Sliding block driving mechanism of multiple slide rod press machine

A driving device and press technology, applied in the field of presses, can solve problems such as non-adjustable reciprocating speed of sliders, troublesome assembly and maintenance, unfavorable balance of presses, etc., so as to improve work stability and safety, facilitate installation and maintenance, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

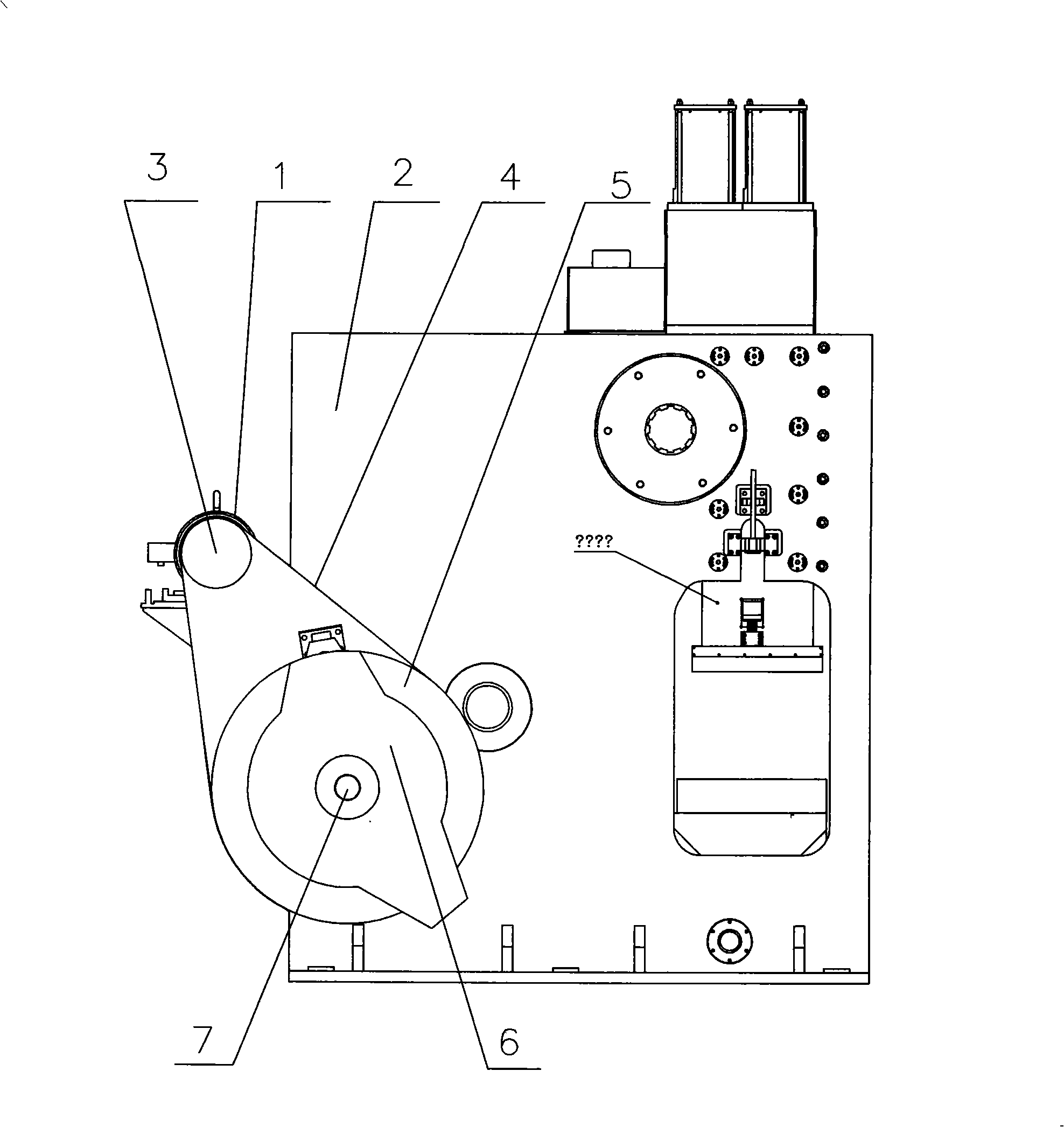

[0028] exist figure 1 Among them, a main motor (1) is installed on the bracket on one side of the frame (2) of the press as a power source. The driving force of the main motor (1) is transmitted to a flywheel (5) installed on the drive shaft (7) through a pulley (3) and a transmission belt (4), and a public The brake clutch (6) used is used to connect or disconnect the flywheel (5) from the drive shaft (7).

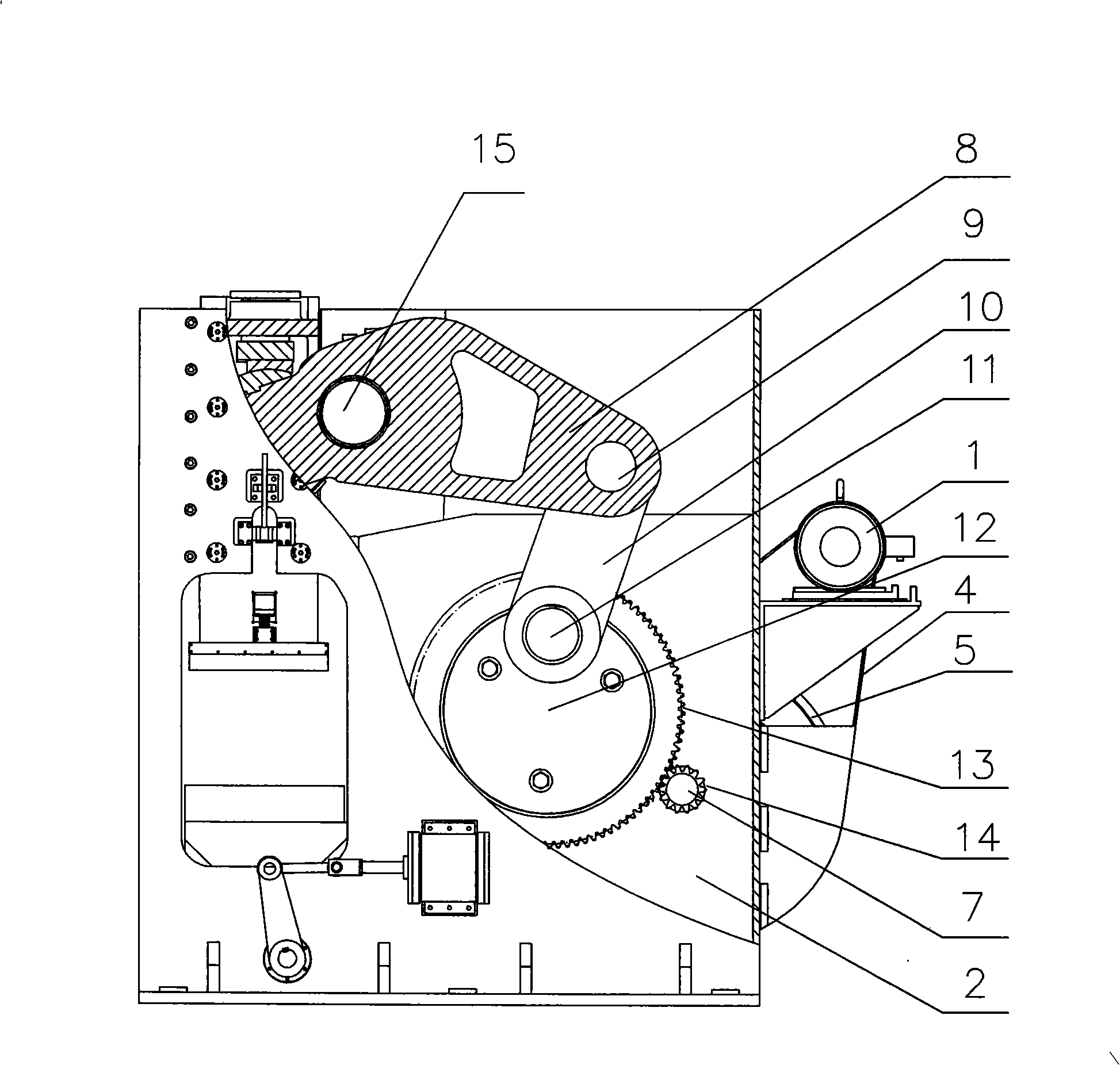

[0029] image 3 A schematic cross-sectional view of the drive structure of the press slider drive device of the present invention is given. Figure 4 A perspective view of the transmission structure of the drive device of the press of the present invention is given. exist image 3 , Figure 4 Among them, a base end of a transmission toggle lever (8) is rotatably connected to a drive link (10) by a connecting shaft (9), and the other end of the drive link (10) is rotatably mounted on a crankshaft ( 12) on the eccentric crank throw (11).

[0030] The crankshaft (12) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com