Cutting device and method for bird leg and removing bone

A cutting equipment and deboning technology, applied in the direction of boning shears/bone crushers, etc., can solve the problems of difficult control of physical health, high labor intensity of workers, easy pollution during handling, etc., achieve compact structure, increase service life, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The poultry leg deboning and cutting equipment and method thereof of the present invention will be described in further detail below in conjunction with the accompanying drawings.

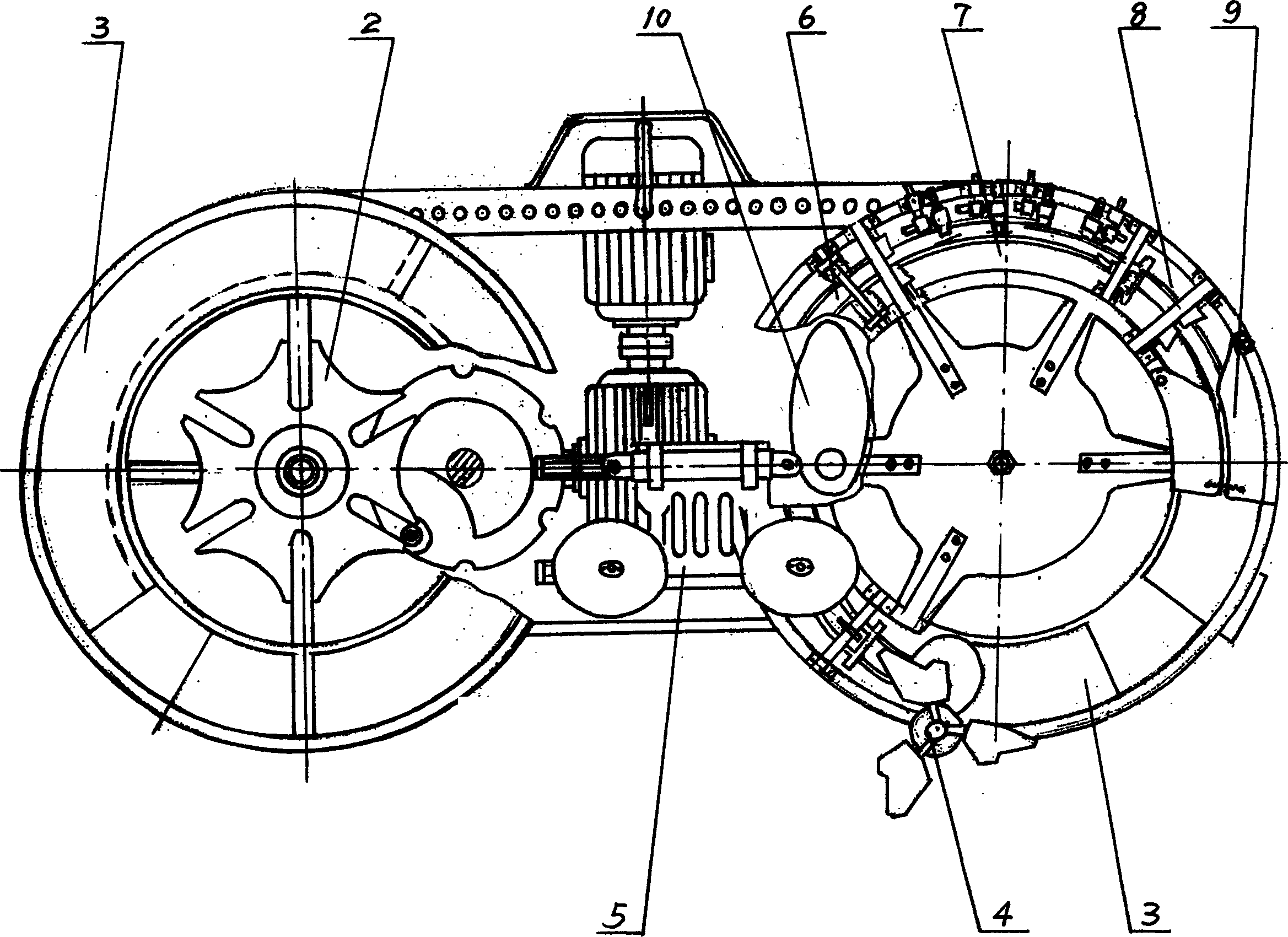

[0044] Such as figure 1 As shown, the poultry leg deboning cutting equipment of the present invention comprises a rotatable work surface 3 driven by a horse-type sheave indexing mechanism 2; the work surface 3 is provided with a feeding device 4, a spine cutting device 5, a cutting Leg meat device 6, peeling device 7, leg meat cutting device 8, bone removal and release device 9; all the above-mentioned devices are controlled by power system, transmission system and signal actuator 1, and the transmission system adopts sheave and gear transmission mechanism.

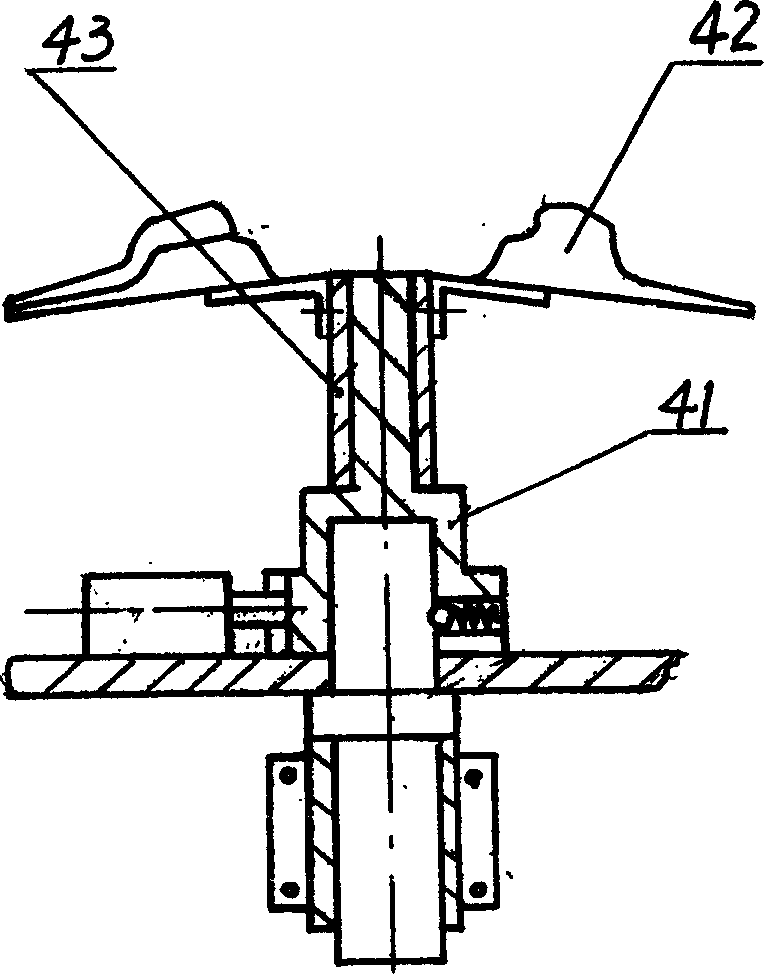

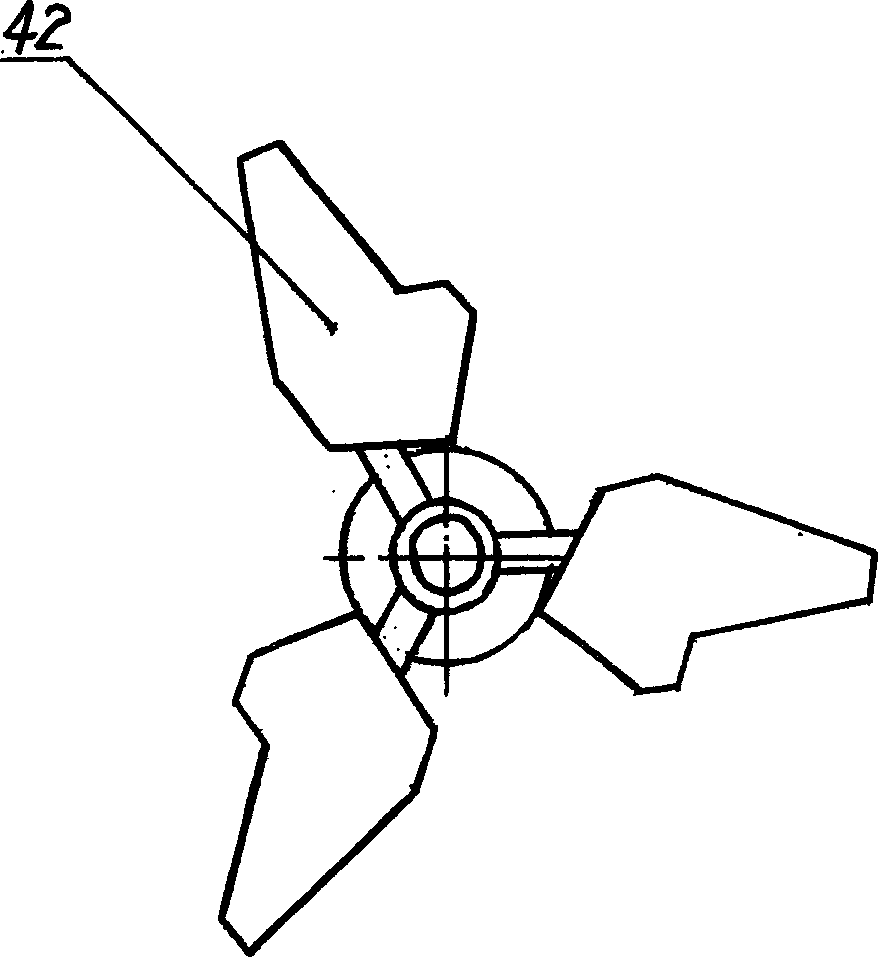

[0045] Fig. 2 shows the structure of the feeding device 4 adopted by the poultry leg deboning and cutting equipment of the present invention, including a ratchet control mechanism 41 and a feeding tray 42 positioned on the shaft, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com