Standardized construction method for hydraulic prefabricated member based on BIM (Building Information Modeling)

A technology of prefabricated components and construction methods, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as difficulties in construction site management and quality requirements, complex three-dimensional shapes of hydraulic components, and difficulty in controlling detailed dimensions. To achieve the effect of ensuring quality traceability, facilitating cost control, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

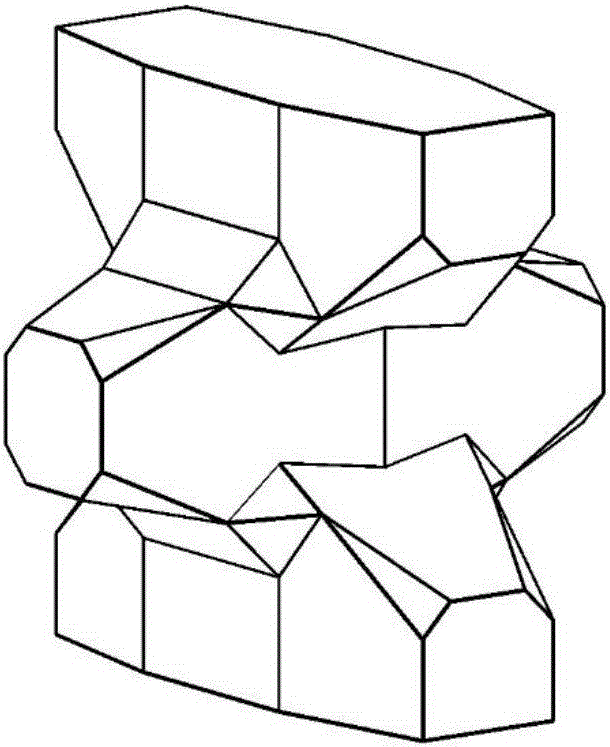

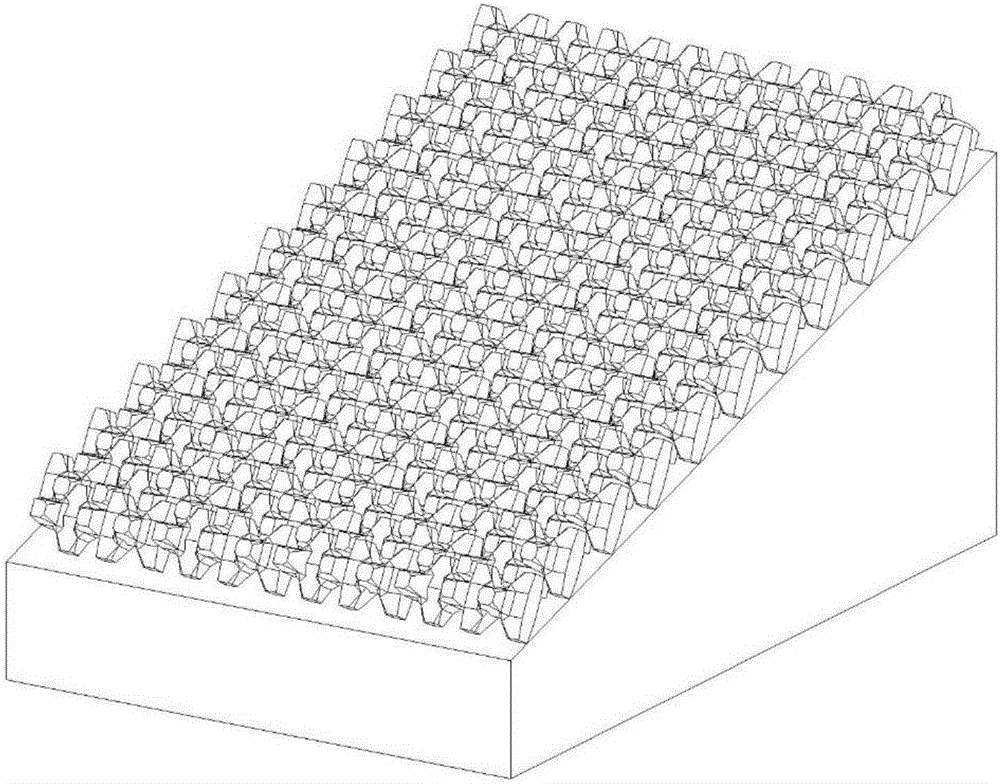

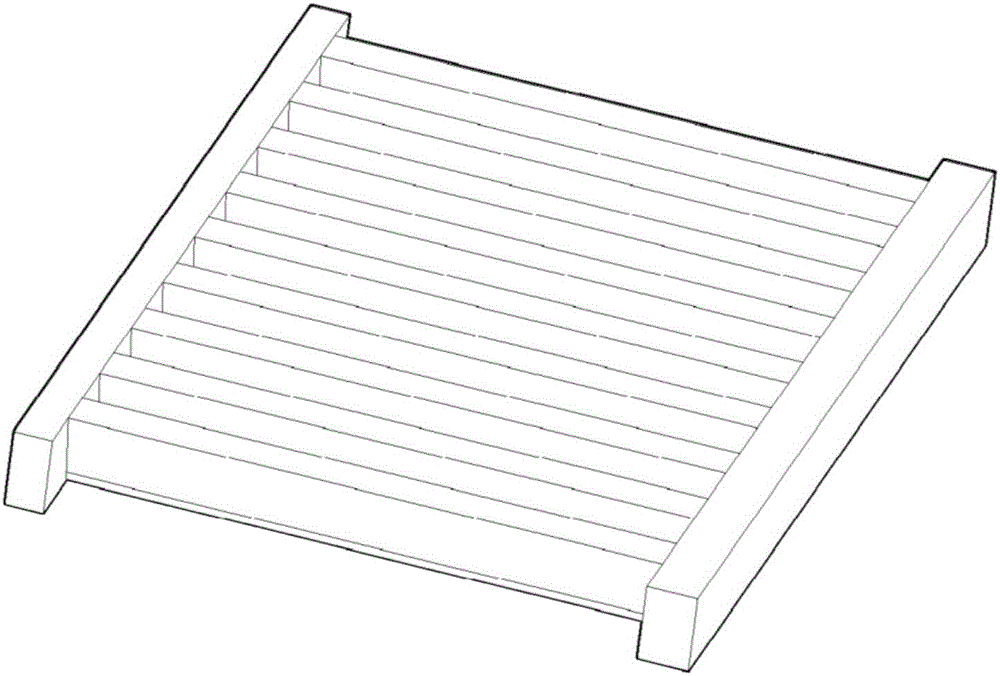

[0040] The following will combine Figure 1 to Figure 5 , to describe in detail the BIM-based standardized construction method of hydraulic prefabricated components provided by the present invention, which is an optional embodiment of the present invention. It can be considered that those skilled in the art can Revise and polish it.

[0041] Please refer to Figure 1 to Figure 5 , the present invention provides a BIM-based standardized construction method for hydraulic prefabricated components, comprising the following steps:

[0042] S1: Use BIM modeling tools to model 3D parametric models, and then design 3D drawings accordingly;

[0043] Specifically, the 3D parametric model of the component can be created in the REVIT software. Further, the 3D family library of the project component can be created according to the design drawings, and the 3D parametric solid model of the component can be created in the REVIT software to facilitate the control of the component. The size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com