Punching and hot riveting type precise binding machine

A hot riveting, binding machine technology, applied in binding, metal processing and other directions, can solve the problems of gear without positioning device, drill and shim damage, and can not guarantee effective penetration, etc., to achieve reasonable transmission, reduce the overall area, Good linkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

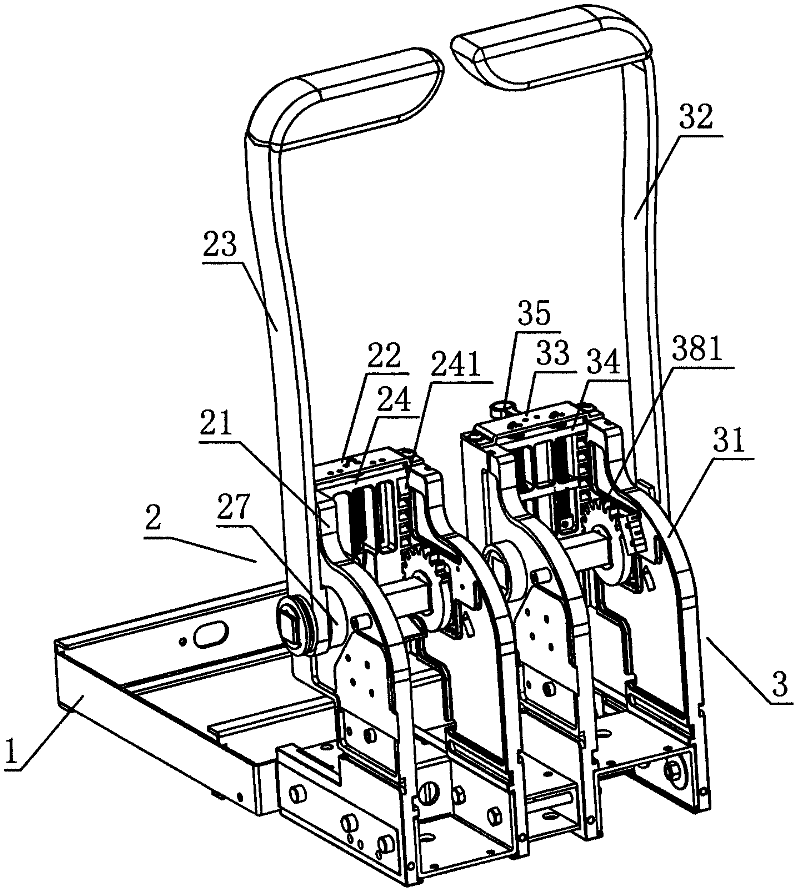

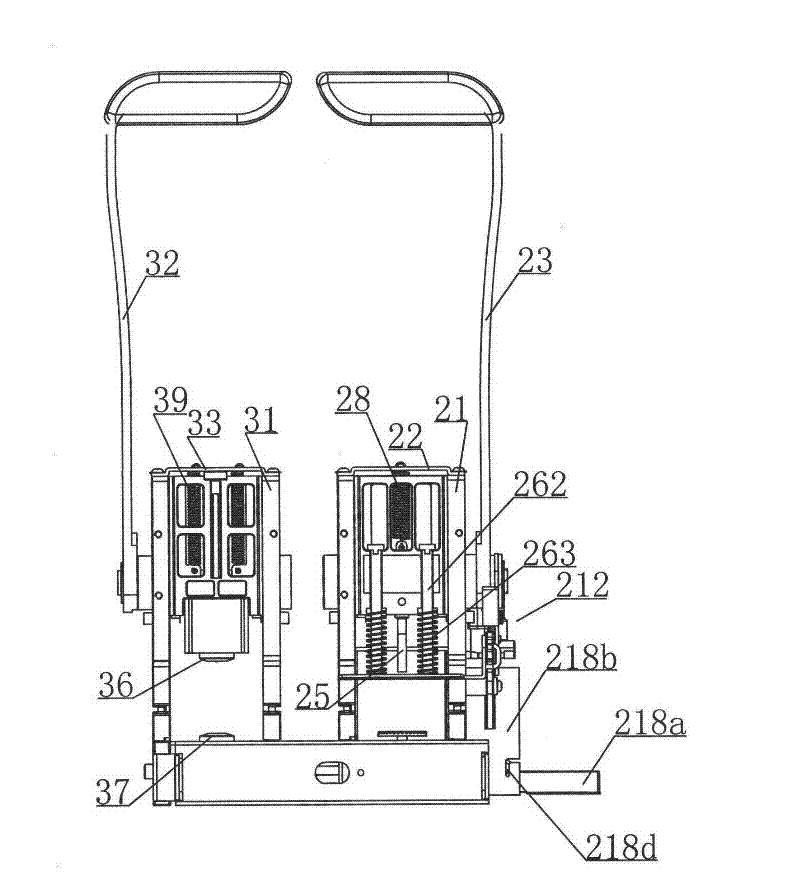

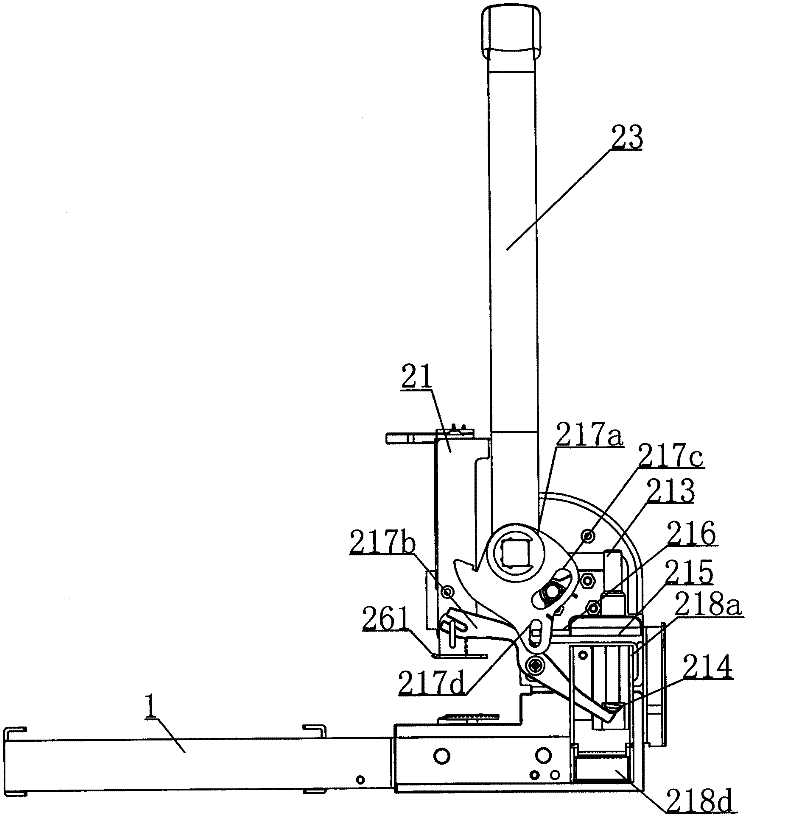

[0035] like Figure 1 to Figure 14 As shown, a punching hot riveting type precision binding machine includes a punching unit 2 fixed on a base 1, and the punching unit 2 includes a punching fixing seat 21, a cover plate 22, a handle 23, a punching slider 24, Drill 25, paper pressing device 26 and pipe cutting device 212, drill 25 and paper pressing device 26 are arranged on the bottom of punching slider 24, punching holder 21 is horizontally pierced with rotating shaft 27, handle 23 is fixed with rotating shaft 27 Connect, the both sides of rotating shaft 27 in the punching holder 21 are provided with gear 271, the both sides of punching holder 21 are provided with guide rails 211, the punching slider 24 is connected between the two guide rails 211, and the inside of the punching slider 24 is provided with There is a vertical rack 241 meshing with a gear 271, a cavity 242 is provided in the middle of the punching slider 24, the cover plate 22 is fixed on the top of the punchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com