Wind blade device for wind generating system

A technology of wind power generation system and wind blades, which is applied to the assembly of wind power generators, wind power generator components, wind power generation, etc. It can solve the problems of not being suitable for ordinary families and small companies, taking up a lot of space, and the weight of the machine, etc., to achieve Low noise, small space occupation and low self-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

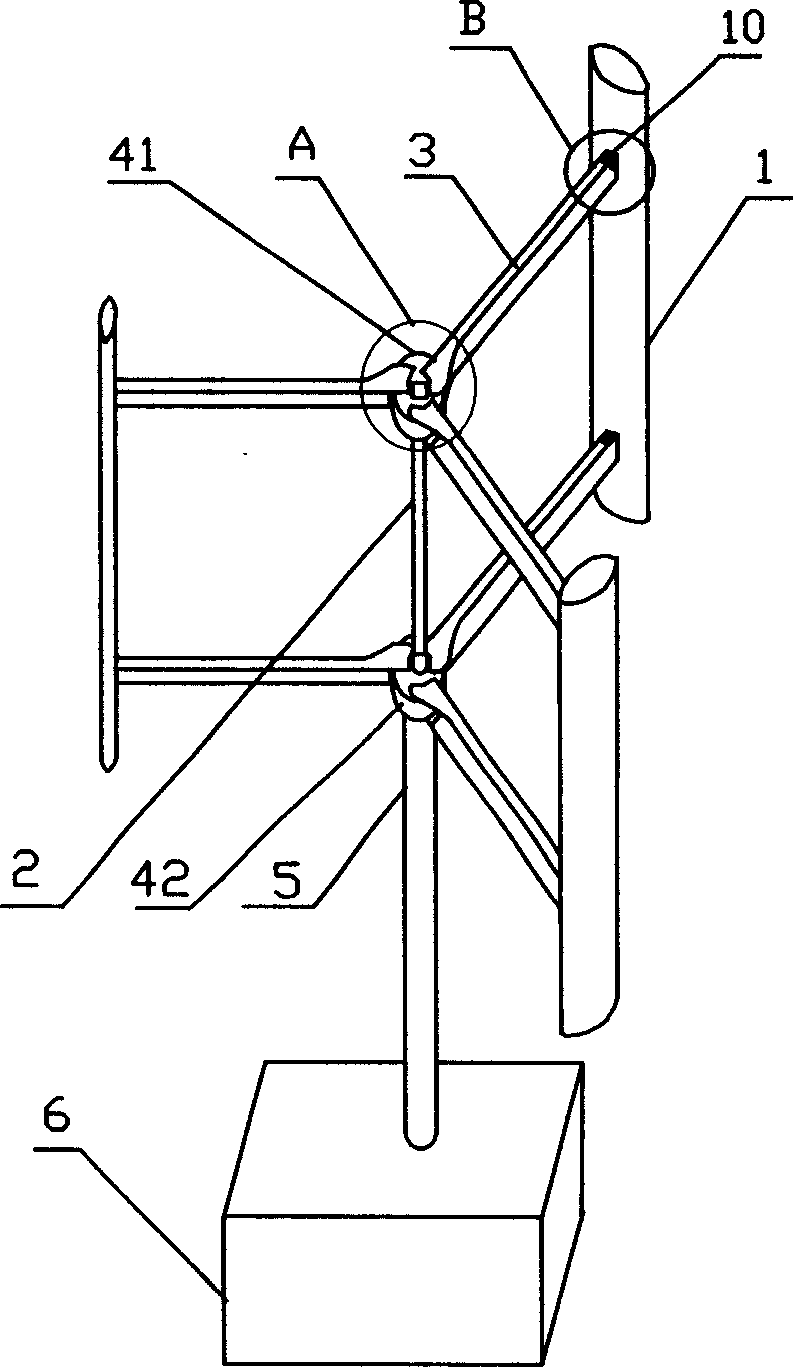

[0021] like figure 1 shown. The device adopts a vertical shaft type, and a vertical rotating shaft 2 is arranged in the middle. The rotating shaft 2 is connected with three blades 1 through a connecting mechanism, and the lower end of the rotating shaft 2 is connected to a generator 6 through a hollow sleeve 5 .

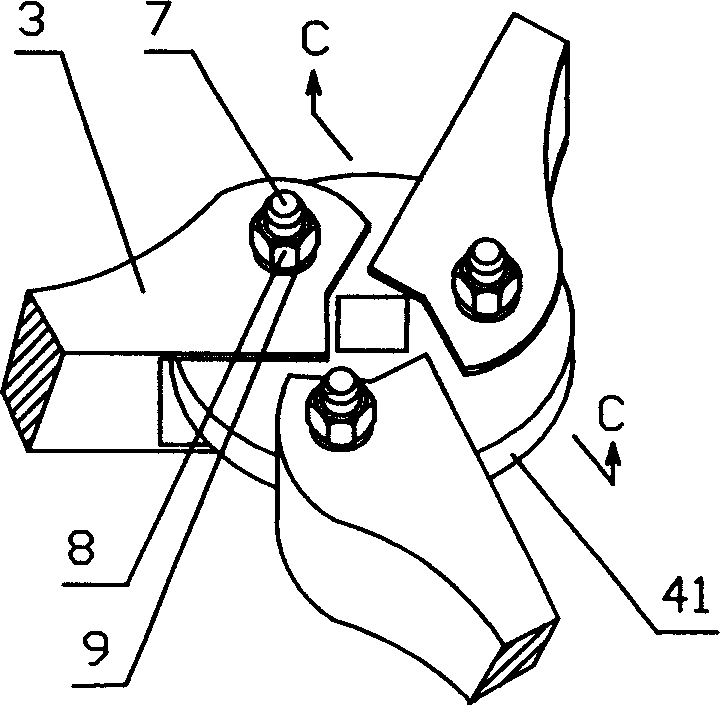

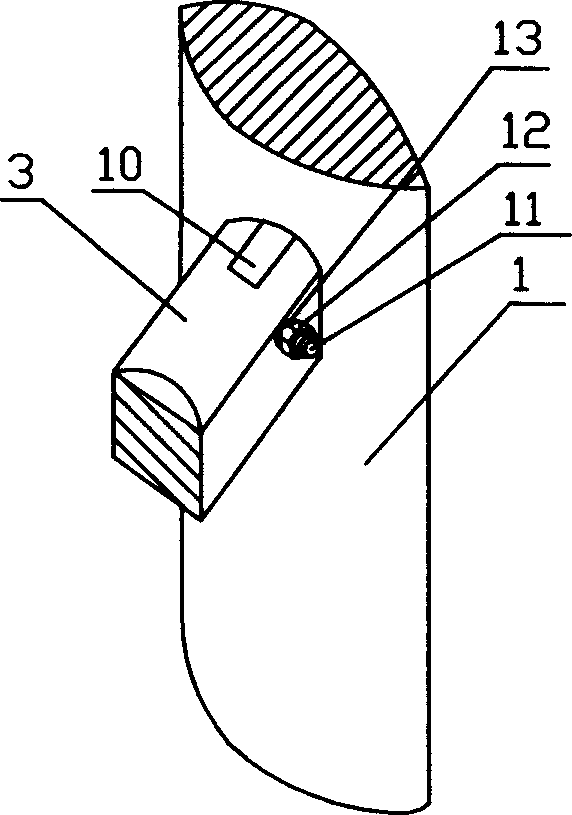

[0022] like figure 1 , image 3 , Figure 5 shown. Wind blade 1 is solidified and molded by polymer composite material, which is light and durable, and the weight of a single blade is less than 2 kg; its cross section is designed using modern aviation technology, and adopts NACA0009 airfoil: double-sided symmetrical convex arc shape, The chord length is 200 mm, the maximum wall thickness is 18 mm, and the length is 2400 mm. Aluminum alloy mounting joints 10 are prefabricated on the fan blades 1 respectively. The potential of the polymer composite material used in the fan blade 1 is close to that of the aluminum alloy parts used in the installation joint 10 to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com