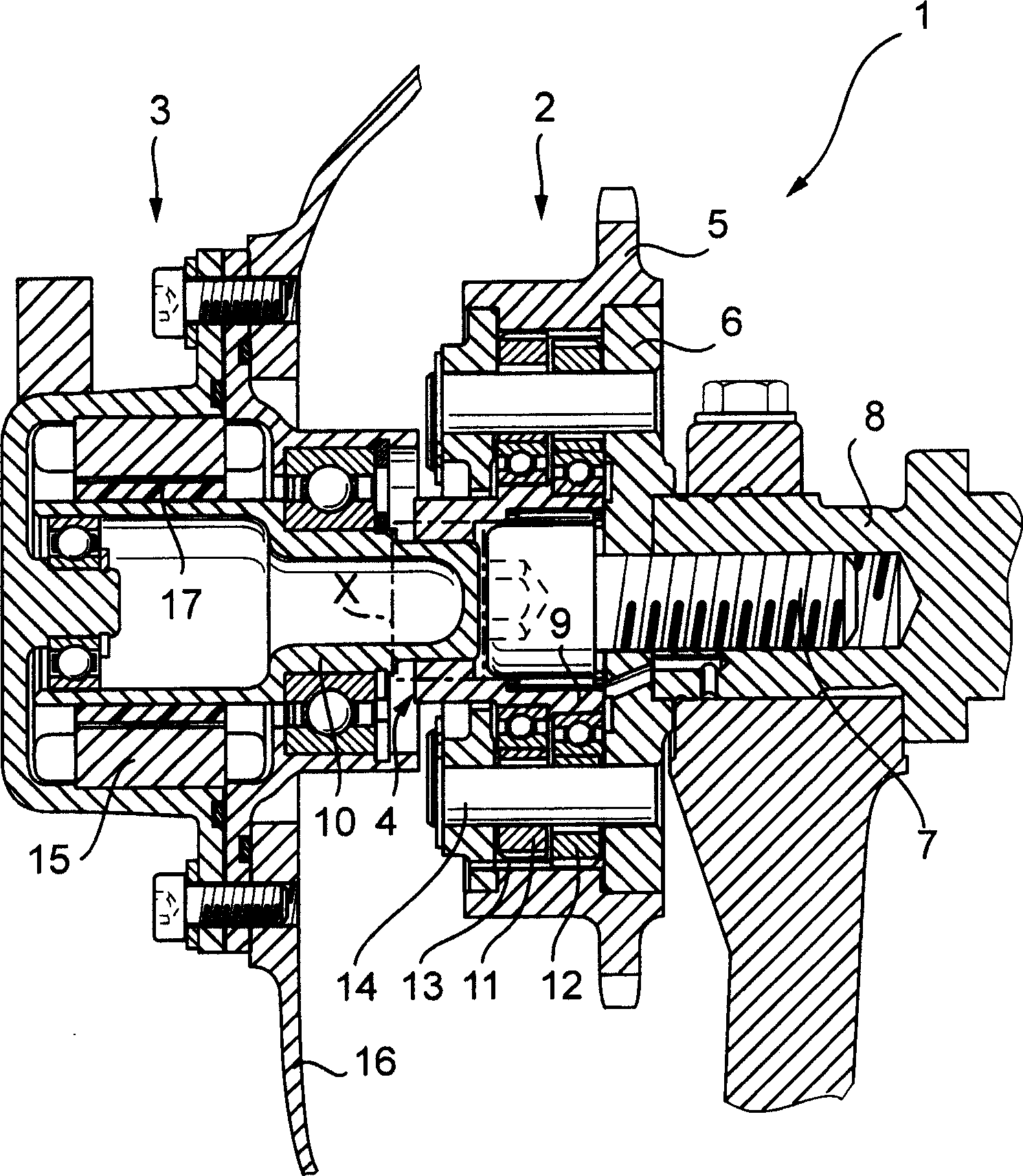

[0046] figure 1 An electric camshaft adjusting device 1 is shown with a gear mechanism 2 and an electric servomotor 3 , which are formed as separate units and are detachably connected via a coupling.

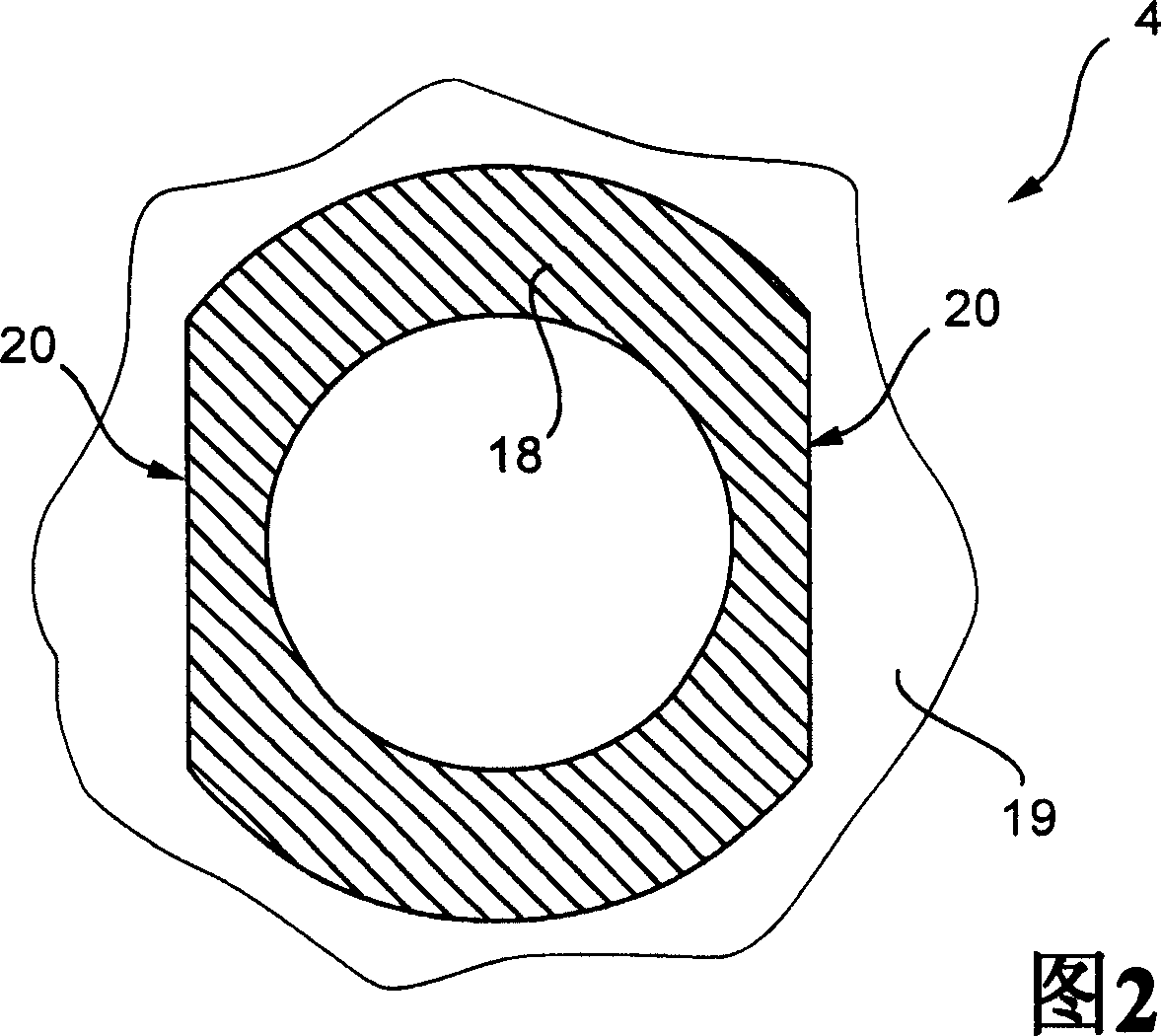

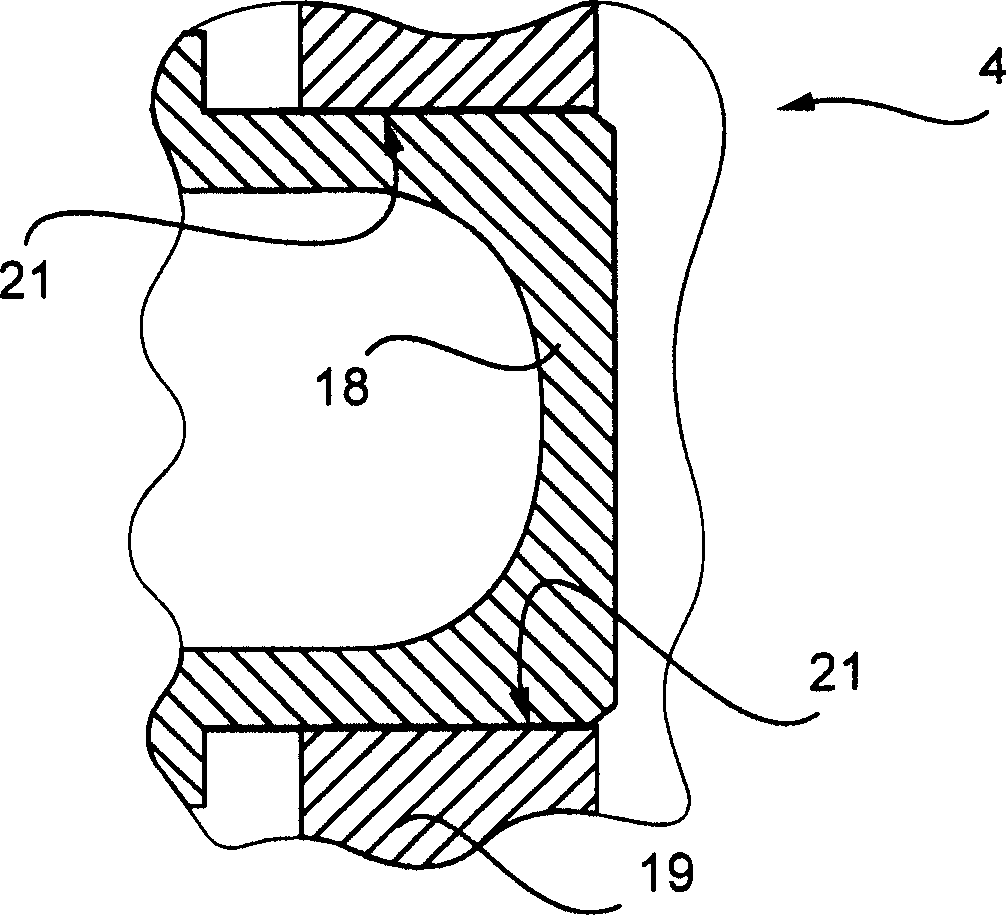

[0047] The speed change transmission mechanism 2 is a three-axis transmission mechanism, which has a high reduction ratio (reduction ratio range 1:30-1:250) and high efficiency as an eccentric transmission mechanism. The transmission 2 has a drive shaft and a driven shaft as well as an adjusting shaft 9 . The drive shaft is designed as sprocket 5 and is connected in a rotationally fixed manner to a crankshaft (not shown) via a chain (also not shown). The output shaft is formed as a closing wall 6 and is connected in a rotationally fixed manner to the camshaft 8 by means of a clamping screw 7 . The adjustment shaft 9 is formed as an eccentric shaft, and is connected to the servo motor shaft 10 through the double-edge shaft coupling 4 with practically no rotational play but can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com