Patents

Literature

115results about How to "Reasonable transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

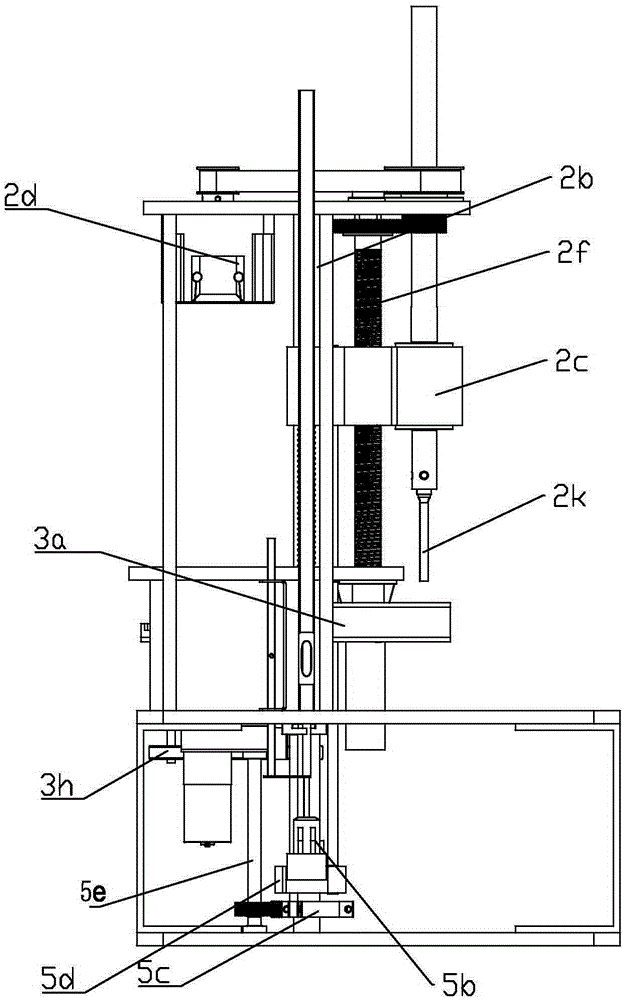

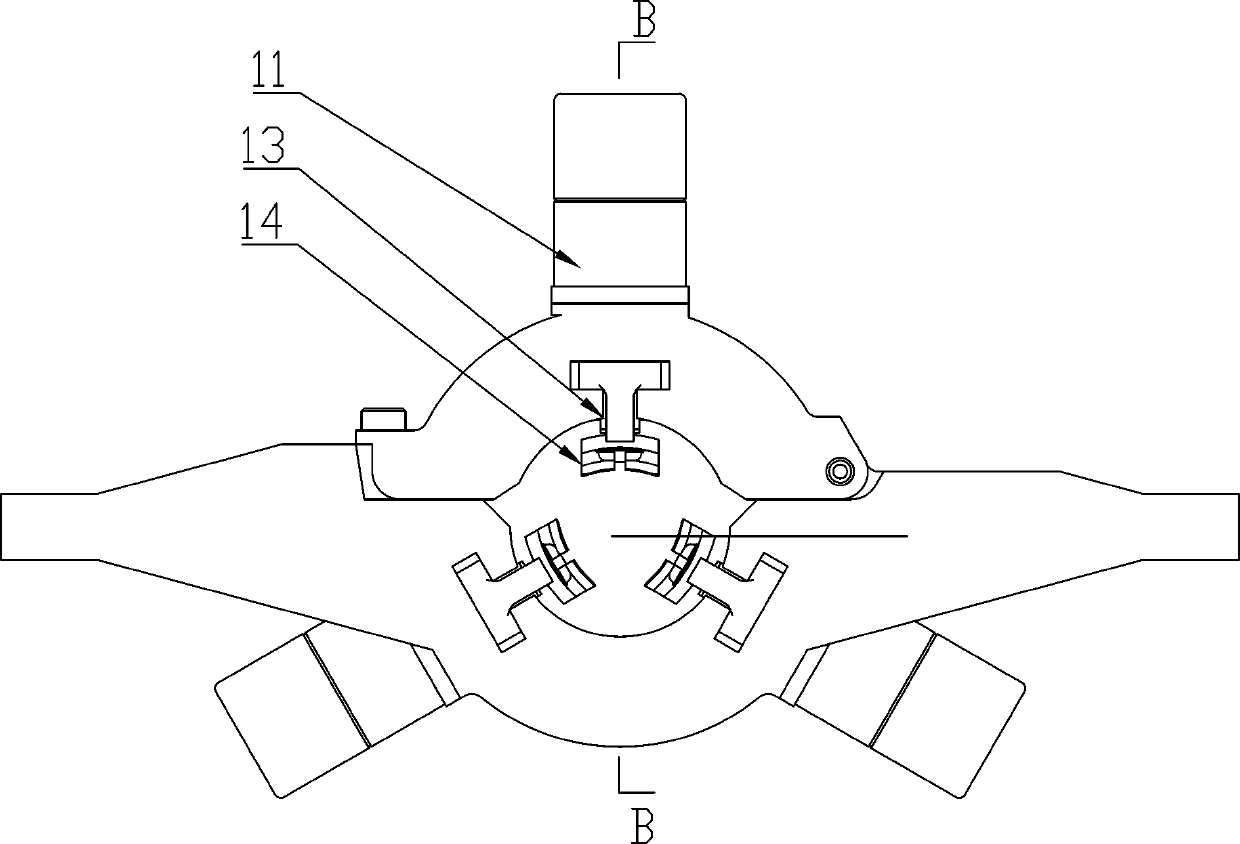

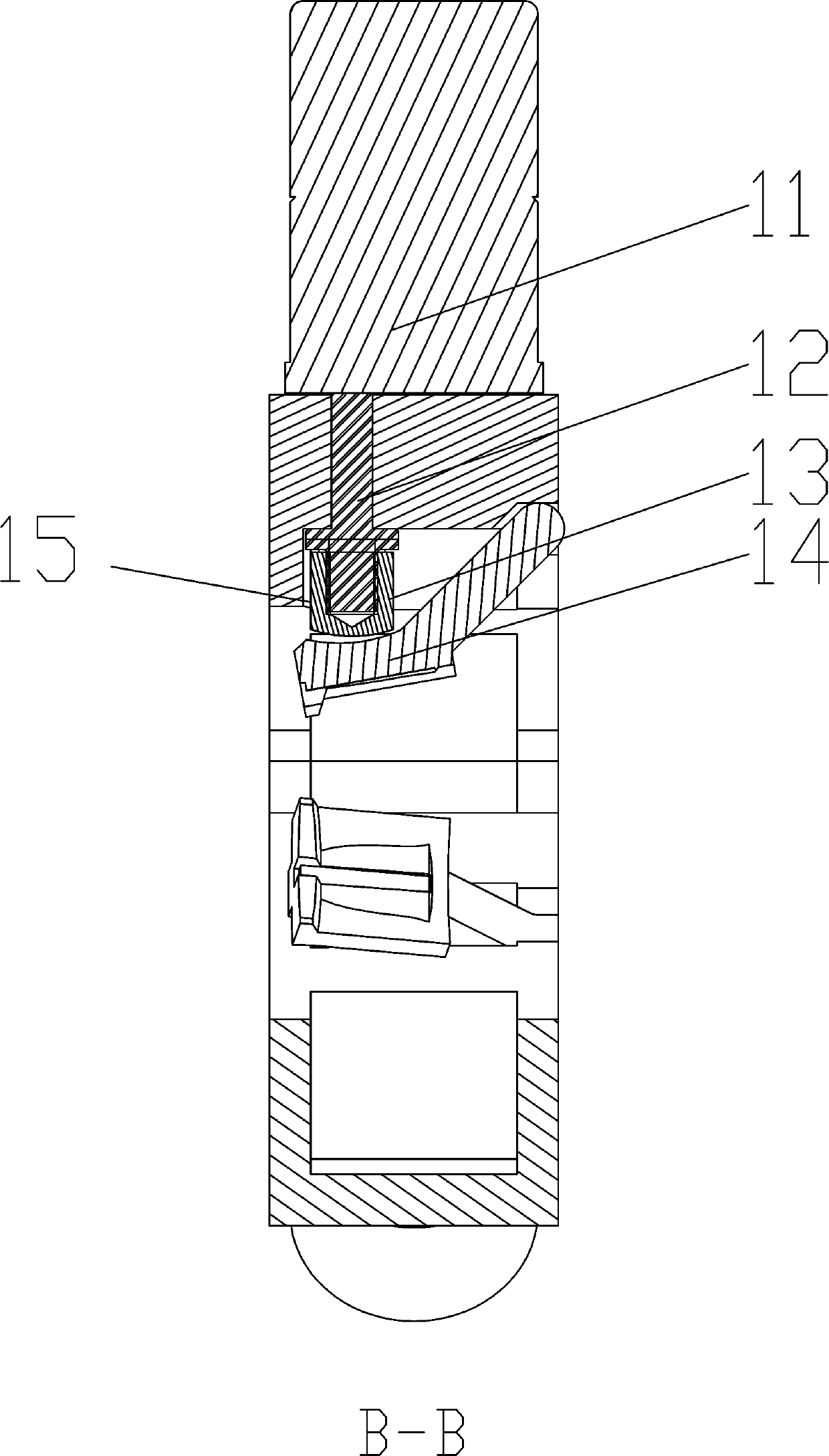

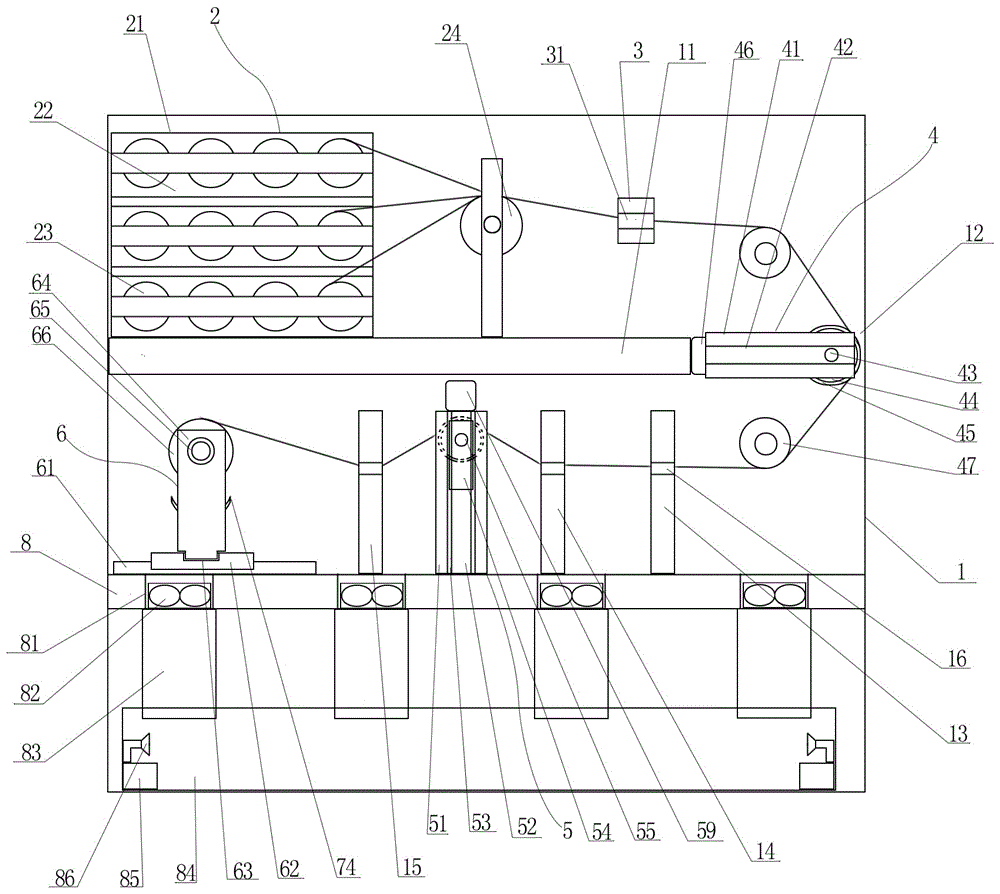

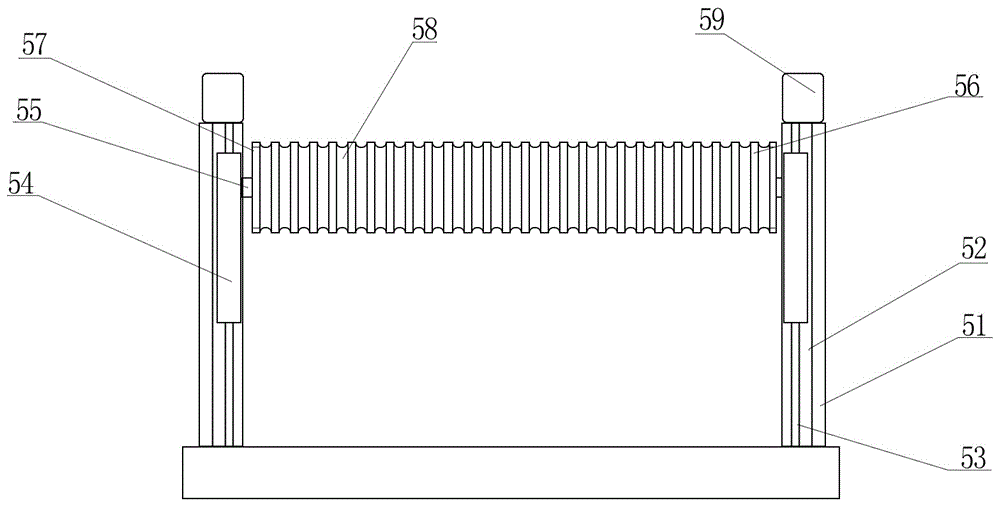

Automatic sectional material cutting production equipment and method

ActiveCN110153730AReasonable transmissionReasonable connectionMeasurement/indication equipmentsOther manufacturing equipments/toolsMachiningInkjet printing

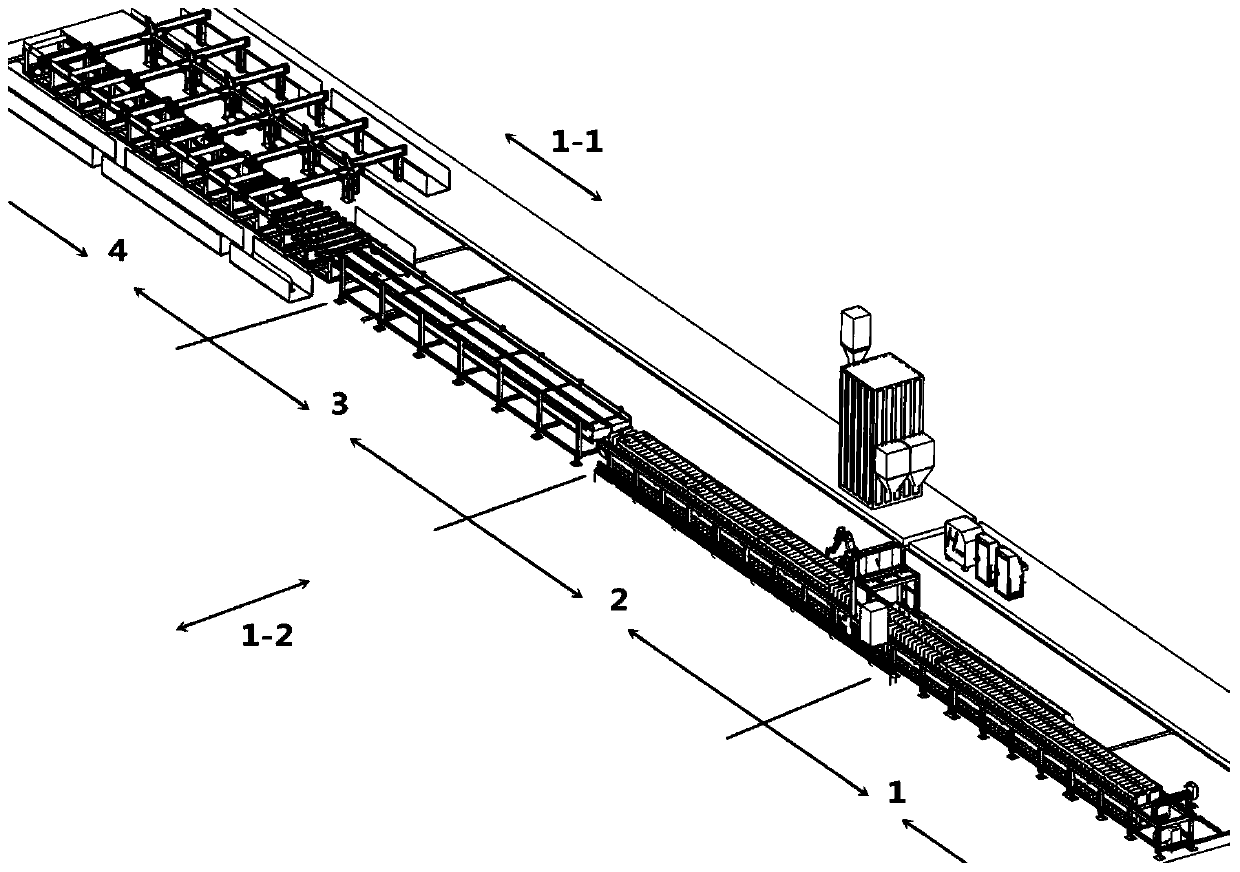

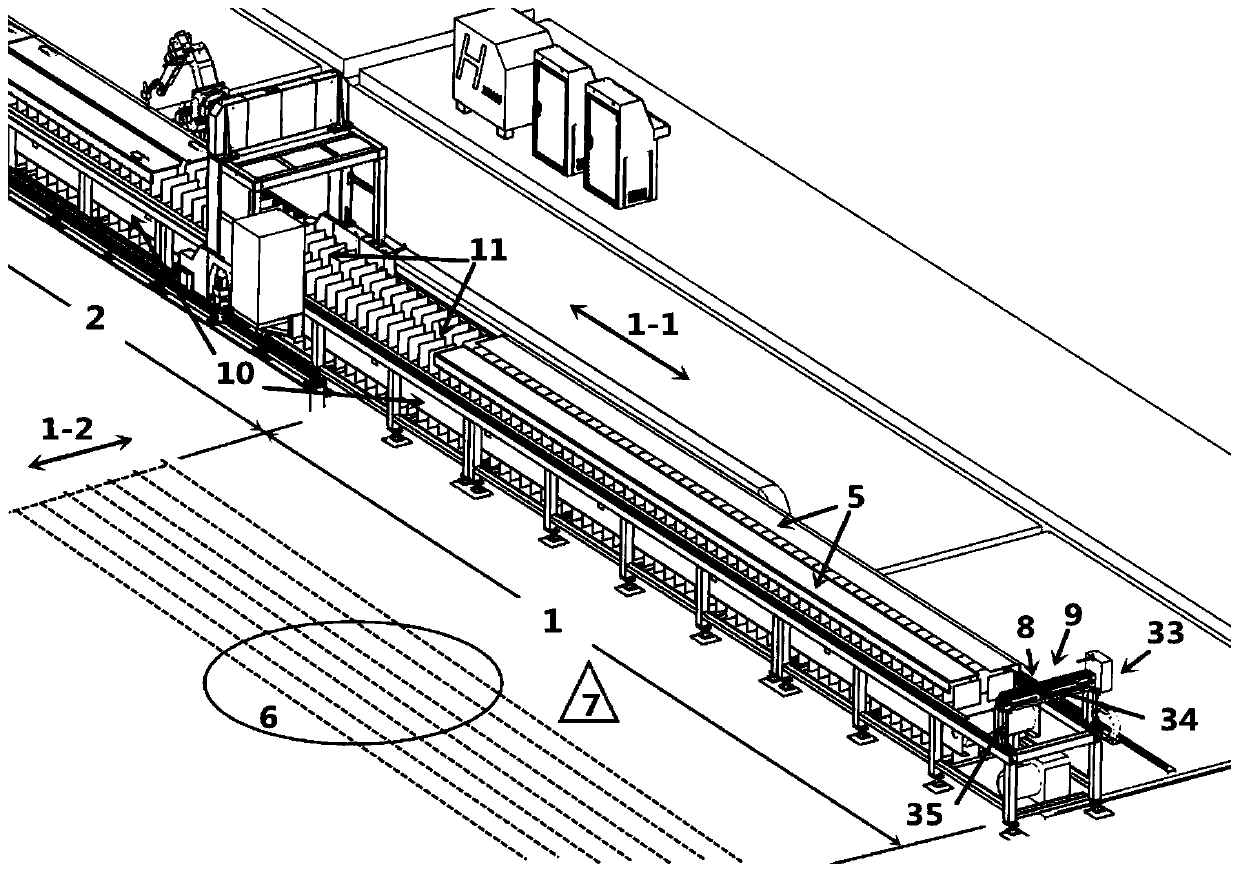

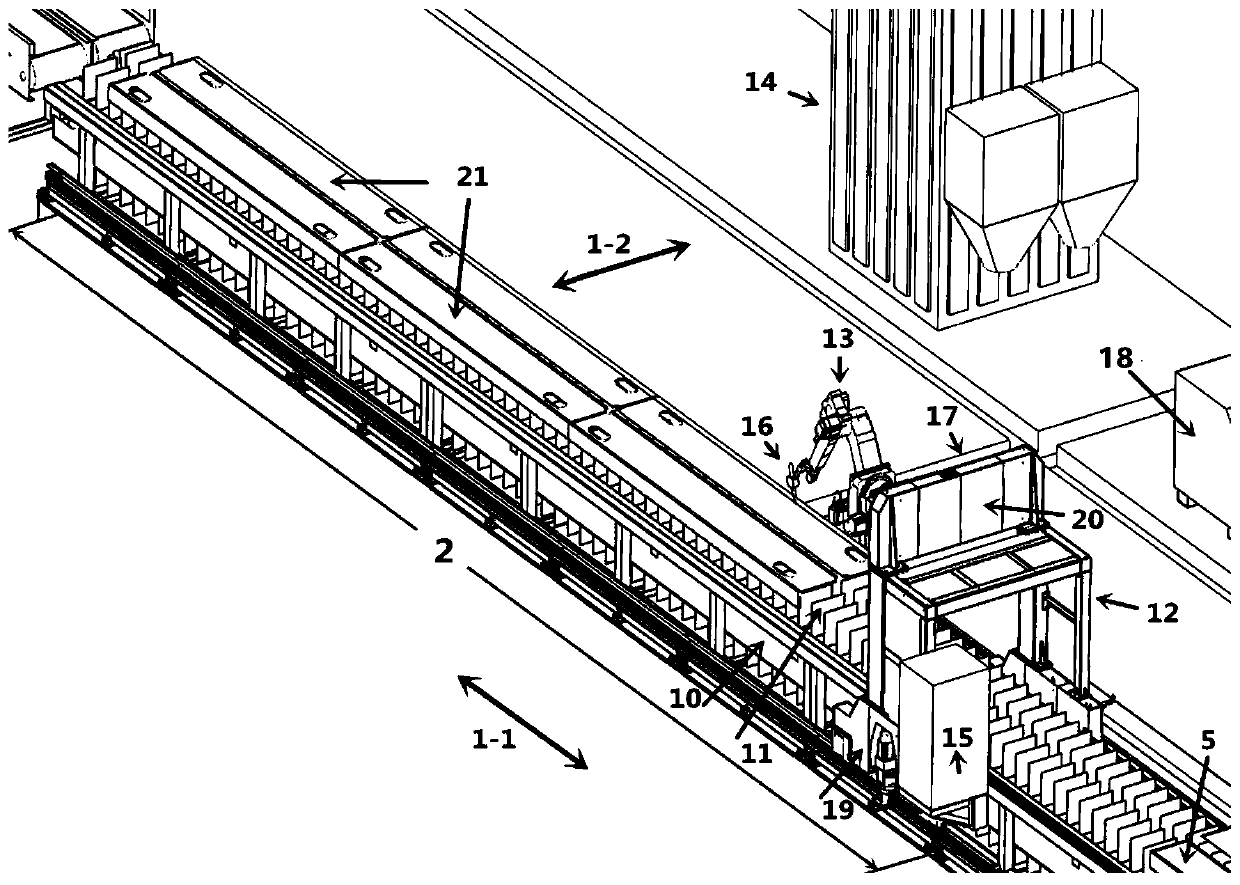

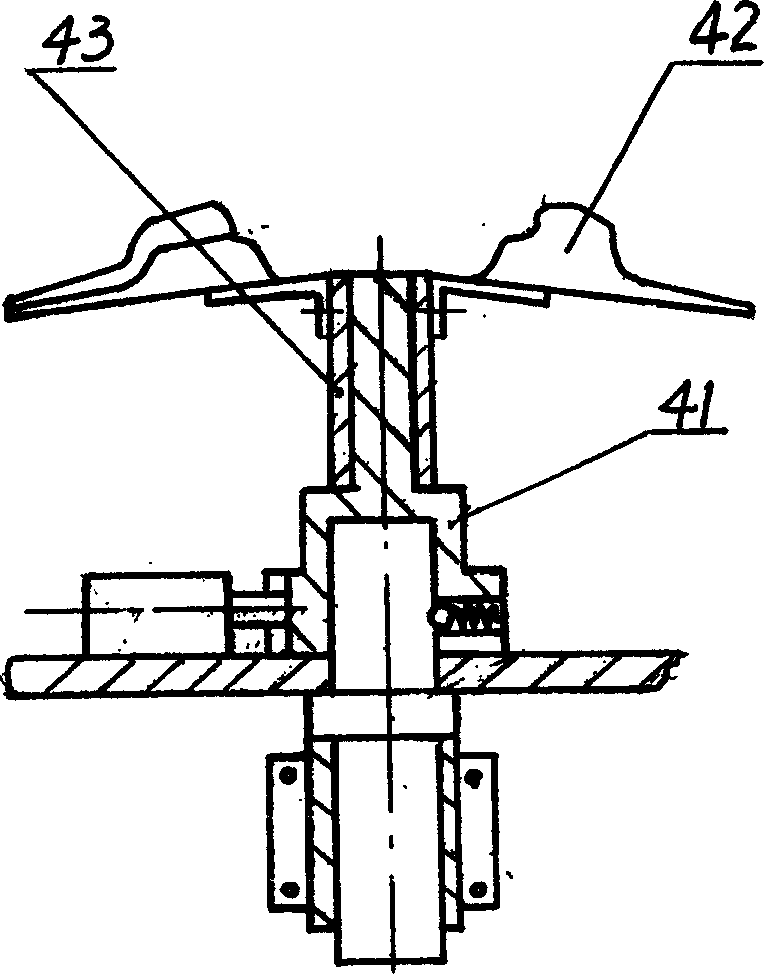

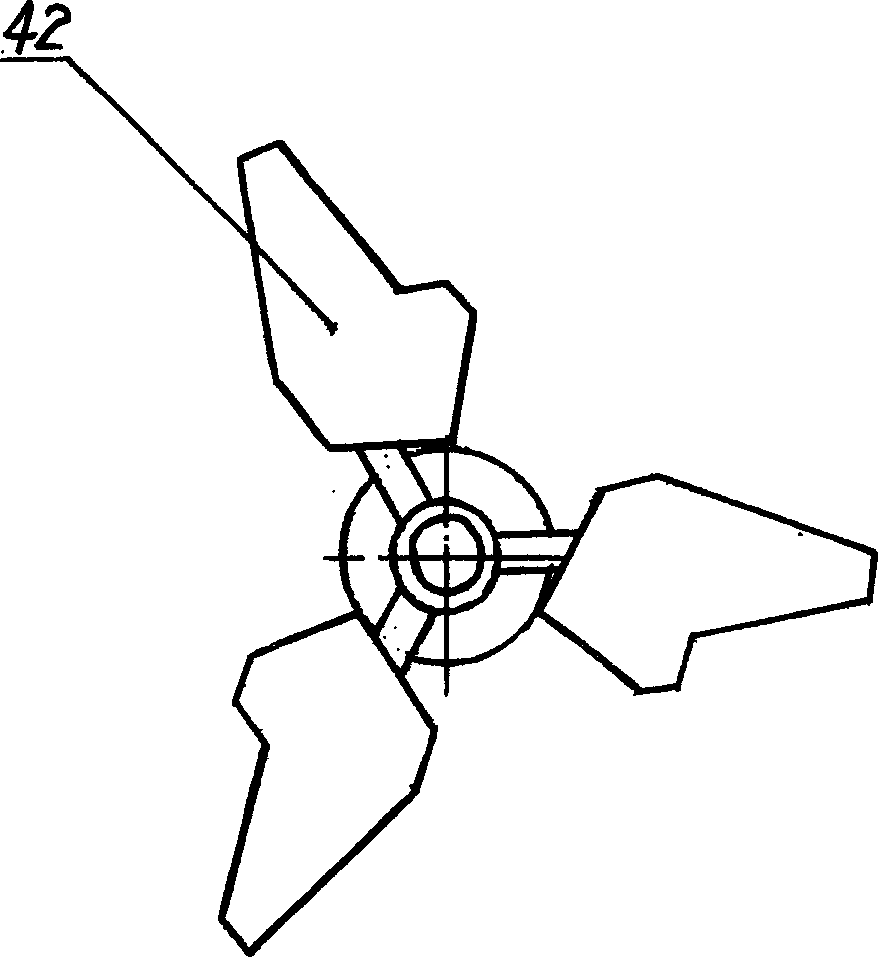

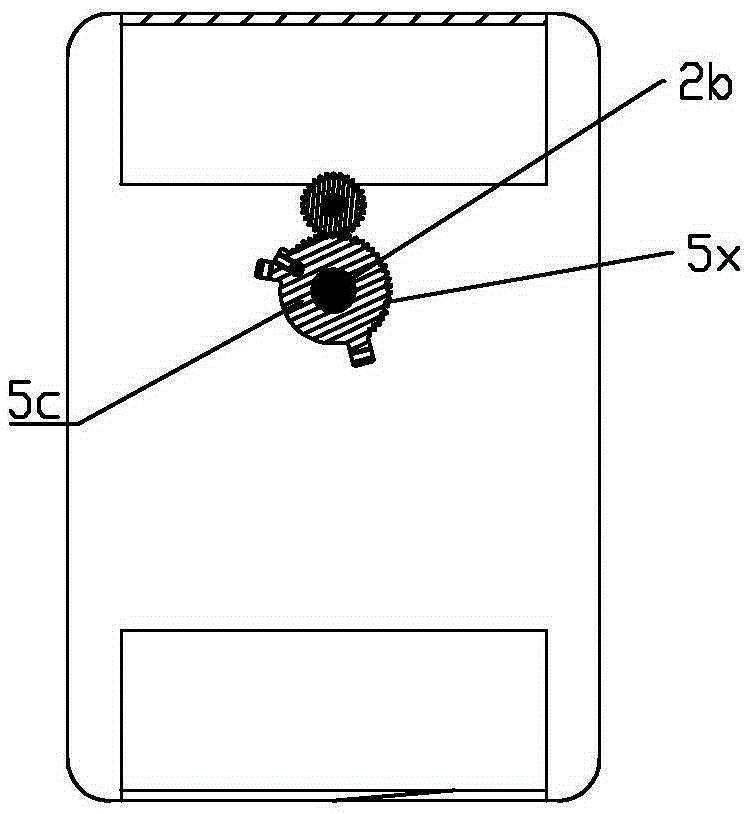

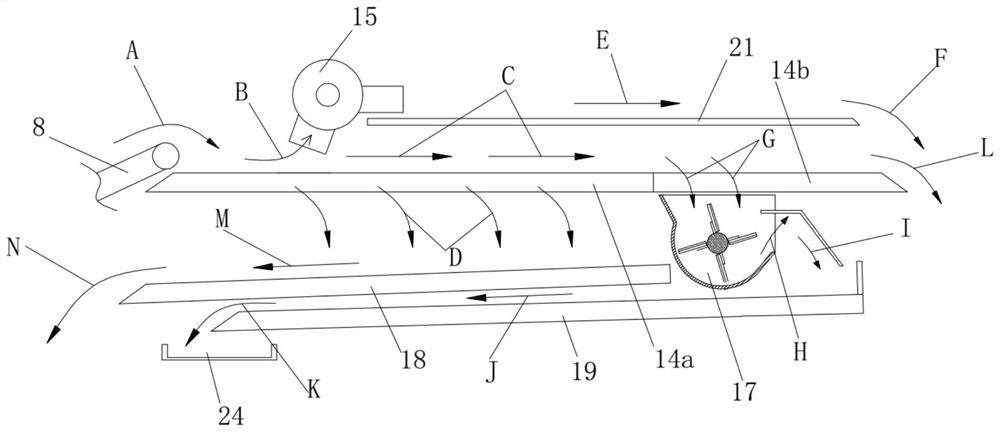

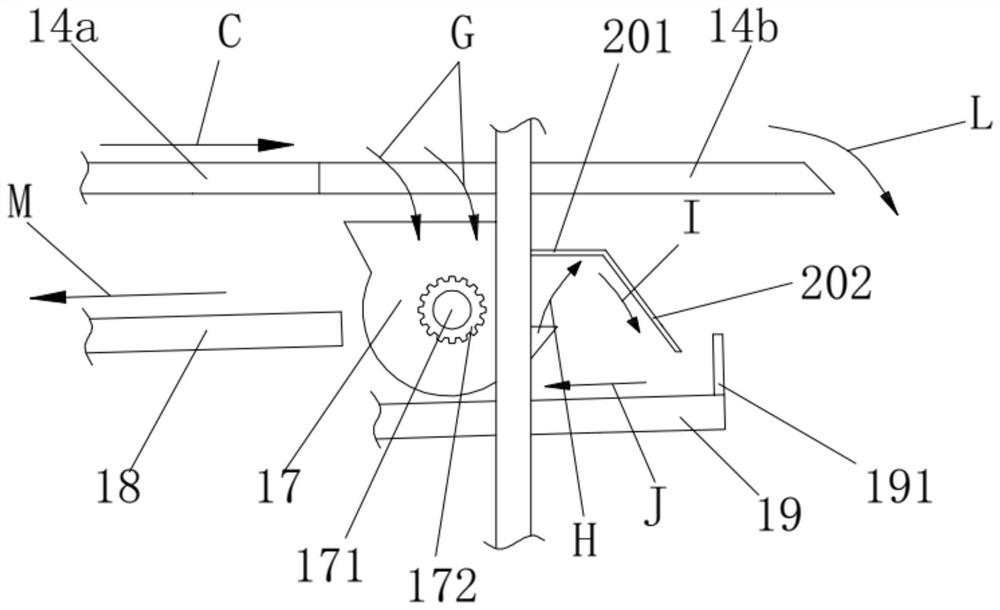

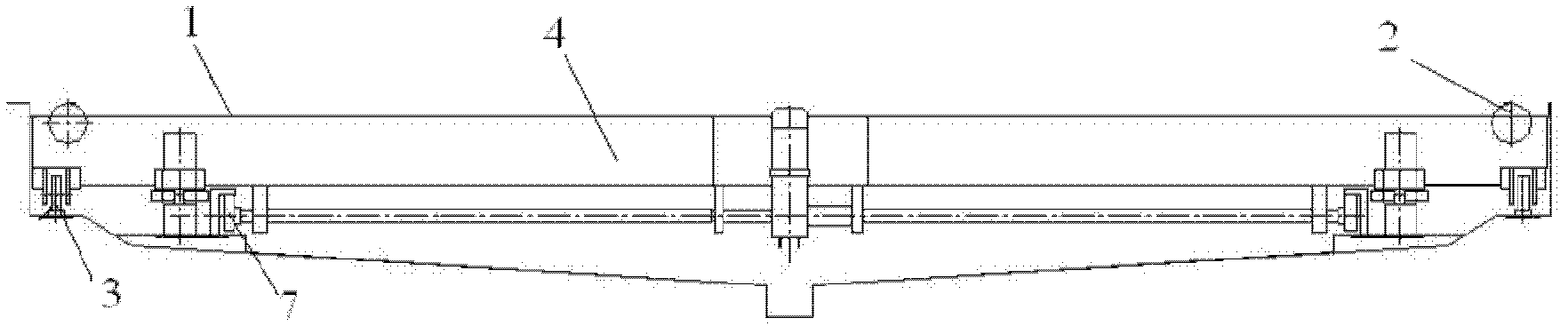

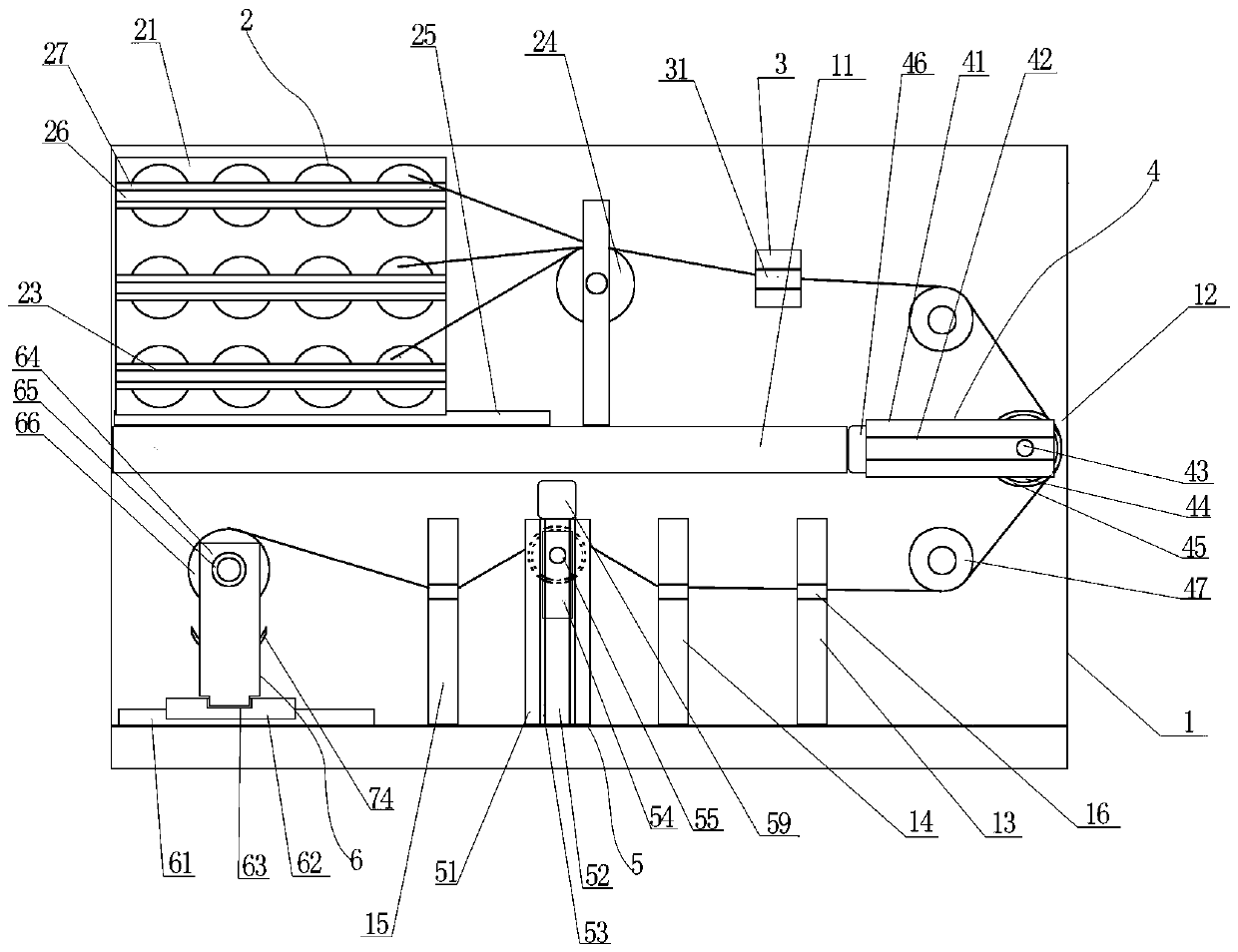

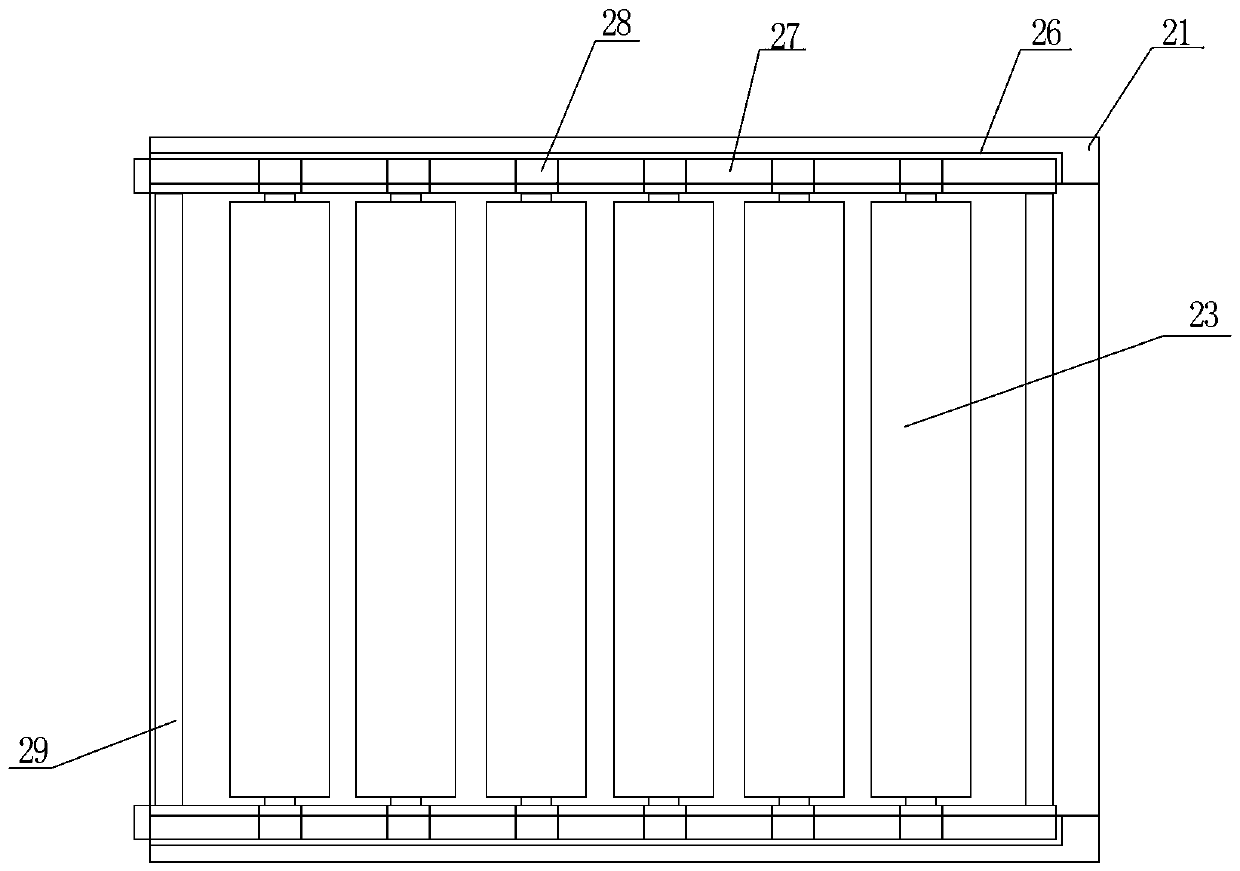

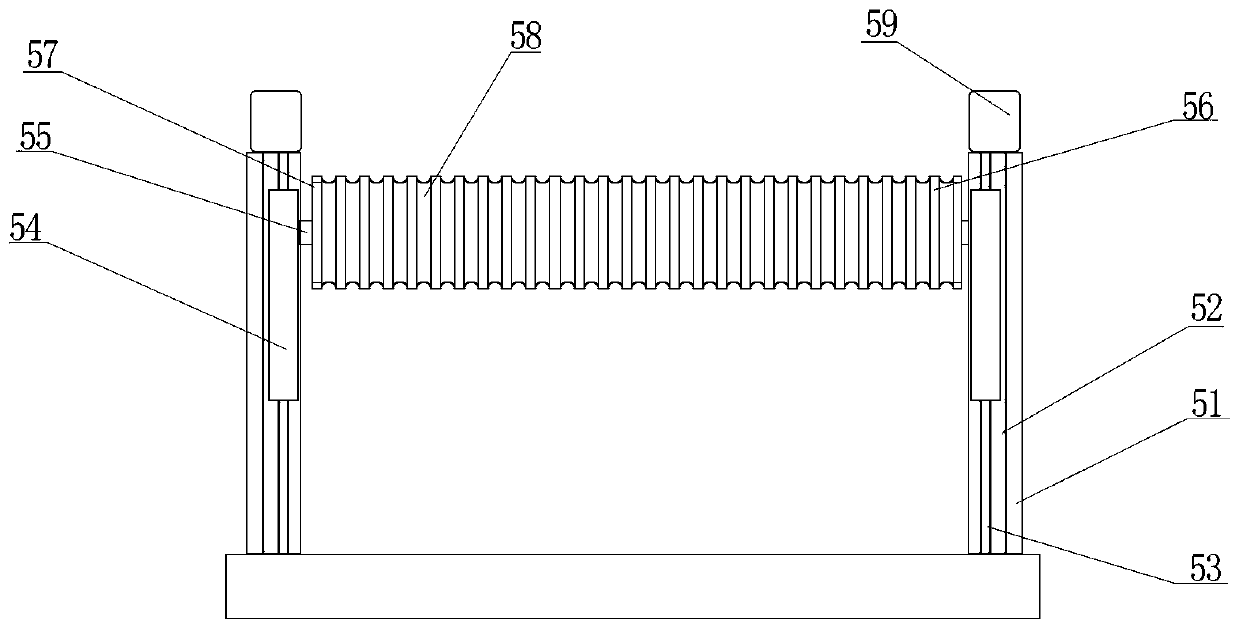

The invention discloses automatic sectional material cutting production equipment and a method. The equipment solves the problem that the efficiency is low, the quality is poor, the maintenance and machining cost is high, the machining difficulty of a complex wedge-head workpiece is high when cutting workpieces in the prior art. The production equipment comprises a feeding and code inkjet printingarea (1), a cutting area (2), a to-be-sorted area (3) and a discharging area (4), the feeding and code inkjet printing area (1), the cutting area (2), the to-be-sorted area (3) and the discharging area (4) are arranged in sequence, the the feeding and code inkjet printing area (1) and the cutting area (2) are provided and a first rotary type chain plate conveying mechanism (10) and a material table (11), the to-be-sorted area (3) is provided with two sets of second rotary type chain plate conveying mechanisms (22) which are arranged in parallel, and the discharging area (4) is provided with adischarging mechanism longitudinal conveying roller set device (24) and a discharging mechanism transverse rotating chain moving device (25). According to the equipment and the method, the efficiencyof cutting the workpiece is greatly improved.

Owner:北京林克曼数控技术股份有限公司

Cutting device and method for bird leg and removing bone

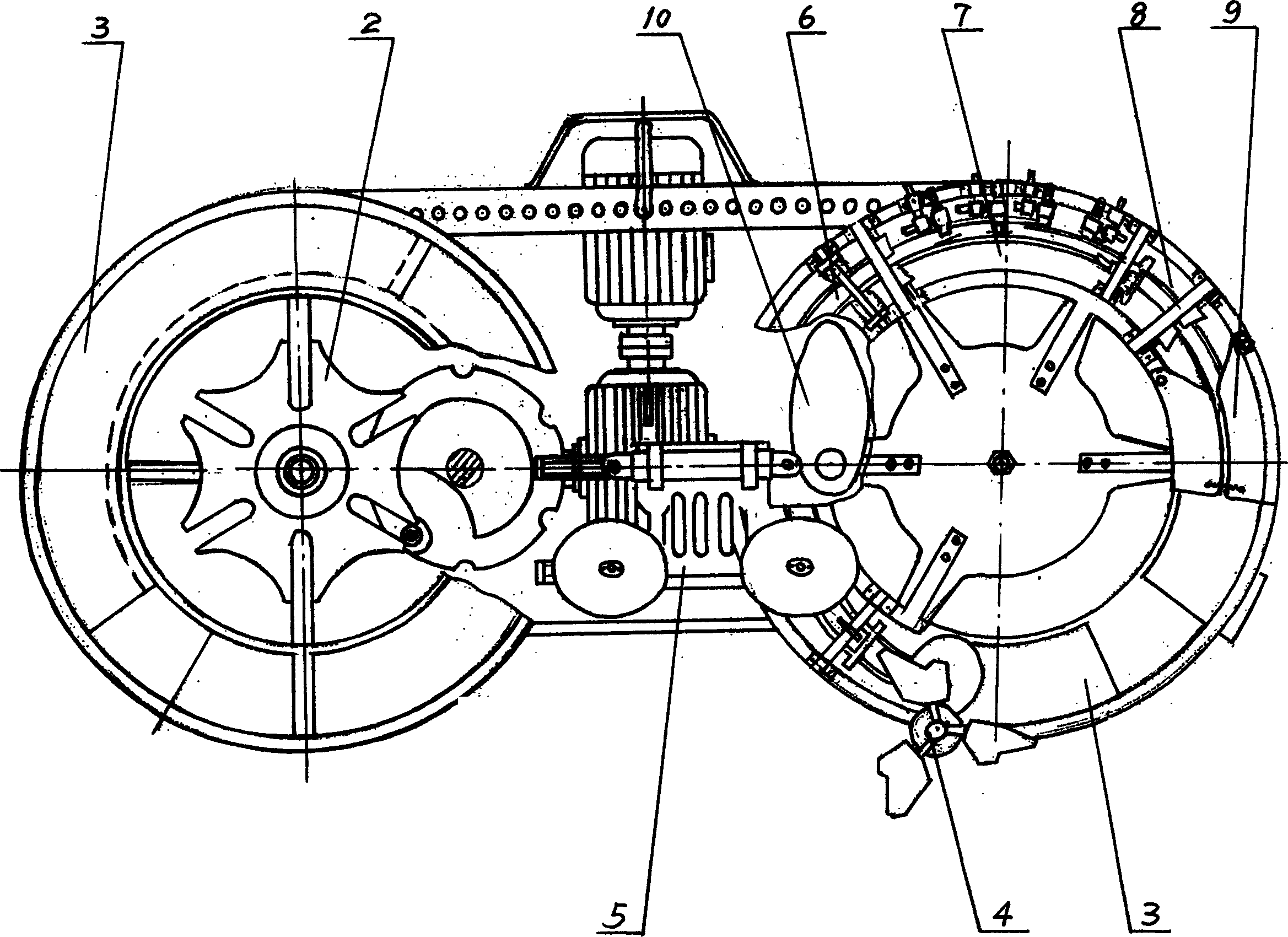

A cutting apparatus for removing bone from the leg of fowls is composed of indexing mechanism with horse-type slotted wheel, rotary bench, feeder, spine cutter, leg meat cutter, skin removing unit, leg meat splitter, bone separating and releasing unit power system, drive system and signal executing unit. Its method is also disclosed.

Owner:郁天永

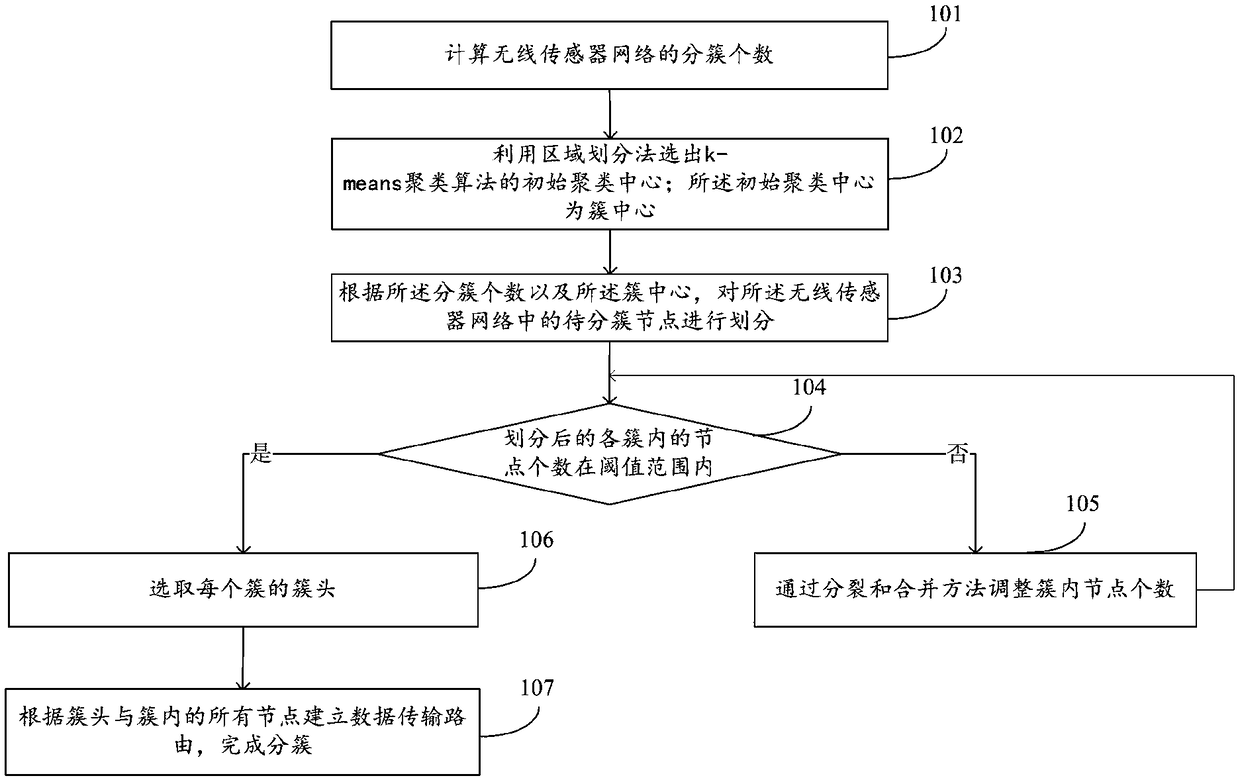

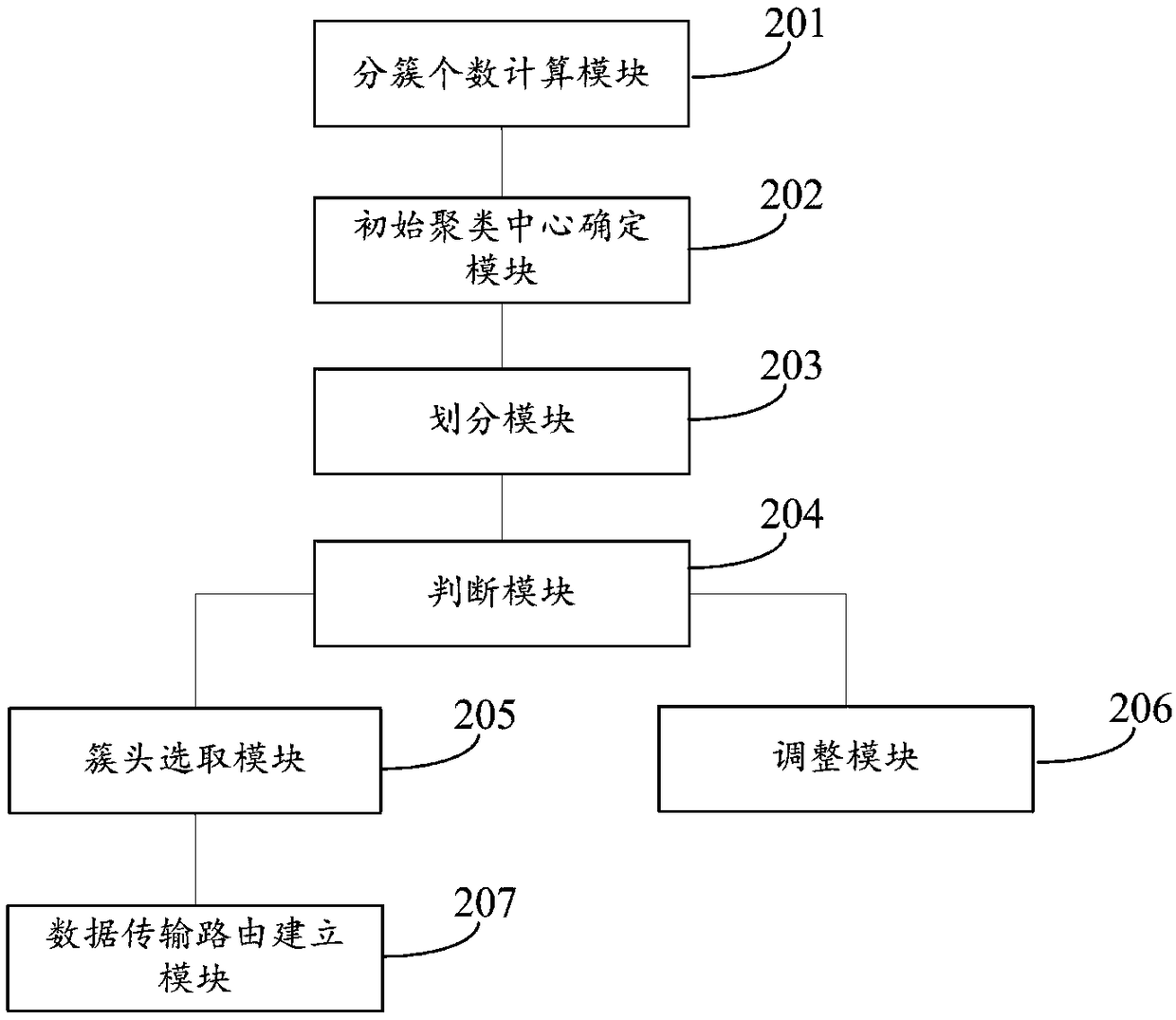

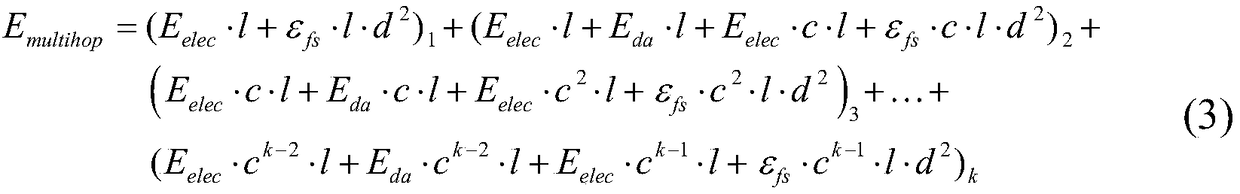

Wireless sensor network clustering method and system

ActiveCN108990129ABalanced energy consumptionEnergy-efficient method to obtain optimal clustering uniformityNetwork topologiesHigh level techniquesLine sensorWireless mesh network

The invention discloses a wireless sensor network clustering method and system. The method comprises the following steps of: calculating the number of clusters of a wireless sensor network; selectingthe initial clustering center of k-means clustering algorithm by a region method, the initial clustering center being a cluster center; dividing nodes to be clustered in the wireless sensor network according to the number of clusters and the cluster center; judging whether the number of nodes in each divided cluster is within the threshold range; if yes, selecting a cluster head of each cluster; if not, adjusting the number of nodes in the cluster by splitting and merging; according to the cluster head and all nodes in the cluster, establishing data transmission routing, and completing clustering. The method and the system can make the clustering more uniform and the energy consumption of nodes in the network more uniform.

Owner:CHANGCHUN UNIV OF SCI & TECH

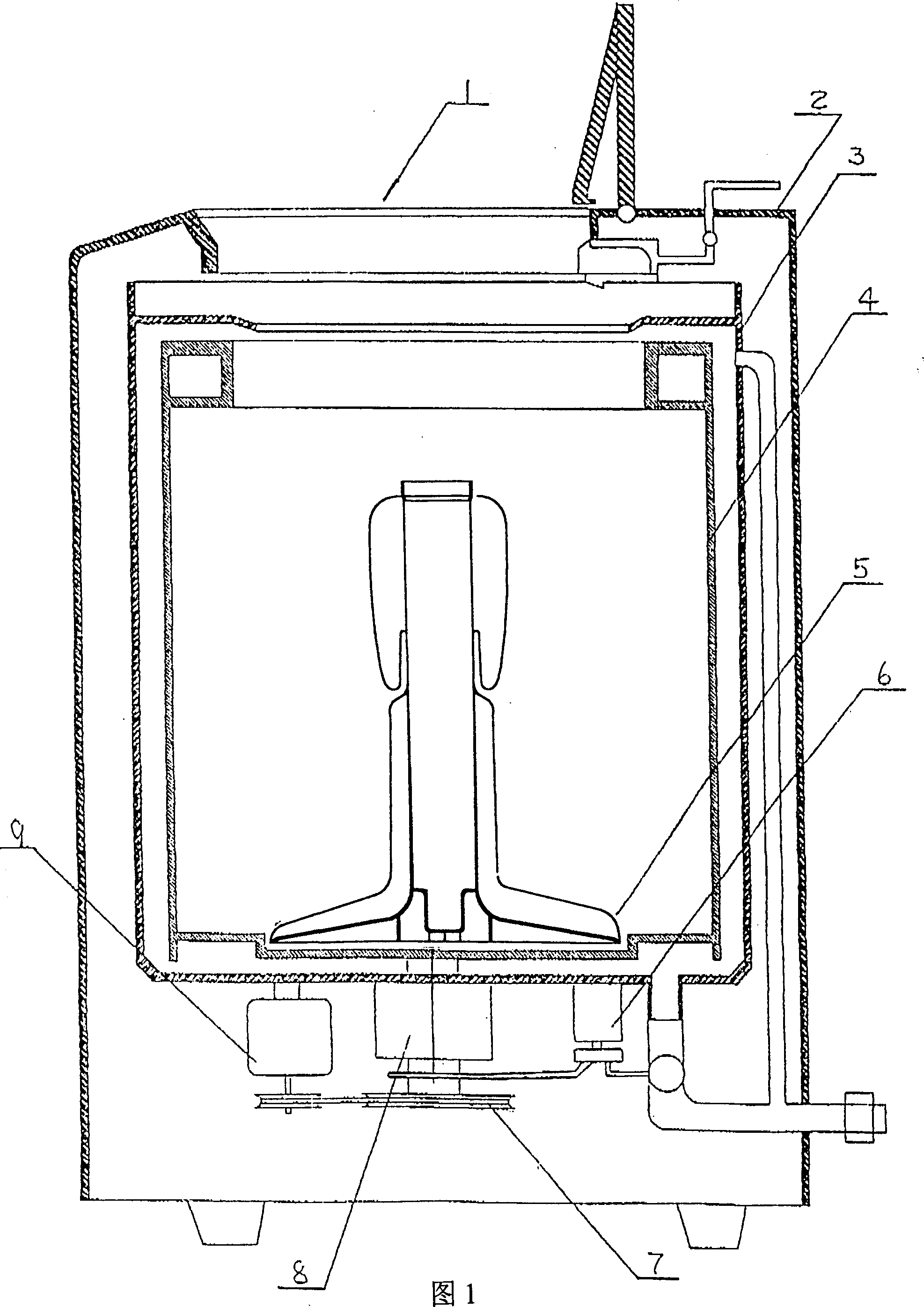

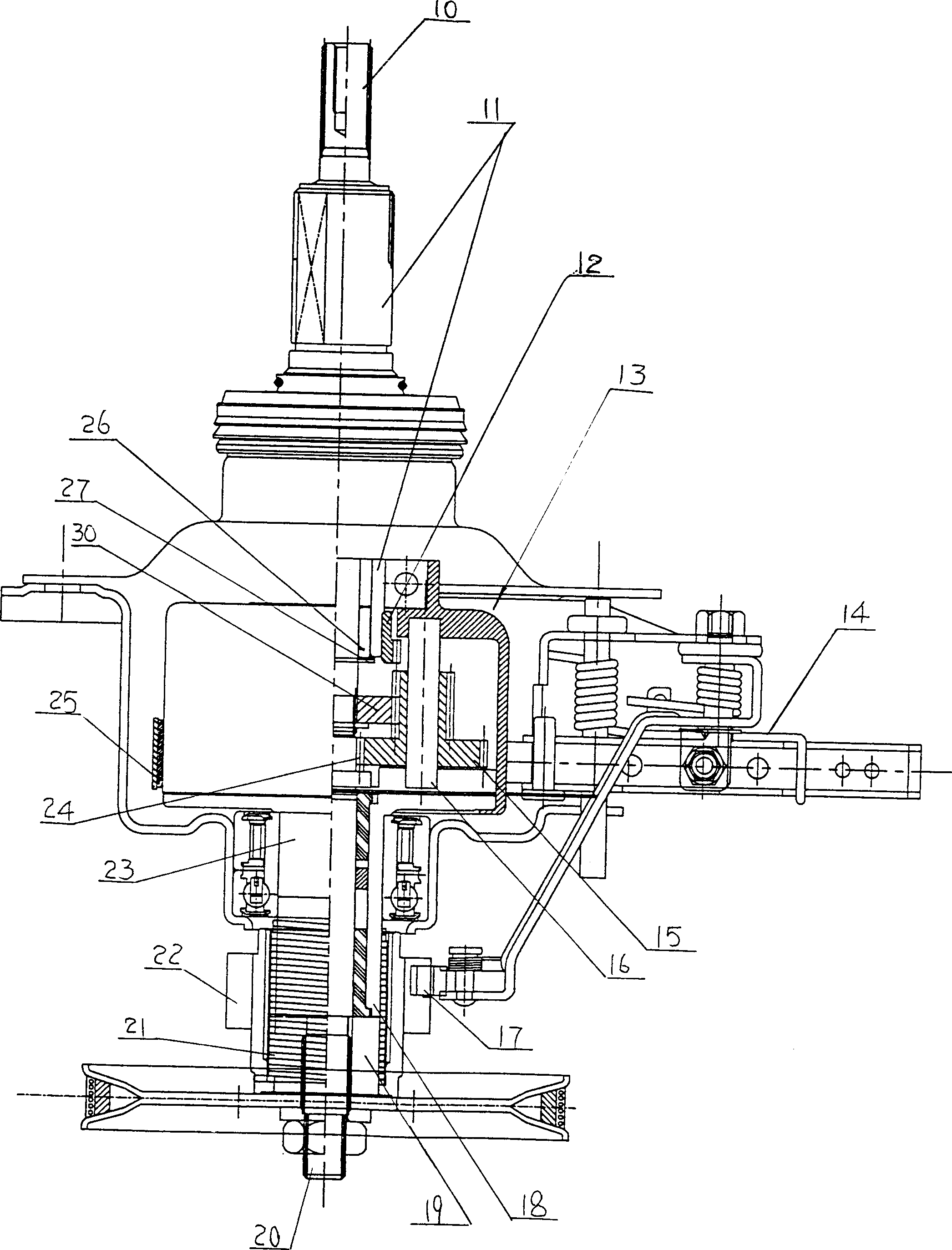

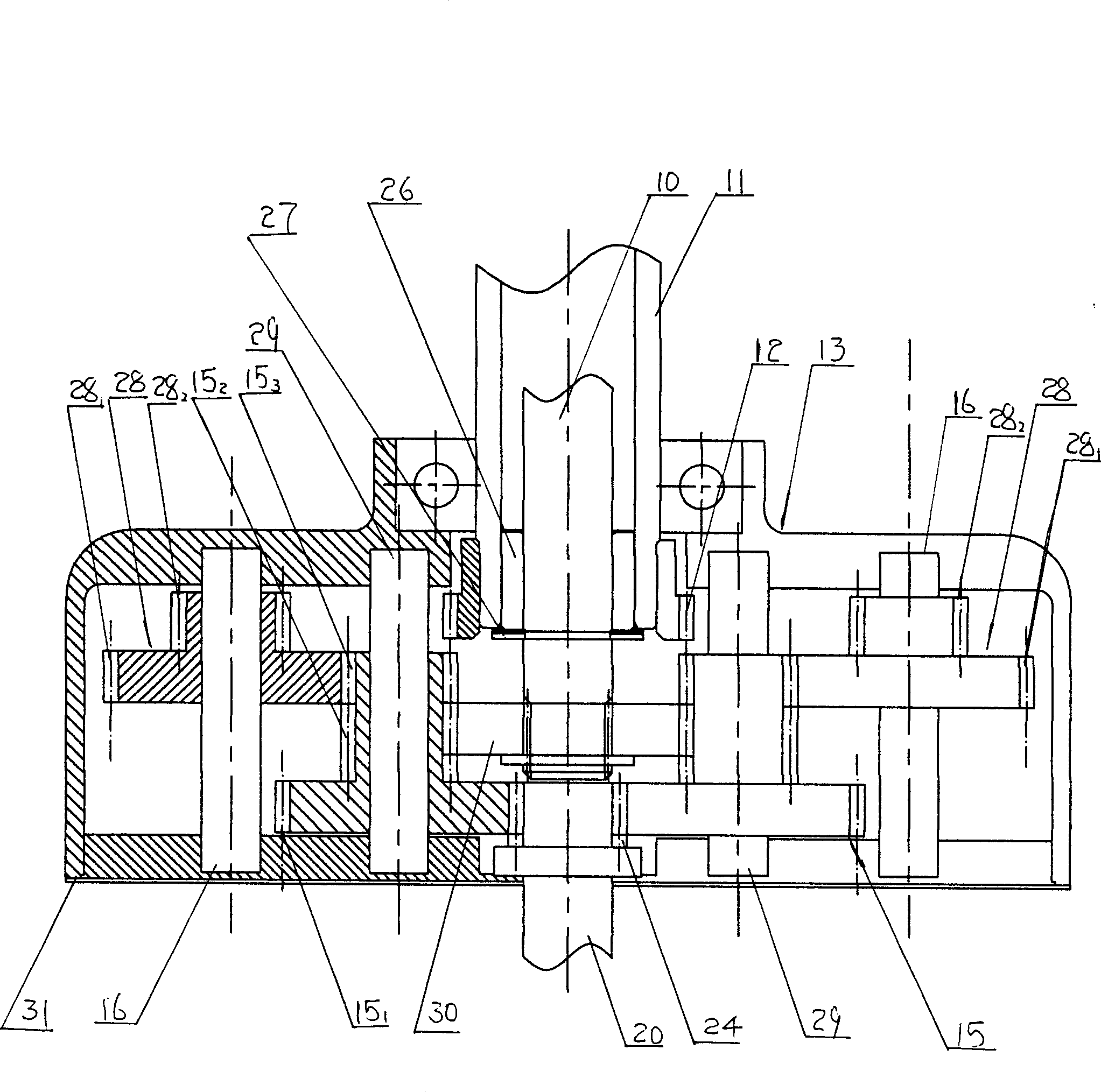

Washing method of agitatory washer and its washer

InactiveCN1381634AReduce entanglementIncrease the strength of the currentOther washing machinesWashing machine with receptaclesWater flowEngineering

Owner:HAIER GRP CORP +1

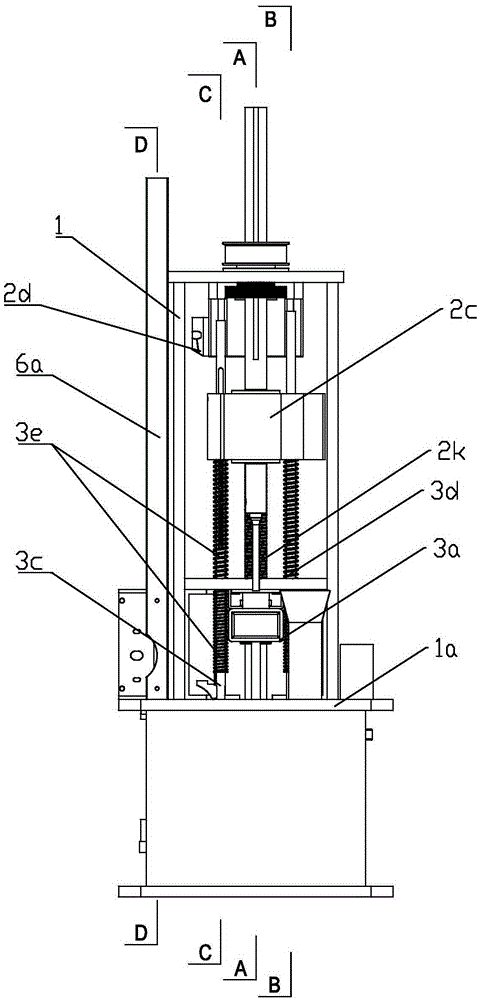

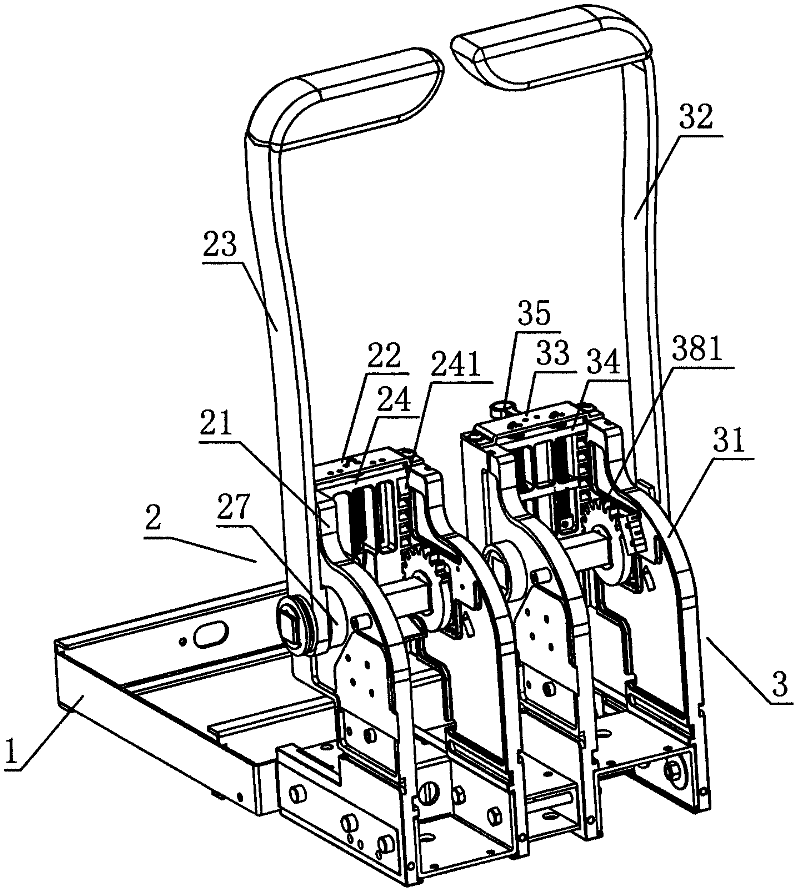

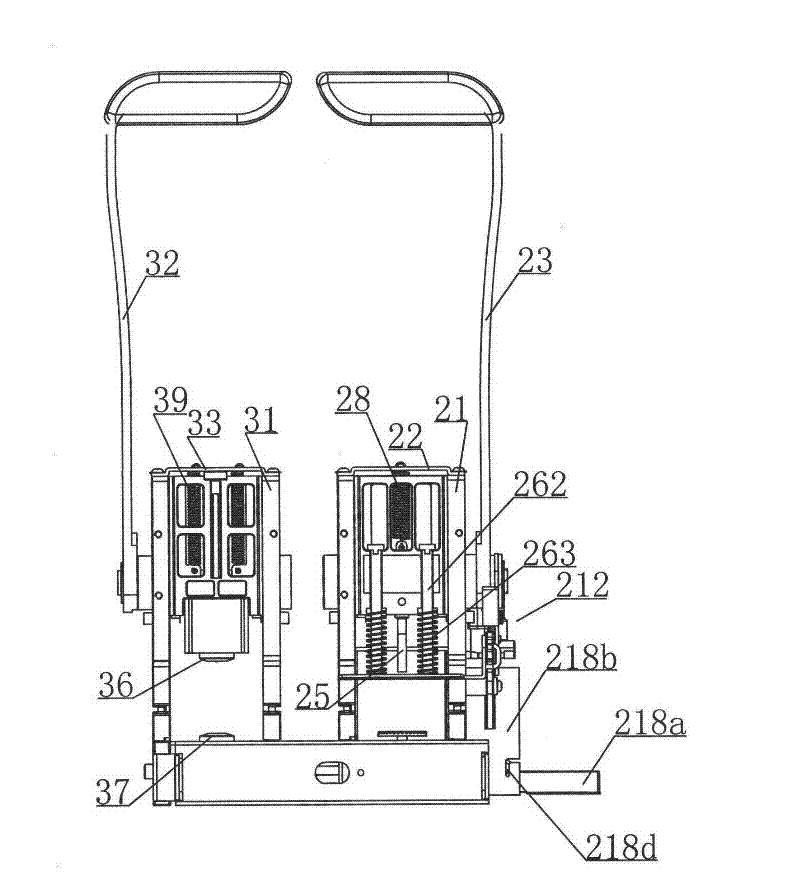

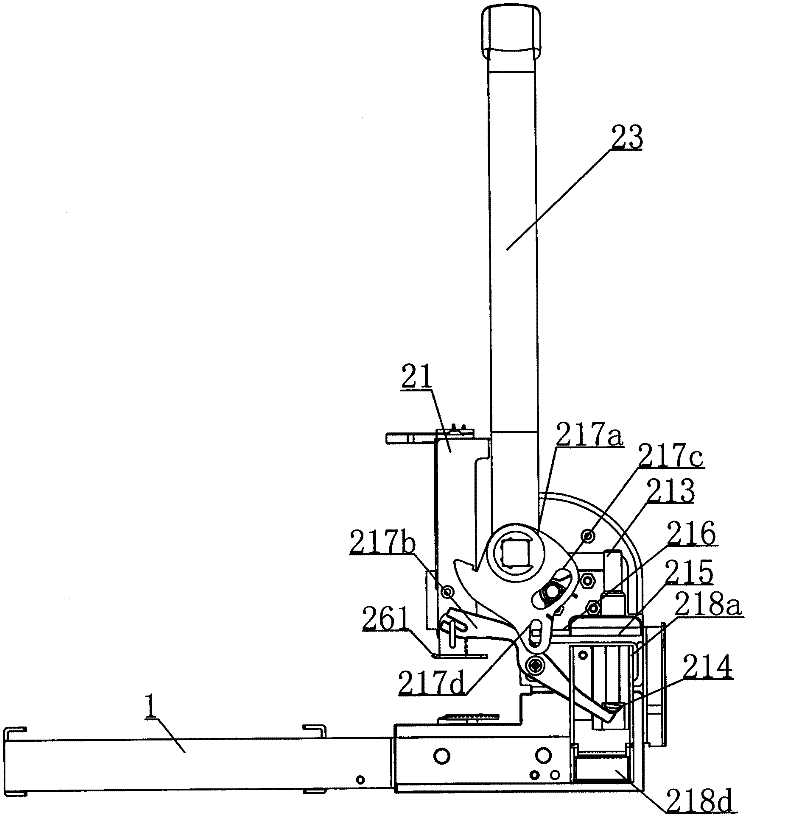

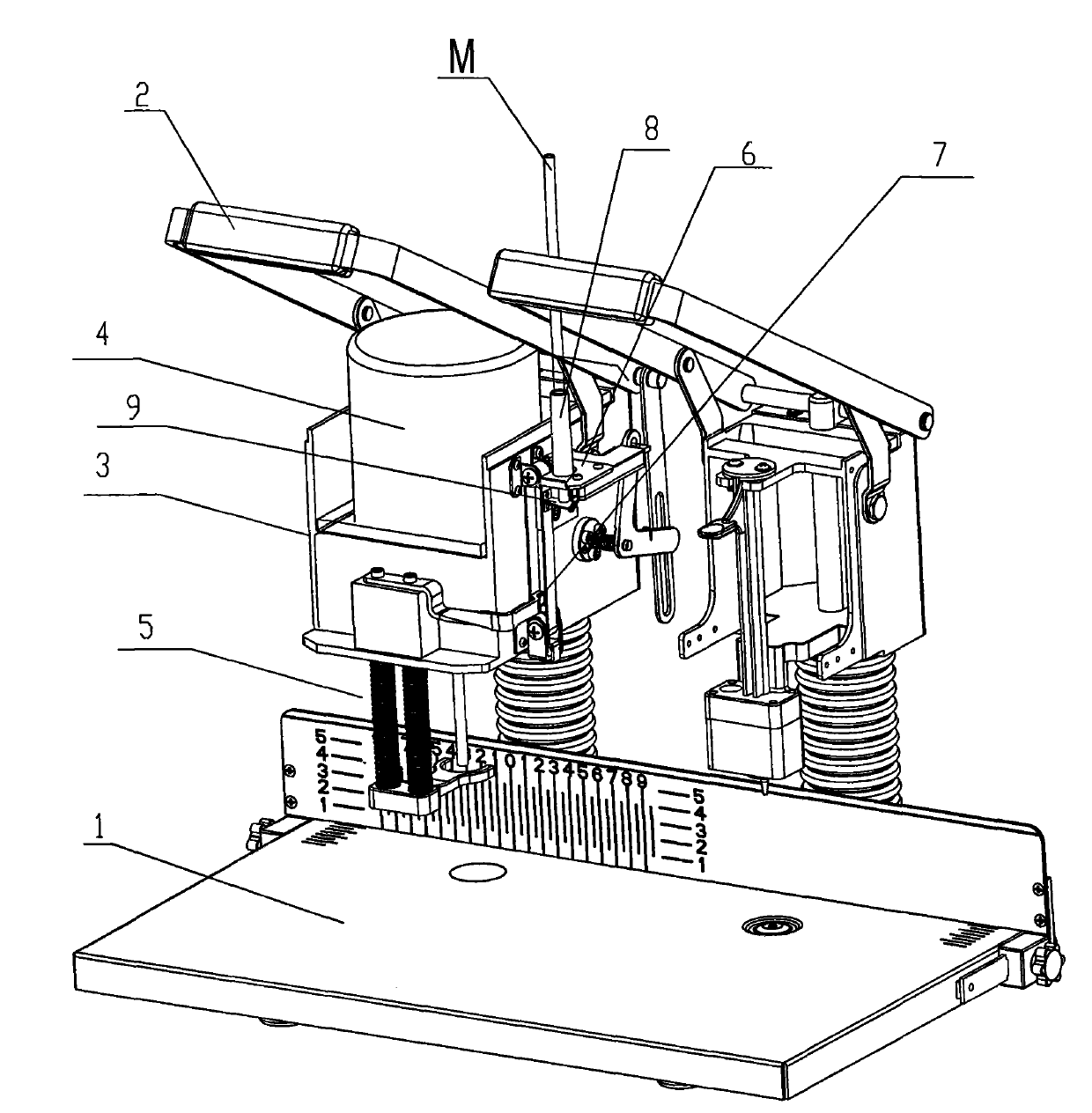

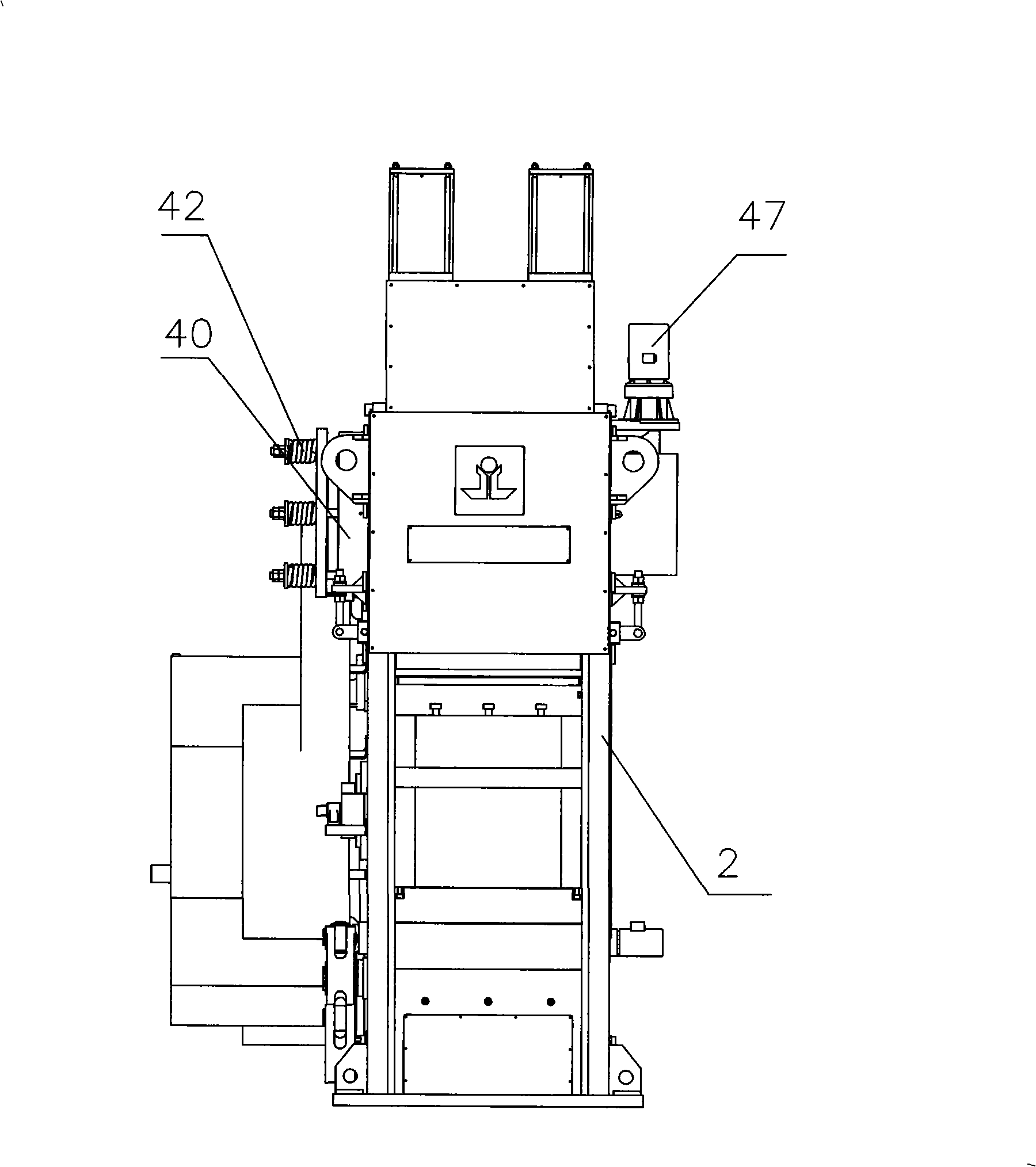

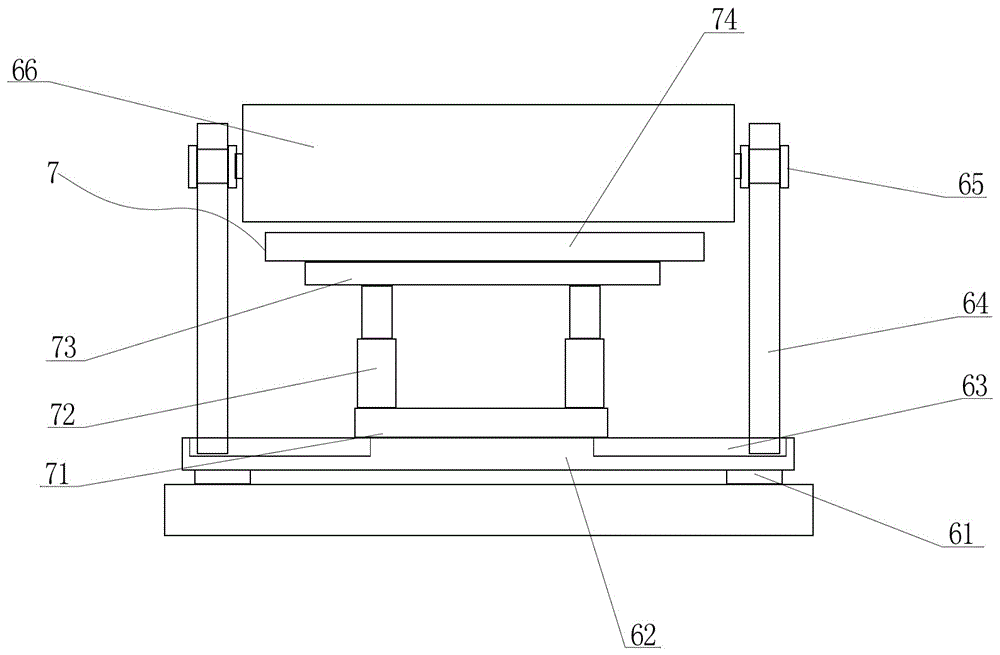

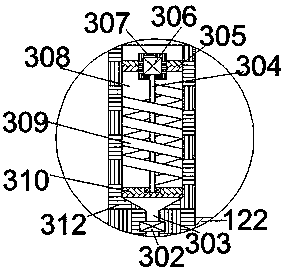

Lower riveting head rivet pulling device and full-automatic binding machine

ActiveCN105270002AAchieve horizontal dislocation movementRealize rivetingMetal working apparatusSheet bindingHorizontal and verticalRivet

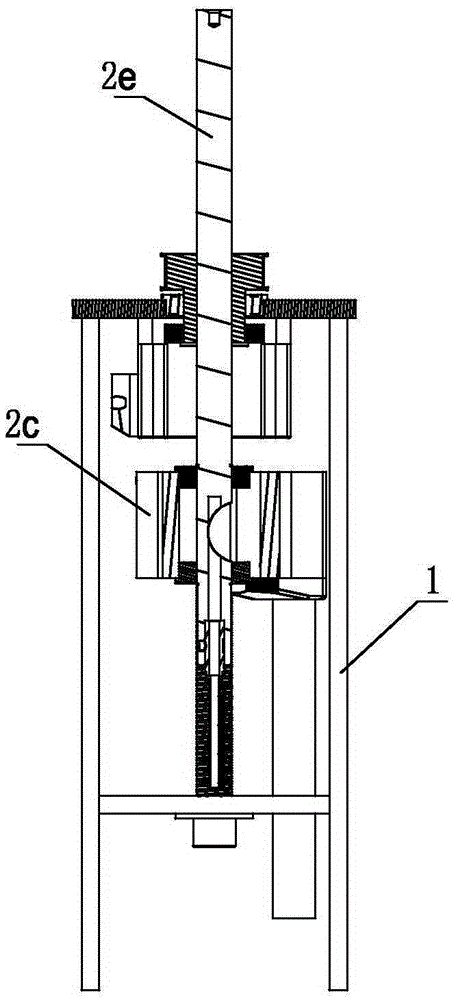

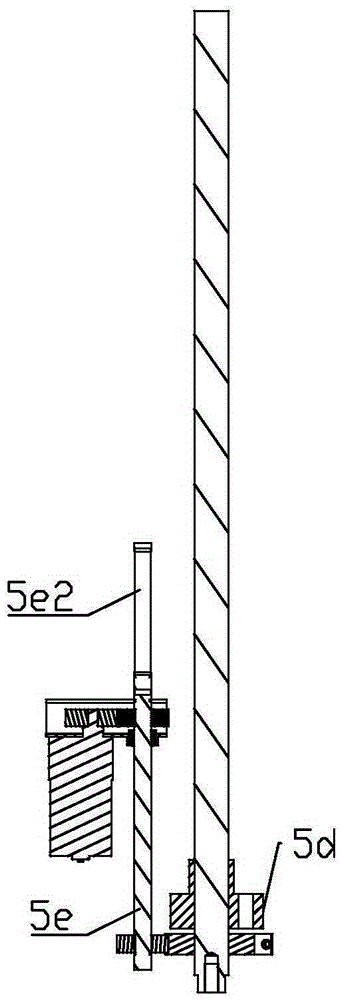

The invention relates to a lower riveting head rivet pulling device and a full-automatic binding machine. The lower riveting head rivet pulling device comprises a first motor, a lifting base, a vertical guide column, a lower riveting head and a switchover device, all of which are arranged in a rack. The lifting base is positioned at the upper portion of the vertical guide column and driven by the first motor to vertically ascend and descend. The lower riveting head is arranged on the switchover device and is capable of doing horizontal and vertical movement through the switchover device. A vertical rivet pulling rod is arranged between the lifting base and the switchover device. When the lifting base ascends, the switchover device is pulled to vertically move upwards. The full-automatic lower riveting head rivet pulling device and the full-automatic bonding machine utilizing the drilling lifting base for upward linkage rivet pulling are provided and have the beneficial effects of being simple in structure and reasonable in transmission.

Owner:DELI GROUP CO LTD

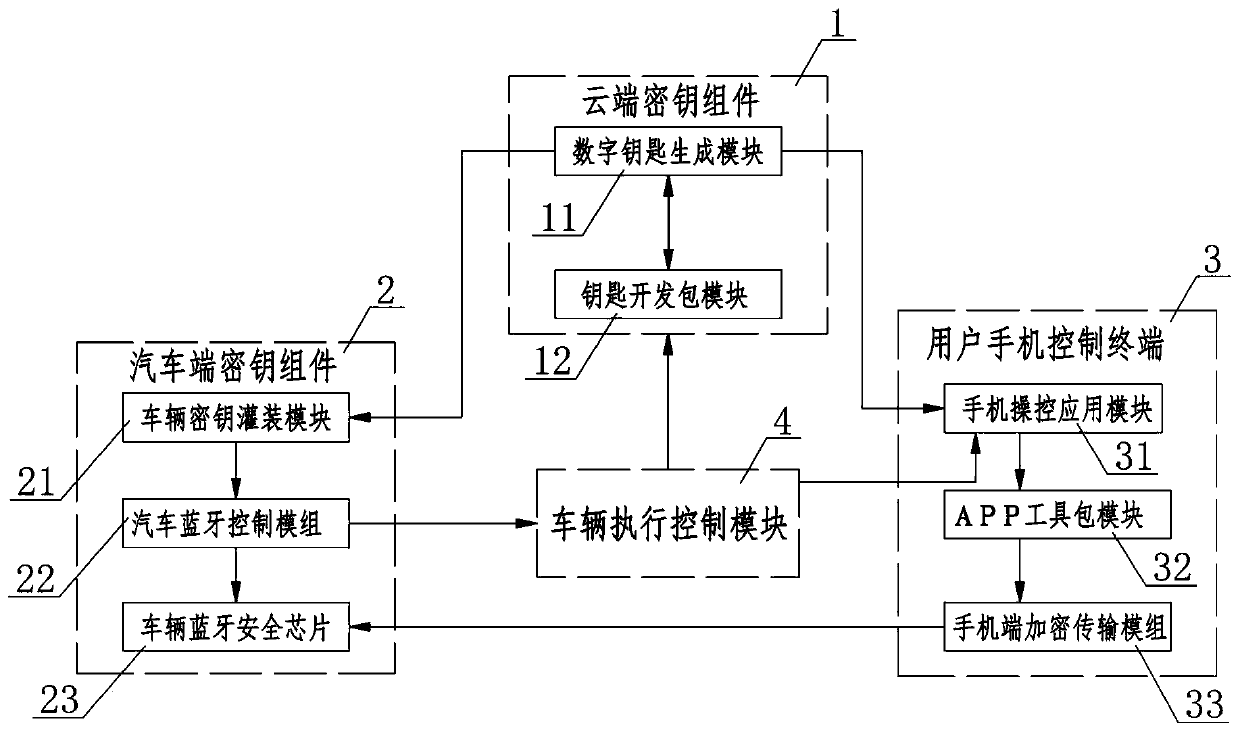

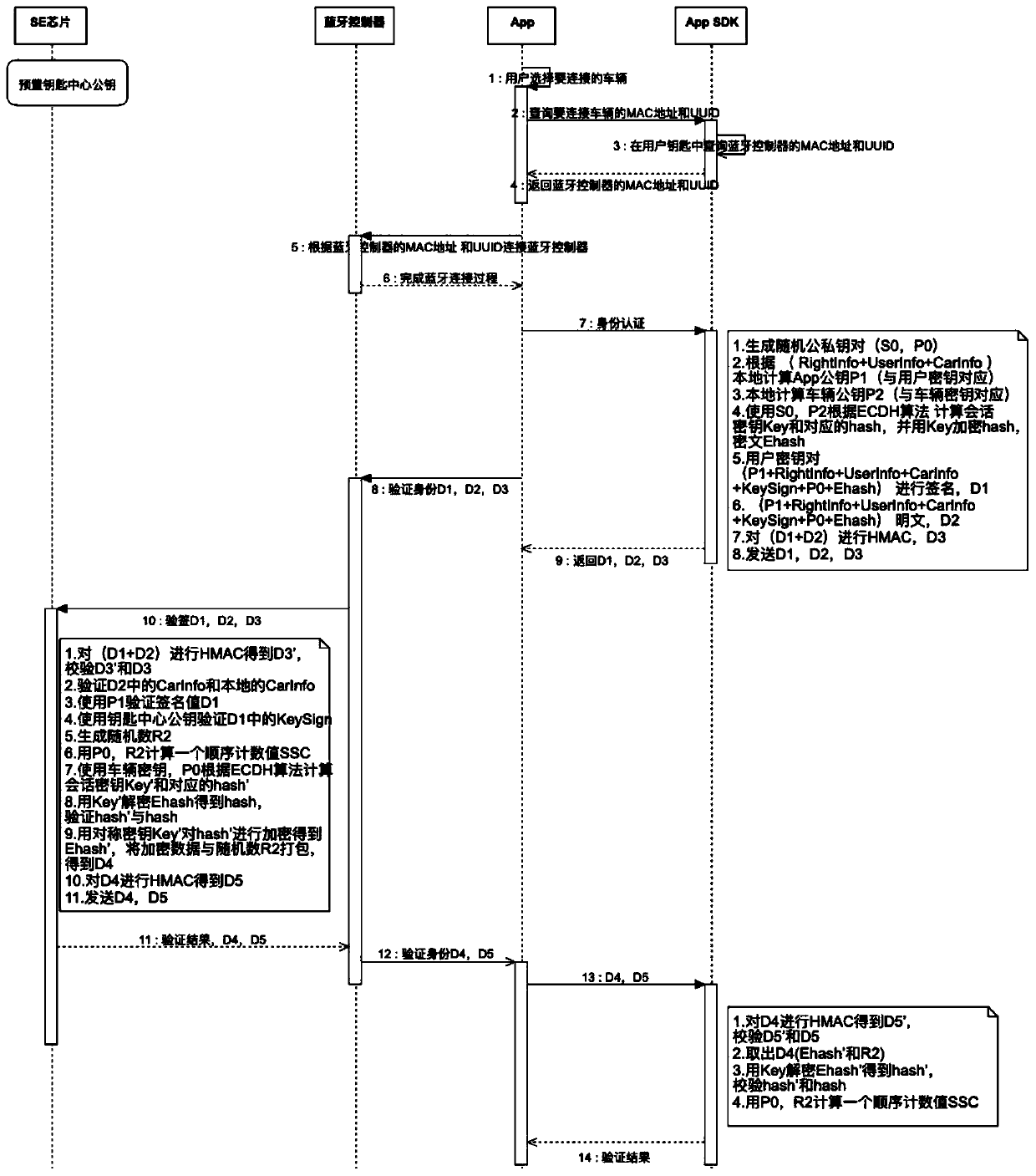

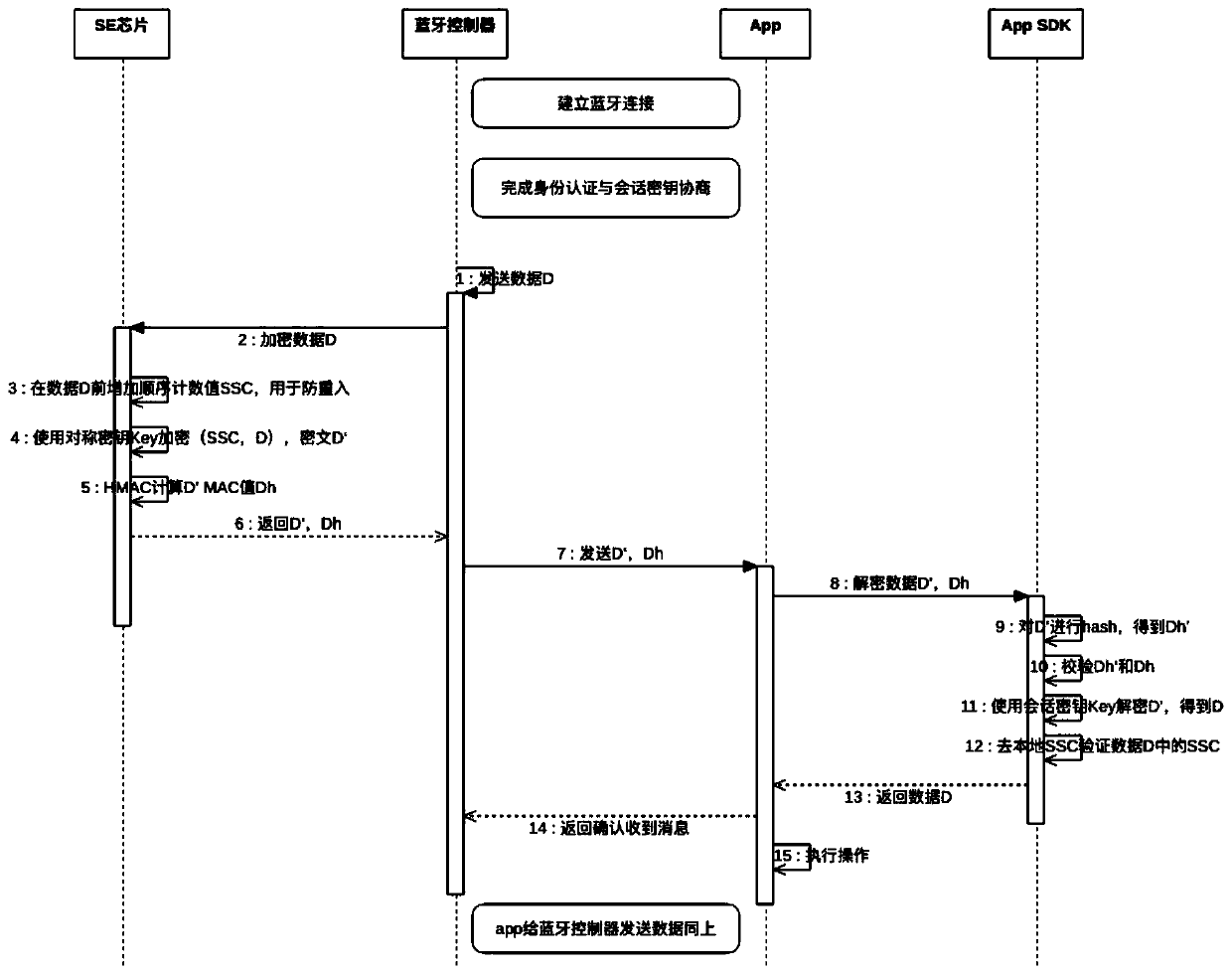

Automobile Bluetooth key safety management system and method

InactiveCN111186414AReasonable transmissionData transfer is reasonableAnti-theft devicesData connectionSafety management systems

The invention relates to an automobile Bluetooth key safety management system and method. An automobile end key assembly comprises an automobile key filling module, an automobile Bluetooth control module and an automobile Bluetooth safety chip. A user mobile phone control terminal comprises a mobile phone control application module, a toolkit module and a mobile phone end encryption transmission module. A digital key generation module is in data connection with the automobile key filling module and the mobile phone control application module. The automobile Bluetooth control module sends an execution instruction to an automobile execution control module. The mobile phone end encryption transmission module transmits the encryption information to the automobile Bluetooth safety chip. The automobile execution control module executes a control instruction and feeds back an automobile parameter state to a key development kit module and the mobile phone control application module. Accordingto the automobile Bluetooth key safety management system and method, Bluetooth communication control over a mobile phone and an automobile can be achieved, the communication feedback speed is high, and the safety coefficient is high.

Owner:深圳前海智安信息科技有限公司

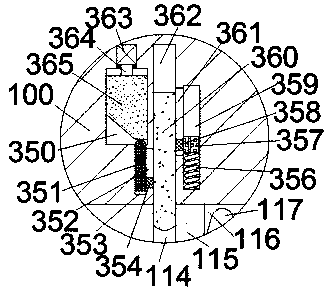

Automatic binding machine

The invention relates to an automatic binding machine which comprises a rack, a second motor, a drilling device, a lifting base, a paper pressing device, an upper hot-riveting head, a cutter pad and a lower hot-riveting head. A vertical guide column and a horizontal work table board are arranged in the rack. The lifting base is located on a vertical guide rail in a lifting manner. The paper pressing device is located between the lifting base and the work table board through springs in a lifting manner. The upper hot-riveting head is arranged in the paper pressing device and can horizontally move. The cutter pad is arranged on the work table board and can horizontally move. The lower hot-riveting head is located on the vertical guide column on the lower side of the horizontal work table board and can ascend, descend and rotate. A first rotating connecting rod arranged among the upper hot-riveting head, the cutter pad and the lower hot-riveting head is in rotating linkage. The second motor is connected with the first rotating connecting rod to switch over horizontal dislocation movement between the upper hot-riveting head and the cutter pad and drive the lower hot-riveting head to do rotating dislocation movement. The automatic binding machine can achieve linkage switchover of the upper hot-riveting head, the cutter pad and the lower hot-riveting head through the single motor, and has the advantages that the structure is simple, transmission is reasonable, machining is achieved, and the size and cost are reduced.

Owner:DELI GROUP CO LTD

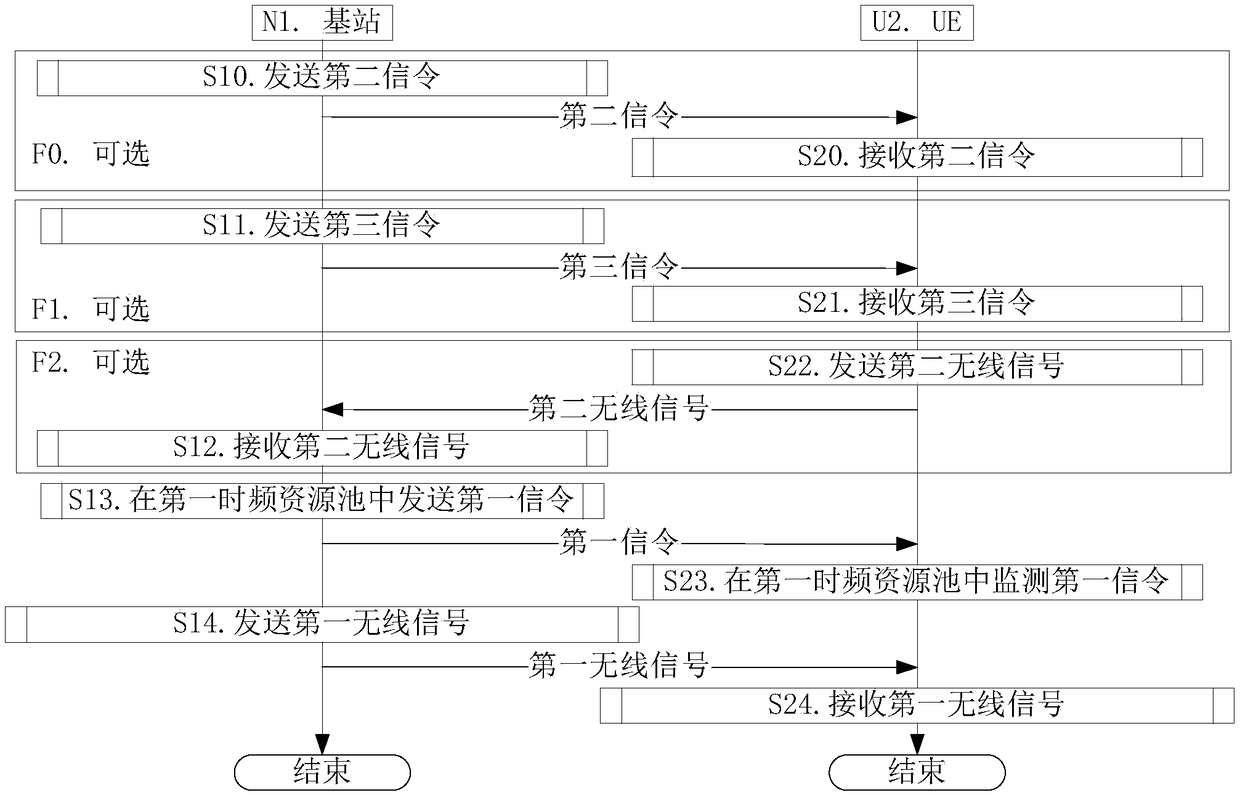

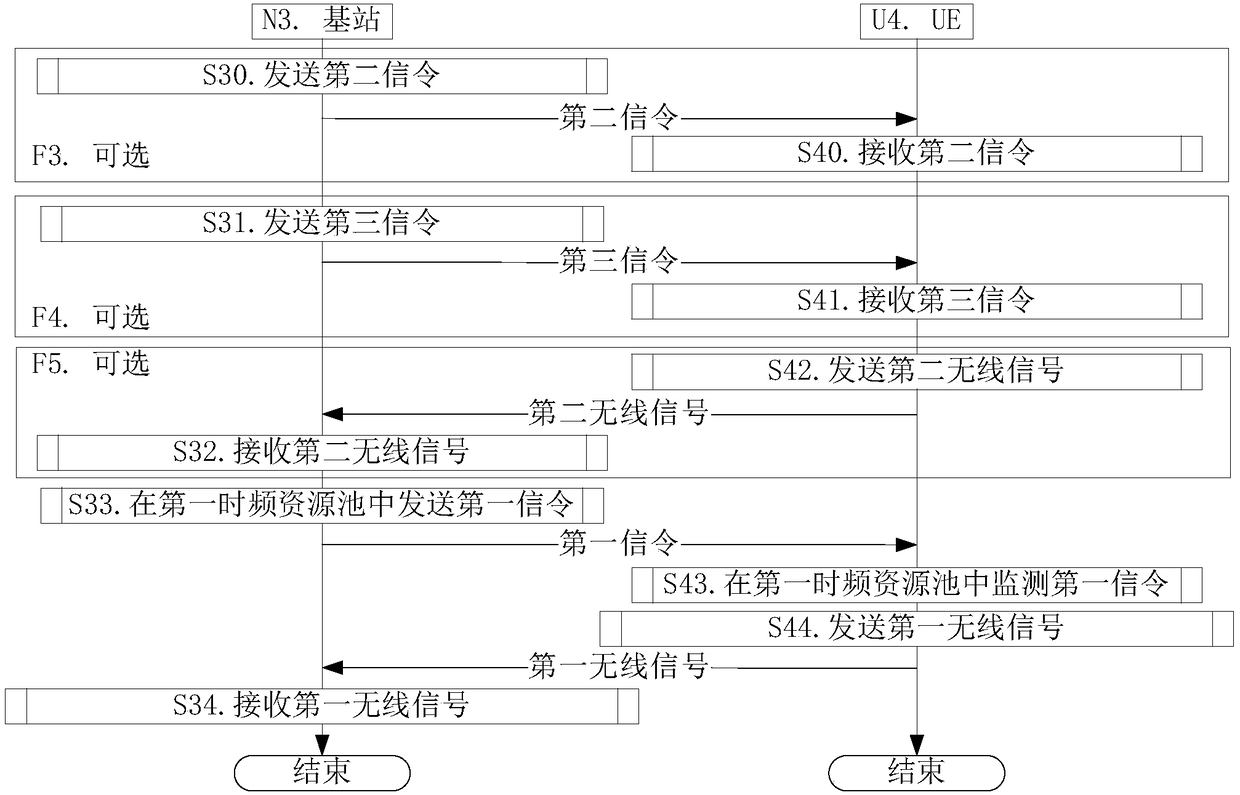

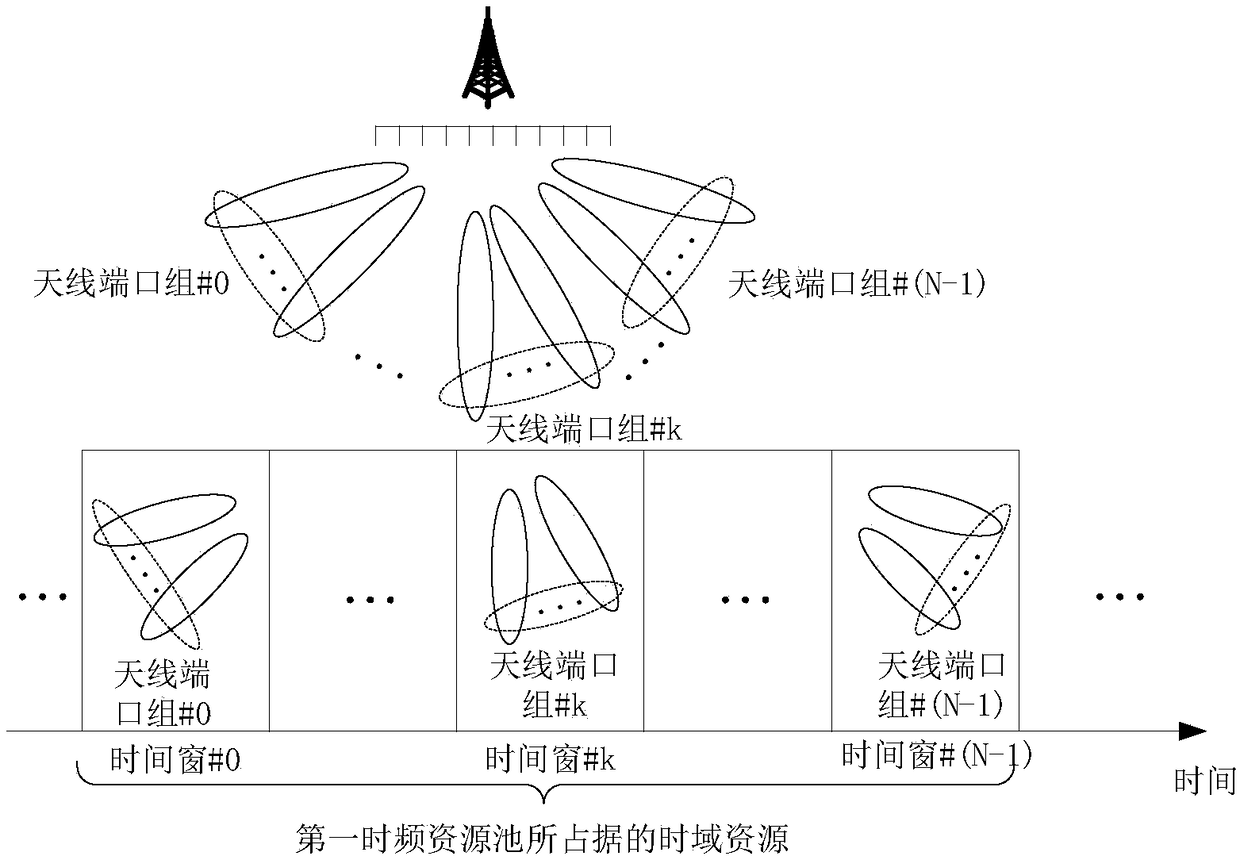

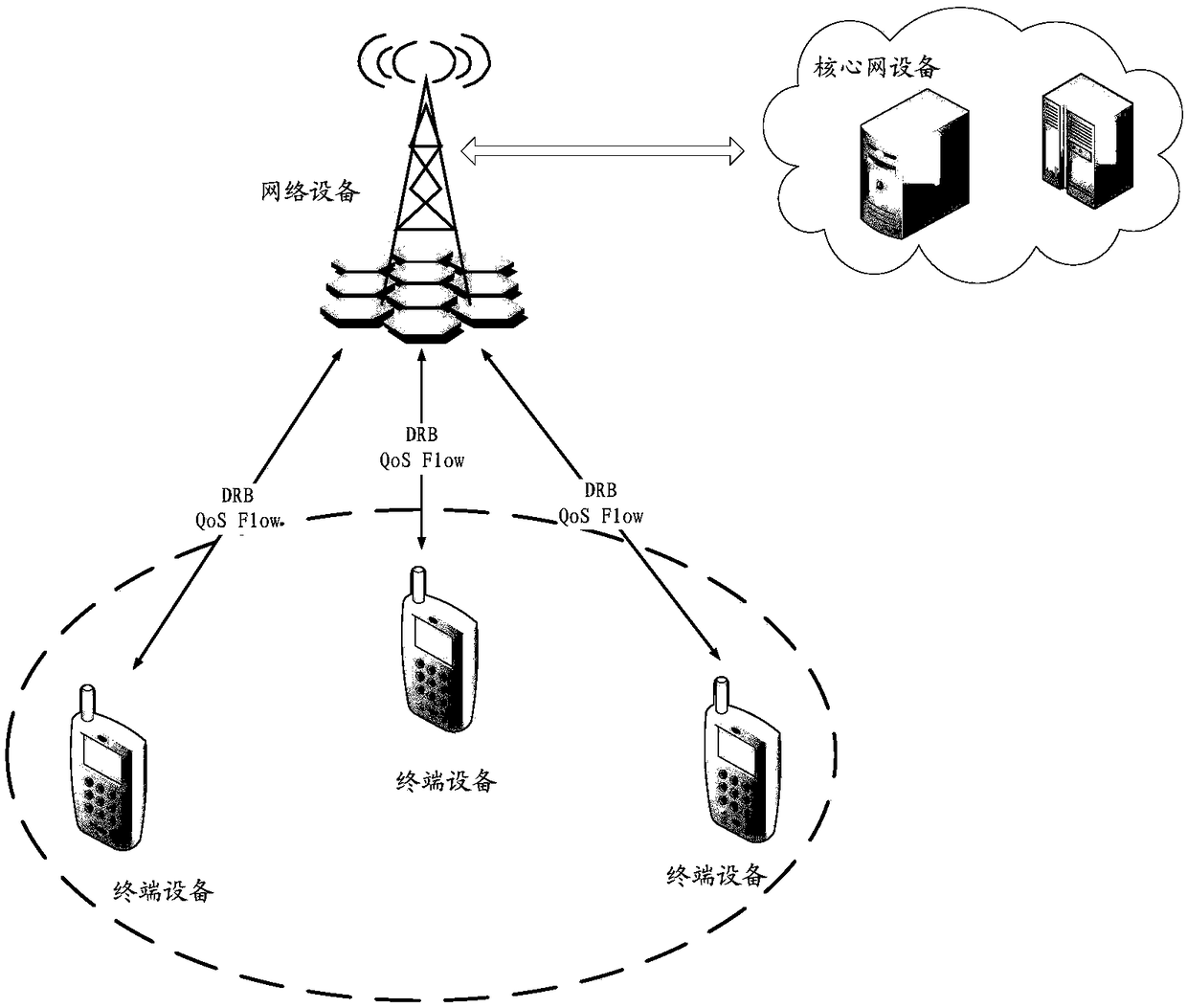

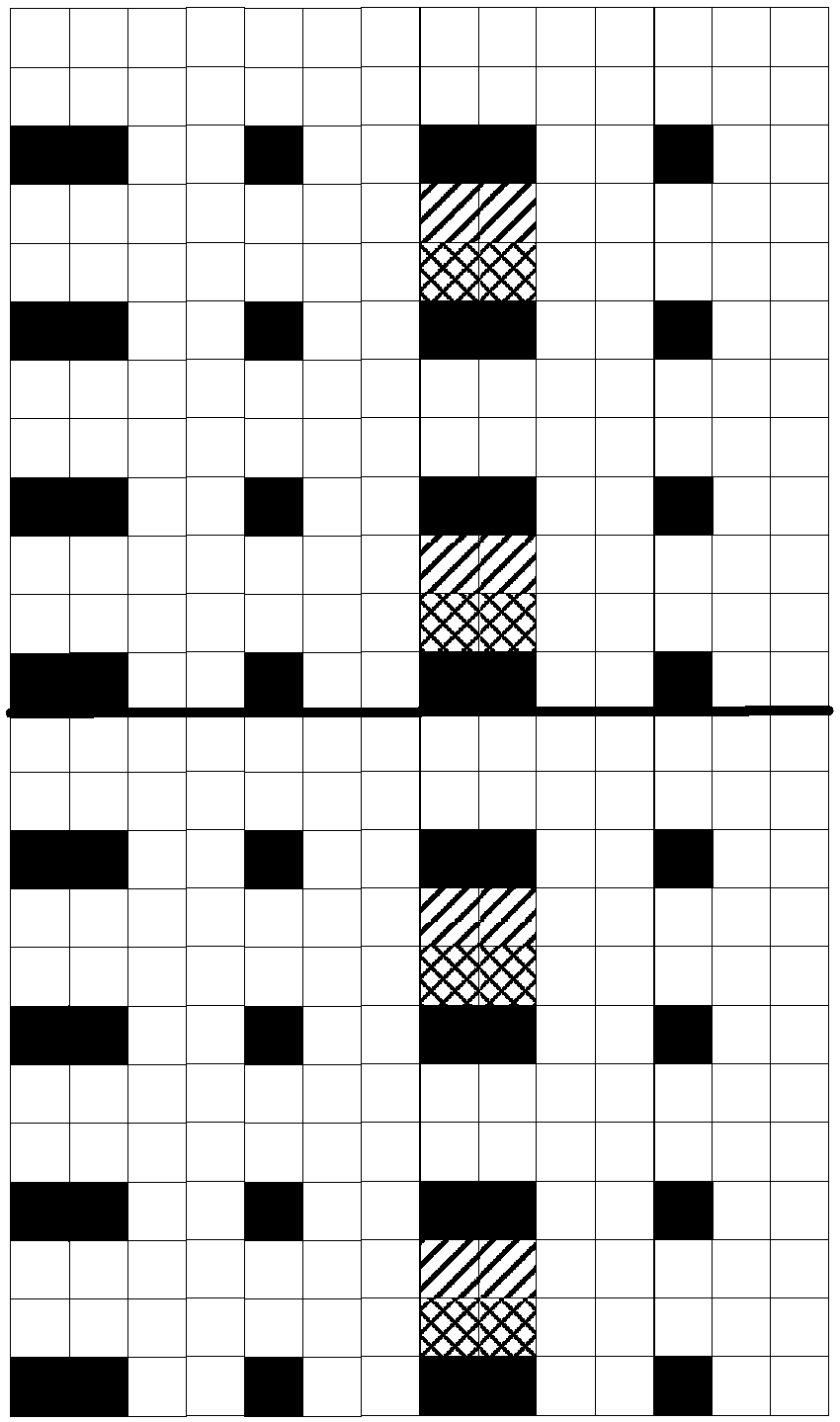

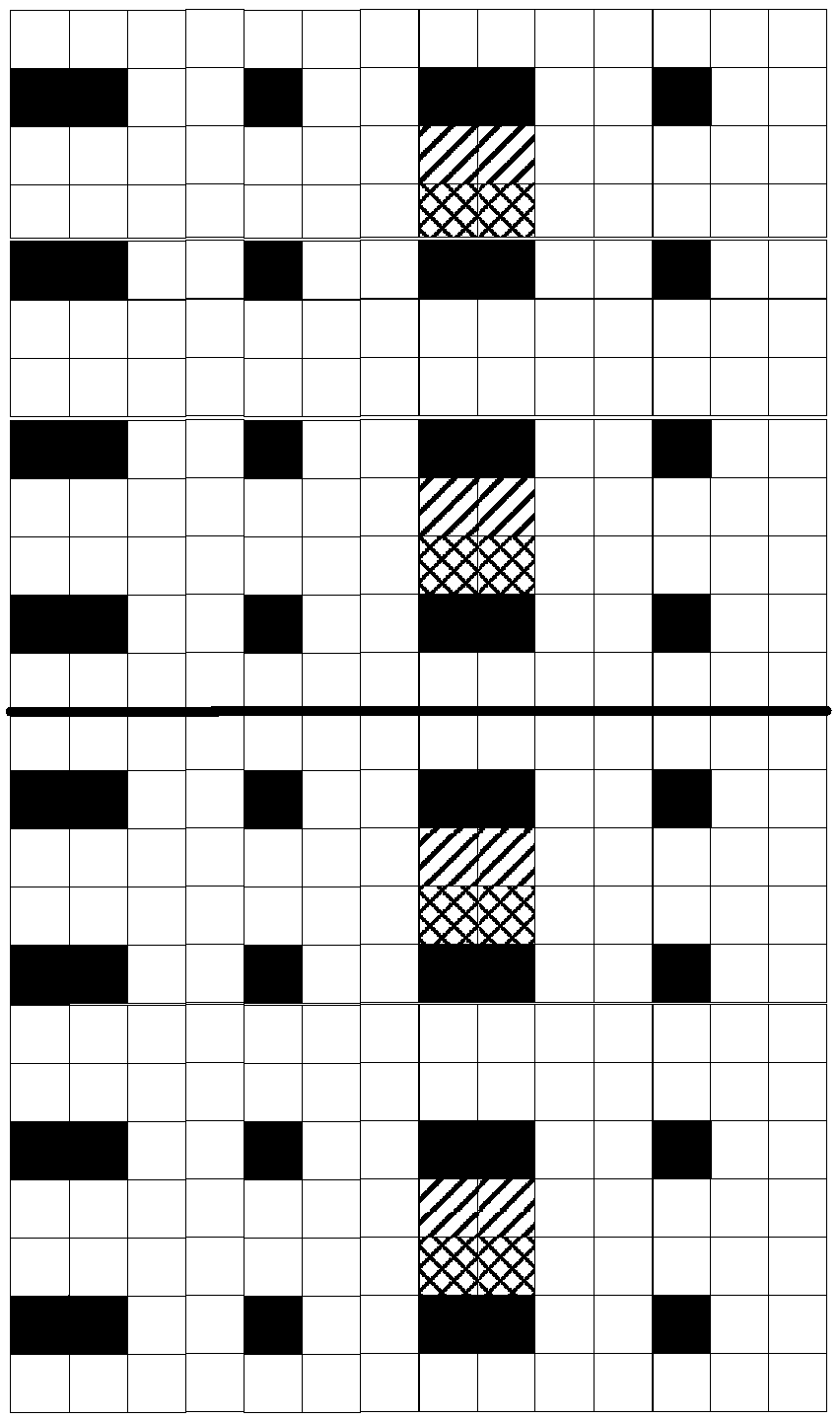

Dynamic scheduling methods and devices in base station and UE

ActiveCN108123738AAvoid problems with not being received correctlyImprove robustnessSpatial transmit diversityResource poolTime domain

The invention discloses dynamic scheduling methods and devices in a base station and UE. The UE monitors a first signal in a first time-frequency resource pool; the first time-frequency resource pooloccupies N time windows in the time domain; the N time windows and N antenna port groups are in one-to-one correspondence; the first signal is a physical layer signal; detection for X times at most iscarried out for the first signal; the detection for X times is separately for X RE sets; in the X RE sets, Y1 first-type RE sets exist; REs included in the first-type RE sets are positioned in N1 time windows; and the N1 time windows belong to the N time windows. According to the dynamic scheduling methods and devices in the base station and the UE disclosed by the invention, the Y1 first-type REsets are designed; furthermore, the first signal is transmitted on different antenna port groups; therefore, the first signal transmission robustness is improved; and thus, the control signal transmission performance and the overall spectral efficiency of a system are improved.

Owner:SHANGHAI LANGBO COMM TECH CO LTD

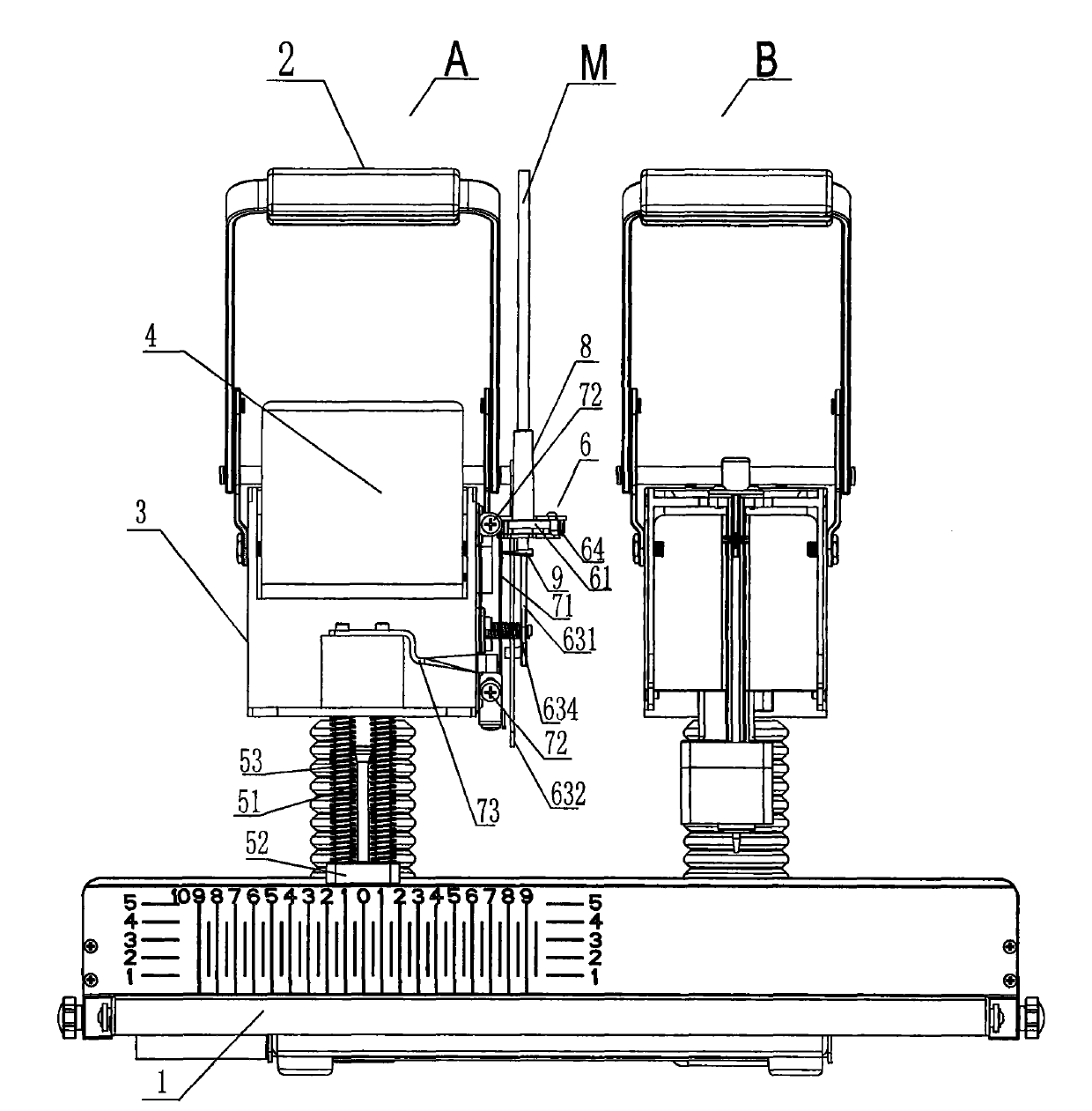

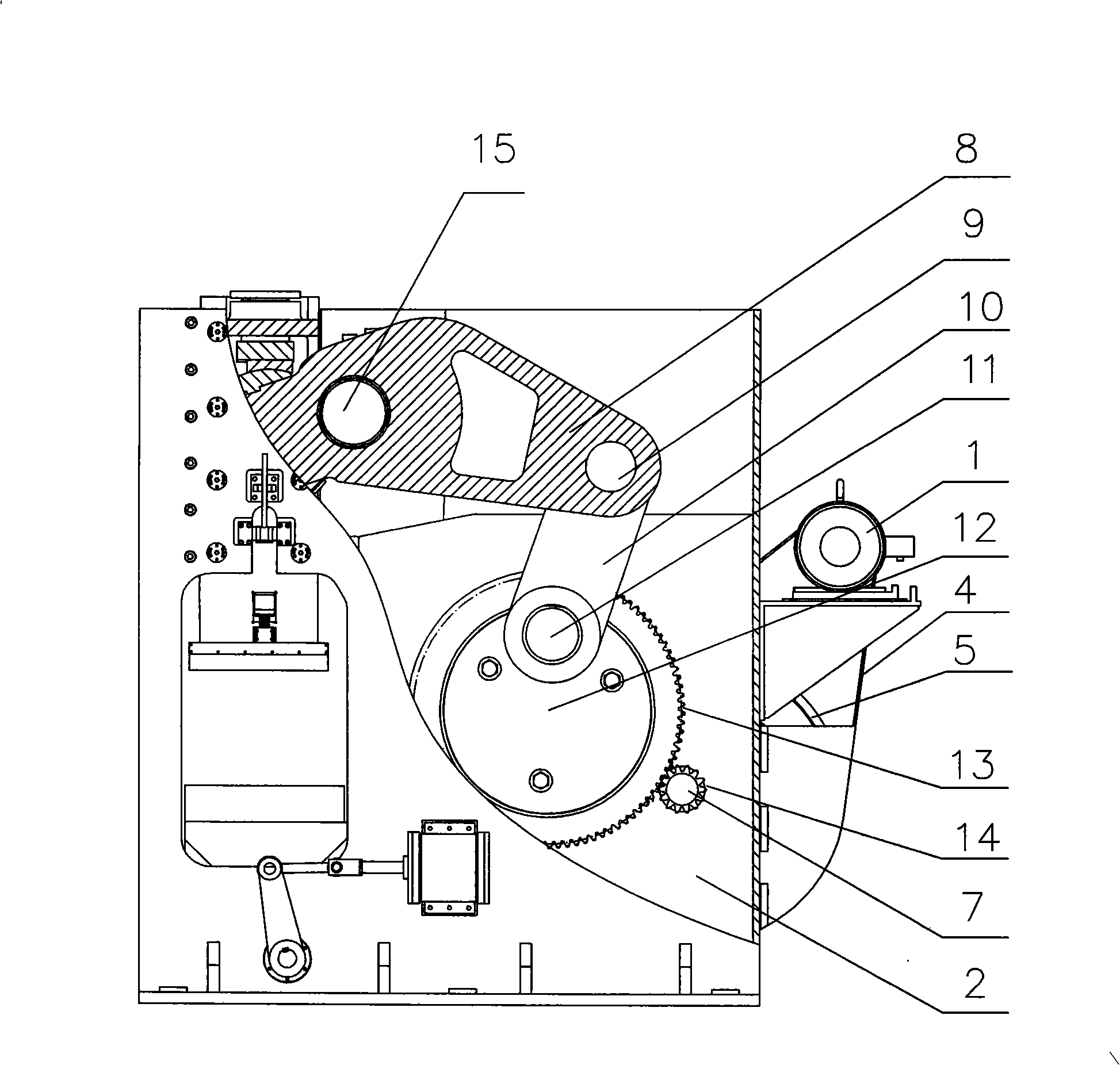

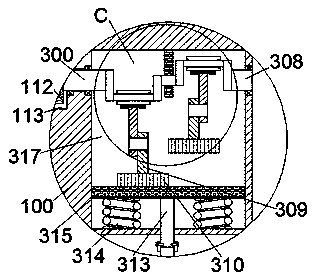

Punching and hot riveting type precise binding machine

ActiveCN102407710ALower the altitudeReduced in heightMetal working apparatusSheet bindingPunchingPulp and paper industry

The invention relates to a punching and hot riveting type precise binding machine. The machine comprises a punching unit and a hot riveting unit, which are arranged on a base in parallel, wherein the punching unit comprises a punching fixed base, a cover plate, a handle, a punching slider, a drill, paper pressing devices and a pipe cutting device; the drill and the paper pressing devices are arranged on the lower part of the punching slider; a rotating shaft horizontally penetrates through the punching fixed base; the handle is fixedly connected with the rotating shaft; gears are arranged at the two sides of the rotating shaft in the punching fixed base; guide rails are arranged at the two sides of the punching fixed base; the punching slider is joined between the two guide rails; vertical racks are arranged at the inner sides of the punching slider and are meshed with the gears; a bulk cavity is arranged in the middle of the punching slider; the cover plate is fixedly arranged on the upper part of the punching fixed base; and a reset tension spring is arranged between the bulk cavity and the cover plate. The machine has the advantages of simple and reasonable structure, balanced and stable driving, high accuracy and low cost.

Owner:DELI GROUP CO LTD

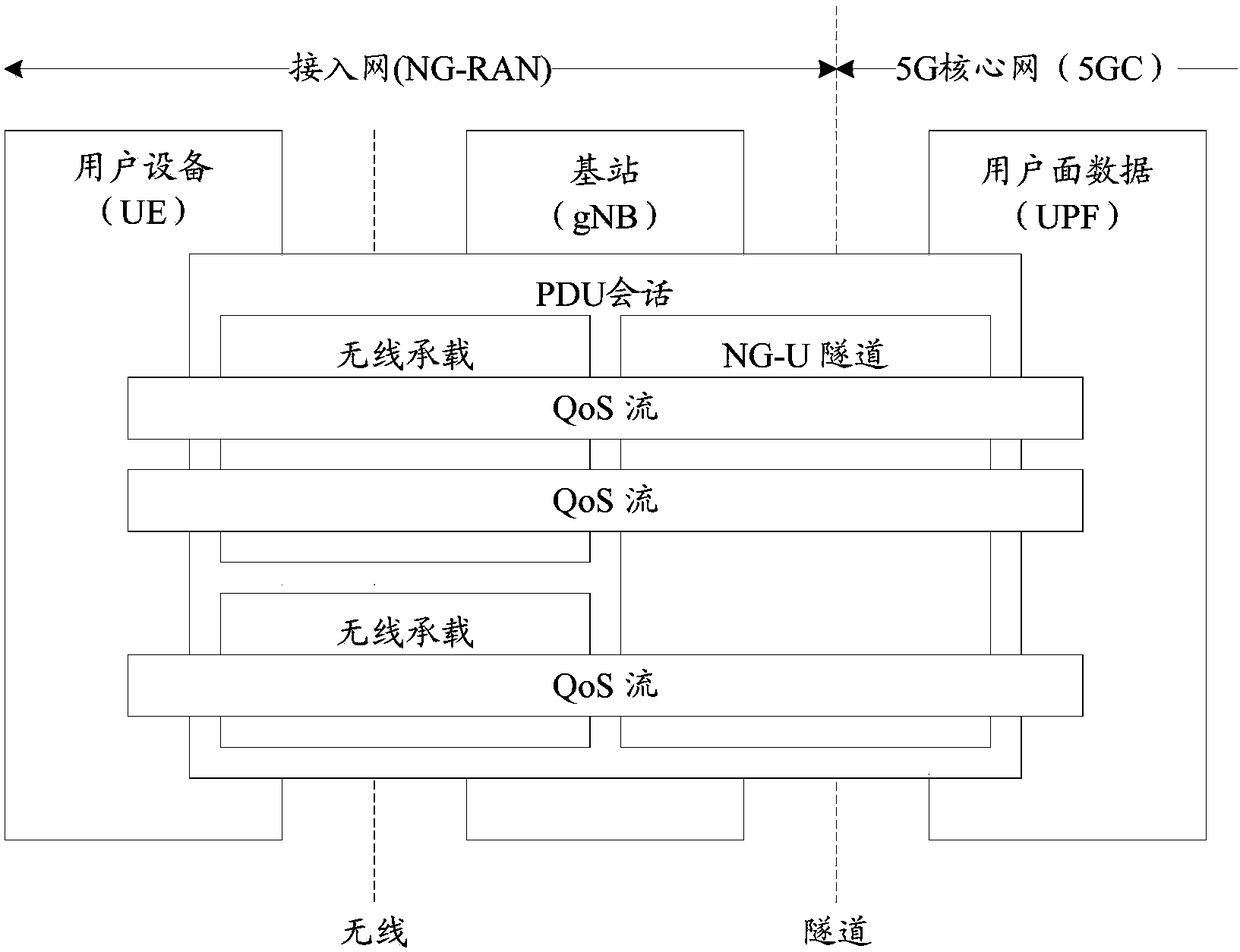

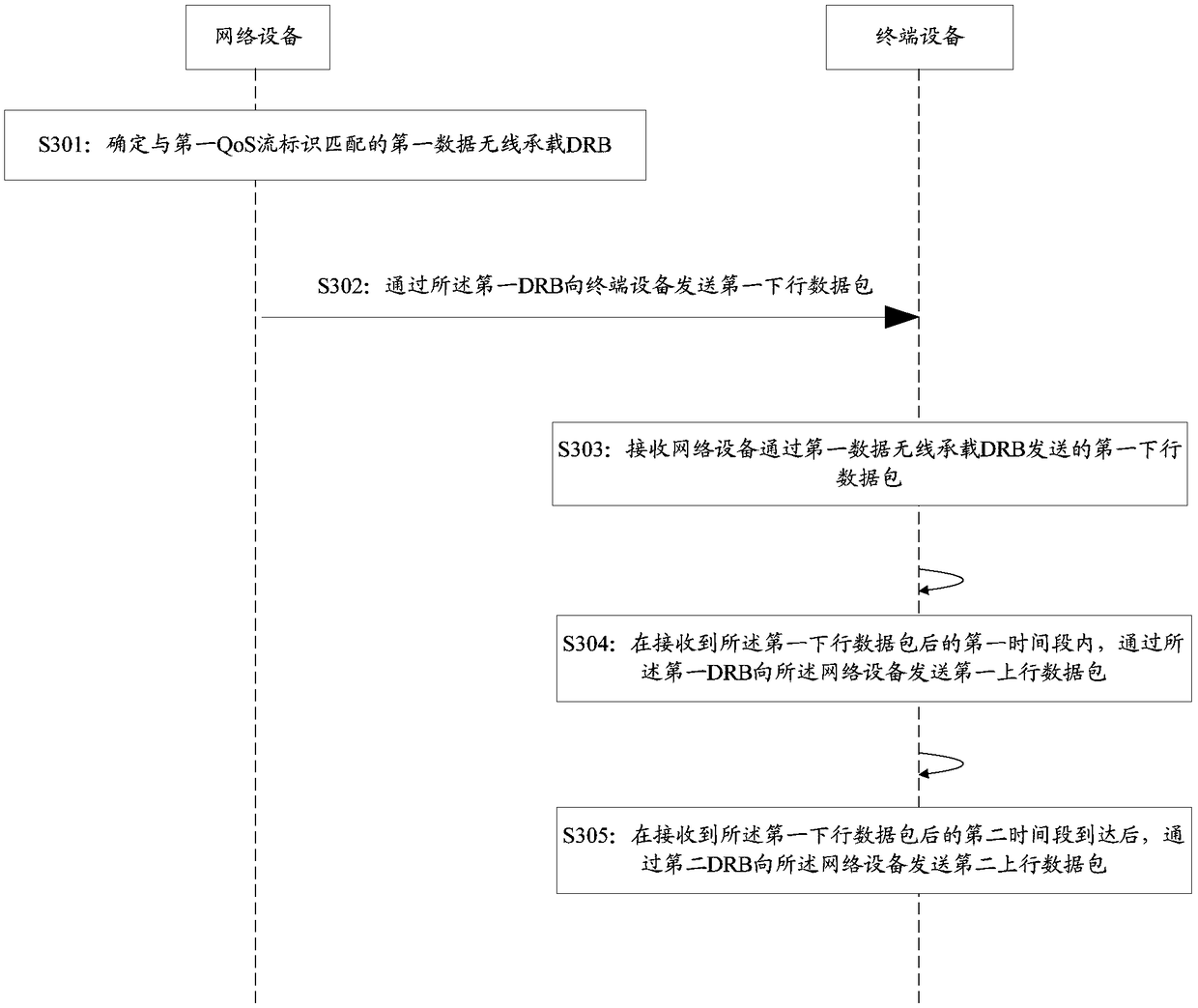

Data transmission method and related devices

ActiveCN109150749AReduce overheadReduce transmission delayData switching networksQuality of serviceComputer hardware

The embodiments of the invention disclose a data transmission method and related devices. The method may include the following steps that: a network device generates first downlink control signaling,wherein the first downlink control signaling carries a first quality of service (QoS) flow identifier and a reflected QoS identifier, wherein the reflected QoS identifier is used to indicate that theturning off of a terminal device or the enabling of a reflective QoS function; and the network device sends the first downlink control signaling to the terminal device by using a first data radio bearer (DRB). With the data transmission method and related devices provided by the embodiments of the present invention adopted, a current reflective QoS function can be effectively disabled when the terminal device does not receive a downlink data packet again.

Owner:HUAWEI TECH CO LTD

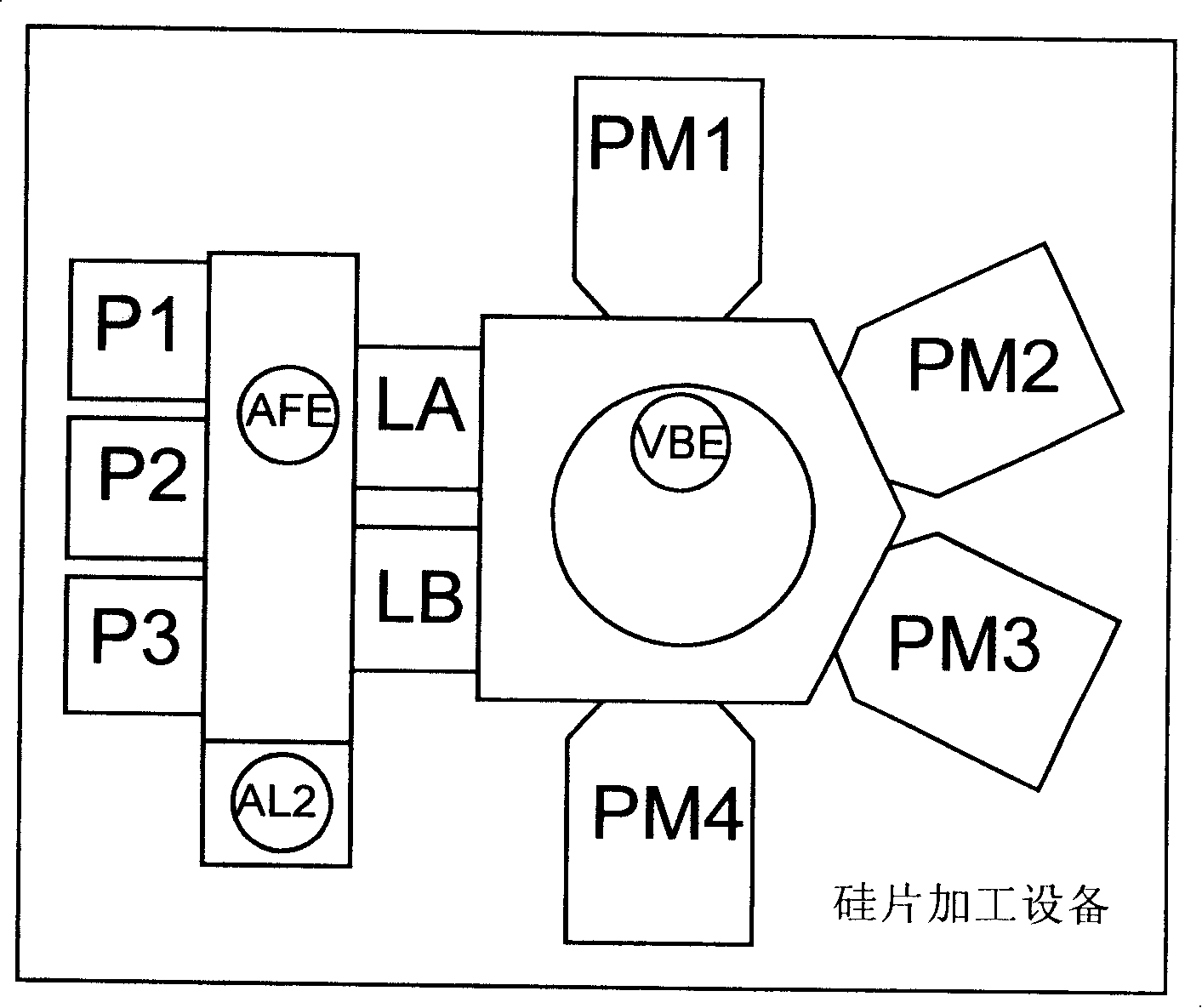

Scheduling method of silicon slice transmission course

ActiveCN101226870AReasonable transmissionShort preparation cycleSemiconductor/solid-state device manufacturingProgramme control in sequence/logic controllersSilicon chipSemiconductor

The invention discloses a dispatching method in the process of transiting silicon chips, which comprises firstly calculating the transmission cost S(i)(j) of joints from the ith to the jth of any silicon chip in a plurality of silicon chips, then calculating the transmission costs S(i)(k)+S(i)(k) of joints from the ith to the kth and from the kth to the jth of the silicon chip, comparing S(i)(j) with S(i)(k)+S(i)(k), if S(i)(j)>S(i)(k)+S(i)(k), then replacing S(i)(j) with S(i)(k)+S(i)(k), and so forth, finally obtaining the least transmission cost S(i)(j) min of joints from the ith to the jth of the silicon chip, which is the shortest way. The invention has the advantages that the transmission of the silicon chip is reasonable, the manufacturing period is short, the work efficiency is high, and the invention is mainly adapted to the manufacturing procedure of semi-conductor silicon chip and dispatches the transmission of the silicon chips in the silicon chip processing device.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

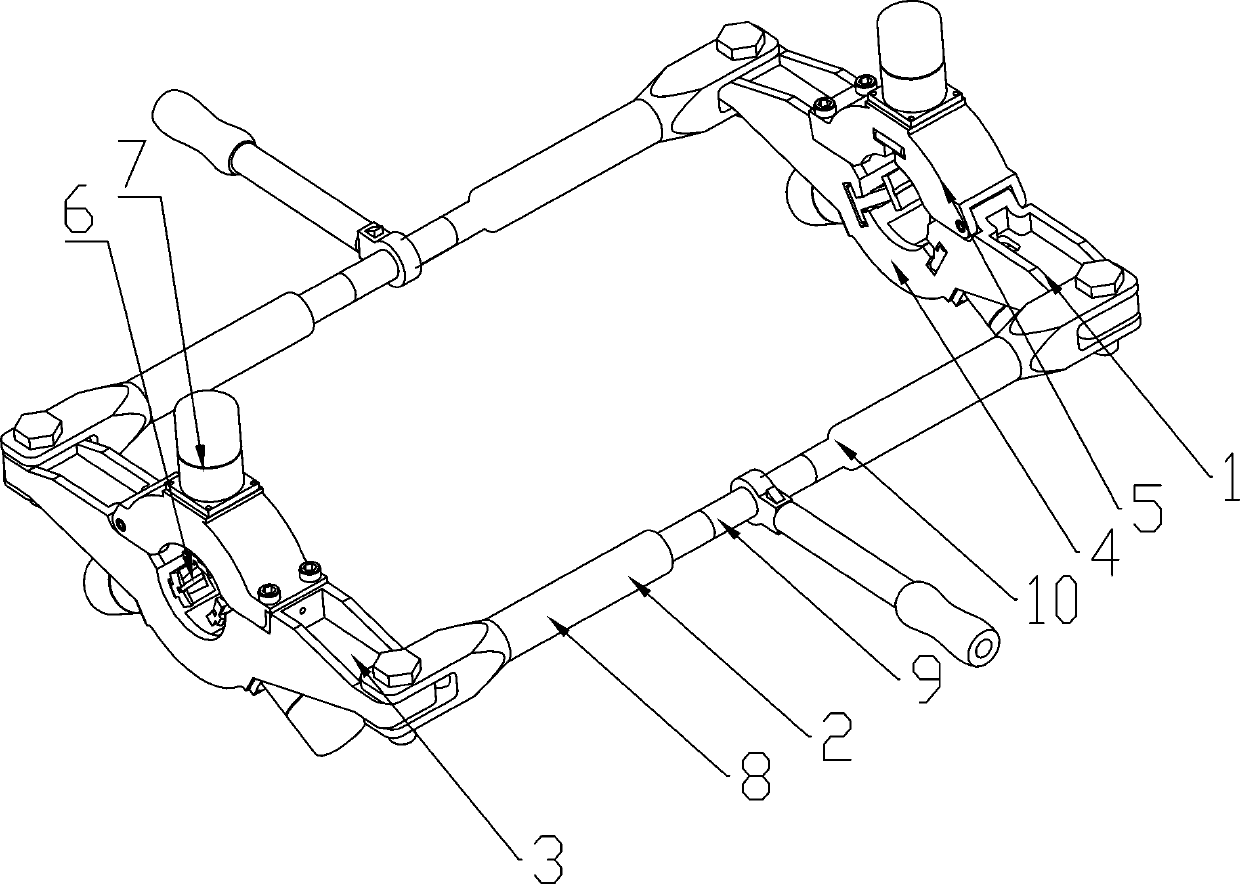

Insulator replacement device and method enabling chucks to be adjusted synchronously

ActiveCN107565450AImprove reliabilityReduce the intensity of manual operationApparatus for overhead lines/cablesUltimate tensile strengthMechanical engineering

Owner:CHINA THREE GORGES UNIV

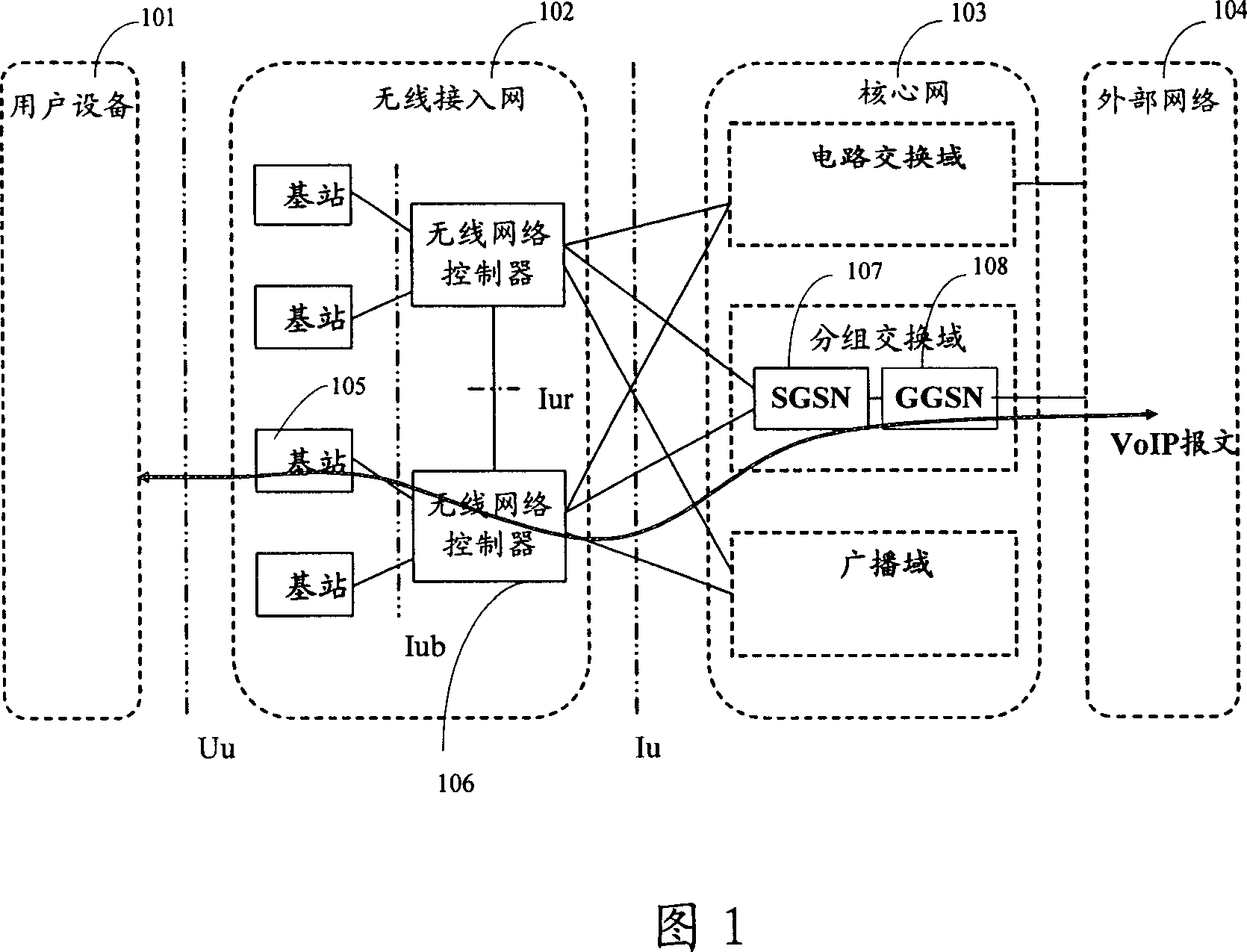

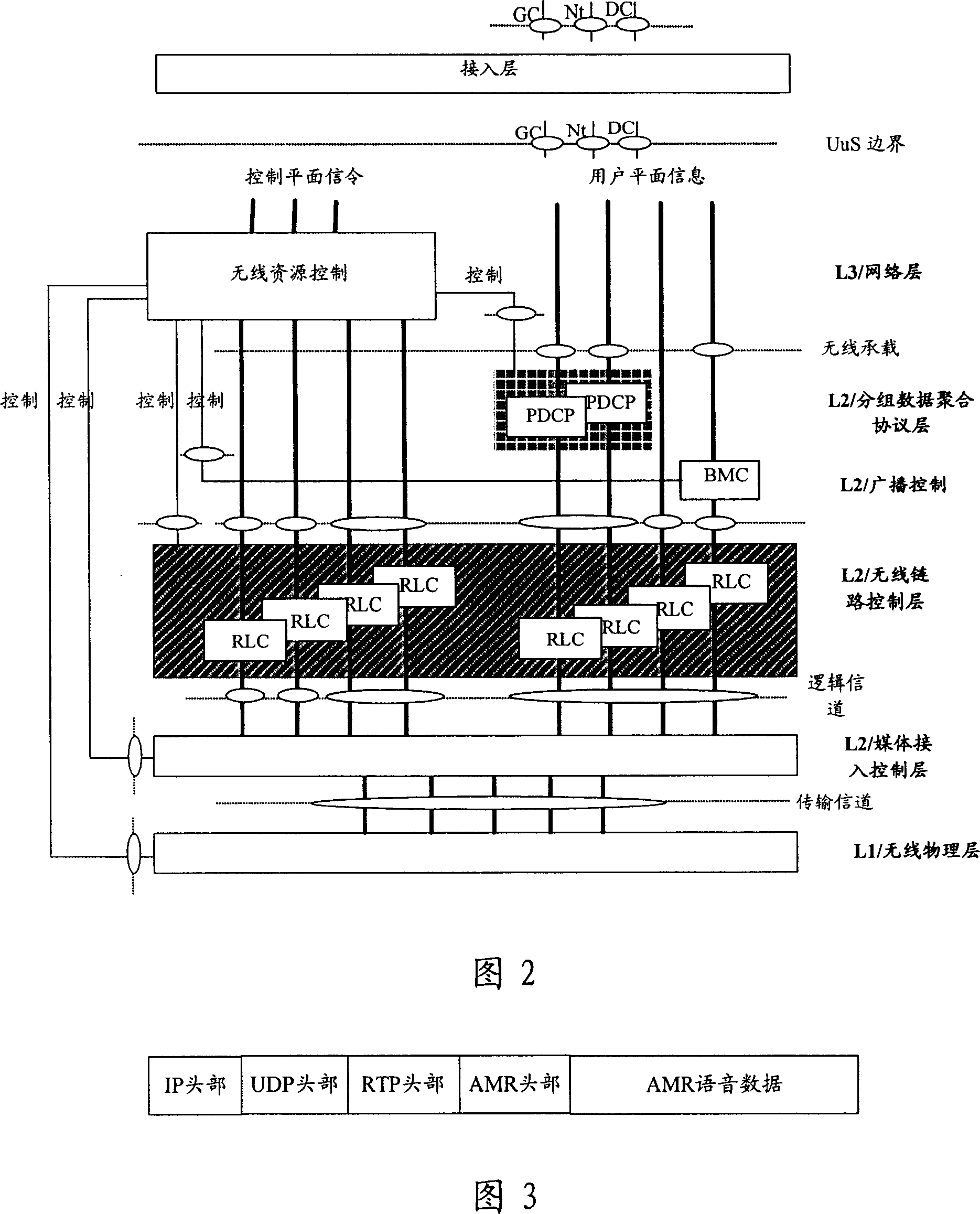

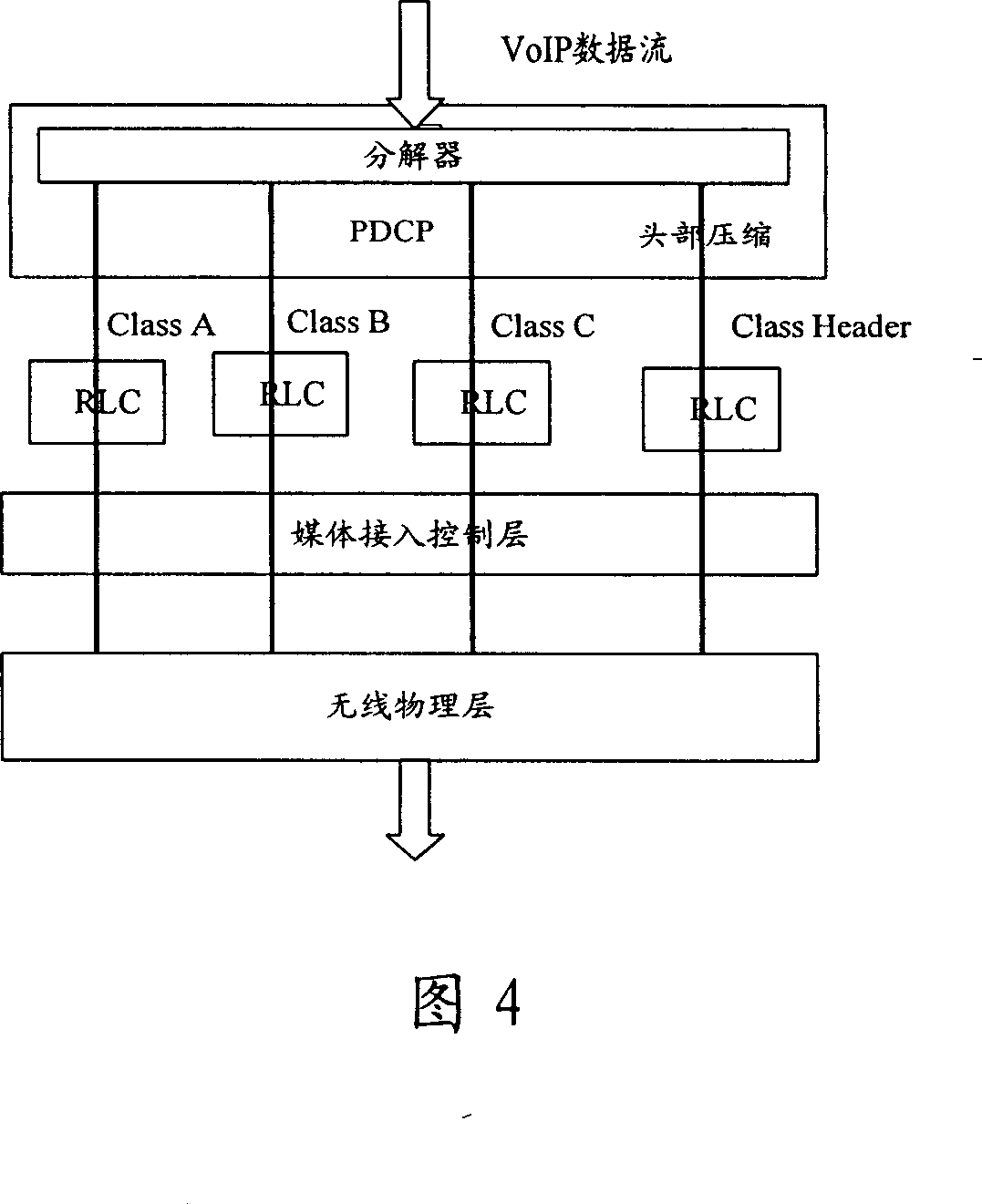

A method for loading and transferring packet voice

ActiveCN101009688AImprove transmission efficiencyIncrease profitError preventionTransmission path multiple useWireless transmissionThird generation

The disclosed loading and transmitting method for group speech comprises: the transmitter divides group speech message into some classes as different importance, selects transmission format combined set for different conditions to transmit every-class data with individual channel, and protects data by unequal error protection strategy; the receiver combines received data to generate group speech message. This invention improves transmission efficiency, reduces bandwidth waste, and fit to 3G wireless communication network.

Owner:XFUSION DIGITAL TECH CO LTD

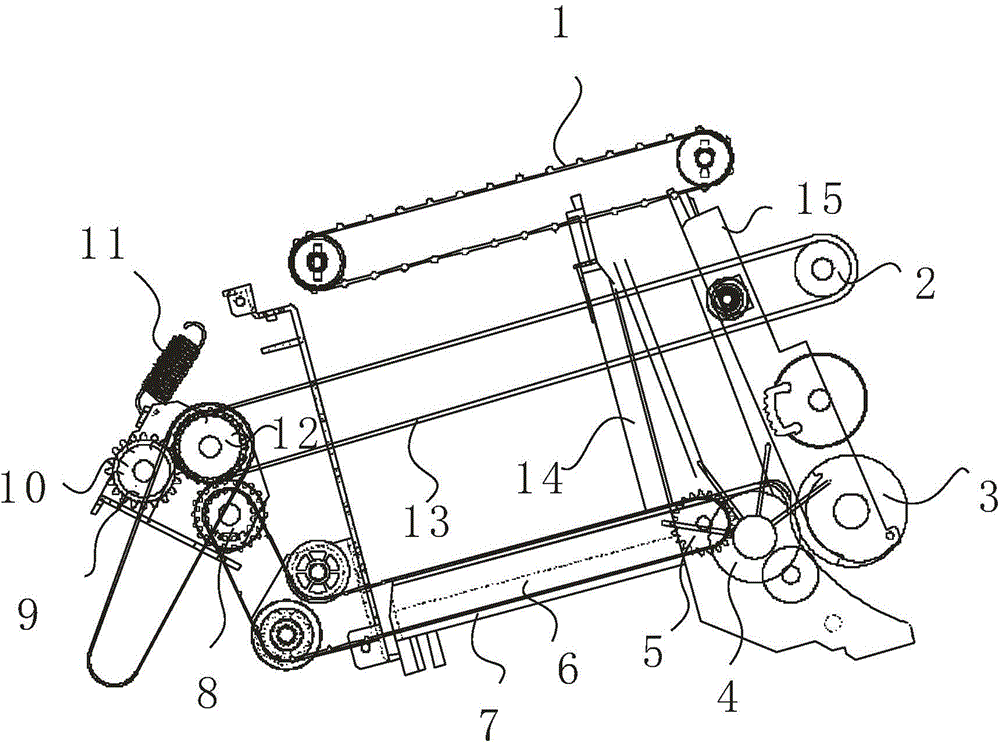

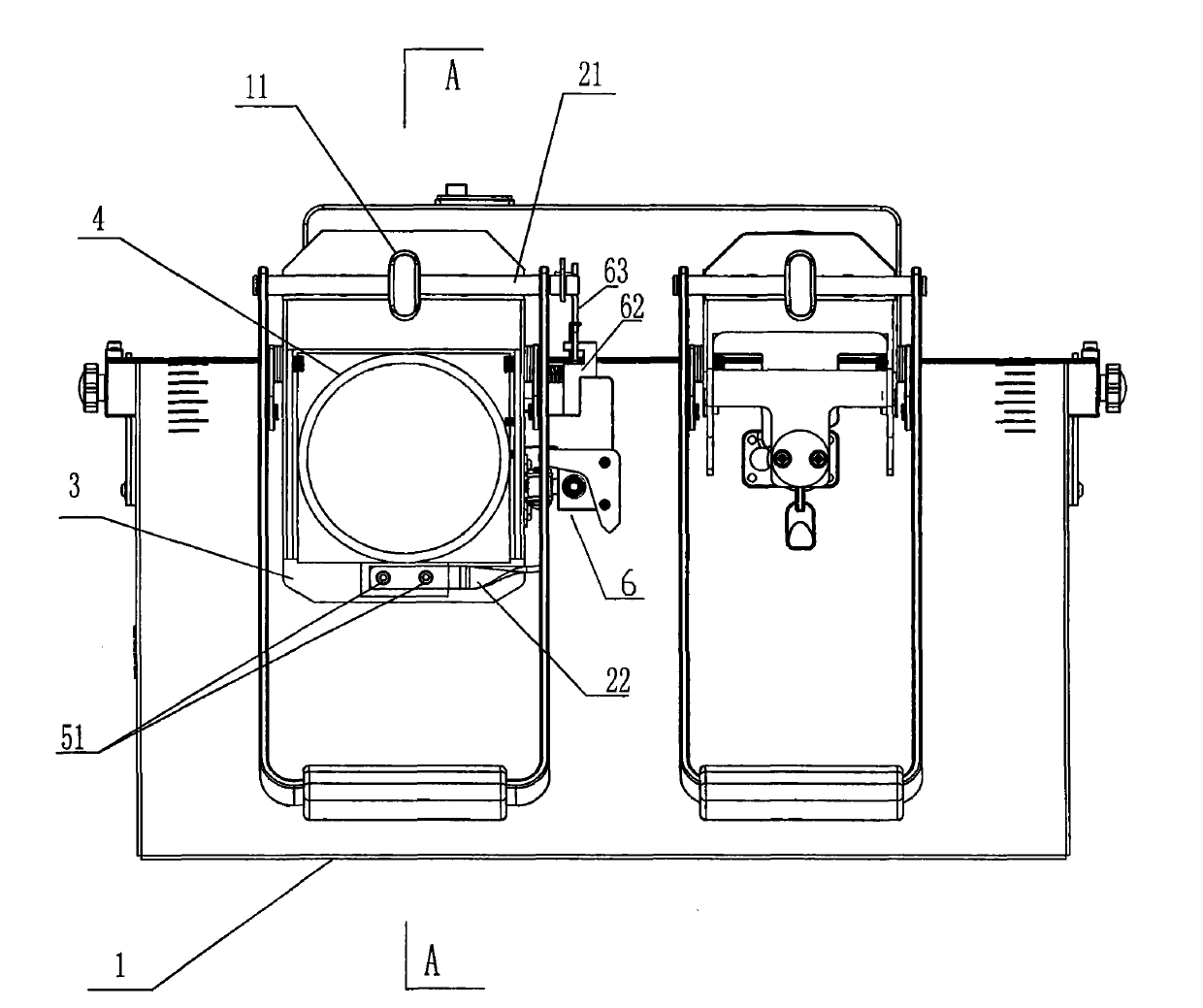

Large-capacity bill storage device for financial self-service terminal

InactiveCN105139511ALarge capacityReasonable transmissionCoin/currency accepting devicesDrive wheelTransmission belt

The present invention relates to a device for a financial self-service terminal and particularly relates to a large-capacity bill storage device for a financial self-service terminal. The device comprises a bill storage and withdrawal warehouse formed by a bill guidance plate, an elastic limit belt, a bill pushing plate and a bill support frame. The bill storage and withdrawal warehouse is inclined to the direction of the bill pushing plate. The lower end of the bill guidance plate is provided with a friction wheel. The bill pushing plate moves back and forth through a transmission belt which is fixedly connected to the bill pushing plate. One end of the transmission belt sleeves a tension driven wheel, and the other end sleeves a power output wheel. The power output wheel drives a bill synchronous belt to move through transmission gear transmission. The front end of the bill synchronous belt drives a bill push wheel. The upper plane of the bill synchronous belt is arranged above the bill support frame. The teeth of the bill thumbwheel are raised from a bill support frame plane. The front end of the bill support frame is provided with push leaves. Both a power output wheel bearing and a transmission gear bearing are fixedly connected to a sheet metal bracket. One end of the sheet metal bracket is fixedly connected to a stretched spring, the capacity of the bill storage and withdrawal warehouse is effectively increased, and the overall transmission is reasonable and safe.

Owner:CASHWAY FINTECH CO LTD

New-type binding machine

ActiveCN102166901ALink structure is simpleSimple structureMetal working apparatusSheet bindingPulp and paper industryGuide tube

The invention relates to a new-type binding machine, comprising a drilling motor which can be arranged on an elevated motor base, a paper pressing device, a tube-cutting device and a conduit barrel, wherein the paper pressing device is positioned on the motor base and can be reset and elevated; the tube-cutting device is vertically opposite to the conduit barrel; and the new-type binding machine also comprises a delivery guide device with reverse guiding elevation with the paper pressing device; and the delivery guide device is provided with a measuring tube supporting plate opposite to the pipe orifice of the conduit barrel. The new-type binding machine provided by the invention has the advantages of simple structure, reasonable transmission, stable connection, good linkage effect and the like.

Owner:DELI GROUP CO LTD

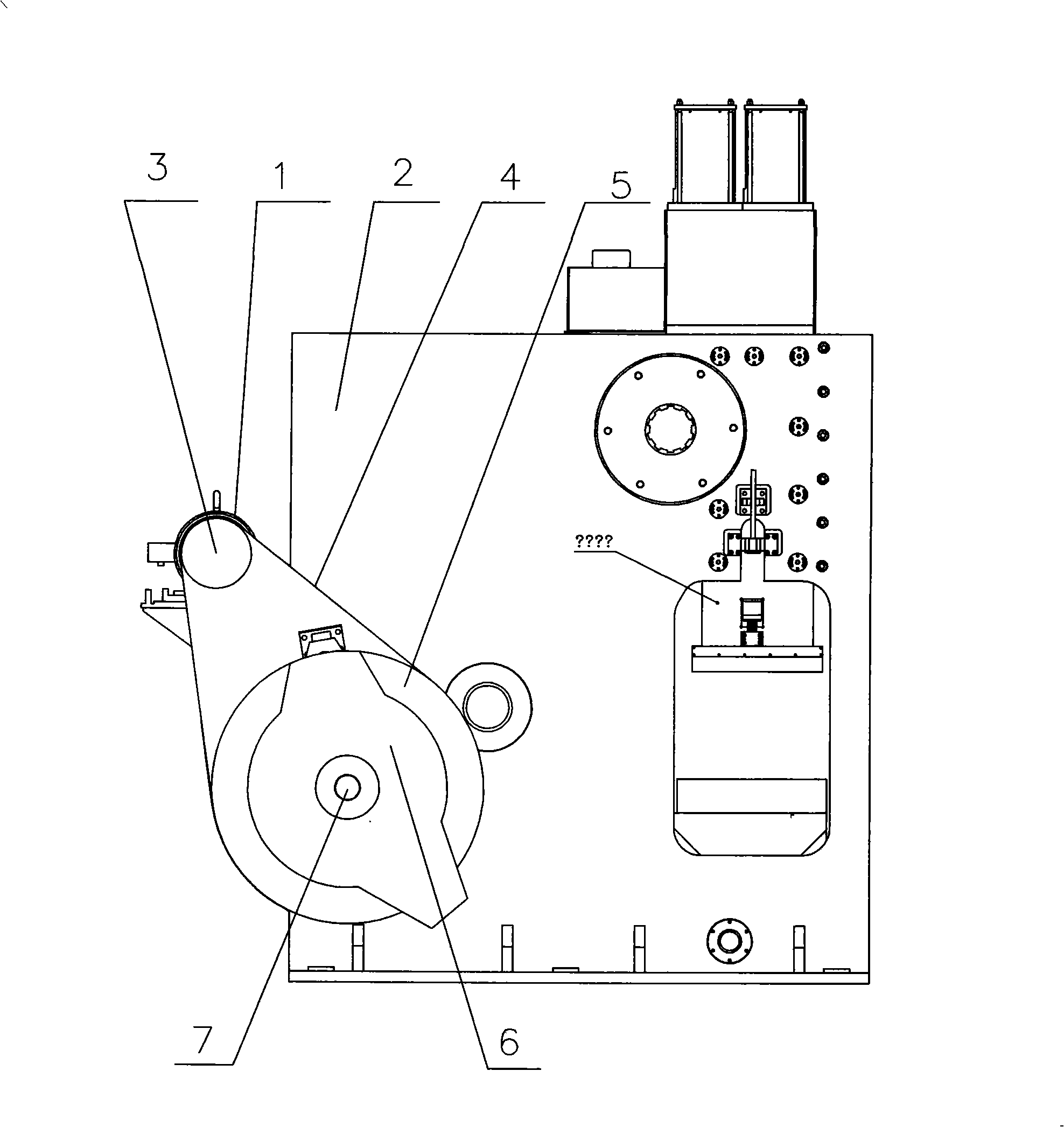

Sliding block driving mechanism of multiple slide rod press machine

The invention relates to a slide block driving device for multi-connecting-rod press machine. The slide block driving device comprises a frame, a motor, a fly wheel, a drive shaft, a transmission member, a slide block and a slide block lead rail. One end of the drive knuckle-lever of the transmission member is connected with and drives a connecting rod by a connection shaft and the other end of which is arranged on the side leg of a crank shaft. The coaxial deceleration gear of the crank shaft gears into a transmission gear arranged on the drive shaft. The slide block driving device is characterized in that the drive shaft is supported below one side of the frame by a bearing; the drive knuckle-lever is supported against the frame by the bearing in the manner of mismatched length; a drive tee is arranged at the other end; an upper fixed block and a lower fixed block are arranged in the drive chamber of the slide block; an upper rubbing block and a lower rubbing block are arranged between the drive tee and two fixed blocks respectively; the sphere of the drive tee is matched with two rubbing blocks and the drive tee can relatively slide between the running-in surfaces of two rubbing blocks; the upper fixed block is assembled by an adjustment bolt that is against the upper fixed block; and the lower fixed block is supported by a strut member that is against the lower fixed block. The slide block driving device has the advantages of stable running, small eccentric load and quick clearance adjustment, and thus is suitable for the such technologies as precise cold forging, cold warm forging, etc.

Owner:SHANDONG JINCHEN MACHINERY CORP LTD LTD

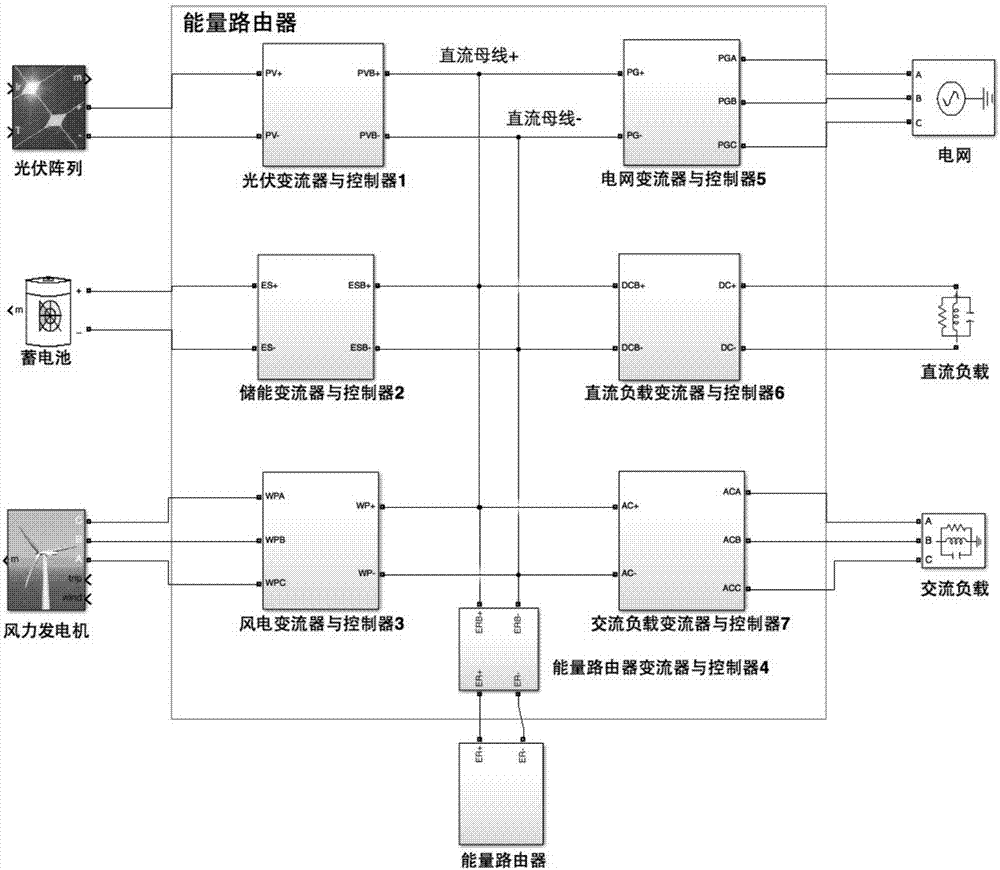

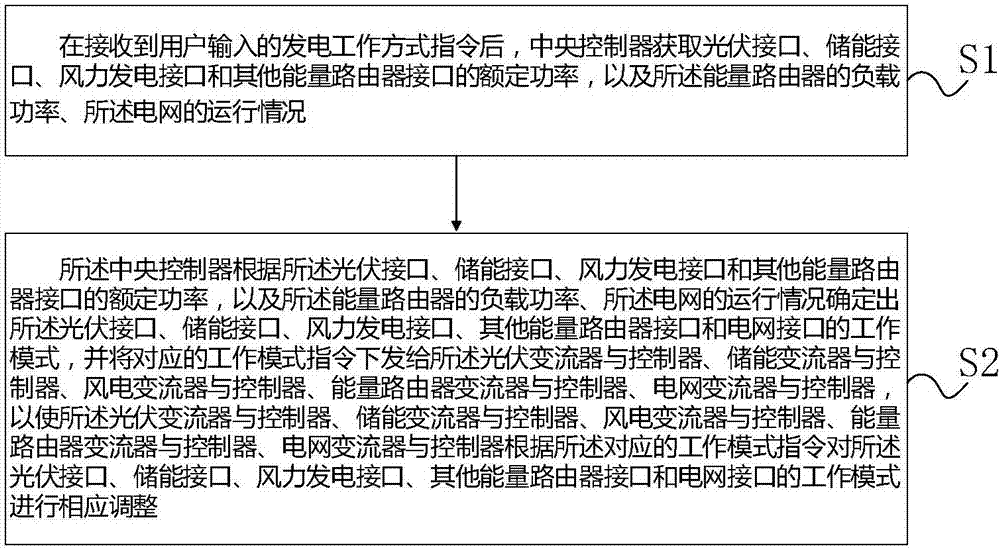

Energy router and power generation control method based on the energy router

ActiveCN107516893AReasonable transmissionSingle network parallel feeding arrangementsAc network with energy trading/transmission rightsPower gridSystem stability

The invention discloses an energy router and a power generation control method based on the energy router. When a plurality of ports cooperatively work, system stability is guaranteed and a work mode is reasonably designed. The invention provides a seven-interface direct current bus energy router model. The model comprises wind energy, photovoltaic power generation, energy storage and alternating current and direct current loads, a power grid and other energy router interfaces. Aiming at the above configuration, an integral control strategy of the energy router is designed. Two working modes of on-demand power generation and maximum power generation are included and energy can be reasonably transmitted.

Owner:TSINGHUA UNIV +2

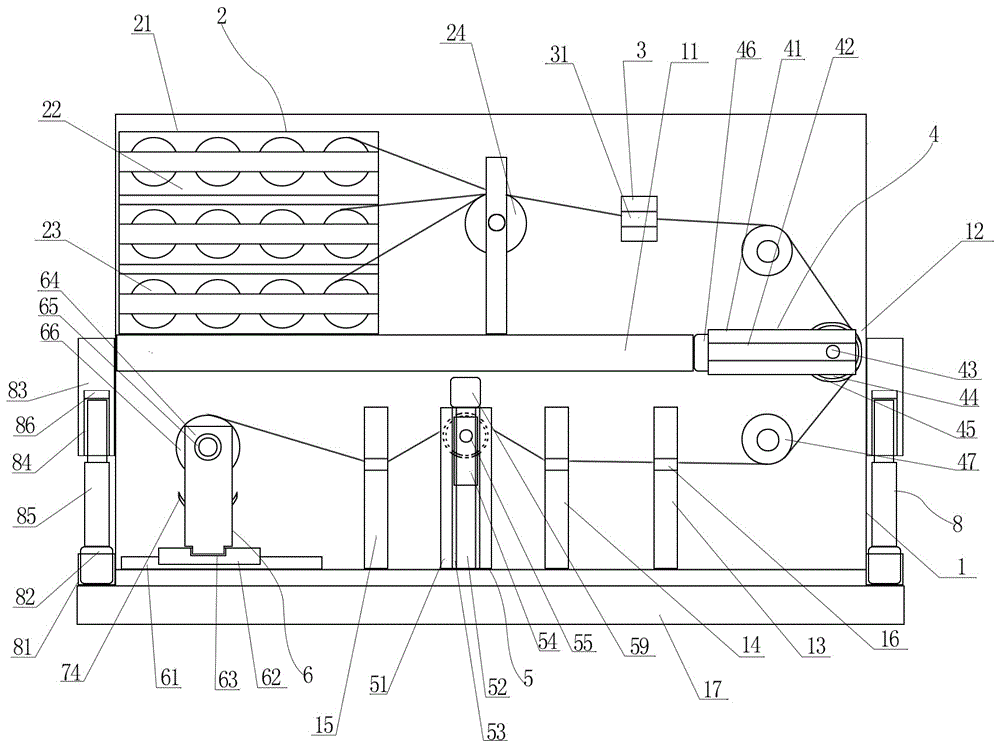

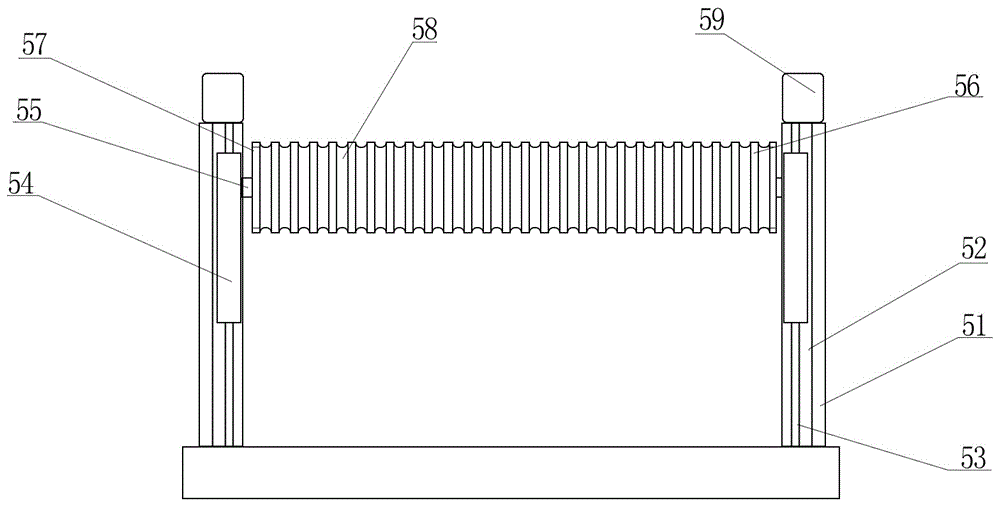

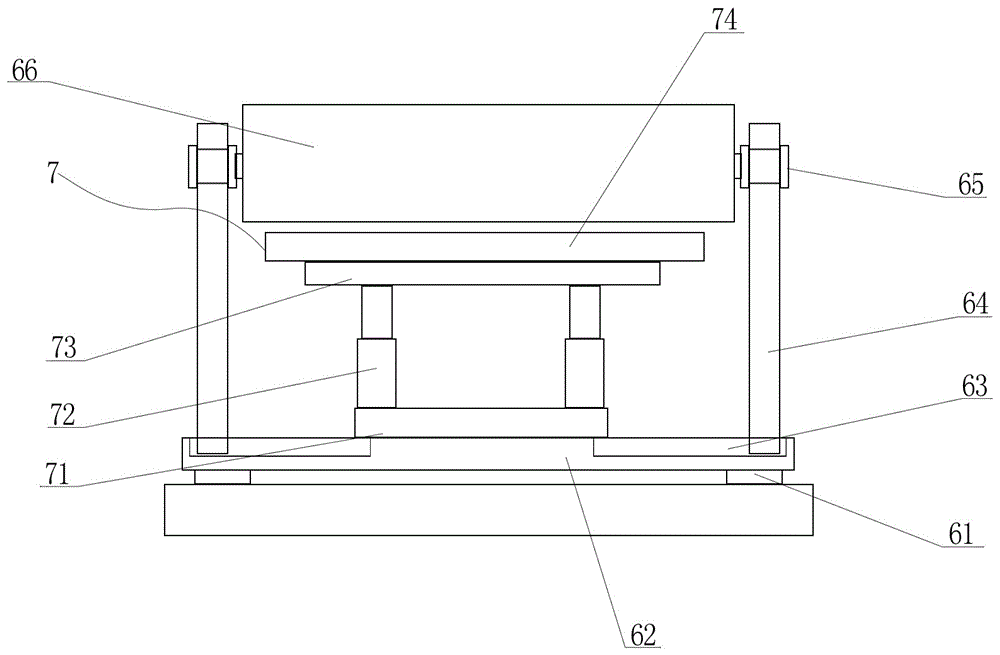

Double-layer clean-type warping machine

ActiveCN106283323AReasonable transmissionAvoid wastingWarping machinesOther manufacturing equipments/toolsYarnEngineering

The invention discloses a double-layer clean-type warping machine. The double-layer clean-type warping machine comprises a frame, a partition plate is arranged in the middle of the frame horizontally and partitions the frame into an upper layer and a lower layer, and a passage is formed on one side of the partition plate. A bottom plate is arranged at the bottom of the lower layer, a yarn unwinding component is arranged on the upper layer, a first rotating roller is arranged on one side of the yarn unwinding component, a yarn collecting beam is arranged on one side of the first rotating roller, and a tensioning component is arranged on one side of the yarn collecting beam and in the passage. A first dividing frame is arranged on the lower layer and disposed below the tensioning component, a second dividing frame, a yarn guide component and a third dividing frame are arranged on one side of the first dividing frame, a warping component is arranged on one side of the third dividing frame, the bottom plate is provided with a plurality of rectangular grooves in which negative pressure blowers are disposed, and a plurality of square pipes correspondingly connected with the rectangular grooves are arranged at the bottom of the bottom plate in the frame and are disposed in a collecting box arranged at the bottom of the frame.

Owner:吴江市晓月昱喷织厂

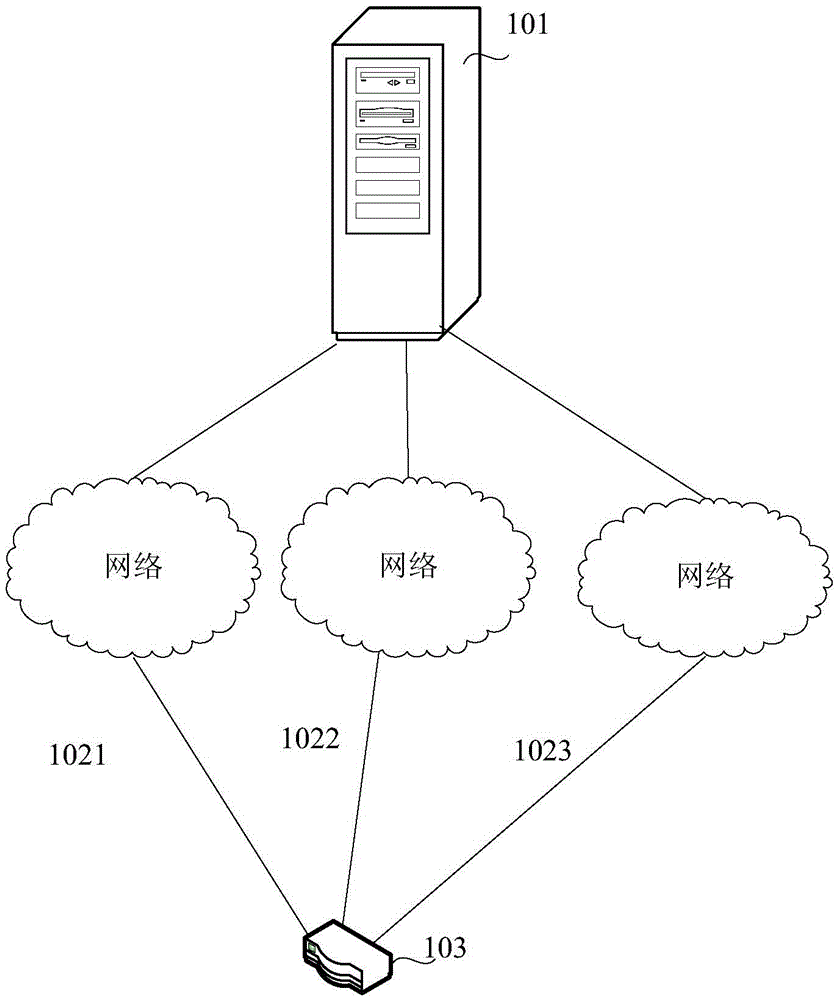

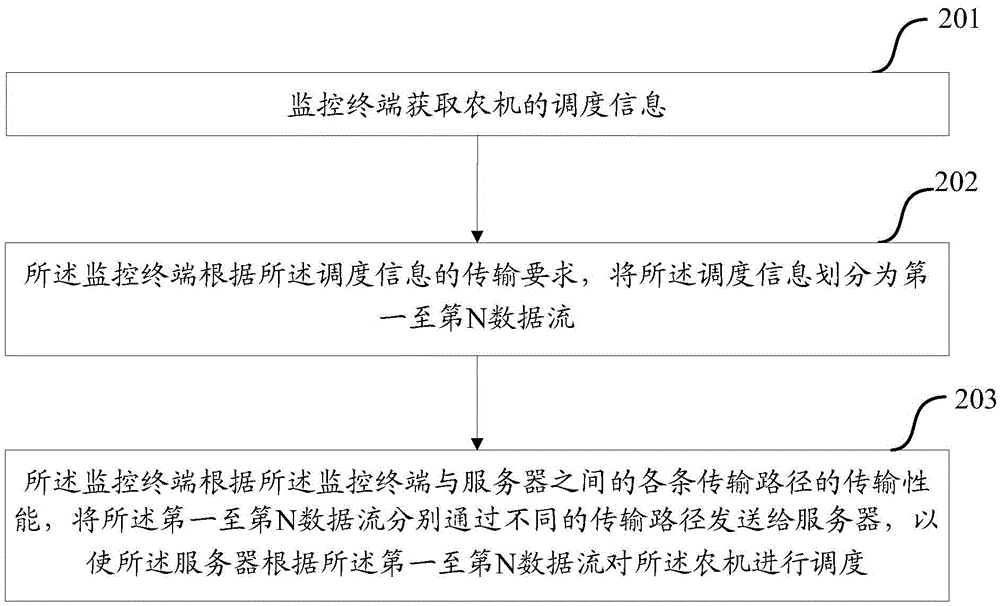

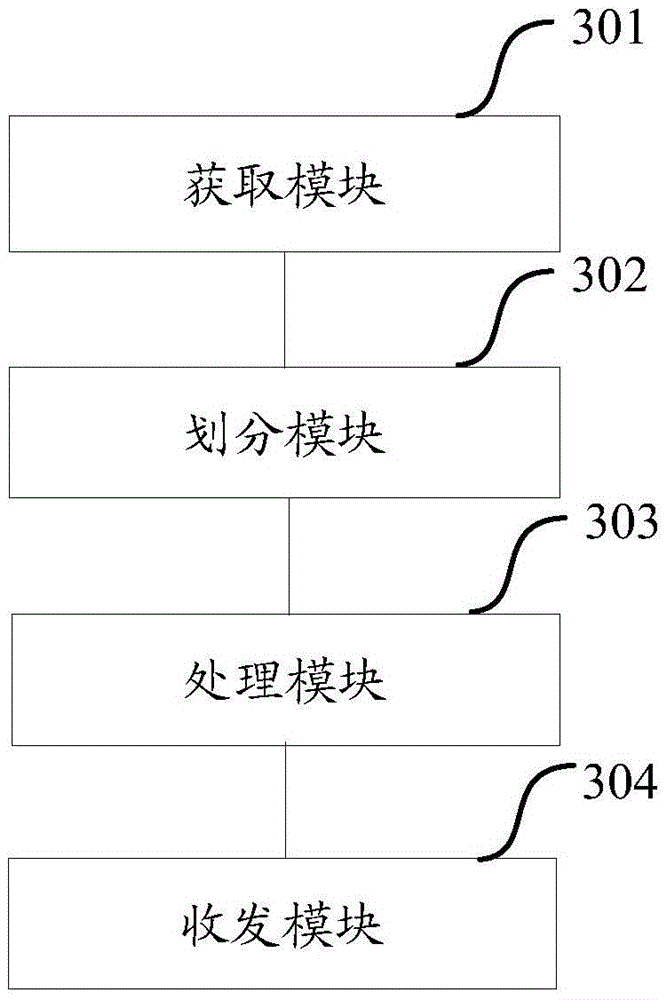

Agriculture machineries scheduling method based on multipath transmission and monitoring terminal

InactiveCN105681423AReasonable transmissionImprove reliabilityData processing applicationsTransmissionData streamDistributed computing

The embodiment of the invention discloses a method for dispatching agricultural machinery based on multipath transmission and a monitoring terminal. In the embodiment of the present invention, the monitoring terminal obtains the scheduling information of agricultural machinery, and according to the transmission requirements of the scheduling information, divides the scheduling information into the first to the Nth data streams, and further divides the first to the Nth data streams according to the transmission performance of each transmission path. The N data streams are sent to the server through different transmission paths, so that the server schedules the agricultural machines according to the first to Nth data streams. In the embodiment of the present invention, the scheduling information of the agricultural machinery is divided into multiple data streams, and the multiple data streams are sent to the server through different transmission paths, thereby improving the reliability of communication; and, in the embodiment of the present invention Comprehensively considering the transmission requirements of the data stream and the transmission performance of the transmission path, the transmission path for the transmission of the data stream is allocated, so that the transmission of the data stream is more reasonable and effective, and the stability of the communication is greatly improved.

Owner:SHANDONG COMP SCI CENTNAT SUPERCOMP CENT IN JINAN

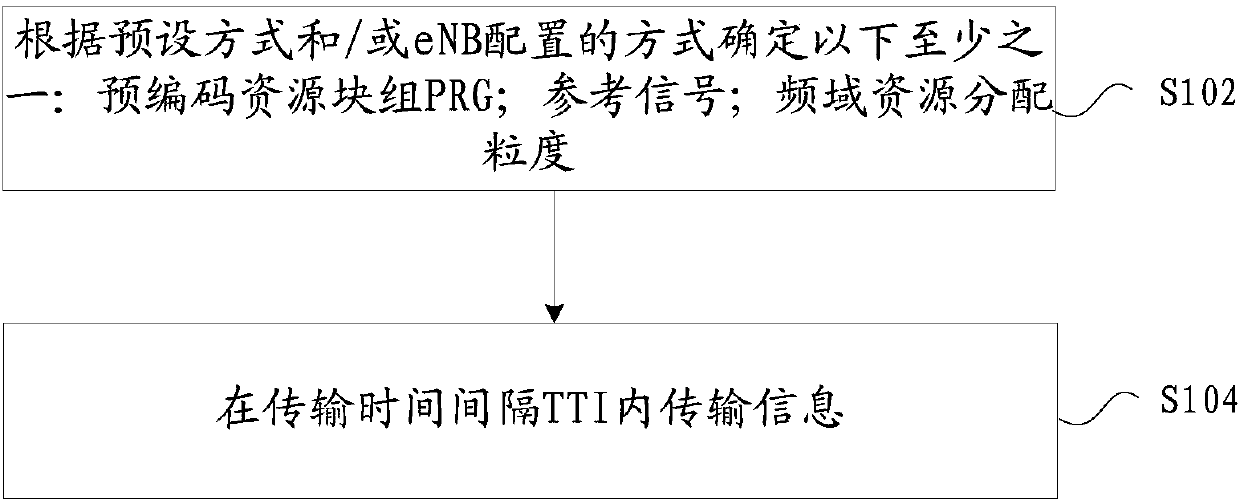

Information transmission method and device

ActiveCN107371252ASolve the problem of unreasonable data transmissionReasonable transmissionTransmission path divisionPilot signal allocationInformation transmissionResource block

The invention provides an information transmission method and device. The method comprises the following steps: at least one of the following is determined according to a preset mode and / or an eNB-configured mode: a precoding resource block group PRG, reference signals, frequency domain resource allocation granularity and information transmitted in a transmission time interval TTI. Via adoption of the above method, a problem that unreasonable data transmission is caused due to unreasonable setting of relevant parameters while short TTI technologies are adopted can be solved, and reasonable data transmission can be realized while the short TTI technologies are adopted.

Owner:ZTE CORP

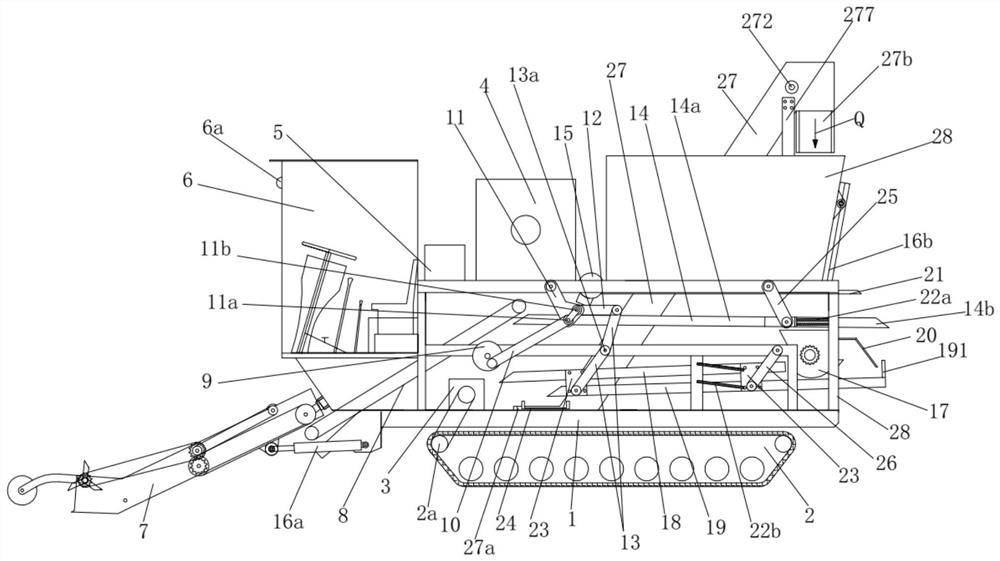

Crawler-type harvester for cyperus esculentus

PendingCN111742687AImprove adaptabilityHigh yieldDiggersEndless track vehiclesAgricultural engineeringAgricultural science

The invention relates to a crawler-type harvester for cyperus esculentus. According to the technical scheme, a soil crushing and feeding device driven by an engine, a lifting and conveying device, anupper layer vibrating screen, an auger-type soil throwing and crushing device, a lower layer vibrating screen, a horizontal conveying vibrating screen and a material receiving and lifting mechanism are arranged on a frame; a feeding end of the soil crushing and feeding device is connected with a feeding end of the lifting and conveying device; a discharge end of the lifting and conveying device isconnected with a feeding end of the upper layer vibrating screen; a discharge end of the lower layer vibrating screen is connected with a feeding end of the horizontal conveying vibrating screen; a discharge end of the horizontal conveying vibrating screen is connected with a feeding hole of the material receiving and lifting mechanism; a discharge hole of the material receiving and lifting mechanism is connected with a feeding hole of the upper part of a harvesting box; and a travelling mechanism is a travelling crawler arranged at two sides of a chassis. The crawler-type harvester has a wide application range, integrates multiple functions of excavating and soil crushing, root crushing, separating, screening and recycling, is suitable for high-efficiency harvesting of the cyperus esculentus, is easy to move, and has a great popularization prospect.

Owner:新乡地隆药业机械有限公司

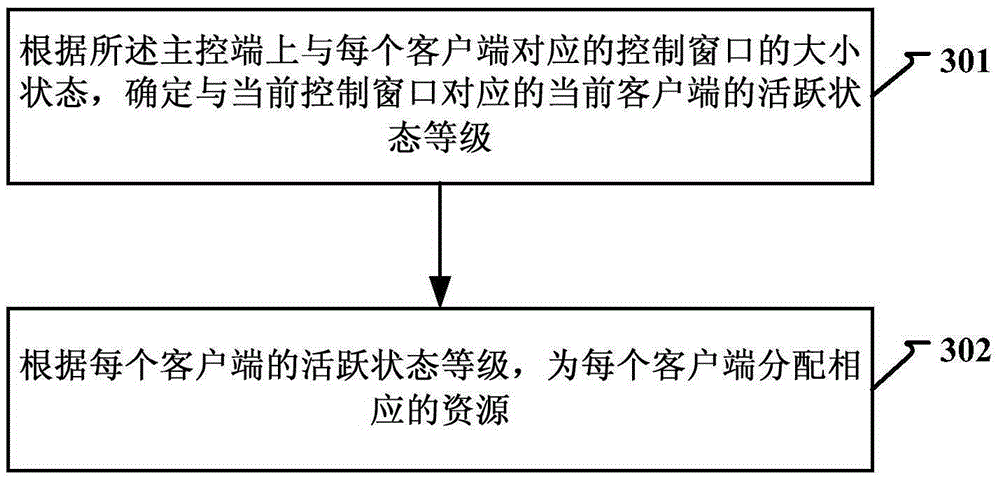

Resource allocation method and device in local area network

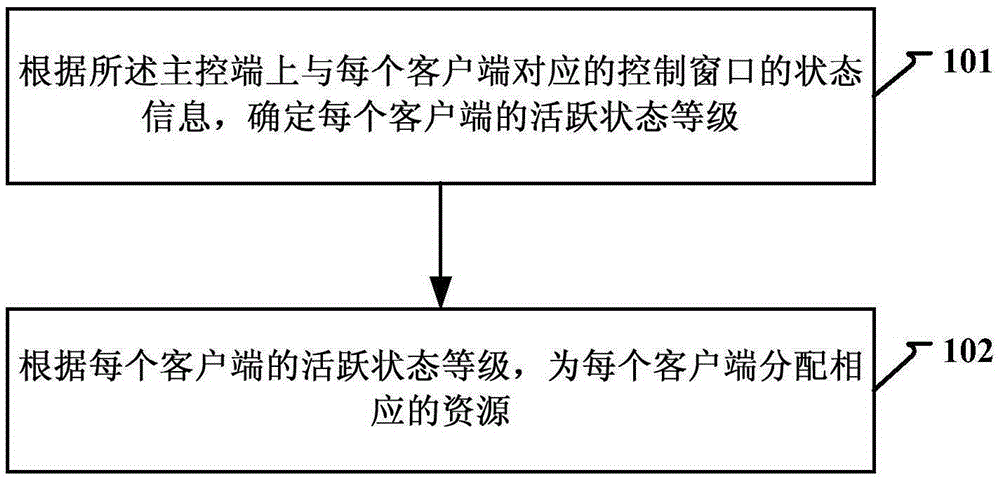

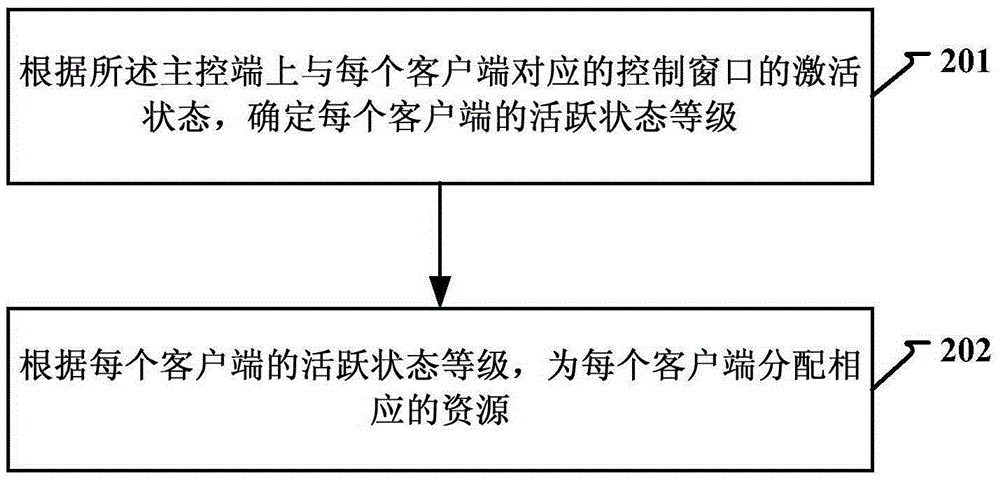

InactiveCN105306386AReasonable transmissionFast transmissionData switching by path configurationClient-sideActive state

The invention discloses a resource allocation method and device in a local area network, which are used for improving the resource allocation rationality. The method comprises the following steps: determining an active state grade of each client according to state information corresponding to each client; and allocating corresponding resources to each client according to the active state grade of each client. In this way, a main control terminal can allocate more resources for the active clients, so that the files with large capacity can be transmitted between the main control terminal and the clients, with regard to some inactive clients, the main control terminal only allocate few resources or allocate no resource, so that the resources are rationally allocated, and no waste of network resources is generated.

Owner:TVM BEIJING EDUCATION SCI & TECH CO LTD

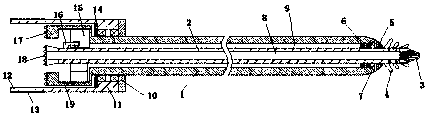

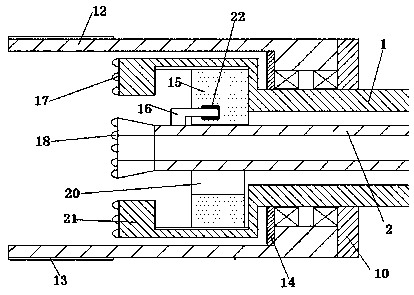

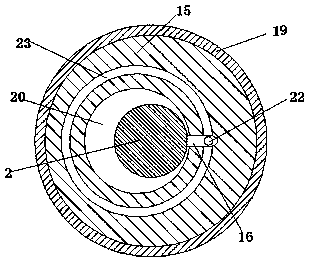

Drilling device for hydraulic fracturing weakening hard roof

ActiveCN109113570AEasy to drillFast drillingDrill bitsDrilling machines and methodsHydraulic fracturingDrill bit

The invention discloses a drilling device for a hydraulic fracturing weakening hard roof. According to the drilling device for the hydraulic fracturing weakening hard roof, when drilling the hard roof, drilling of the hard roof can be conveniently realized, and the drilling efficiency is high; drilling is carried out through an inner drill rod, reaming is carried out through an outer drill rod, drilling of the hard roof can be efficient, and consumption of a drill bit is relatively little; and the hard roof can be drilled quickly by adopting a drilling mode of swinging and rotating of the inner drill rod, axial force of a drill hole can be greatly reduced, and subsequent implementation of the hydraulic fracturing weakening hard roof is facilitated. According to the drilling device for thehydraulic fracturing weakening hard roof, the structure is simple, transmission is reasonable, the drilling efficiency of the hard roof is greatly ensured, and meanwhile the service life of the drillbit is prolonged.

Owner:ANHUI UNIV OF SCI & TECH

Casting transverse moving vehicle

InactiveCN102350725AReasonable transmissionLess investmentCeramic shaping apparatusMobile vehicleAutomotive engineering

The invention discloses a casting transverse moving vehicle, which comprises a transverse moving vehicle body (4), transverse moving vehicle guide rails (5) and traveling wheels (6), wherein the casting transverse moving vehicle (1) is provided with a plurality of friction wheels (2); and a plurality of supporting wheels (3) are arranged below the transverse moving vehicle body (4). By adopting the technical scheme, equipment investment is reduced, so that the transmission of motion of a mechanism of the transverse moving vehicle is more reasonable, the work is more stable, and the body is more stable.

Owner:WUHU SUREMAKER MACHINERY

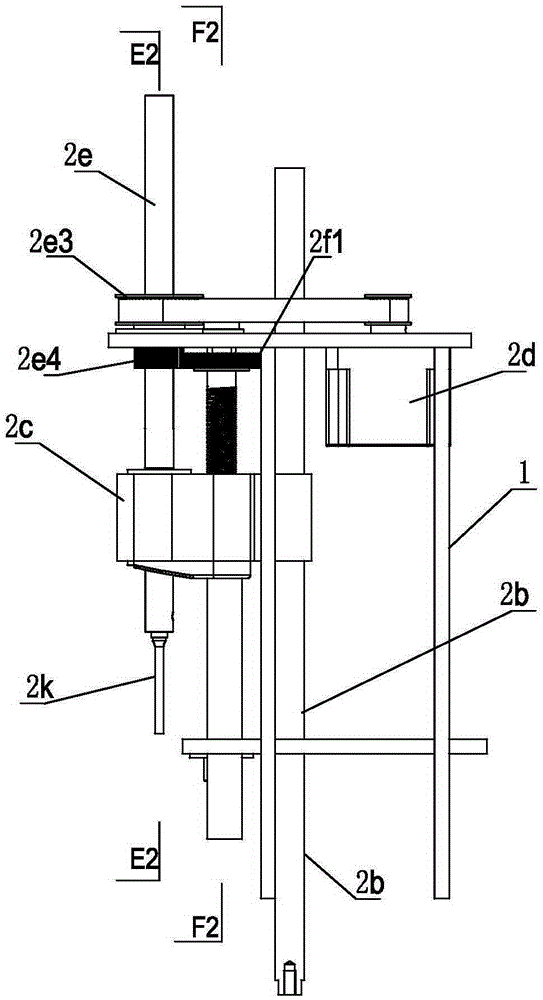

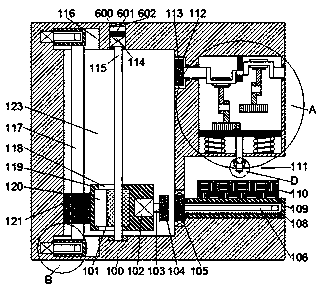

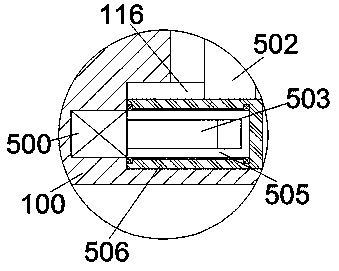

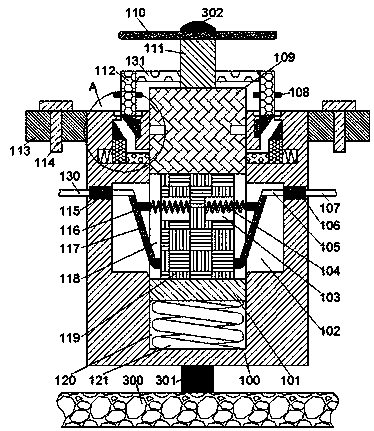

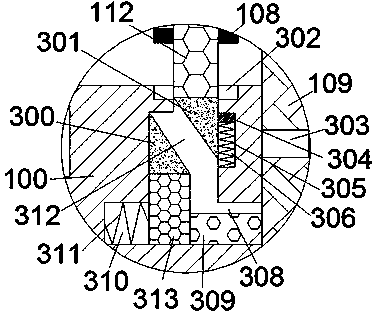

Printing ink-jet head manufacturing apparatus

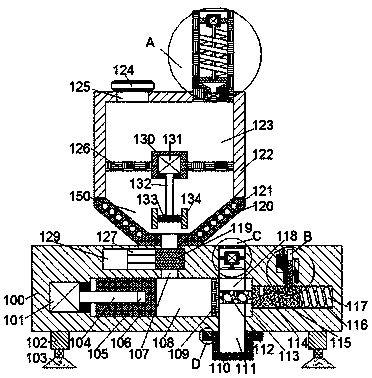

Provided in the invention is a printing ink-jet head manufacturing apparatus comprising a device body and a heating device fixedly mounted above the device body. The heating device includes a heatingchamber body fixedly mounted above the device body; and a heating chamber is formed in the heating chamber body. An inclined surface extending upwardly is arranged at the lower end wall of the heatingchamber; and a heating resistance wire is fixedly installed in the inclined surface. A storage chamber body is fixedly mounted above the heating chamber body; a storage chamber communicated with theheating chamber is arranged in the storage chamber body; a feeding inlet communicated externally is formed in the left side of the upper end wall of the storage chamber; and a sealing cover is installed in the feeding inlet in a sliding manner. A pressurizing chamber body arranged at the right of the sealing cover is fixedly installed above the storage chamber body; a pressurizing chamber with theupward opening is formed in the pressurizing chamber body; and a first fixation block fixedly installed in the pressurizing chamber by a first bracket is arranged at the upper side of the pressurizing chamber.

Owner:QUZHOU SHUNAN ELECTRONICS COMMERCE CO LTD

Novel automatic perforating device

InactiveCN109015863ASimple structureReasonable transmissionMetal working apparatusEngineeringOperating table

A novel automatic perforating device comprises a device body. An operating cavity with an opening rightward is formed in the device body, and a first siding block is slidably mounted on the lower endface of the operating cavity. An operating table is fixedly arranged at the upper end of the first sliding block, and a first rotating cavity with an opening leftward is formed in the first sliding block. A first threaded sleeve with an opening leftward is rotatably mounted in the first rotating cavity, and a first threaded shaft is mounted in the first threaded sleeve in a threaded-fit mode. A first transmission cavity which is located in the left side of the operating cavity and extends upwards is formed in the device body. A first friction wheel is mounted between the first transmission cavity and the operating cavity in a rotating-fit mode, and the right end of the first friction wheel and the left end of the first threaded shaft are fixedly matched. First sliding grooves are formed inthe inner walls of the left and lower sides of the first transmission cavity in a communicating mode correspondingly, second sliding blocks are slidably arranged in the first sliding grooves, and first motors are fixedly arranged in the left end walls of the first sliding grooves.

Owner:林仕长

Double-layer lifting warping machine

ActiveCN106283320AReasonable transmissionAvoid wastingWarping machinesOther manufacturing equipments/toolsYarnEngineering

The invention discloses a double-layer lifting warping machine. The double-layer lifting warping machine comprises a base, a frame is arranged at the top of the base, a partition plate is arranged in the middle of the frame horizontally and partitions the frame into an upper layer and a lower layer, and a passage is arranged on one side of the partition plate. A yarn unwinding component is arranged on the upper layer, a first rotating roller is arranged on one side of the yarn unwinding component, a yarn collecting beam is arranged on one side of the first rotating roller, and a tensioning component is arranged on one side of the yarn collecting beam and in the passage. A first dividing frame is arranged on the lower layer and disposed below the tensioning component, a second dividing frame, a yarn guide component and a third dividing frame are arranged on one side of the first dividing frame, a warping component is arranged on one side of the third dividing frame, and lifting components are arranged on two side faces of the base and the frame. The double-layer lifting warping machine has the advantages of space saving, reasonable conveyance, less proneness to knotting, clear layering, high yarn guide precision, good warping quality and the like.

Owner:WUJIANG XIAOYU JET WEAVING

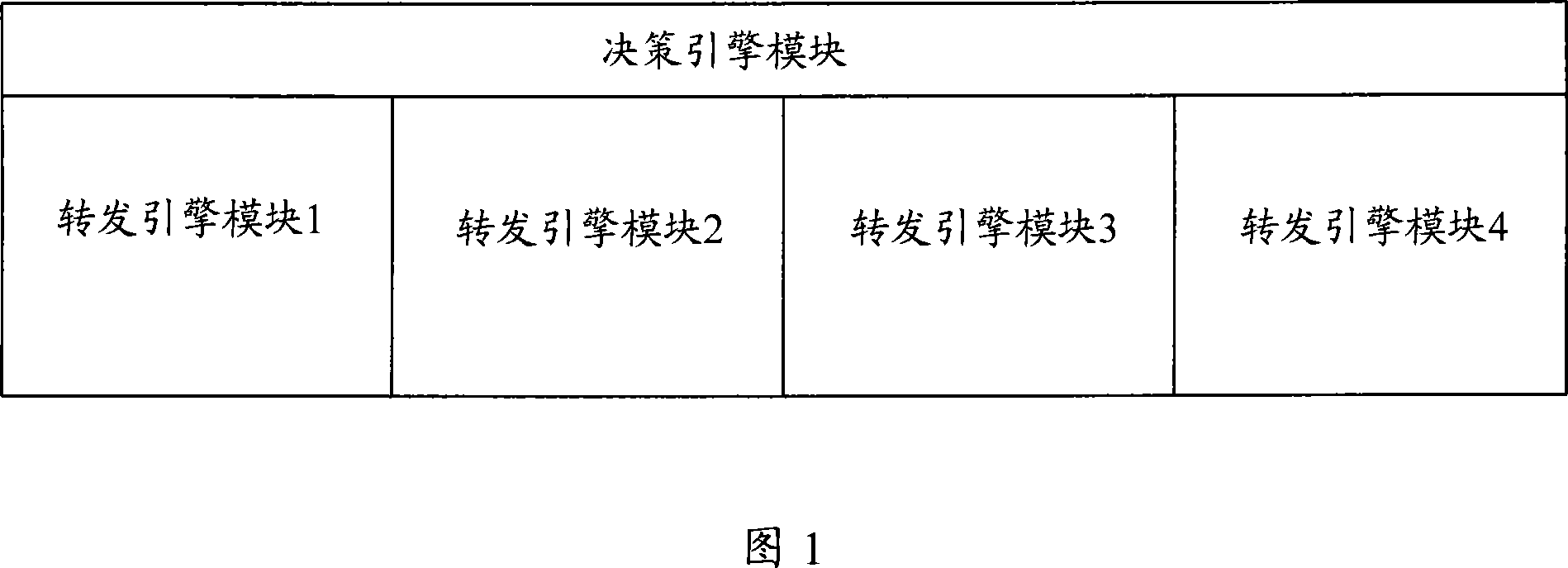

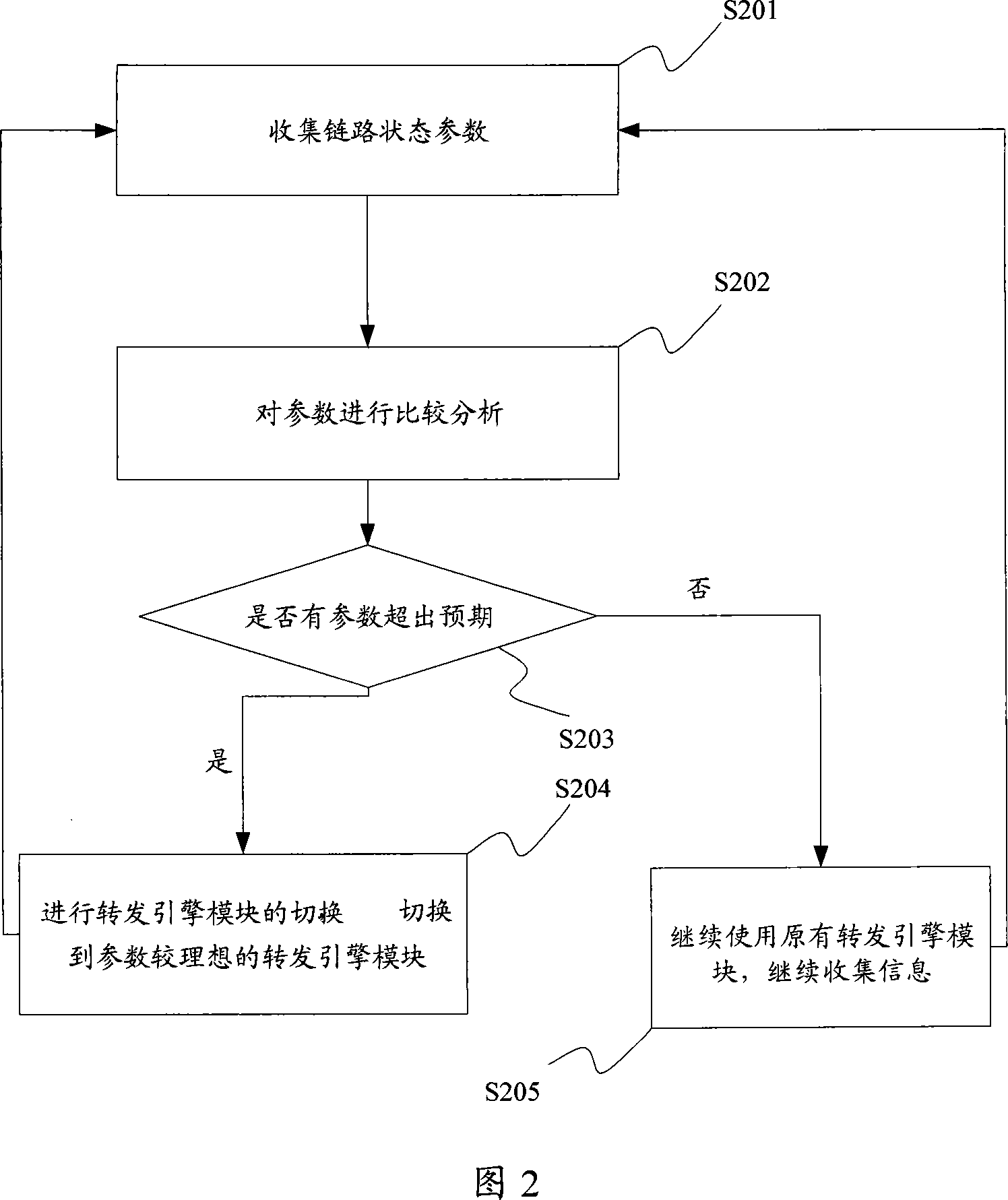

Multiple engine quick master-slave swap and its method

InactiveCN101052010AReasonable transmissionCausing routing flappingData switching networksEngineeringRouting protocol

The apparatus comprises a decision engine module and at least two relay engine modules each comprising independent route protocol and relay strategy and used for receiving or transmitting protocol message. According to the actual state of the link or network corresponding to different relay engine module, said decision engine module decides the switch between relay engine modules; the switched relay engine module is used to process the message. The invention also provides a method for main / standby switch between multi engines.

Owner:ZTE CORP

A novel circuit control device and a use method thereof

InactiveCN109036902ASimple structureReasonable transmissionElectric switchesEngineeringMechanical engineering

A novel circuit control device include a device body, The device comprises a device main body which is provide with a first sliding groove extend upward and downward and an opening upward, A first slider is slidably mounted between the left and right end walls of the first sliding groove, A low end of that first slider is fixedly mount with a first spring, and the lower end of the first spring isfixedly and cooperatively connected with the lower end wall of the first sliding groove, A transmission cavity communicating with the first sliding groove is symmetrically arranged in the main body ofthe device, and the transmission chamber is located above the first slider, A low end wall of that transmission cavity communicates with one end of the first slide groove and is provided with an inclined surface extending downward, The first sliding groove is slidably mounted with a second sliding block located above the transmission cavity, an insulating block is fixedly mounted between the first sliding block and the second sliding block, and an accommodation cavity located on both sides of the insulating block is also arranged between the first sliding block and the second sliding block.

Owner:方星

A kind of double-layer warping equipment

ActiveCN106283322BReasonable transmissionAvoid wastingWarping machinesOther manufacturing equipments/toolsYarnEngineering

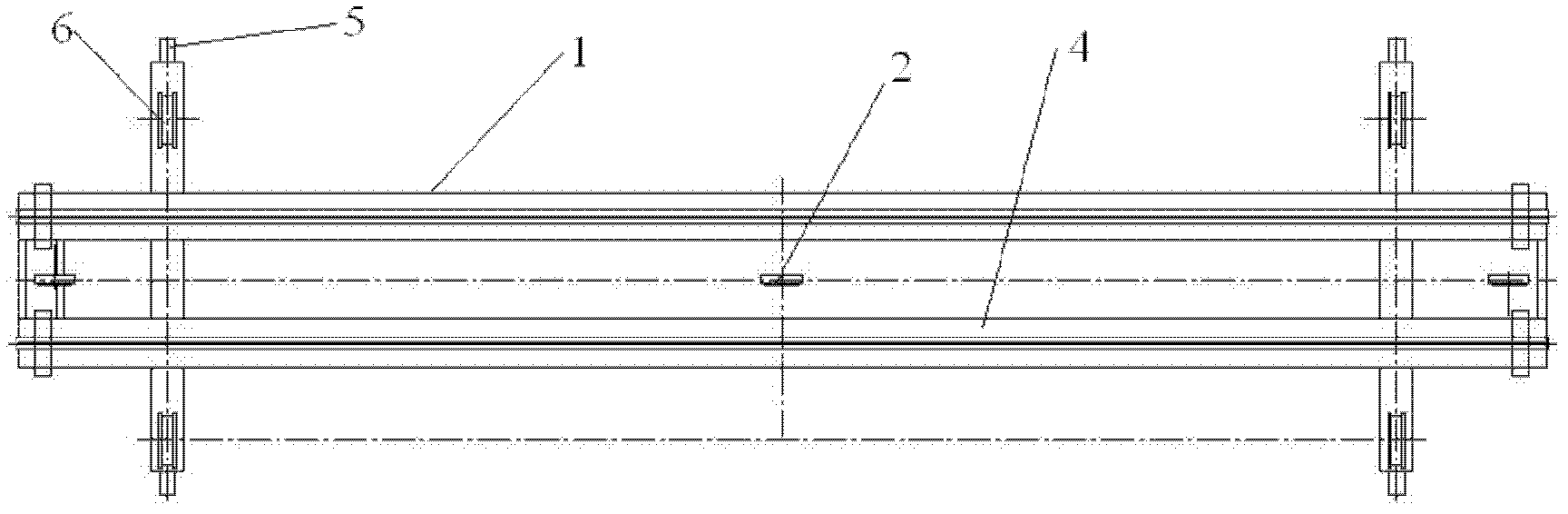

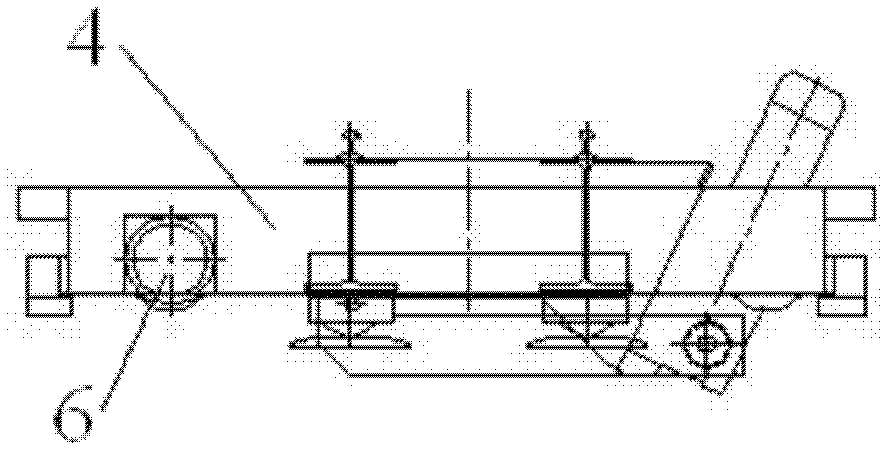

A warping device of a double-layer type, comprising a rack (1) which is horizontally provided at the middle portion of the rack with a partition plate (11), a passage (12) being provided at one side of the partition plate (11), the partition plate (11) separating the rack (1) into an upper layer and a lower layer, the upper layer being provided with a yarn unwinding component (2), a first rotary roller (24) and a yarn collecting beam (3), a tensioning component (4), which is provided between the passages (12), being provided at one side of the yarn collecting beam (3); the lower layer being provided with a first yarn separating frame (13), a second yarn separating frame (14), a yarn guiding component (5), a third yarn separating frame (15) and a warping component (6). The yarn unwinding component can move into or move out of the rack under the effect of a chute, facilitating a worker to change a yarn package to be processed, improving work efficiency.

Owner:WUJIANG XIAOYU JET WEAVING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com