Process for cutting wire net of silicon wafers

A cutting process and wire mesh technology, which is applied in the field of solar cell silicon wafer wire mesh cutting technology, can solve the problems of increasing the proportion of hidden cracks, missing corners and fragments, affecting the slicing efficiency, and disconnecting the cutting wire network. Fast and accurate mesh layout, improved wafer quality, and reduced line marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

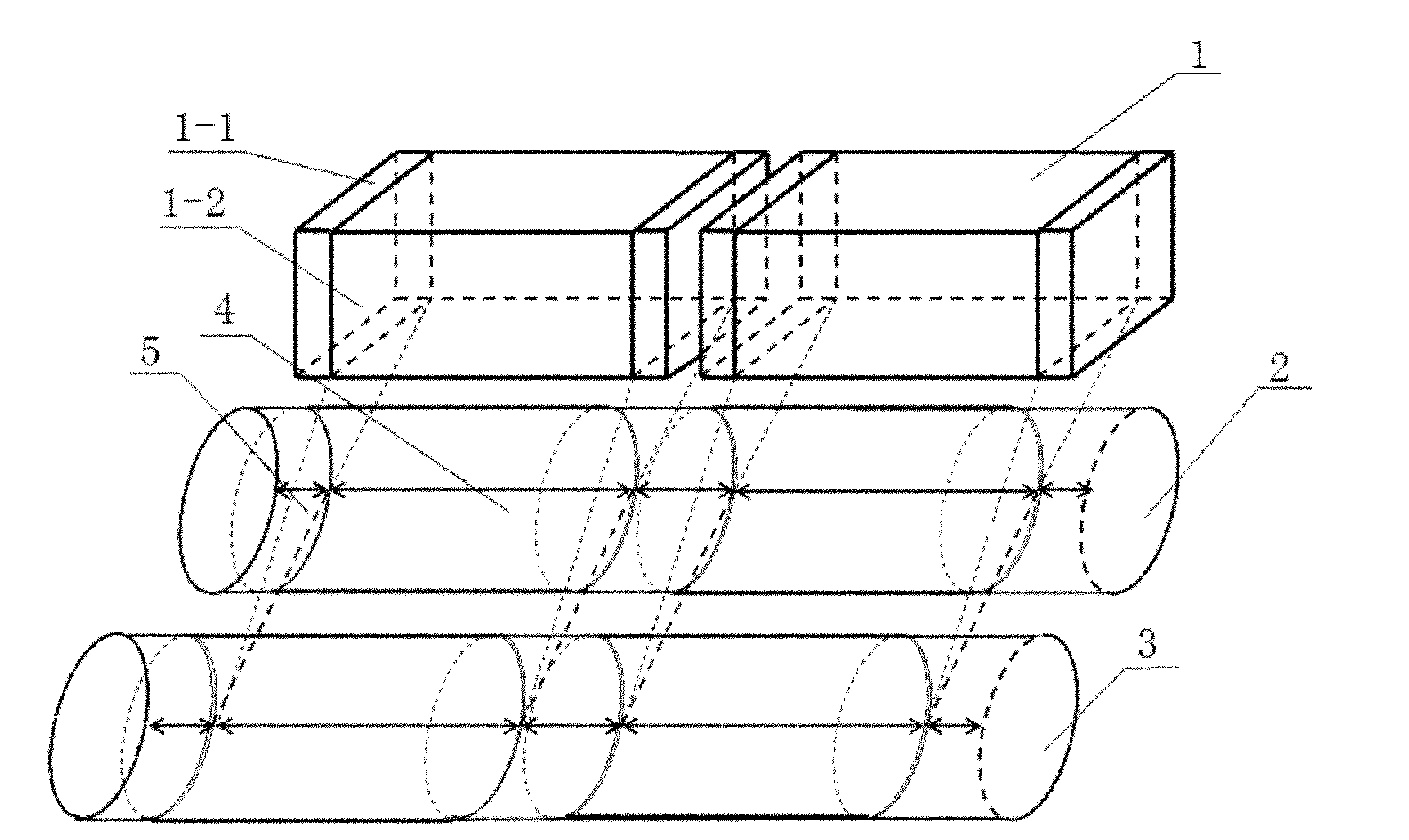

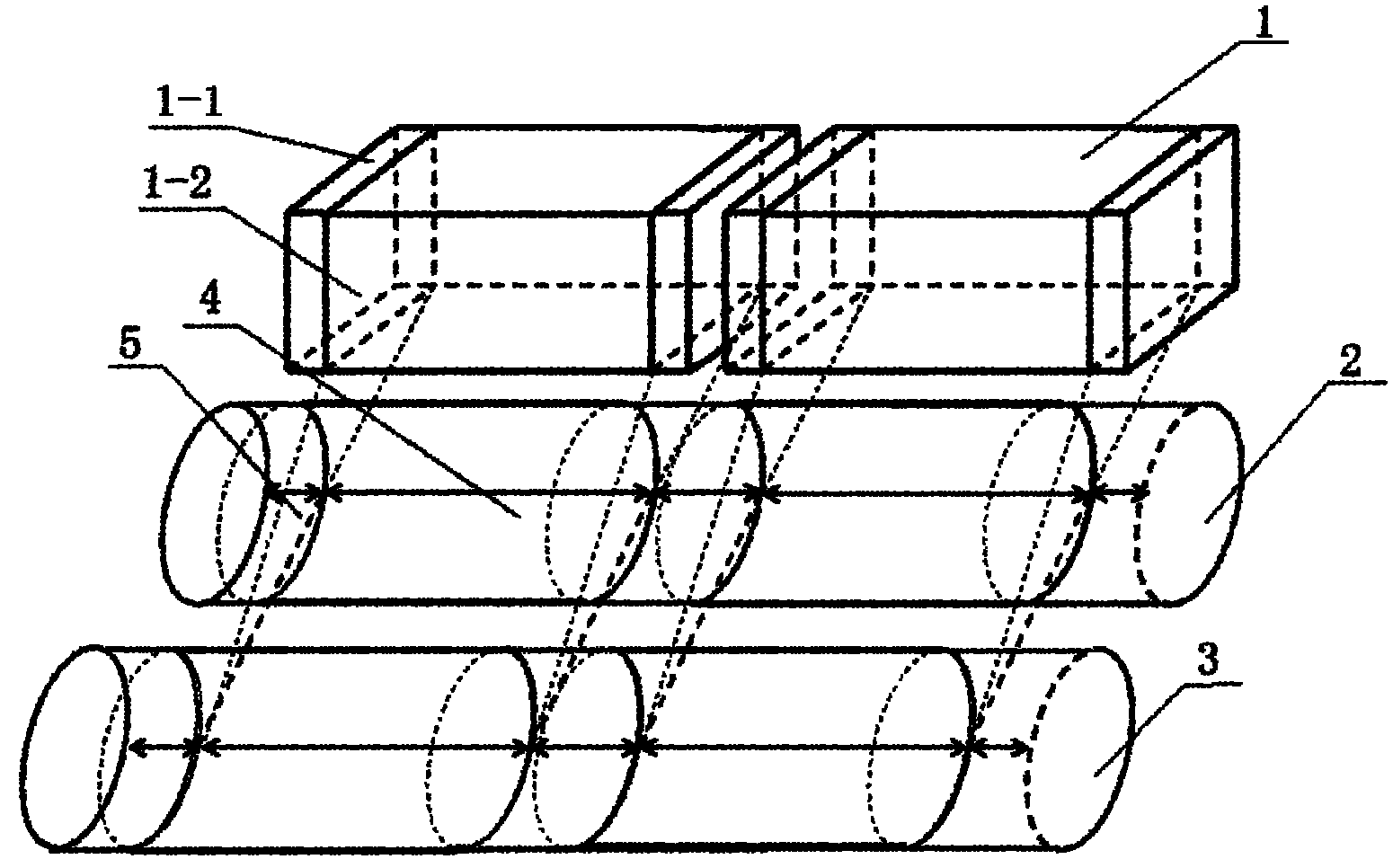

[0010] Such as figure 1 As shown, a silicon wafer wire mesh cutting process is used for slicing the crystal blocks for manufacturing solar cells, and has the following steps:

[0011] (1) First, mark the section 1-1 that does not need to be sliced and the section 1-2 that needs to be sliced for the ingot 1 that has not undergone the truncation process, and record the slice length and ingot length of the ingot 1 . The crystal ingot is squared, inspected, chamfered, and ground to form a crystal block 1 without truncation and truncation process, which saves the head and tail truncation process of the crystal block in the non-separation wire mesh cutting process. Put the crystal block 1 and auxiliary materials such as glass plates in an ultrasonic tank with a soft rubber pad and an appropriate amount of water; The plate is pasted in the center of the aluminum plate, and the glass and the aluminum plate are firmly adhered by the pressure method; the glue is evenly applied to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com