Universal wheel

A technology of universal wheels and rims, which is applied in the direction of casters, wheels, transportation and packaging, etc. It can solve the problems of complex structure and process of half hubs, the inability to install other parts on wheels, and affect the service life of wheel frames, etc., so as to achieve good connection , saving structure rotation space, the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

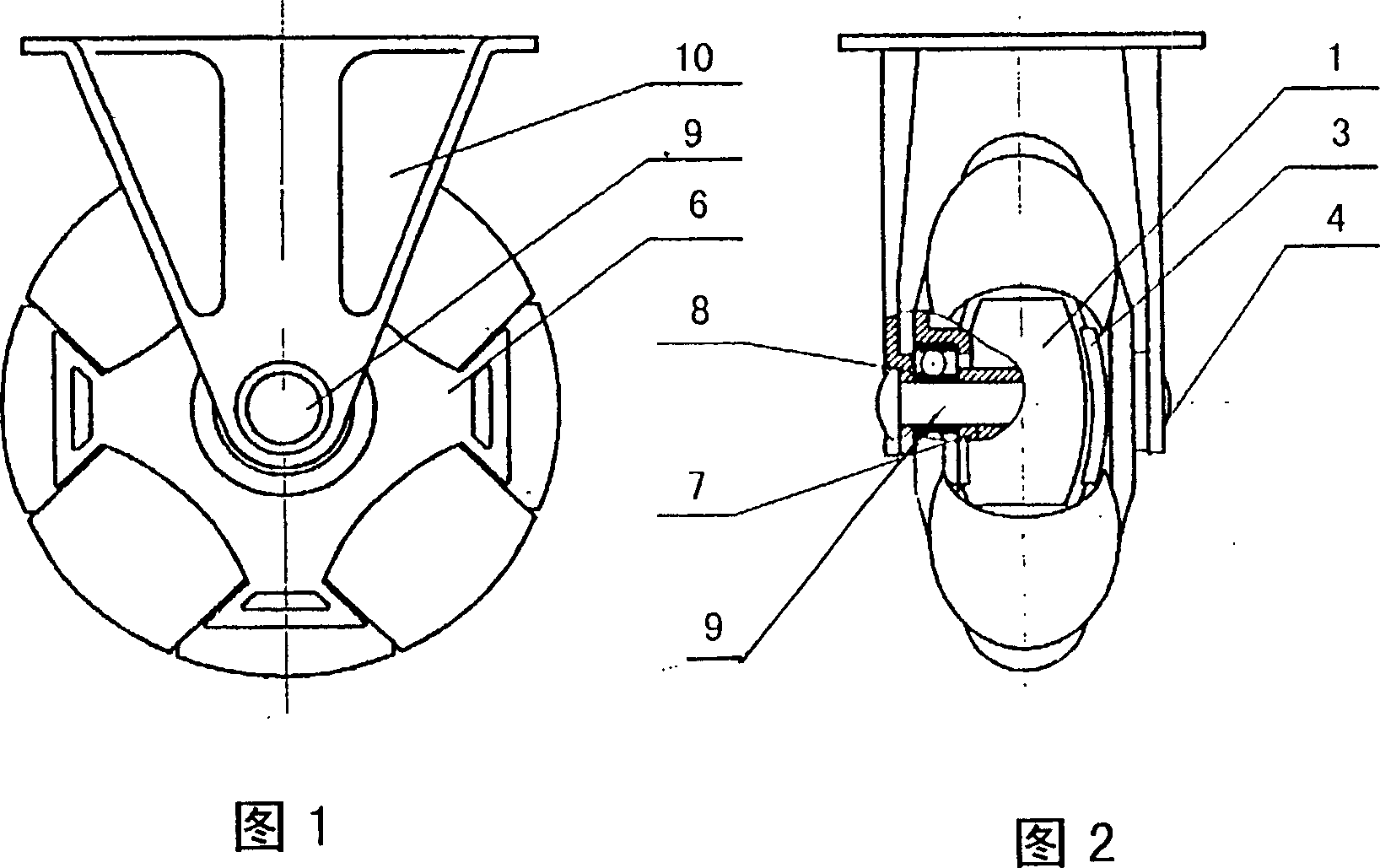

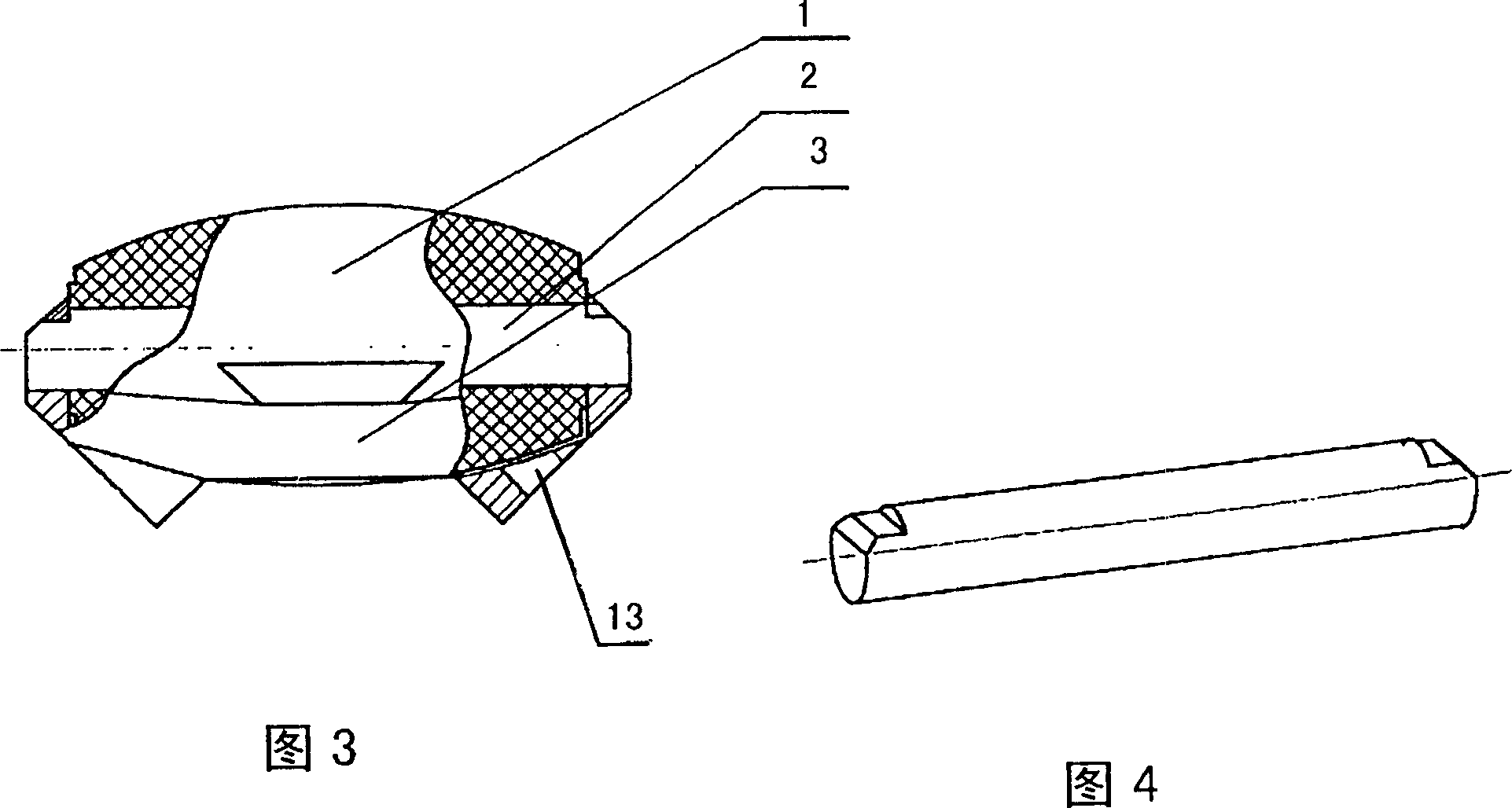

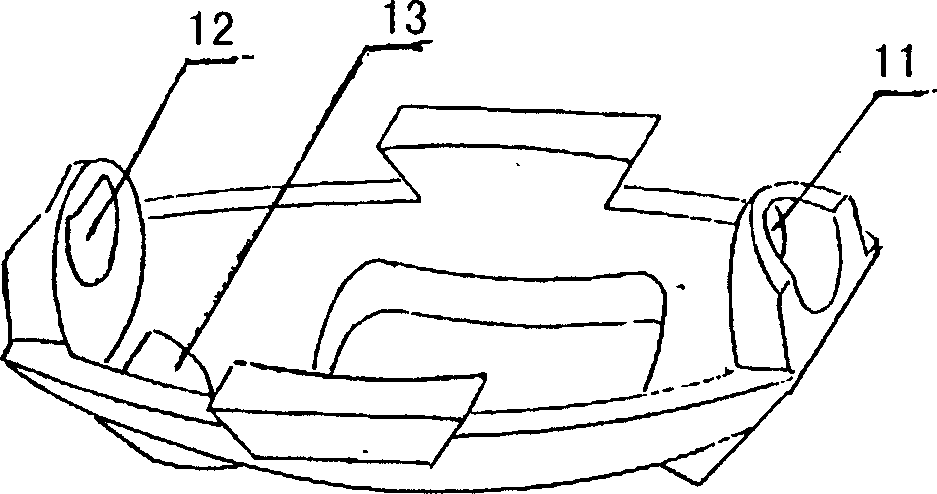

[0019] Please refer to Fig. 1~8, Fig. 1 is the implementation plan figure of the novel universal wheel that four pairs of big and small drum-shaped rollers form. The two ends axle noses of long mandrel 2 are made half moon shape, see Fig. 4. Pass the long mandrel 2 through the shaft hole 11 on the right support of the bat-shaped support 3, then through the center hole of the small waist drum-shaped roller 1, and then insert it into the half-moon-shaped shaft hole 12 on the left support of the bat-shaped support 3 middle. See Figure 5 And Fig. 3, the small waist drum shaped roller 1 has just been installed on the bat support 3 central positions like this, and can rotate freely. Now, the half-moon shaft head at the right end of the long mandrel 2 is riveted on the right side support of the bat-shaped support 3, and a half-moon shaft hole 13 is respectively arranged at the left and right lower parts of the bat-shaped support 3. See Figure 5 As shown in Fig. 3, the drum-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com