Adsorption resin as well as preparation method and application thereof

A technology of adsorption resin and macroporous resin, applied in the field of adsorption resin and its preparation, can solve the problems of inability to significantly improve the 28-day survival rate of patients, inability to effectively treat sepsis, removal of endotoxin and pathogenic bacteria, and the like, Achieve the effect of improving blood compatibility, ensuring hydrophobicity and inhibiting bacterial infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

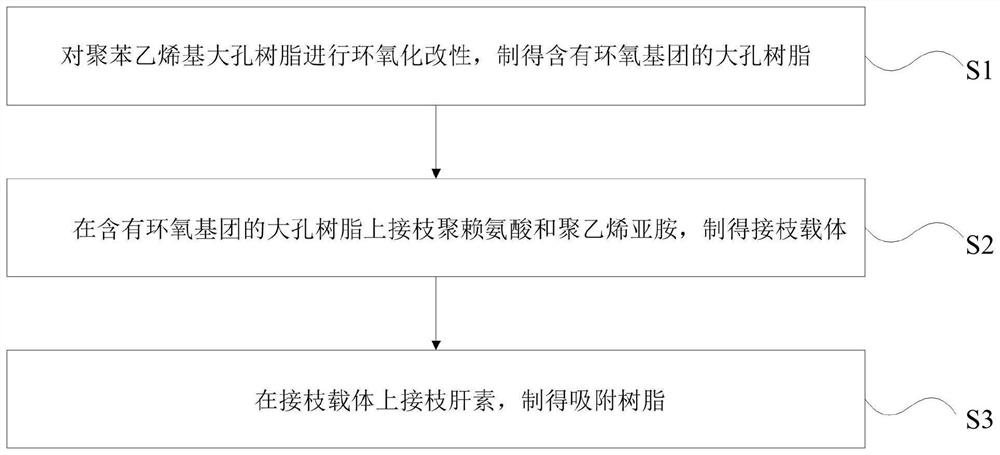

[0033] figure 1 It is a flow chart of the process for preparing the adsorption resin provided in the examples of the present application. to combine figure 1 As shown, the second aspect of the embodiment of the present application provides a method for preparing an adsorbent resin, comprising:

[0034] Step S1. Epoxidatively modifying the polystyrene-based macroporous resin to obtain a macroporous resin containing epoxy groups.

[0035] Specifically, polystyrene monomers and polyvinyl crosslinking agents are suspended and polymerized in a dispersion medium under the action of porogens and initiators to obtain polystyrene-based macroporous resins; A compound containing epoxy groups is added to the vinyl macroporous resin for epoxy modification reaction to obtain a macroporous resin containing epoxy groups.

[0036] In order to ensure that there are enough double bonds to participate in the epoxy modification reaction of compounds containing epoxy groups, ensure that the oute...

Embodiment 1

[0070] The present embodiment provides a kind of preparation method of adsorption resin, comprises the following steps:

[0071] (1) Epoxidation modification of polystyrene-based macroporous resin:

[0072] Add 600mL of aqueous solution containing 1.5wt% gelatin to a 1000mL three-necked flask, add 40g of divinylbenzene, 10g of ethylstyrene, 25g of porogen toluene, 10g of n-heptane, 25g of n-octanol, and diisobutyl ketone 20g, initiator 0.5g mixed organic phase composed of peroxy-2-hexylhexanoic acid tert-butyl ester, under mechanical stirring, control the size of oil droplet, raise the temperature to 70°C and react for 2h, take a sample to observe the oil droplet after setting , add 10g of allyl glycidyl ether dropwise to the three-necked flask, and keep it at 70°C to continue the reaction for 5 hours, then raise the reaction temperature to 80°C, and continue the reaction for 4 hours to fully cross-link and solidify. After the reaction, Cool, filter out the mother liquor, ext...

Embodiment 2

[0078] The present embodiment provides a kind of preparation method of adsorption resin, comprises the following steps:

[0079] (1) Epoxidation modification of polystyrene-based macroporous resin:

[0080] Add 600mL of aqueous solution containing 1.5wt% gelatin to a 1000mL three-necked flask, add 31.5g of divinylbenzene, 18.5g of ethylstyrene, 35g of porogen toluene, 15g of n-heptane, and 15g of methyl isobutyl carbinol , Methyl isobutyl ketone 15g, initiator 0.5g mixed organic phase of peroxy-2-hexylhexanoic acid tert-butyl ester, under mechanical stirring, control the size of the oil droplet, heat up to 70 ° C after 2 hours of reaction, After taking a sample to observe the shape of the oil droplets, add 15g of allyl glycidyl ether dropwise to the three-necked flask, and keep it at 70°C for 5 hours, then raise the reaction temperature to 80°C, and continue the reaction for 4 hours to fully crosslink After solidification, after the reaction, cool down, filter out the mother ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com