Sludge drying burning treatment method and integrated apparatus

A sludge drying and integrated device technology, which is applied in combustion methods, dewatering/drying/concentrating sludge treatment, and oxidation treatment of sludge, etc., can solve problems such as restricting popularization and use, and achieve high heat utilization rate and comprehensive treatment effect. , the effect of operating safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further specifically described below through examples.

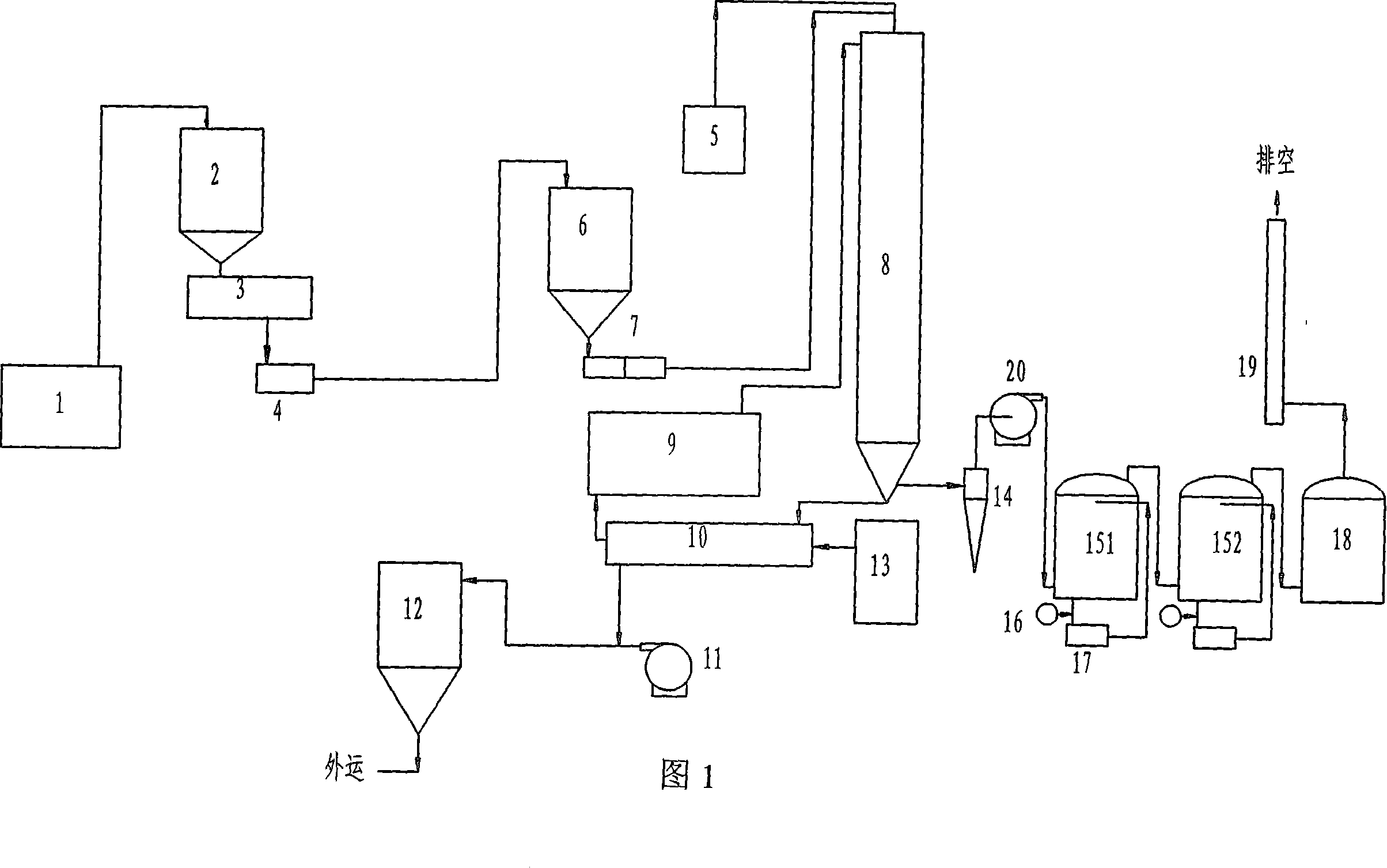

[0023] Example. As shown in Figure 1, the sludge drying and incineration integrated device in this example has a daily sludge treatment capacity of 50 tons, and it is composed of four functional parts connected.

[0024] I-sludge pretreatment part: beater 2, screening machine 3, transfer pump 4, mud storage tank 6 (capacity 5m 3 ) are connected in turn, and connected with the spray drying tower 8 air-flow nozzles through the high-pressure pump 7 (the pressure is 1.5Mpa~2.4MPa).

[0025] II-Drying and incineration part: It is a spray drying tower 8 with a height of 40m and a diameter of 3.5m. The top part of the tower has an airflow nozzle / air compressor 5, a high-temperature gas inlet, a tail gas outlet at the bottom of the tower, and a discharge port at the bottom of the tower The nozzle of the drying tower is connected with the high-pressure pump 7 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com