Patents

Literature

125 results about "Eccentric loading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Eccentric loading on column. When the load acting on the column is offset from the centroid of the column, then it establishes the bending of column along with the axial stress. This offset loading of the column is referred as eccentric loading. Eccentric loading will not be at the middle of cross-section of the column.

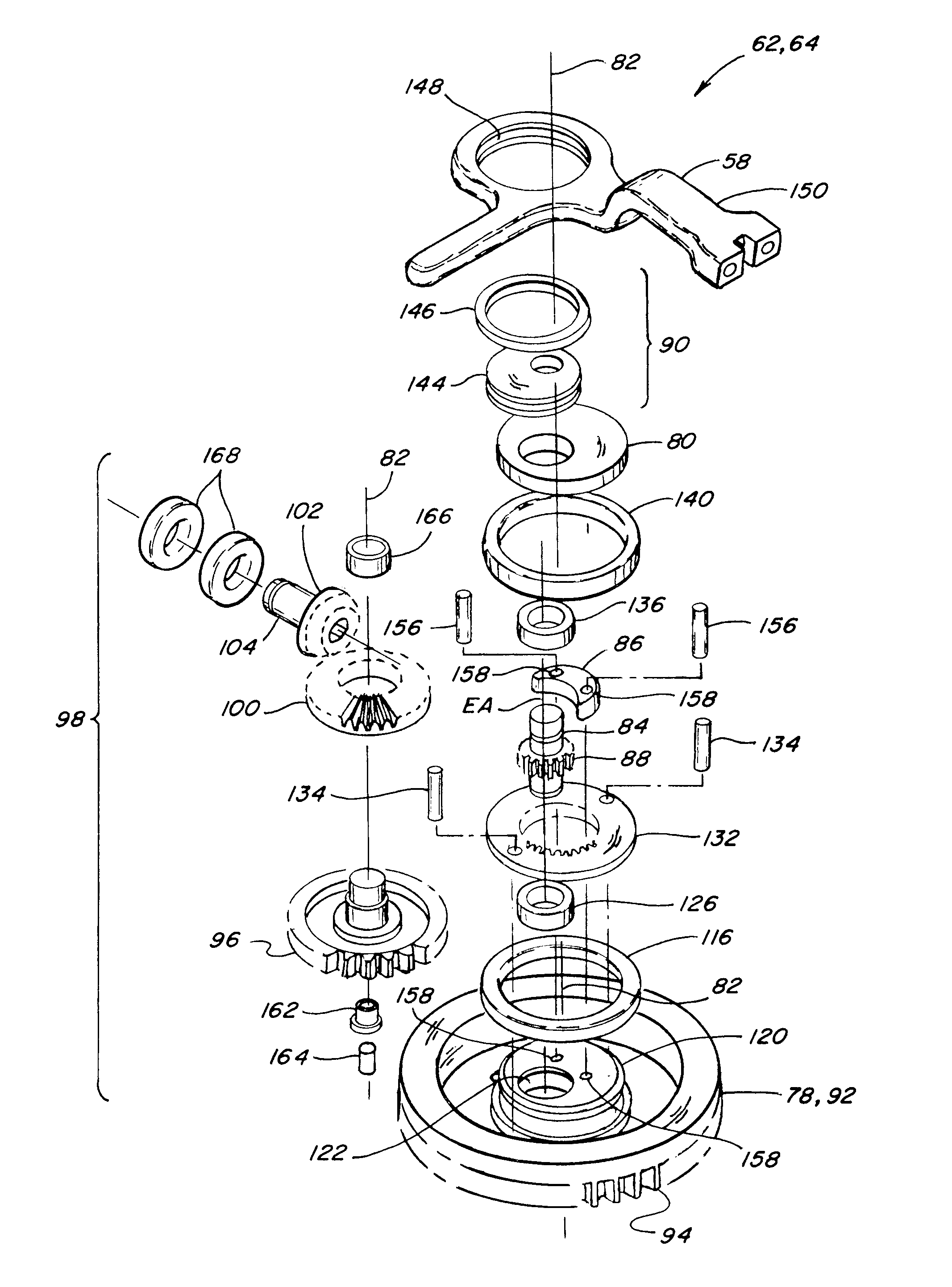

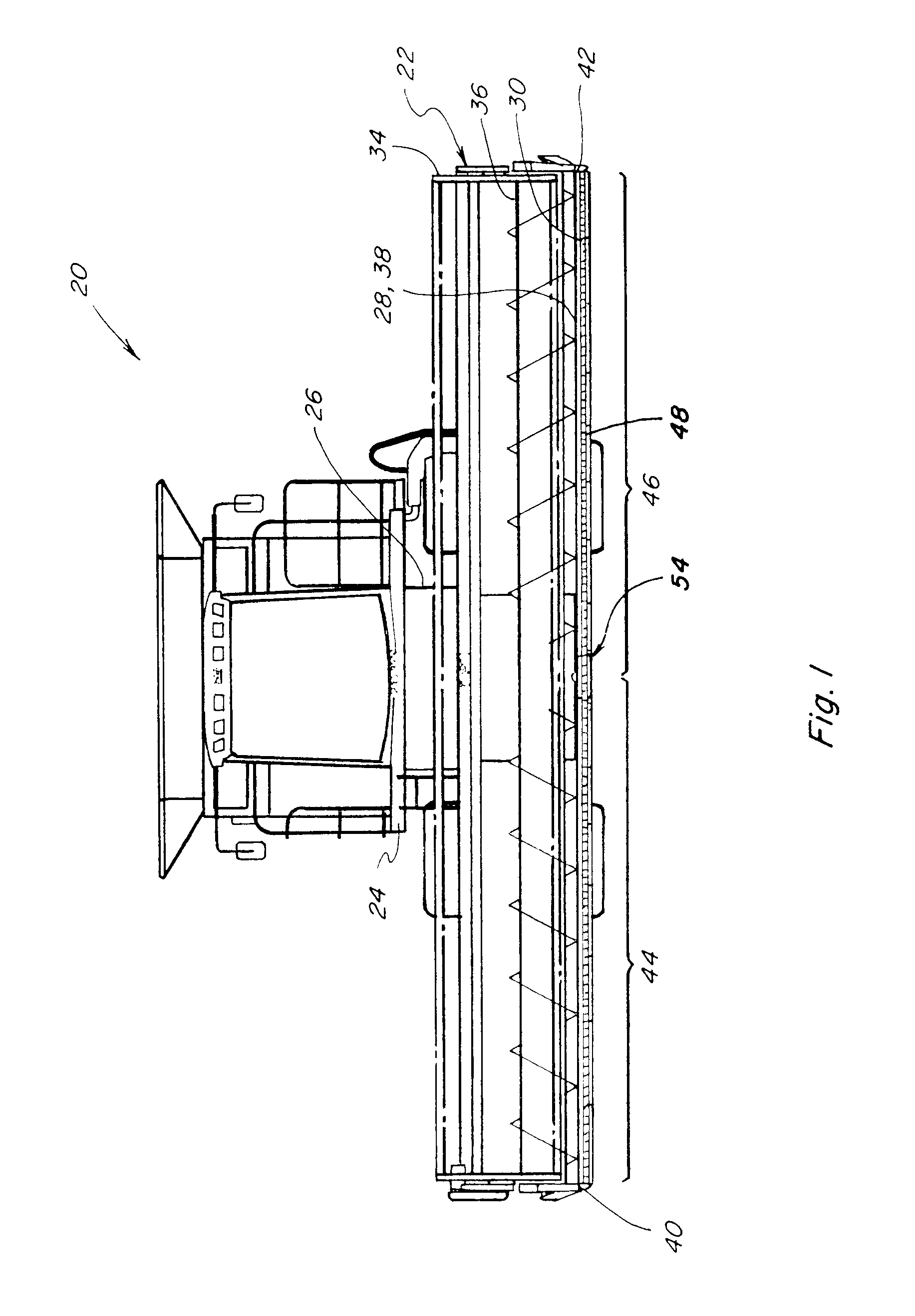

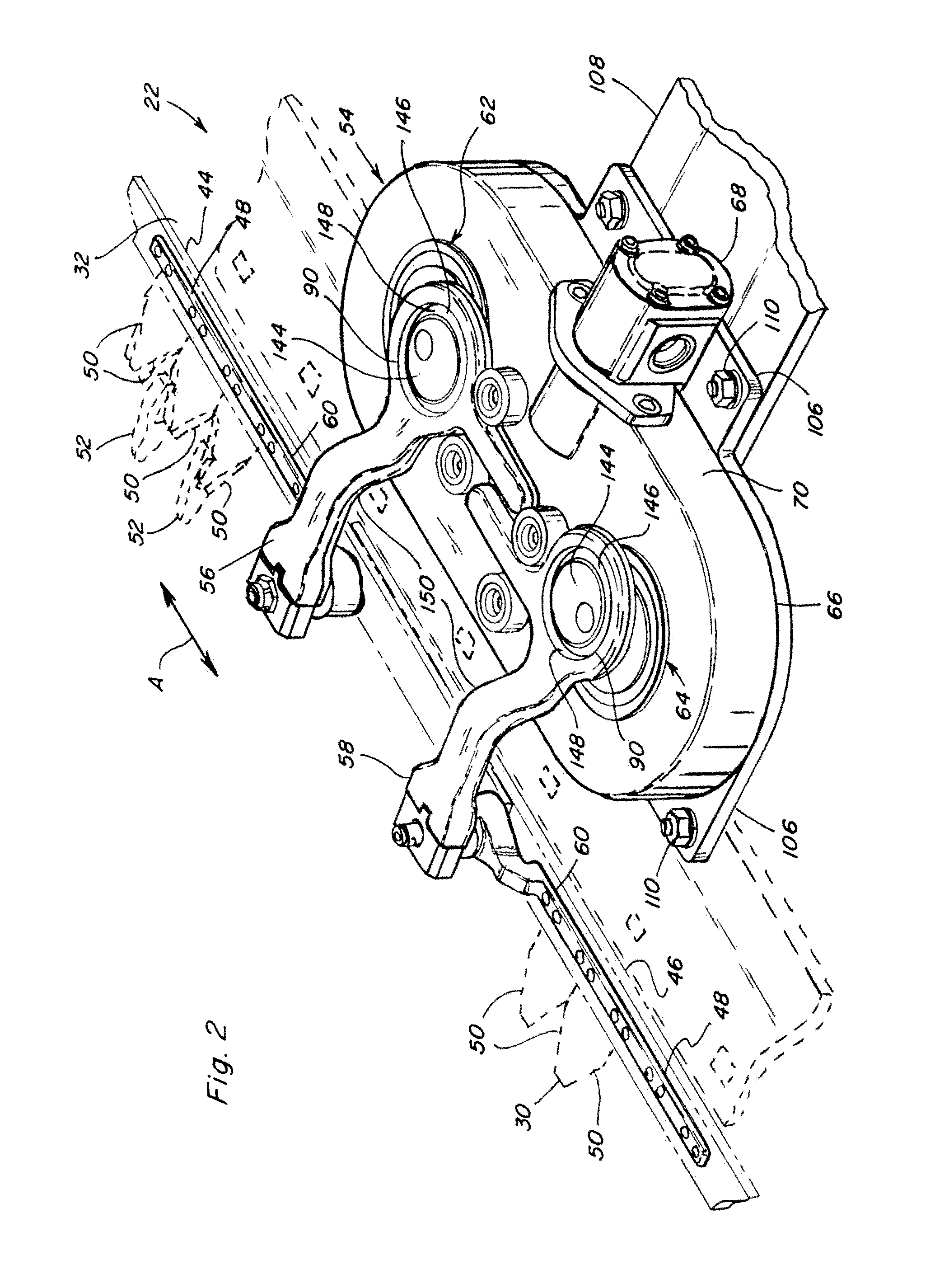

Dual flywheel axially compact epicyclical drive

The epicyclical drive incorporates a dual flywheel carrying a pinion in a balanced axially compact assembly. The assembly includes a counterweight for the pinion nested between the flywheels, which also connects the flywheels and transfers loading conditions therebetween, to reduce and distribute torsional and eccentric loading conditions and reduce vibrations. The use of a second flywheel also provides an improved rotary seal capability for keeping out dust, debris and moisture. The drive is adapted for incorporation into a floor of a header of an agricultural harvesting machine for reciprocatingly driving a sickle thereof, advantageously jointly with a mirror image companion drive in a side by side relationship and timed such that forces generated by the reciprocating actions are cancelled.

Owner:BLUE LEAF I P INC

Vibrationary exercise equipment

InactiveUS20100311552A1Good vibration transmission characteristicReduce fatigueChiropractic devicesVibration massageMuscle trainingEngineering

A muscle training apparatus arranged for cyclic concentric and eccentric loading phases including load imposition means arranged for a user to exercise against load variation means arranged for varying the load as between concentric and eccentric loading phases, a vibrator operational to apply vibration between the user and the load, a controller operational to control the vibrator and to vary the extent of vibration as between concentric and eccentric phases.

Owner:SOUTH BANK UNIV ENTERPRISES LTD

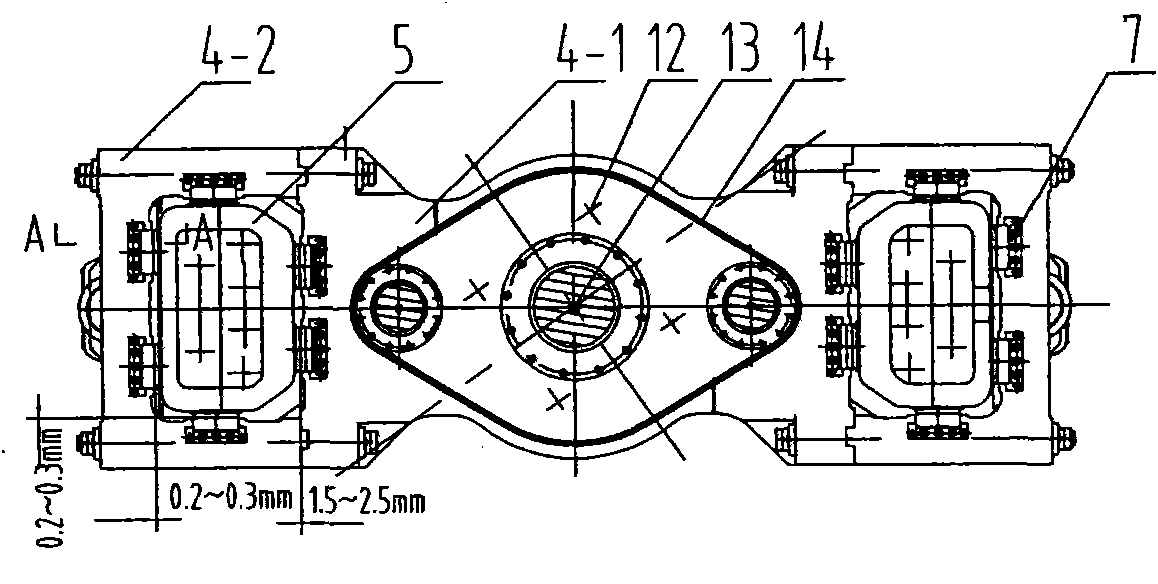

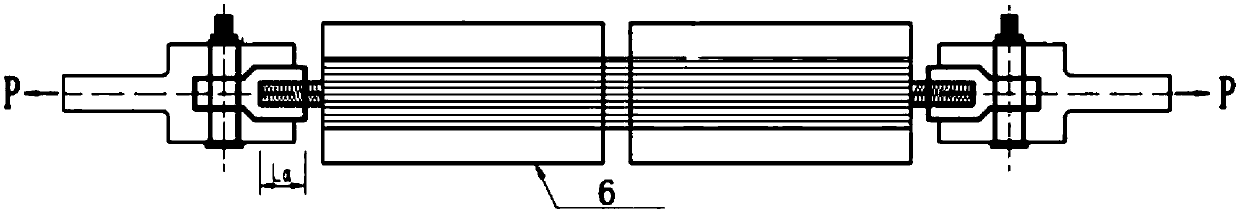

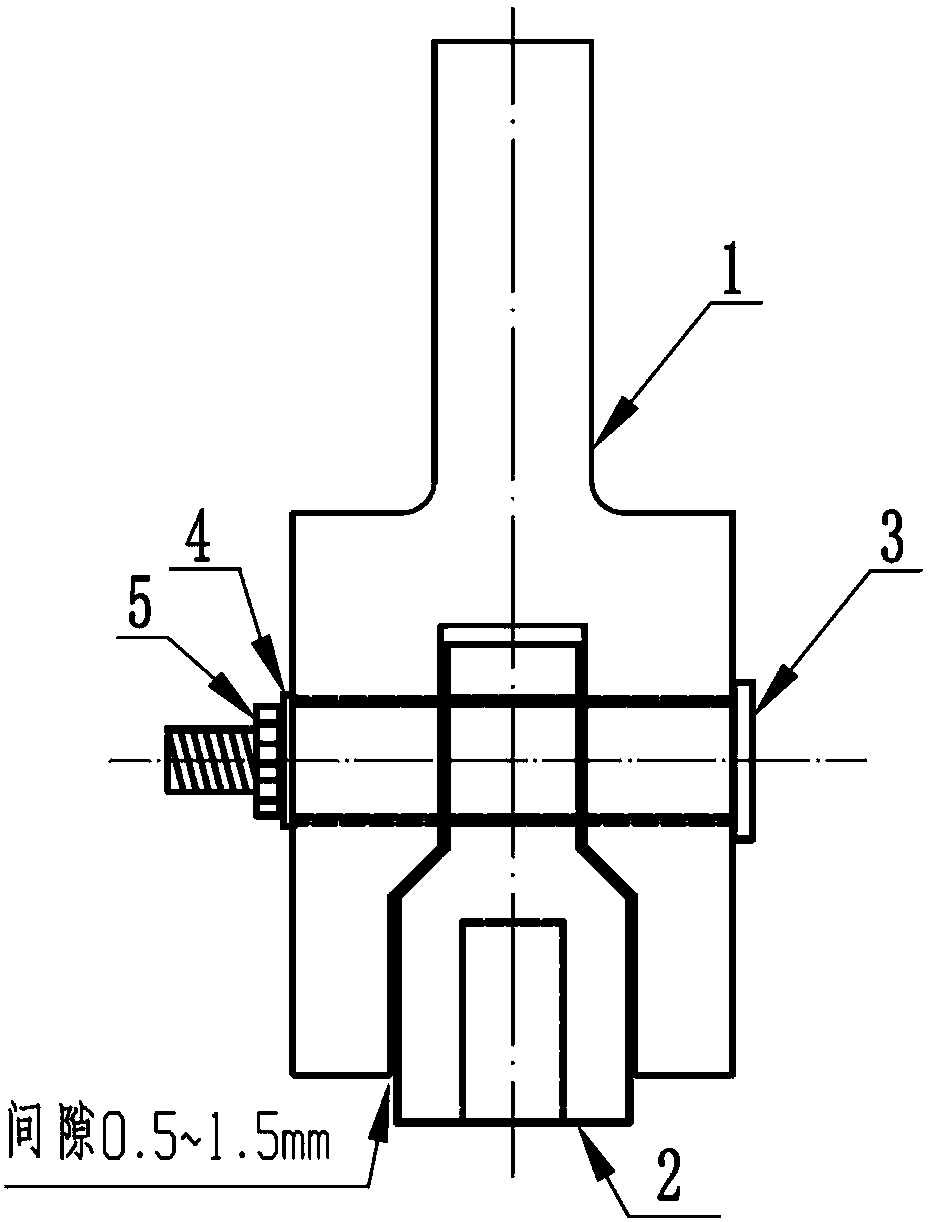

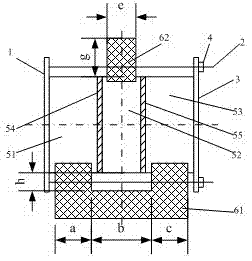

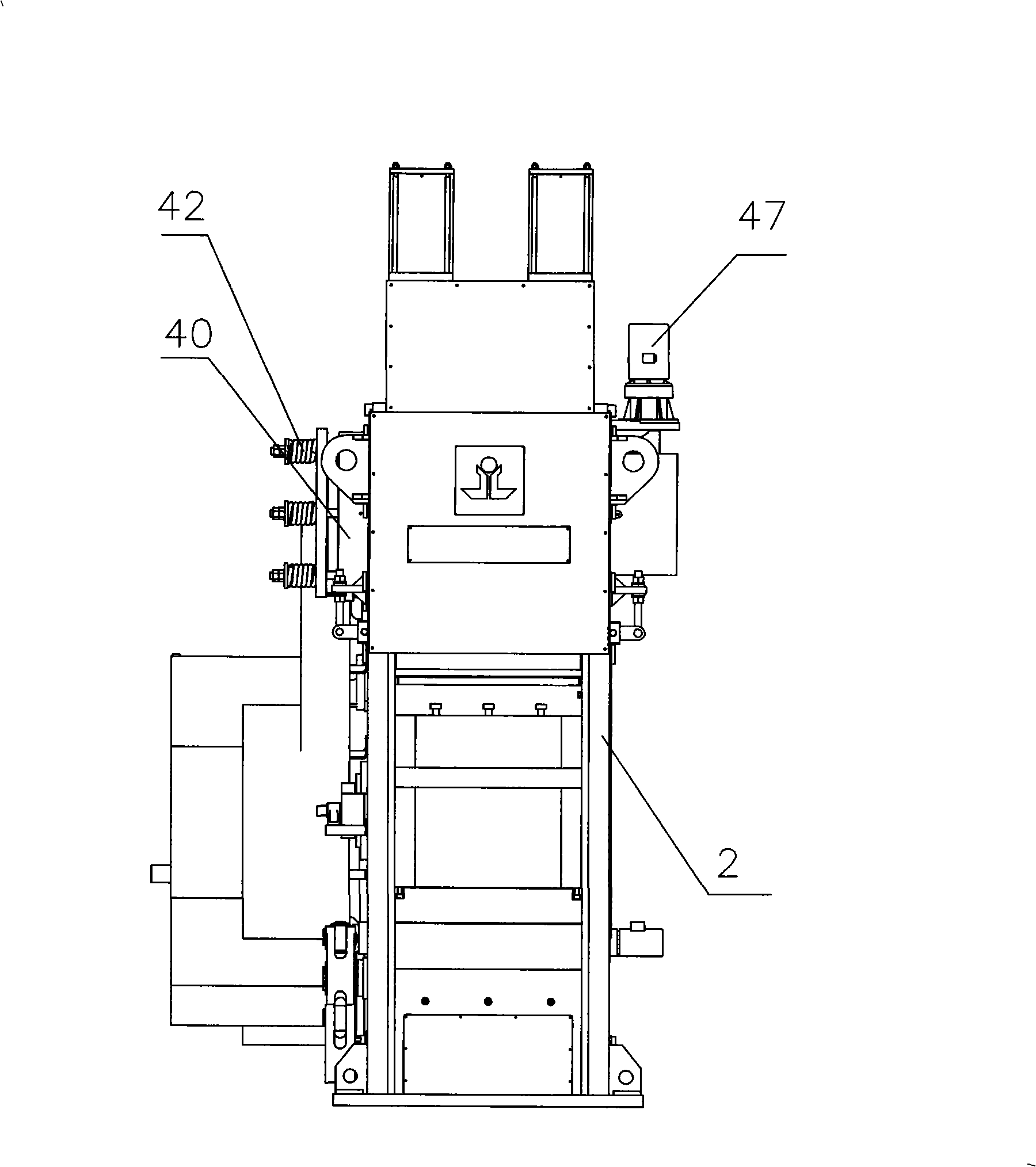

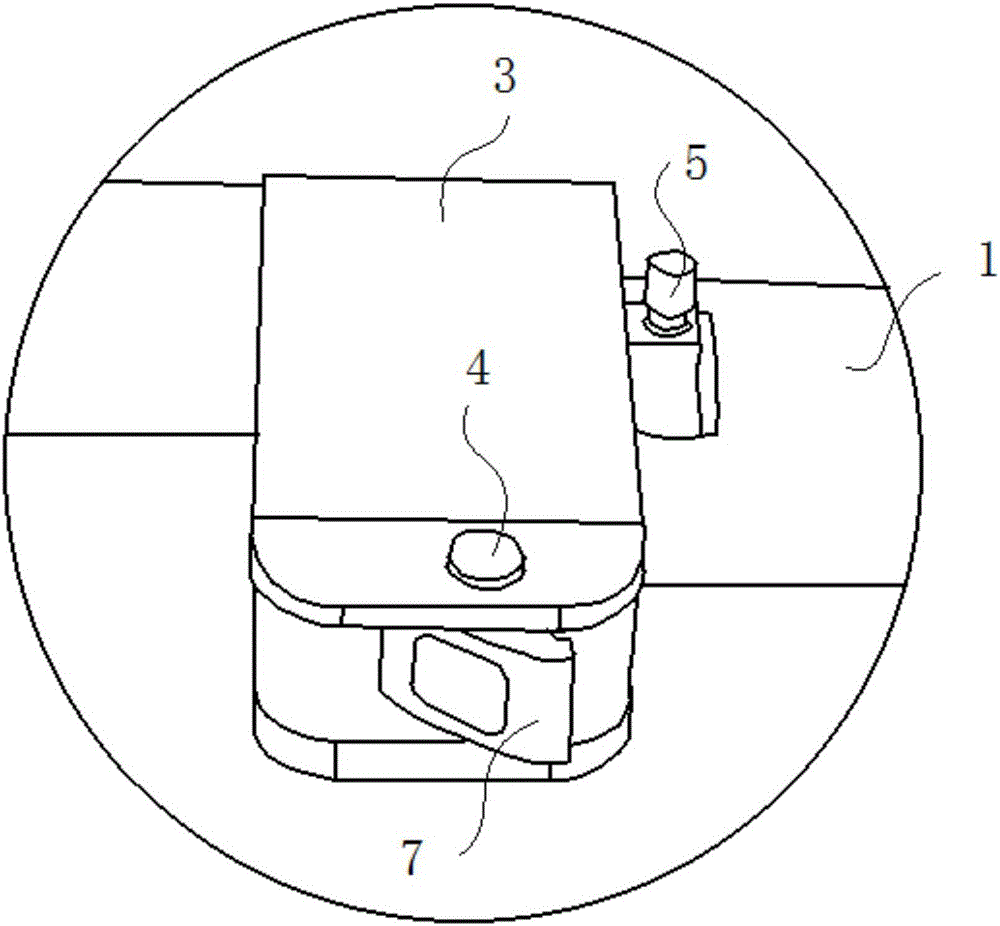

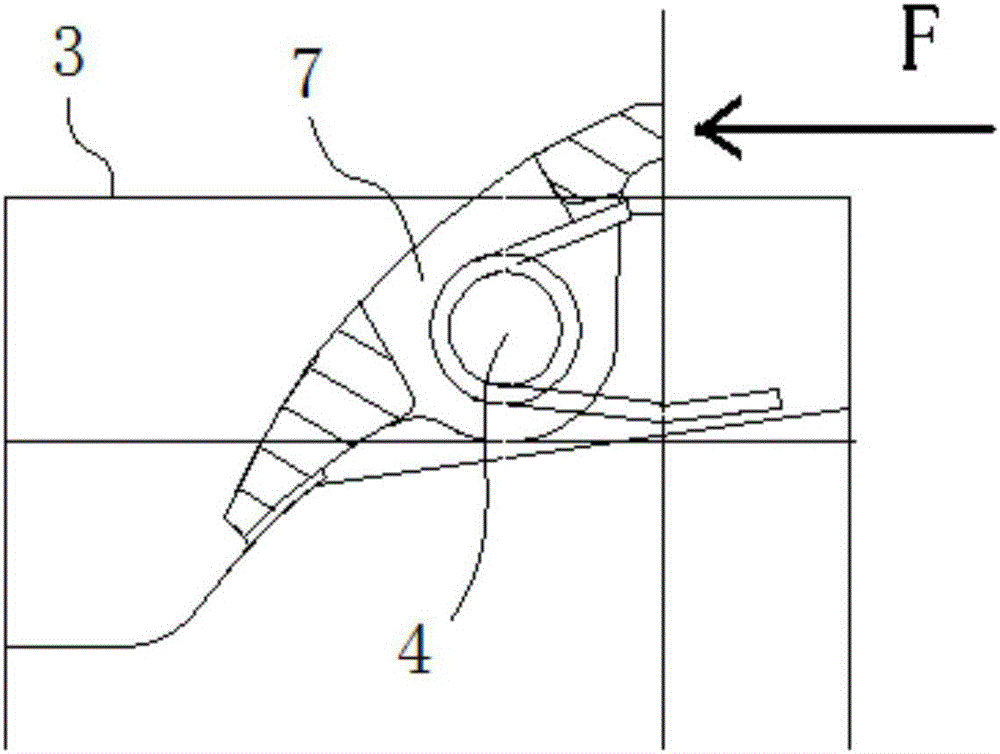

Load-deflection resistant loading system for free hydraulic forging press

ActiveCN101837416AHigh dimensional accuracyImprove forging qualityForging press drivesEngineeringCopper

The invention discloses a load-deflection resistance loading system for a free forging hydraulic press, and relates to the forging hydraulic press. The invention solves the problem that in the conventional loading system for the free forging hydraulic press, as a plunger and a movable cross beam are in rigid connection, the movable cross beam is subjected to eccentric load in the eccentric forging process to accelerate abrasion of a guide copper sleeve and a seal to cause earlier failure and leakage of seal of a main working cylinder so as to cause poor eccentric forging resistance of the loading system. The loading system for transmitting forging pressure of the free forging hydraulic press is characterized in that the combination movable cross beam with an overlong guide structure, fully enclosed wedge-shaped plane guide devices which can adjust gaps of the peripheries of upright posts, a double concave ball hinged short cylindrical rocker shaft device of which the main plunger is connected with the movable cross beam, and a levelness sensor monitoring device of the movable cross beam are adopted on the free forging hydraulic press. The load-deflection resistant loading system not only can be applied to various free forging hydraulic presses, but also can be popularized and applied to other vertical hydraulic presses suitable for the process.

Owner:TAIYUAN HEAVY IND

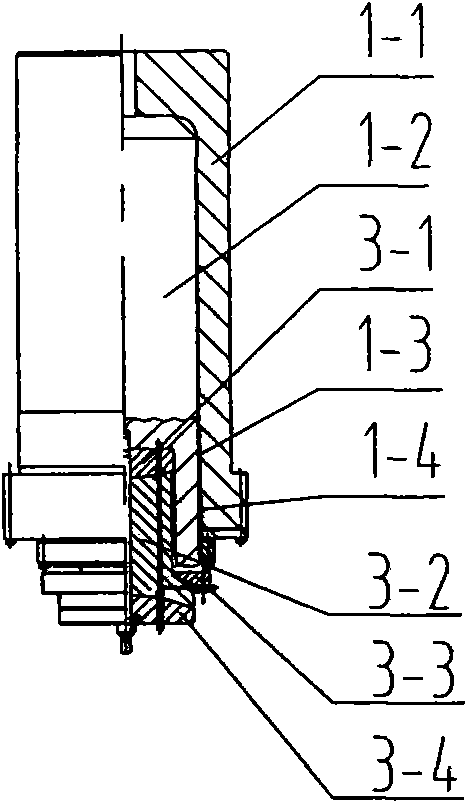

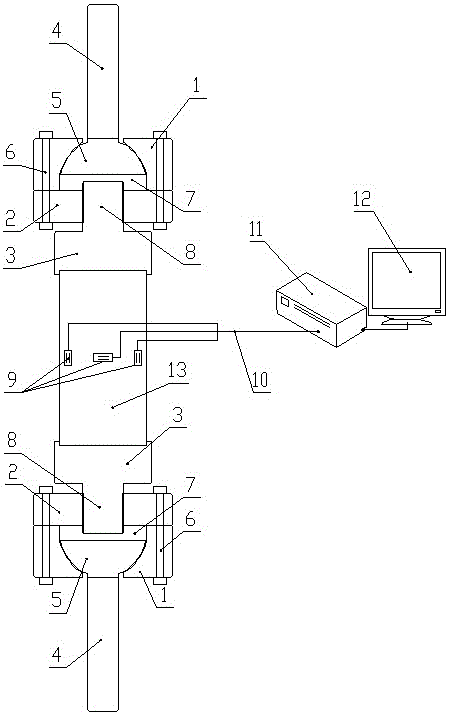

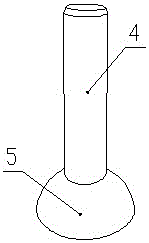

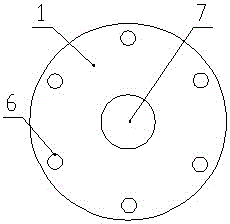

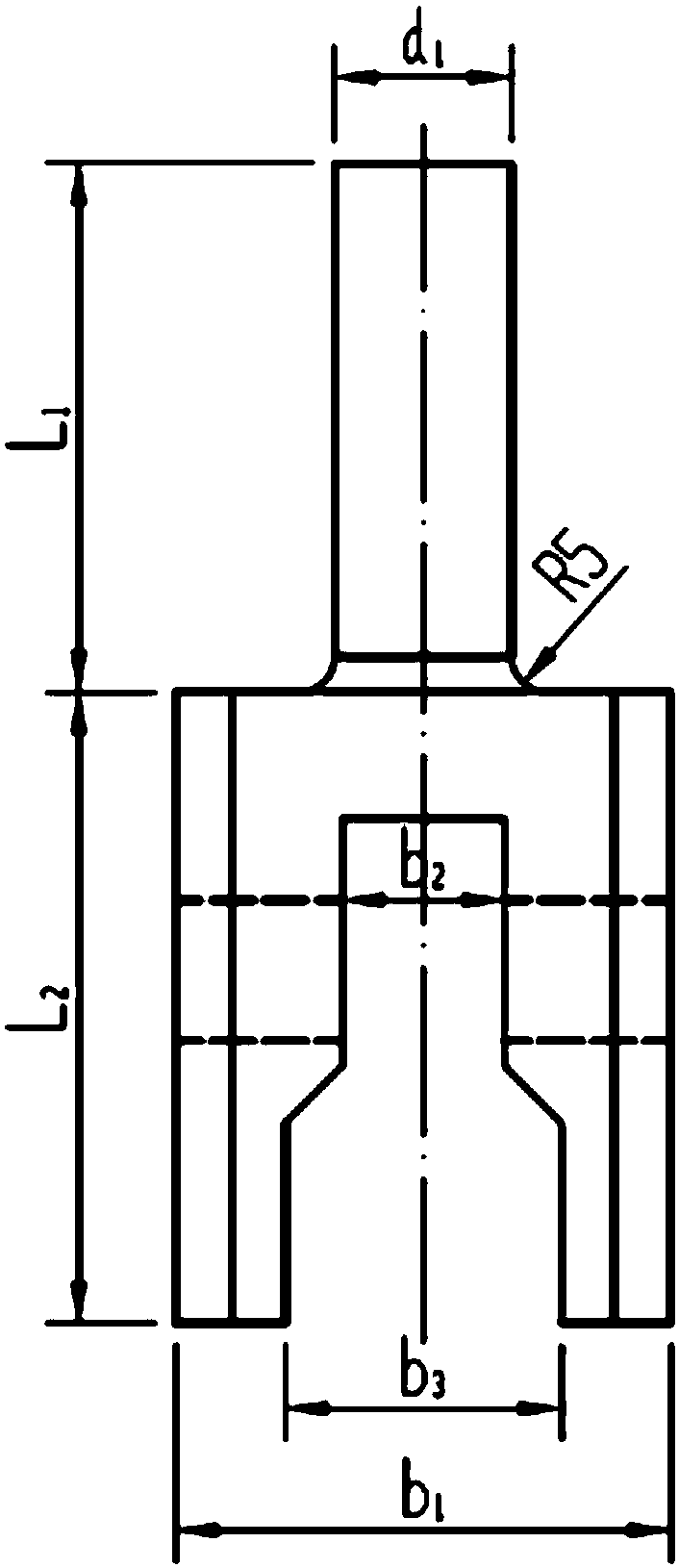

Device and measuring method for measuring direct stretching mechanical parameter of rock

InactiveCN105910908AInfluence deflectionAffect rotationPreparing sample for investigationMaterial strength using tensile/compressive forcesEngineeringEccentric loading

The invention relates to a device and a method for measuring a direct stretching mechanical parameter of rock. The device comprises a strain gage, a resistance strain gauge, a computer, an upper pull rod component and a lower pull rod component which are same in structure, wherein the upper pull rod component comprises a ball hinge pull rod, an upper connecting base, a lower connecting base and a clamping sleeve; a mounting hole is formed at the center of the upper connecting base; the ball hinge pull rod is inserted into the mounting hole; the clamping sleeve is in threaded connection with the interior of the threaded hole of the lower connecting base through a connecting pillar; a rock sample is arranged between the clamping sleeves of the upper pull rod component and the lower pull rod component; the strain gage is arranged on the surface of the rock sample. The device applies the stretching load to the ball hinge pull rod so as to perform direct stretching test on the rock sample; the eccentric loading when the rock sample is pulled can be effectively avoided; the operation is simple and convenient; the rock sample is conveniently detached; the loading deforming condition of the rock sample can be directly measured through the strain gage; the measurement is accurate.

Owner:HENAN POLYTECHNIC UNIV

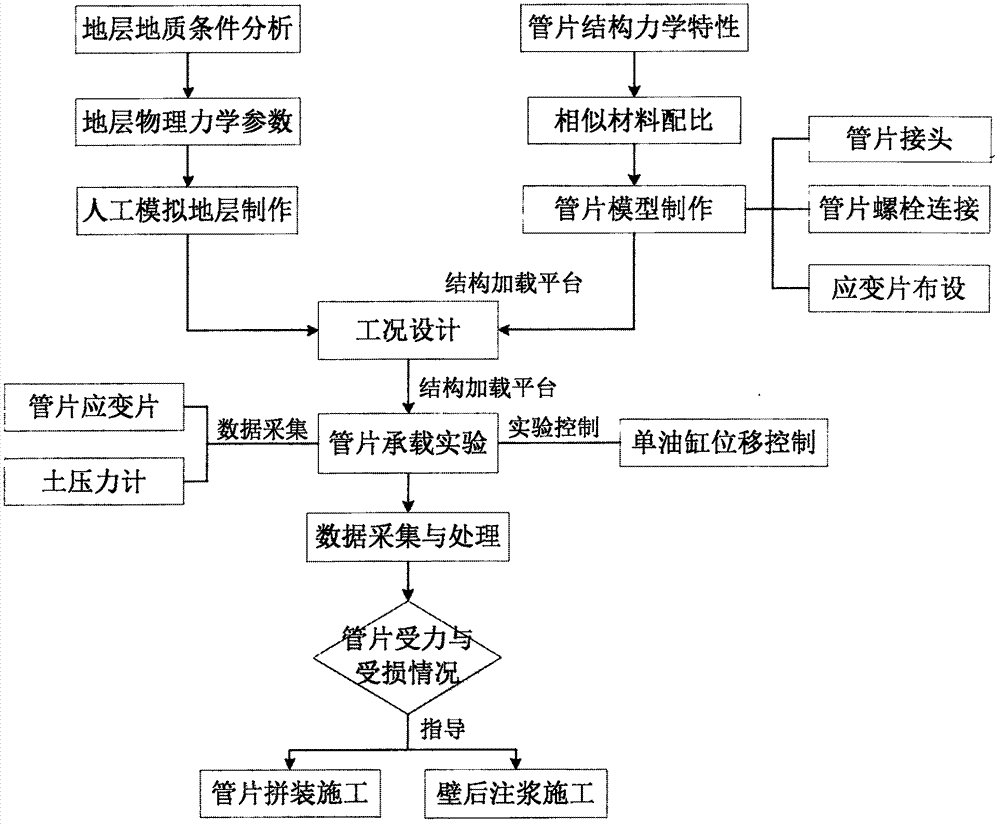

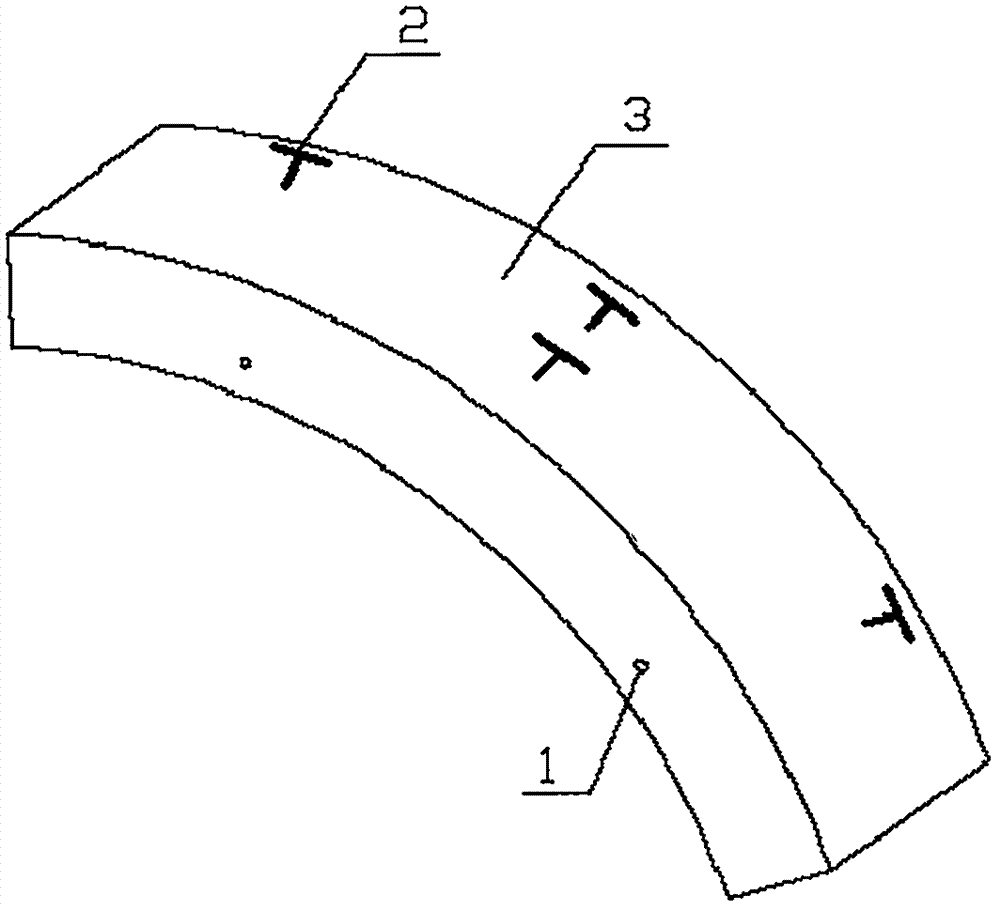

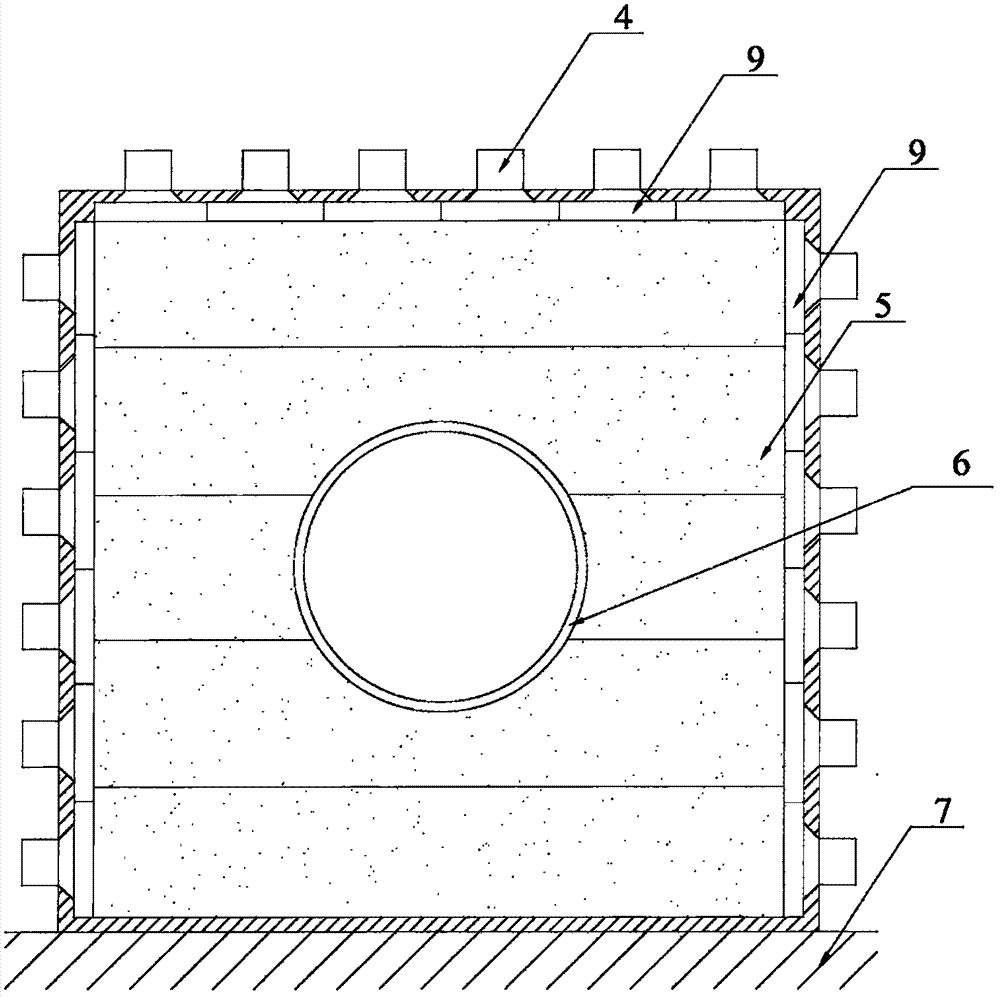

Modeling method for realizing structural mechanical performance of pipe segment three-dimensional loading

ActiveCN107301305AAvoid interferenceGeometric CADSpecial data processing applicationsSystems designData acquisition

The invention discloses a modeling method for realizing structural mechanical performance of pipe segment three-dimensional loading. The modeling method mainly includes: analyzing and remodeling geological conditions; making a stratum model; making a contraction rule pipe segment model; designing a pipe segment monitoring system; performing different loading model experiments on pipe segments; collecting and analyzing data. By adopting the method, pipe segment structural mechanical characteristic experiments on working conditions of horizontal and vertical different loading, of pipe segment rings, pipe segment axial geostress difference and pipe segment staggering and eccentric loading in different geological environments can be realized, real simulation of pipe segment loading environment is realized through stratum remodeling, pipe segment structure is processed by utilizing gypsum to realize detailed construction of the pipe segment structure, joint screwed connection is realized, annular and longitudinal strain gauges are distributed for whole-ring pipe segments to realize monitoring of internal force of the pipe segments, and technical support is provided for subsequent shield pipe segment assembling and wall posterior grouting parameter setting.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

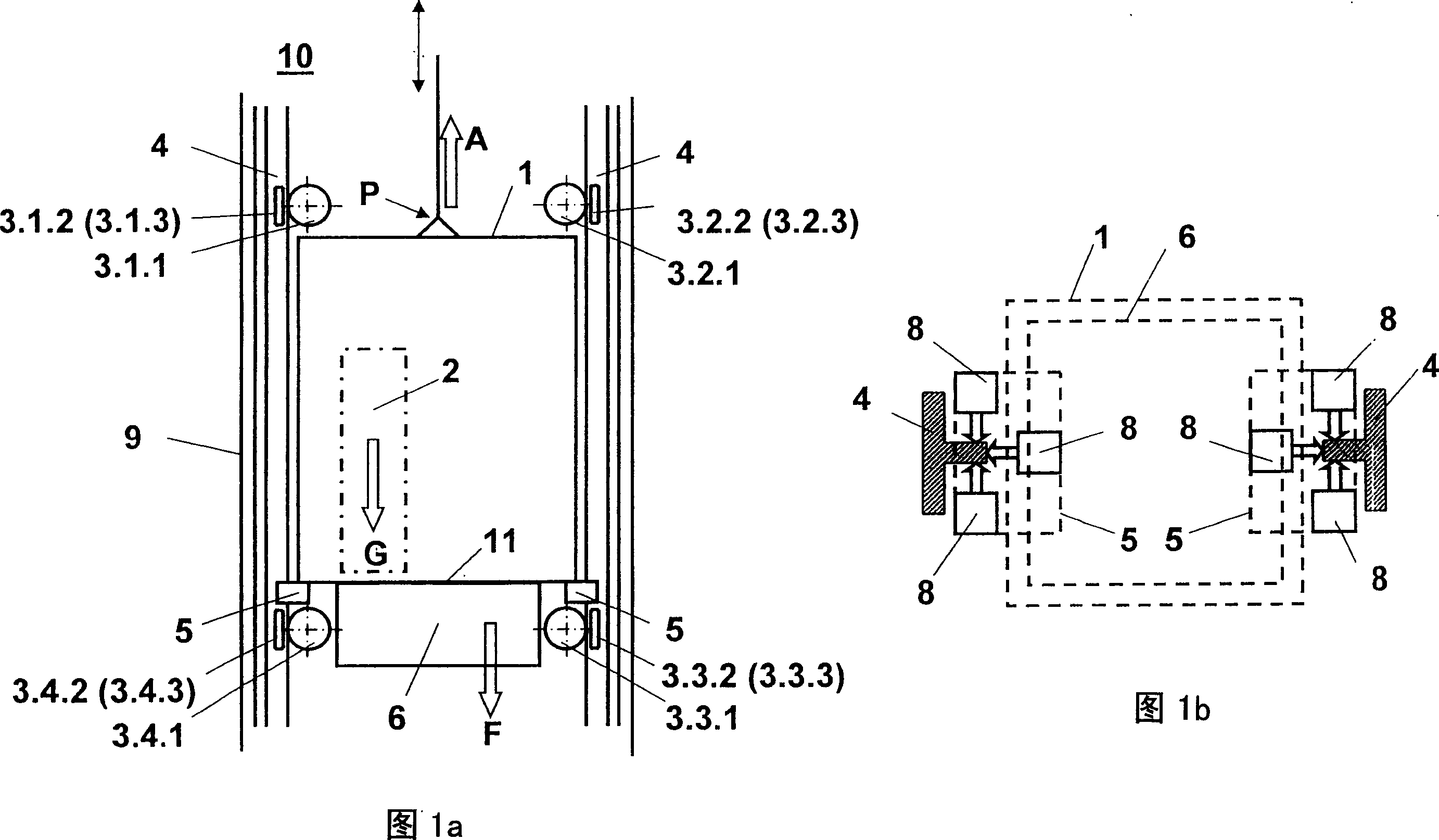

Elevator carriage with horizontal balancing system

The cabin (1) is moved vertically in an elevator shaft (9) with vertical guide rails (4) and has spring-mounted rollers (3.1.1 - 3.4.1) for guiding the cabin along the rails and an arrangement for carrying out weight balancing in the event of eccentric loading of the cabin with a hydraulic balancing system (6).

Owner:INVENTIO AG

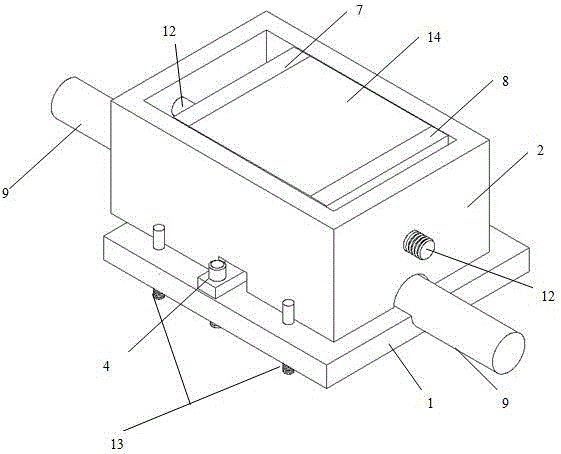

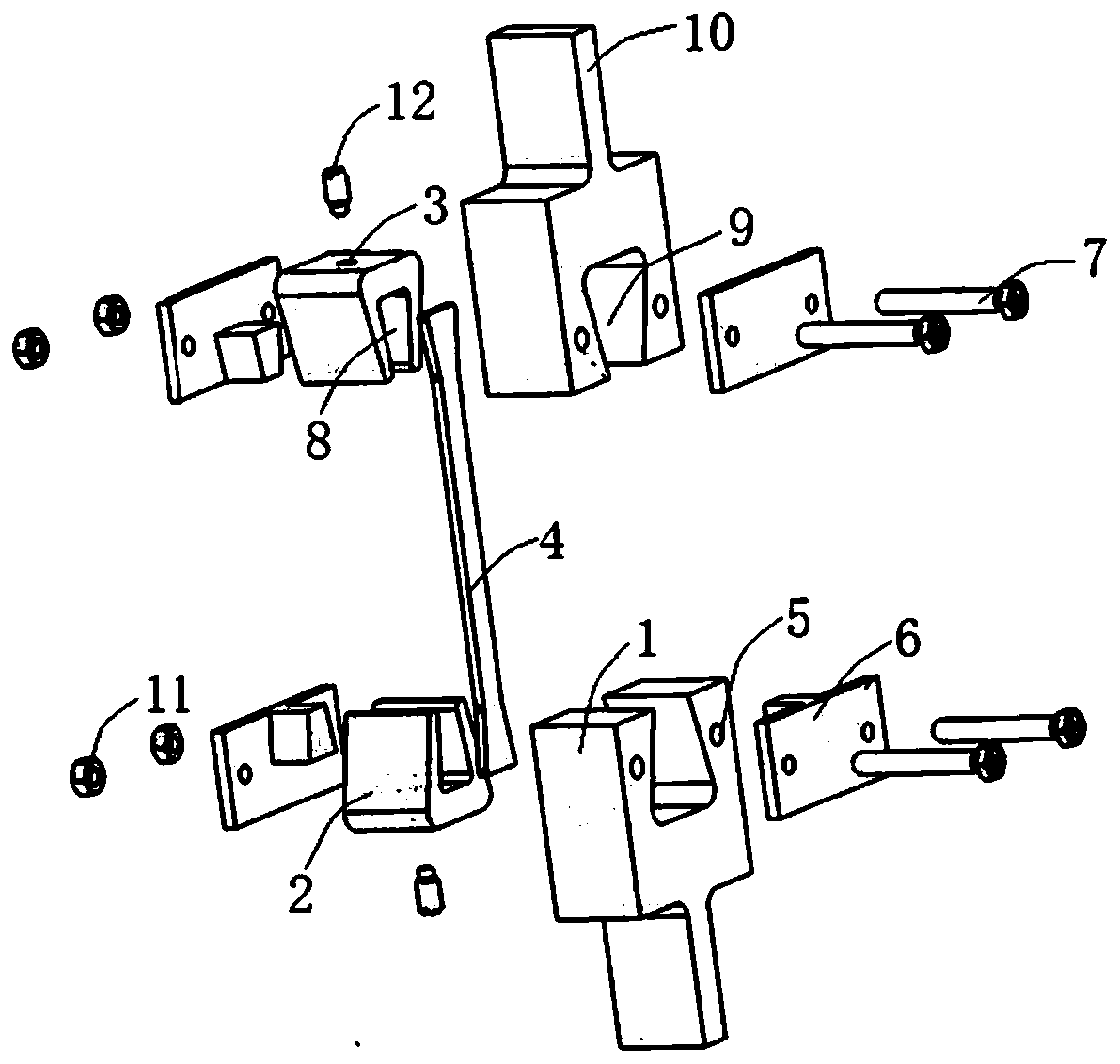

Clamping device and method for anti-eccentric loading of double-shearing experiment

InactiveCN107817172AAvoid accidental peel damageSmall sizeMaterial strength using steady shearing forcesEccentric loadingSurface loading

The invention discloses a clamping device for anti-eccentric loading of double-shearing experiment. The clamping device comprises two combined loading heads with the same structure, and each combinedloading head comprises a fork clamp, a flying ring and a bolt pin connecting device, wherein a straight bar part clamped by a tester is arranged at one end of the fork clamp, an open slot is formed inthe center of the other end of the fork clamp along the axis of the fork clamp, one end of the flying ring is coaxially hinged into the open slot of the fork clamp by the bolt pin connecting device vertically running through the fork clamp, and a threaded hole is formed in the other end of the flying ring. The invention also discloses a clamping method for anti-eccentric loading of double-shearing experiment. The clamping device and the clamping method disclosed by the invention can automatically counteract torque caused by clamping a test piece with the tester while the test piece is installed, balance bending moment caused by manufacture error, and prevent the test piece from being twisted and / or being bent due to eccentric action, so as to eliminate the influence of eccentric loading to result of intra-surface loading experiment, ensure a pure shearing loading state and realize pure double-shearing experiment.

Owner:SOUTH CHINA UNIV OF TECH

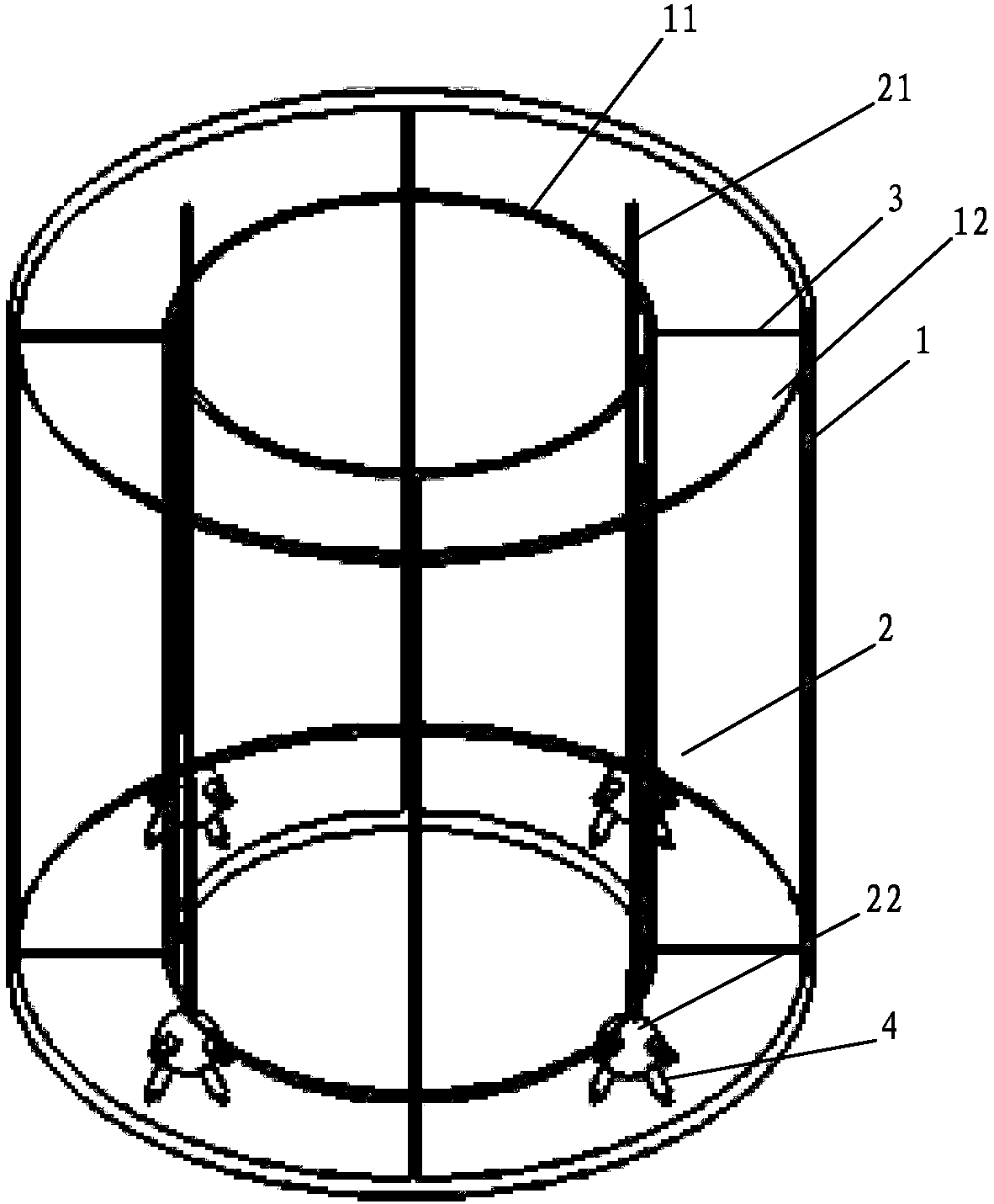

Shock absorbing device of tuned mass damper (TMD) for draught fan and mounting method thereof

InactiveCN108443396AVibration damping fast and timelySwing fast and in timeInertia force compensationSpringsEngineeringEccentric loading

The invention discloses a shock absorbing device of a tuned mass damper (TMD) for a draught fan. The device comprises a tower barrel and a plurality of pendulum devices mounted in the tower barrel, wherein an inner sleeve is fixedly arranged in the tower barrel in a sleeved manner; the inner sleeve is fixedly connected to the tower barrel through a partition plate and divides the space between thetower barrel and the inner sleeve into a plurality of built-in cavities; and the pendulum devices can be mounted in the built-in cavities in a swinging mode. Each pendulum device comprises a connecting rope and a pendulum ball, wherein one end of the connecting rope is vertically connected to the upper end of the tower barrel while the other end of the connecting rope is connected to the pendulumball, and the pendulum ball is opposite to the moving direction of the vibrated tower barrel under the inertial action force. The invention further discloses a mounting method. With adoption of a structure that the plurality of pendulum dampers are uniformly distributed in the circumferential direction of the tower barrel, a condition of an eccentric load is avoided, the swinging direction of thependulum balls is not limited, and the pendulum balls can swing all around at 360 degrees, so that the direction is changed anytime as the vibrating direction of the tower barrel is changed, and therefore, a purpose of absorbing shock of the tower barrel quickly and immediately is achieved.

Owner:GUANGDONG UNIV OF TECH

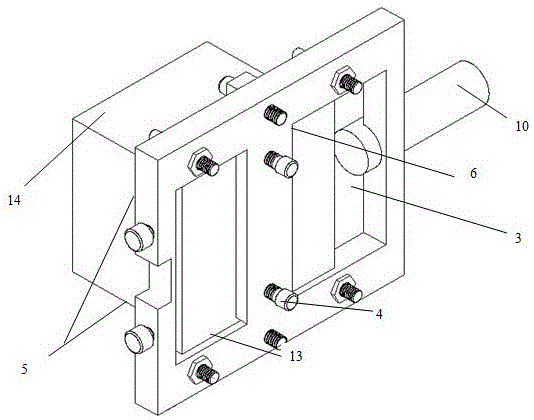

Steel-concrete interface shear force connecting piece fatigue performance test apparatus and application method thereof

ActiveCN105842093AReduce volumeGain fatigueMaterial strength using repeated/pulsating forcesEngineeringEccentric loading

The invention discloses a steel-concrete interface shear force connecting piece fatigue performance test apparatus and an application method thereof. The apparatus comprises a lower clamp, an upper clamp, pressure plates, a positioning cylindrical pin, lateral set bolts, height adjusting bolts, spherical bolts and pads; the lower clamp is provided with a groove used for accommodating a test piece; the upper surface of a steel plate are arranged on the upper surface of the lower clamp through the pressure plates and the height adjusting bolts; the steel plate is compacted by the lateral set bolts; the pads comprise a left push plate and a right pull plate, and are arranged at two sides of concrete and clinging to the test piece; the upper clamp is arranged above the lower clamp according to the positions of the pressure plates and the test piece, and the handle position of the upper clamp aligns at the handle position of the lower clamp to guarantee the centers of the handles being in the interface of the test piece, that is a shear surface; he lower clamp is provided with the positioning cylindrical pin; and the left and right spherical bolts are screwed to make the push plate and the pull plate respectively cling to the left side surface and the right side surface of the test piece. Influences of eccentric loading can be corrected in the invention to obtain the fatigue performance of the shear force connecting piece under cycle load.

Owner:ZHEJIANG UNIV

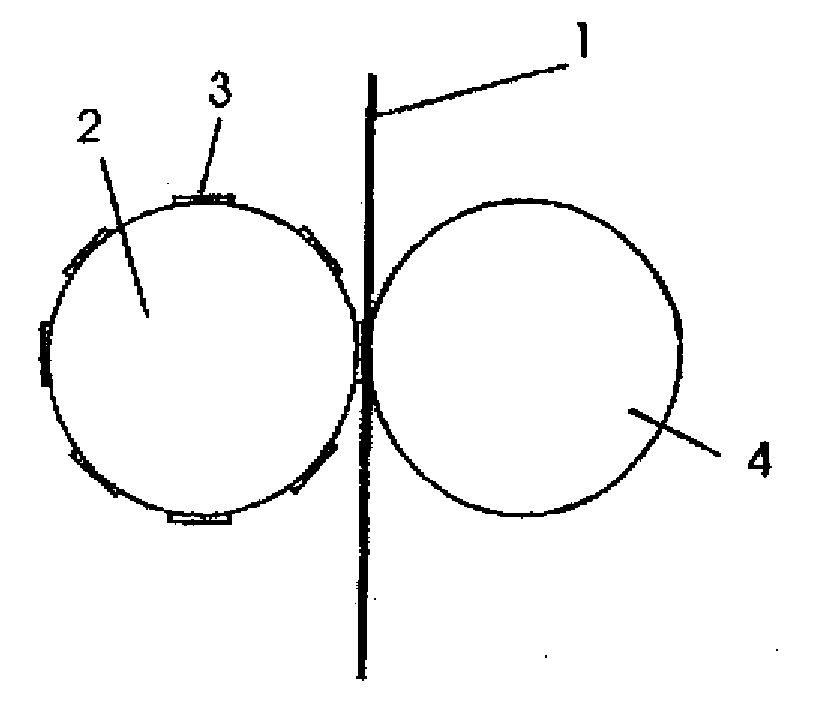

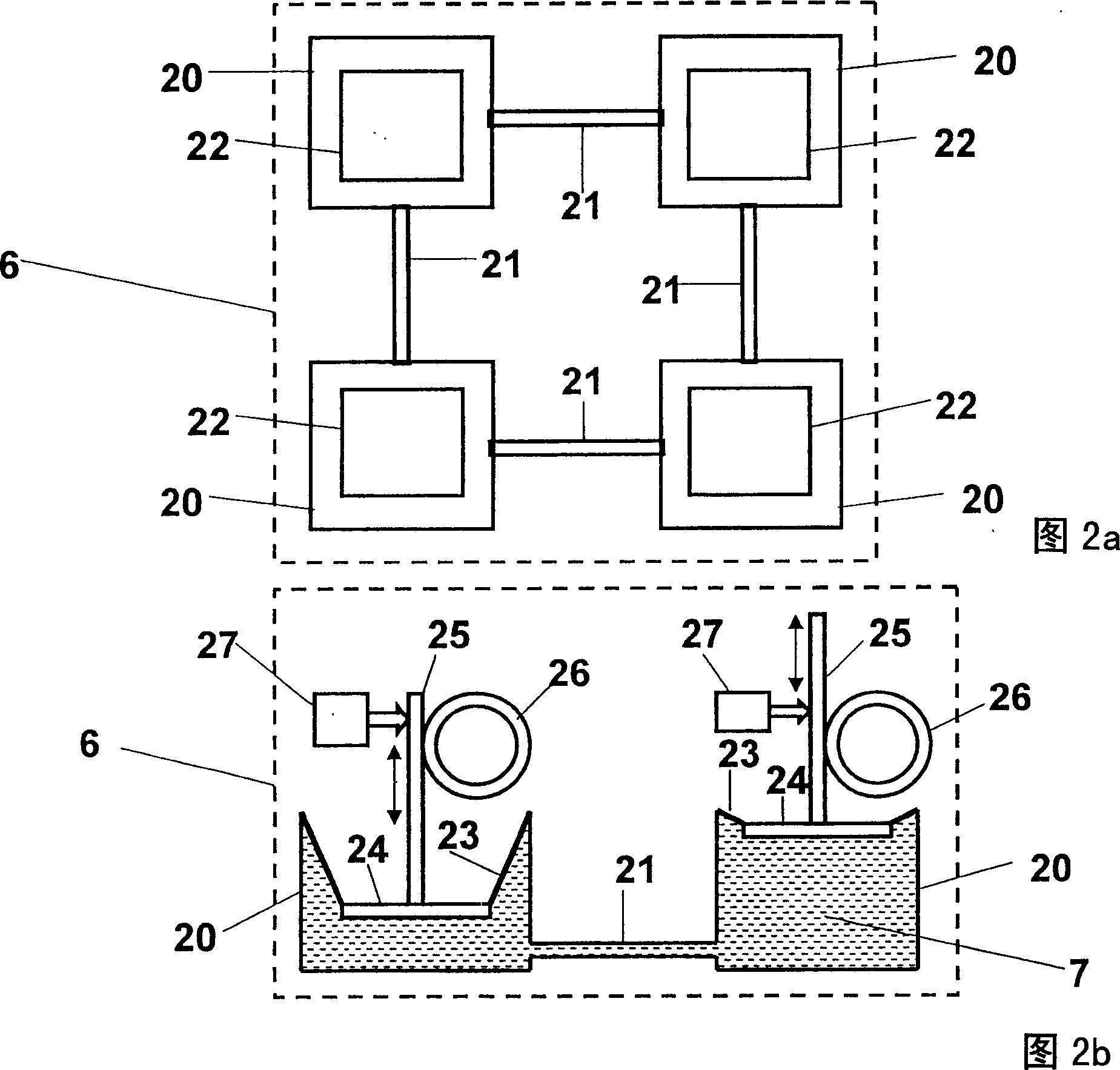

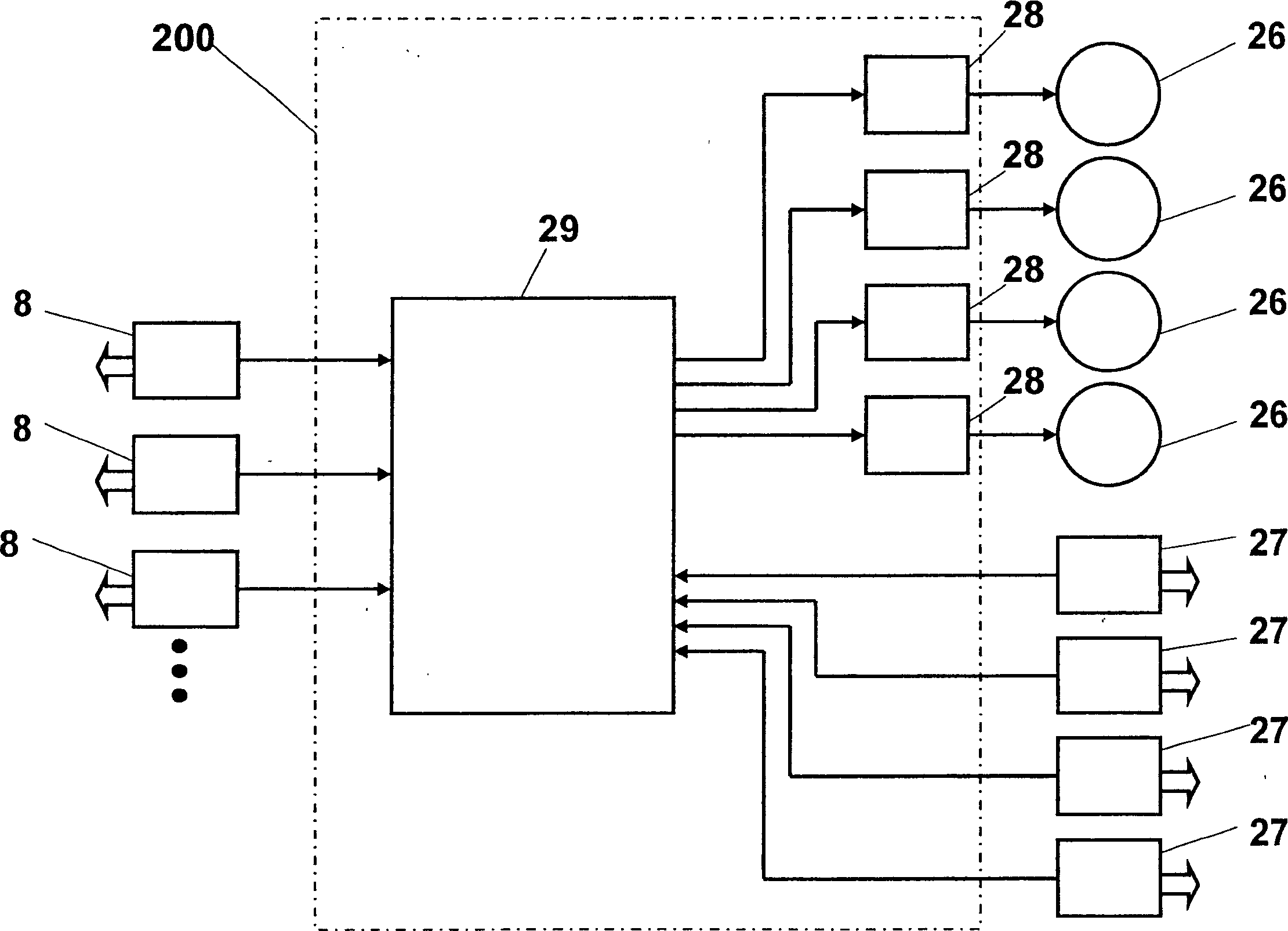

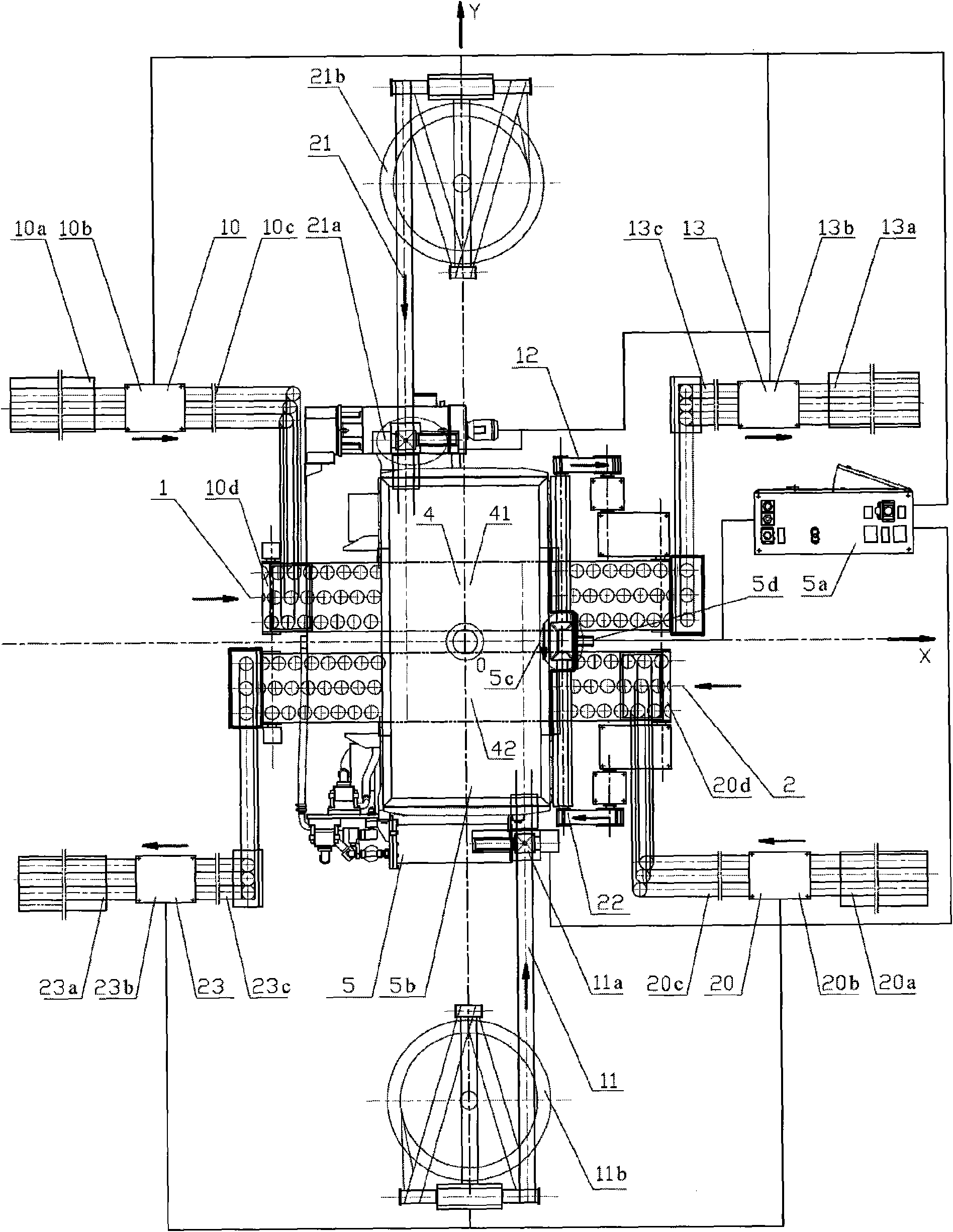

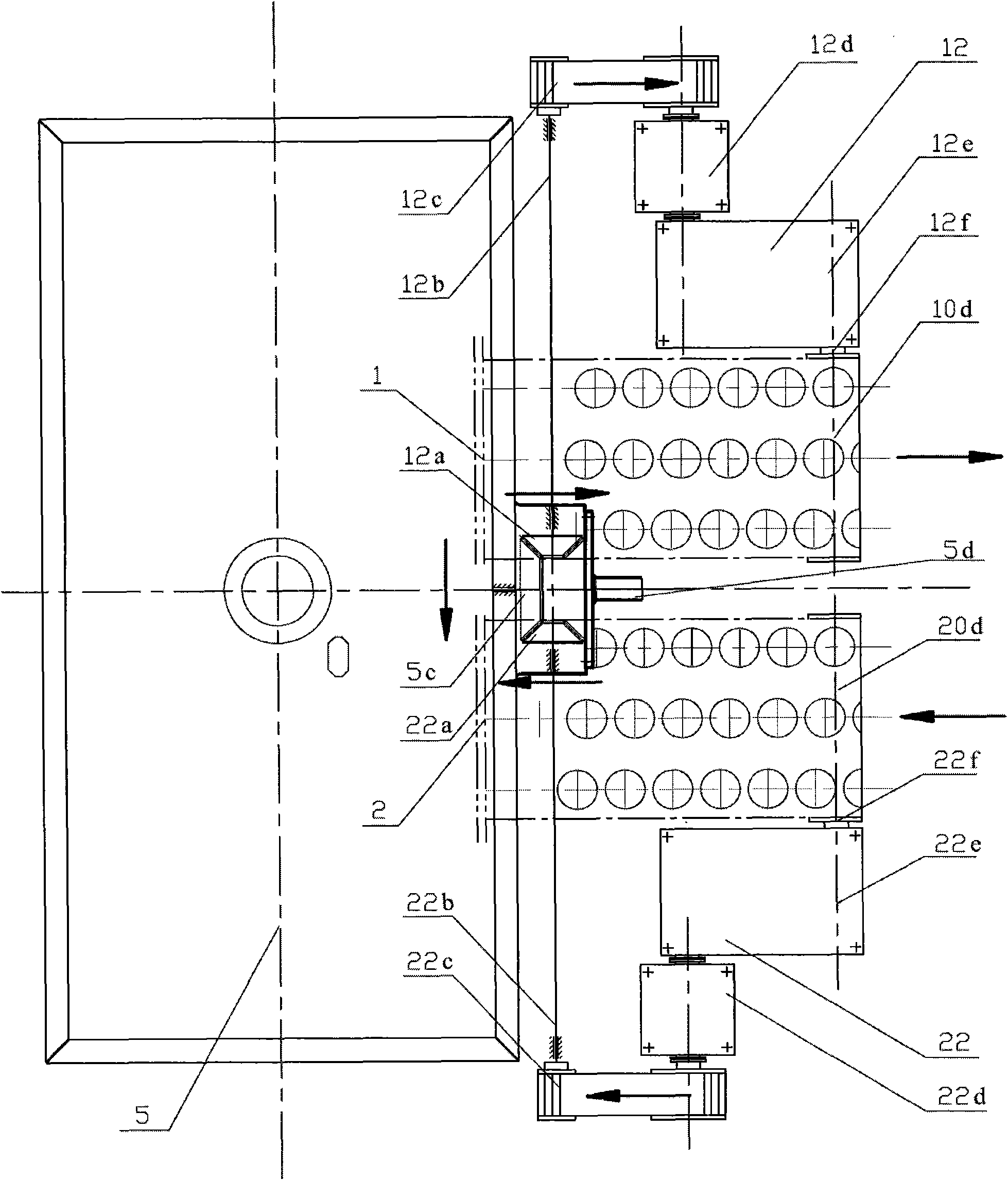

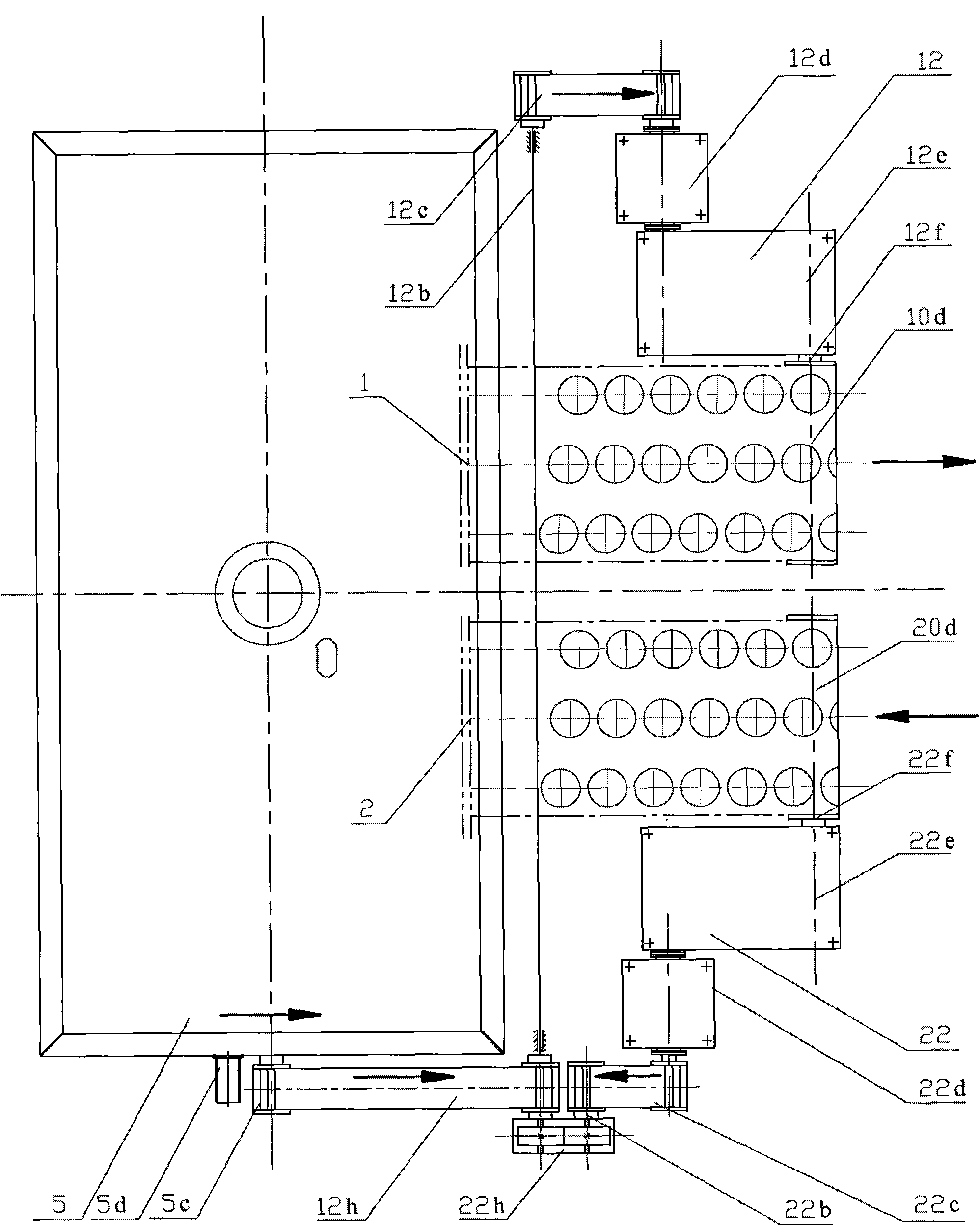

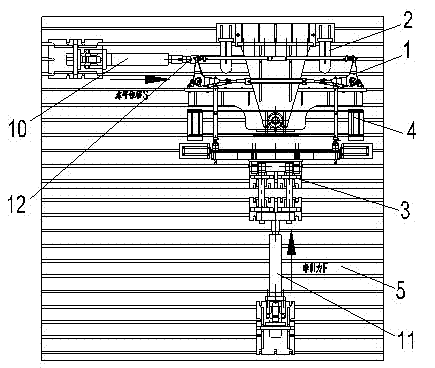

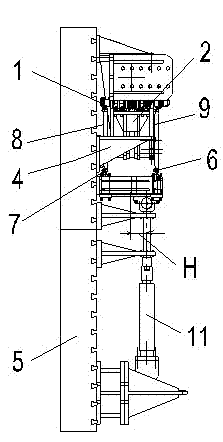

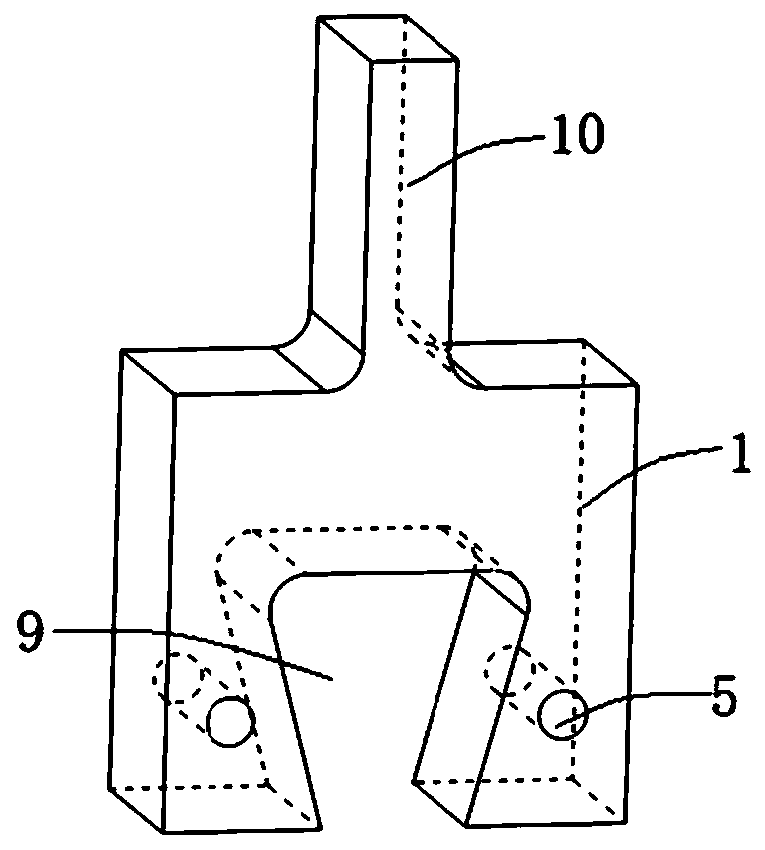

Multi-channel easy-open lid automatic stamping engineering design scheme and production line

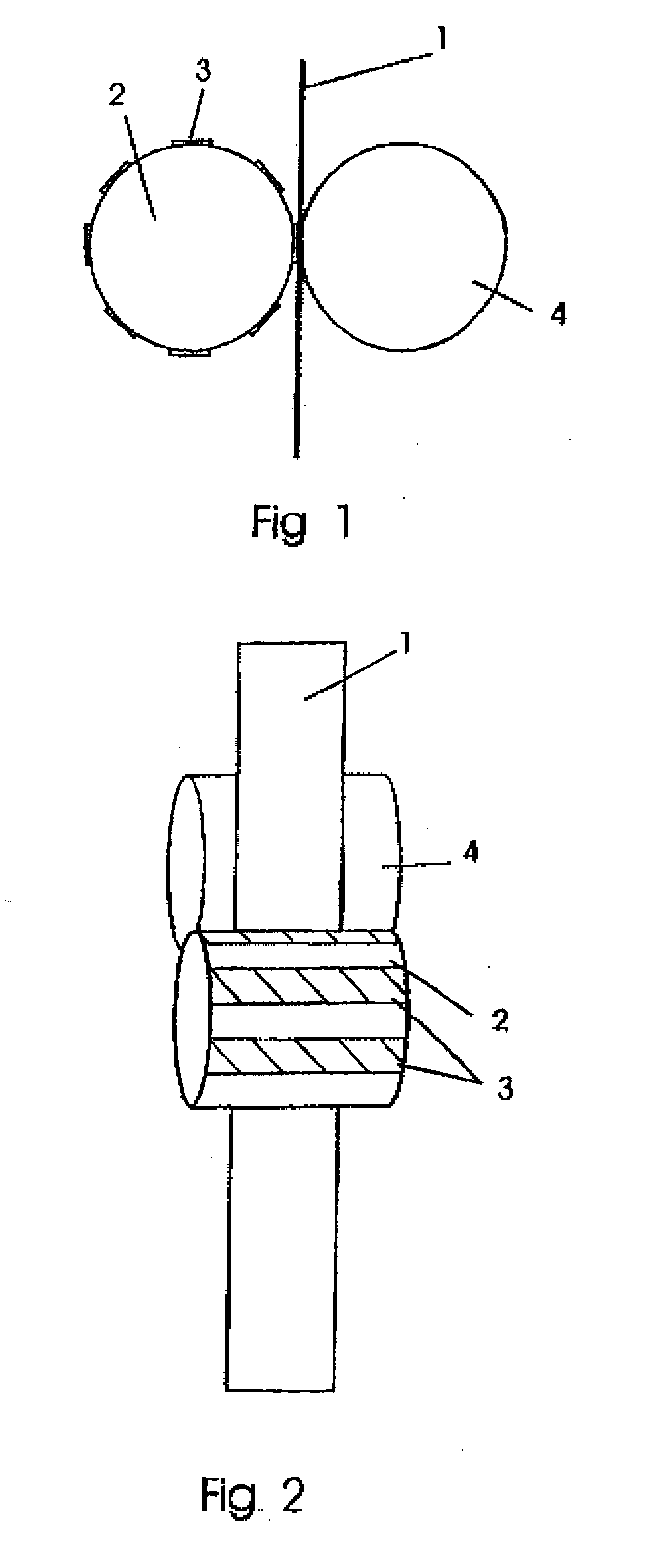

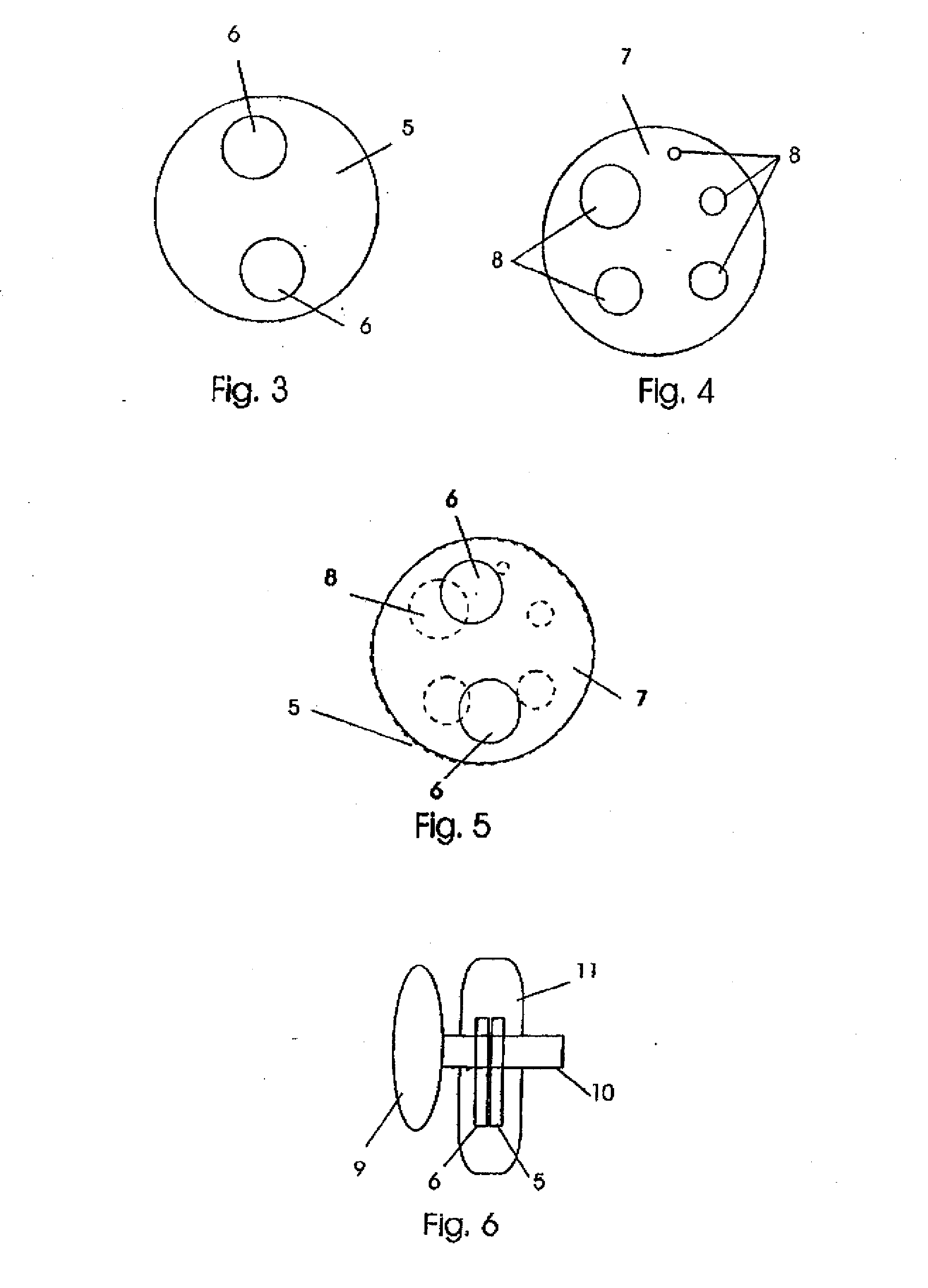

InactiveCN101623728ASolve the problem of stamping eccentric loadBreak through the bottleneck limitHollow articlesProduction linePunch press

The invention relates to a multi-channel easy-open lid automatic stamping engineering design scheme and a production line, particularly suitable for constructing a metal easy-open lid automatic stamping production line with 4 channels, 6 channels, 8 channels, 10 channels or more even channels. An easy-open lid stamping channel group A (1) and a channel group B (2) in opposite progressive directions are arranged in parallel on a high-speed punch; the same numbers of forming channels are respectively arranged on the channel group A (1) and the channel group B (2), and the progressive directions of all the forming channels on either channel group are the same. The invention solves the eccentric load problem of easy-open lid stamping, constructs the automatic stamping production line with 6 channels, 8 channels, 10 channels or more even channels on the high-speed punch, decreases the investment cost and manifolds the yield and the quality stability of the single stamping line, wherein the yield of the production line with 6 channels is larger than 3600 pieces / min, the yield of the production line with 8 channels is larger than 4800 pieces / min, and the yield of the production line with 10 channels is larger than 6000 pieces / min.

Owner:温庆普

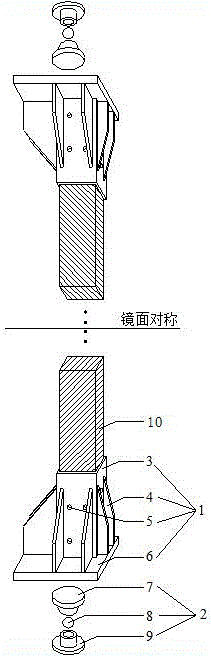

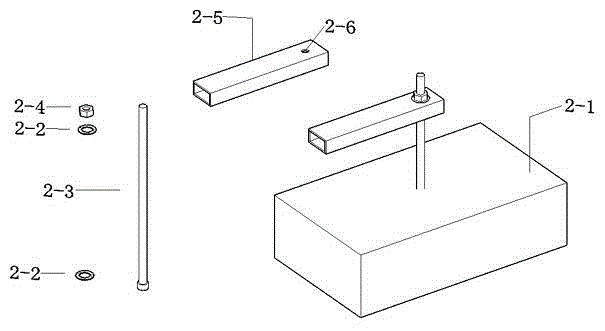

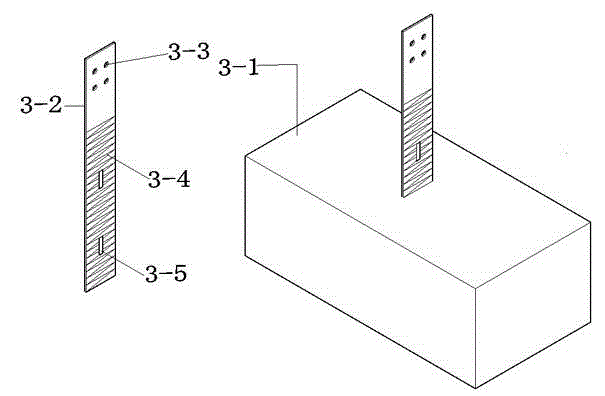

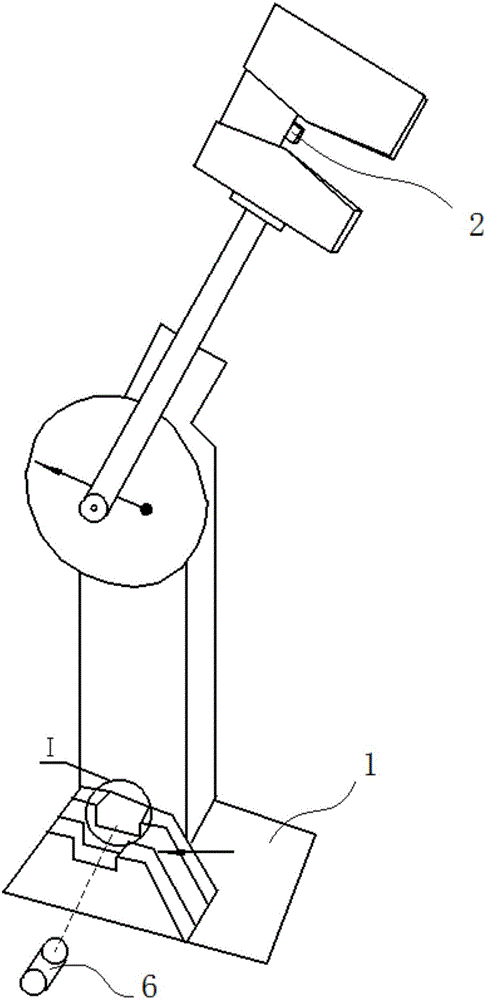

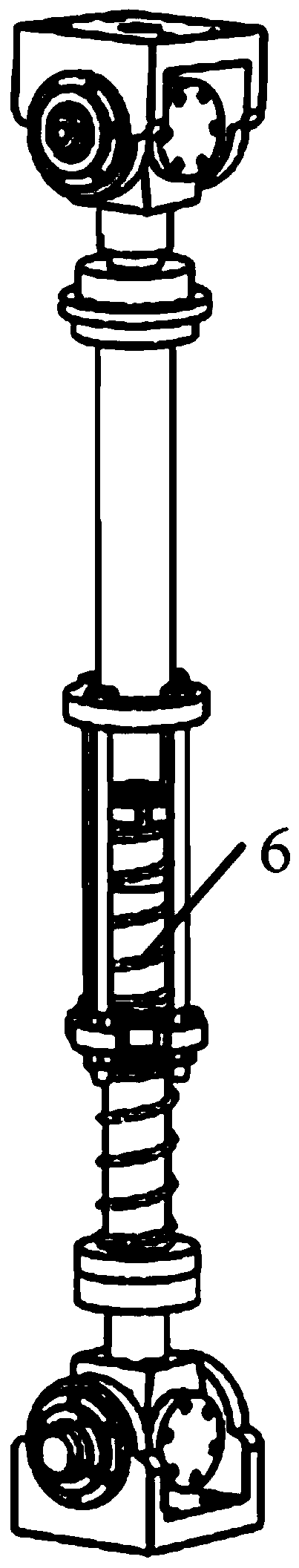

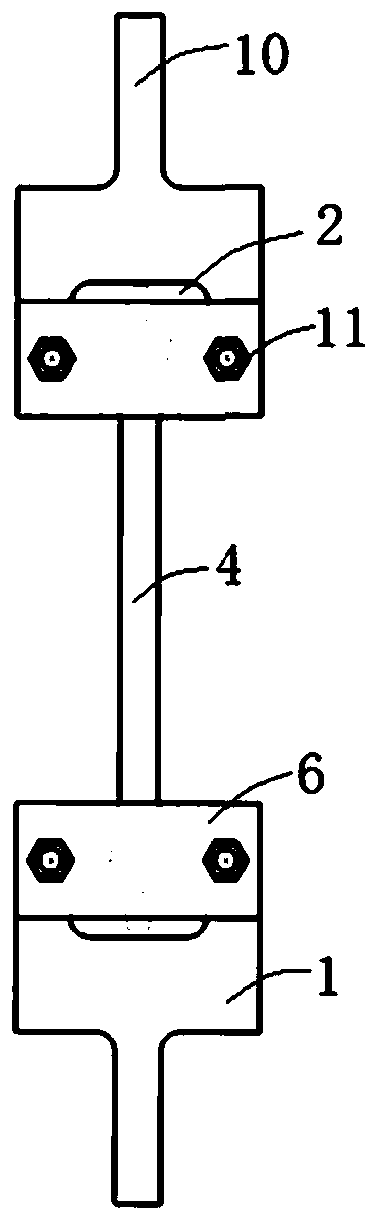

Bidirectional eccentric loading device for bamboo bending members, and installation method

InactiveCN106124179ASimple structureGuaranteed frictionMachine part testingStructural engineeringEccentric loading

The invention relates to a bidirectional eccentric loading device for bamboo bending members, and an installation method. The device comprises two steel cylinder sleeves which are in vertical mirror symmetry, two ball hinged seats, and the bamboo bending members. The steel cylinder sleeves are disposed on the ball hinged seats, and the bamboo bending members are inserted into hollow steel cylinders in the steel cylinder sleeves. The device is advantageous in that 1), the structure is simple and is easy to install, the main body of the loading device only comprises the steel cylinder sleeves and the ball hinged seats, and the installation step is easy; 2), the device is clear in force transmission and is good in integrity, the steel cylinder sleeves can serve as attached corbels fixed at two ends of the member so as to enlarge the force bearing range of an end face, and the ball hinged seats achieve the hinging of the members; 3), the eccentric position is flexible and controllable, ball hinges and the steel cylinder sleeves are connected through holding-on teeth, and the movable ball hinges change the relative position of the steel cylinder sleeves and the ball hinges, thereby achieving the design of different eccentric distances easily; 4), the device is high in popularity, a bamboo member in any rectangular shape can be connected with the device through a steel filling piece and a reserved bolt hole, and the device can be used for carrying out the bidirectional eccentric bearing test of many types of bamboo materials.

Owner:NANJING FORESTRY UNIV

Interlaminar shear device of cylindrical test piece of bituminous paving and shearing method thereof

InactiveCN102830021AEliminate reaction torqueAvoid damageMaterial strength using steady shearing forcesShear stressInterlaminar shear

The invention discloses an interlaminar shear device of a cylindrical test piece of a bituminous paving and a shearing method thereof. The device comprises shearing assembly, a press machine and a cylindrical test piece, and further comprises a pre-compressed member for locking the cylindrical test piece. The shearing assembly comprises a shearing pressure head and a shearing pedestal, wherein the shearing pedestal is mounted on a loading pedestal and provided with an empty groove in the center thereof, the empty groove is symmetrically provided with contact parts at two sides thereof, and the contact parts are respectively contacted with a first structural layer and a third structural layer. The shearing method provided by the invention can symmetrically apply shear stress, eliminate countertorque to instruments caused by eccentric loading, and therefore prevent damage to loading devices of the instruments.

Owner:广东大象交通科技有限公司

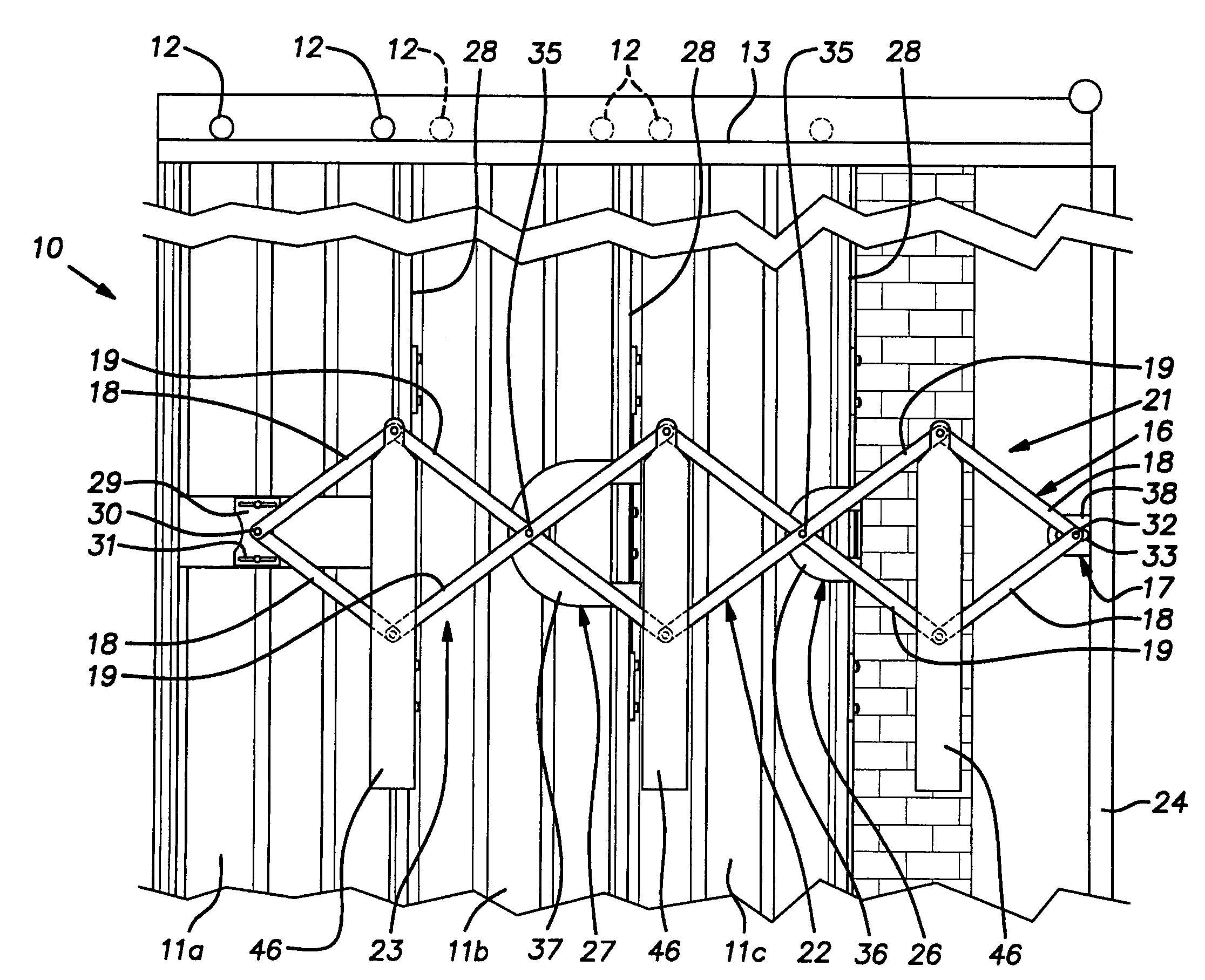

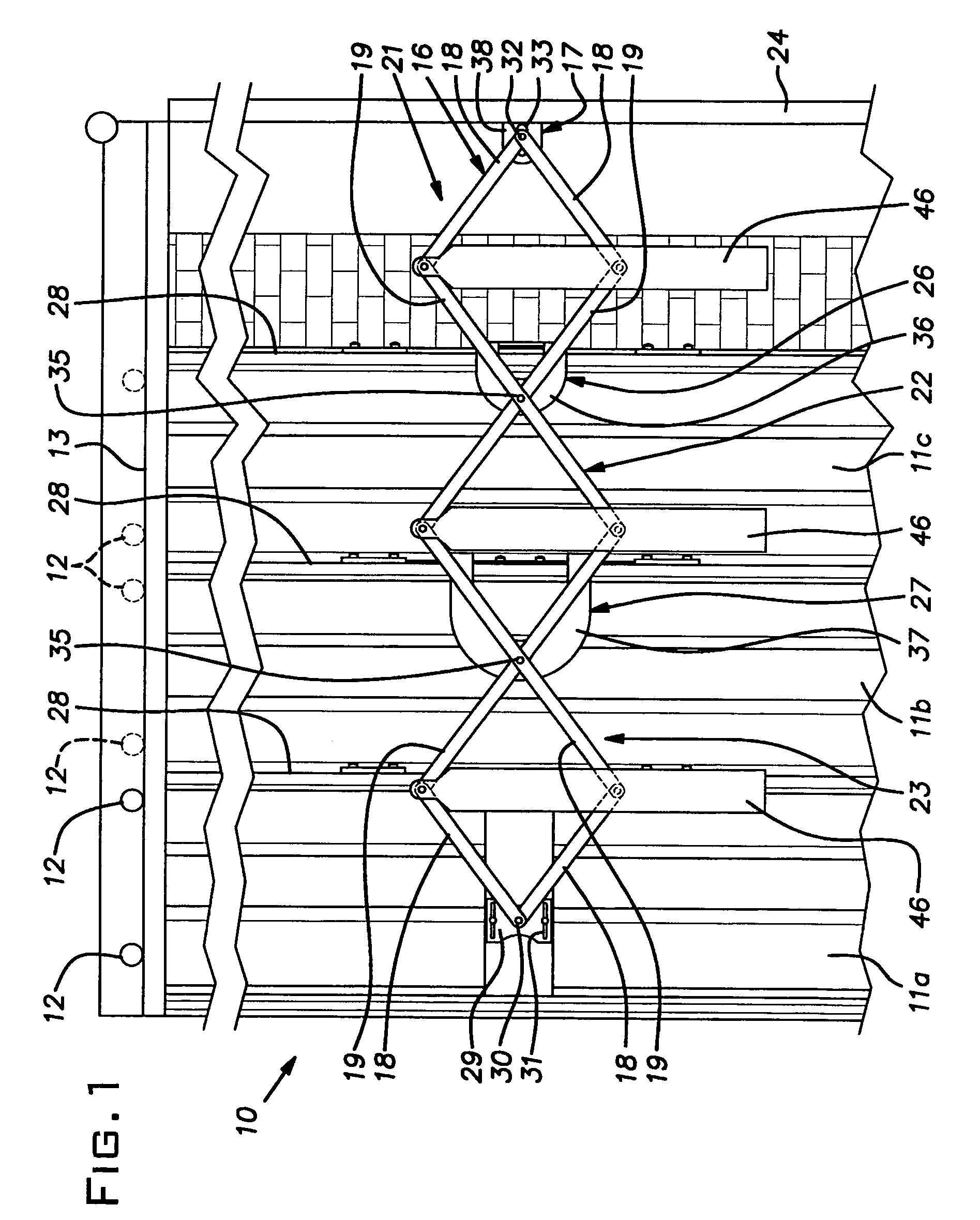

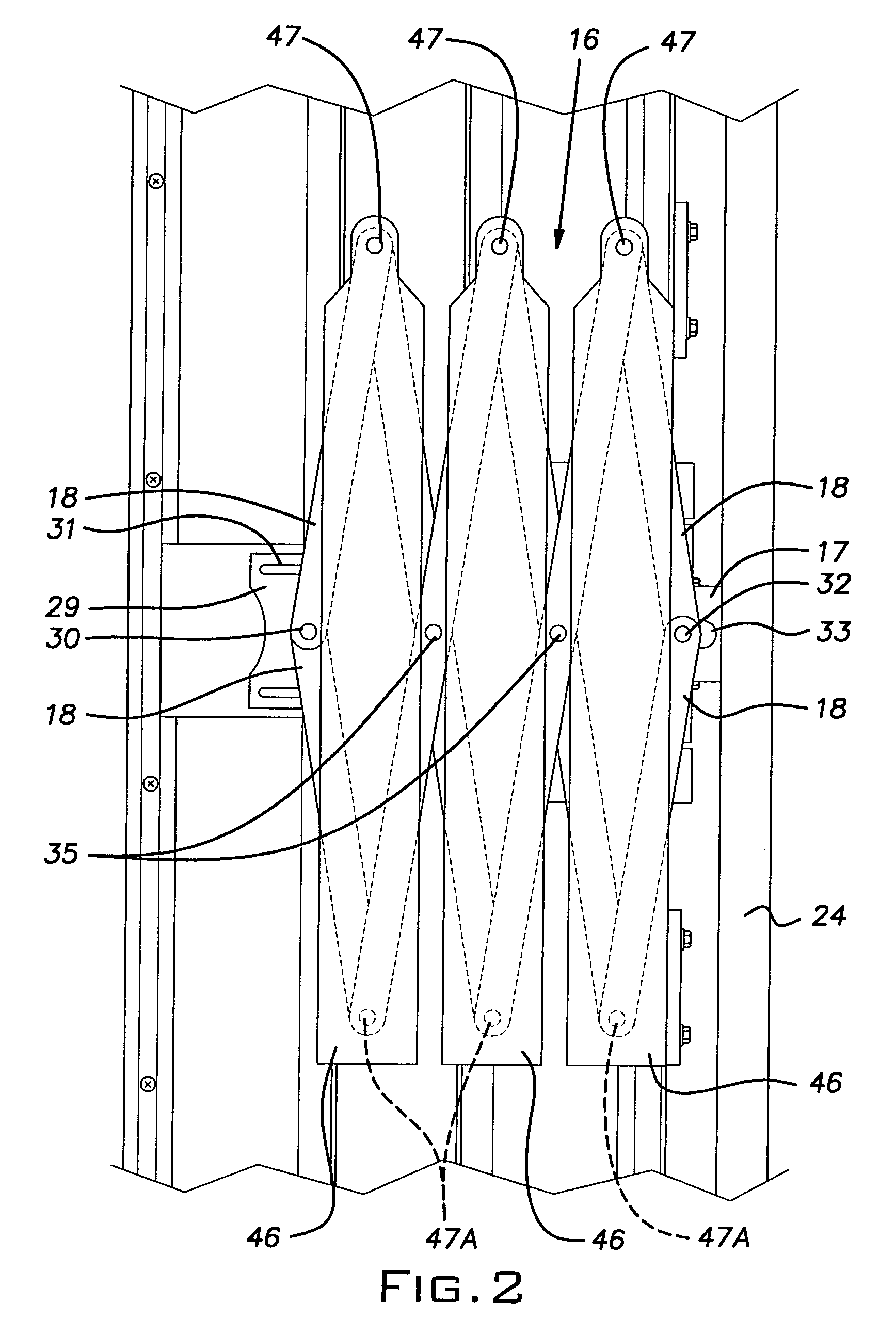

Door interlocking system

InactiveUS7308973B2Simplified linkage arrangementEasy to installExtensible doors/windowsCurtain accessoriesVertical planeEngineering

A door panel position control mechanism for a multiple panel horizontal sliding door assembly of a freight elevator landing. The mechanism comprises a multiple node scissors linkage that is configured to be easily installed and initially adjusted and which has its parts symmetrically balanced about a vertical plane such that excessive eccentric loading on the components is reduced and a long service life is obtained with reduced wear and a reduced need for periodic adjustment.

Owner:PEELLE COMPANY LTD THE

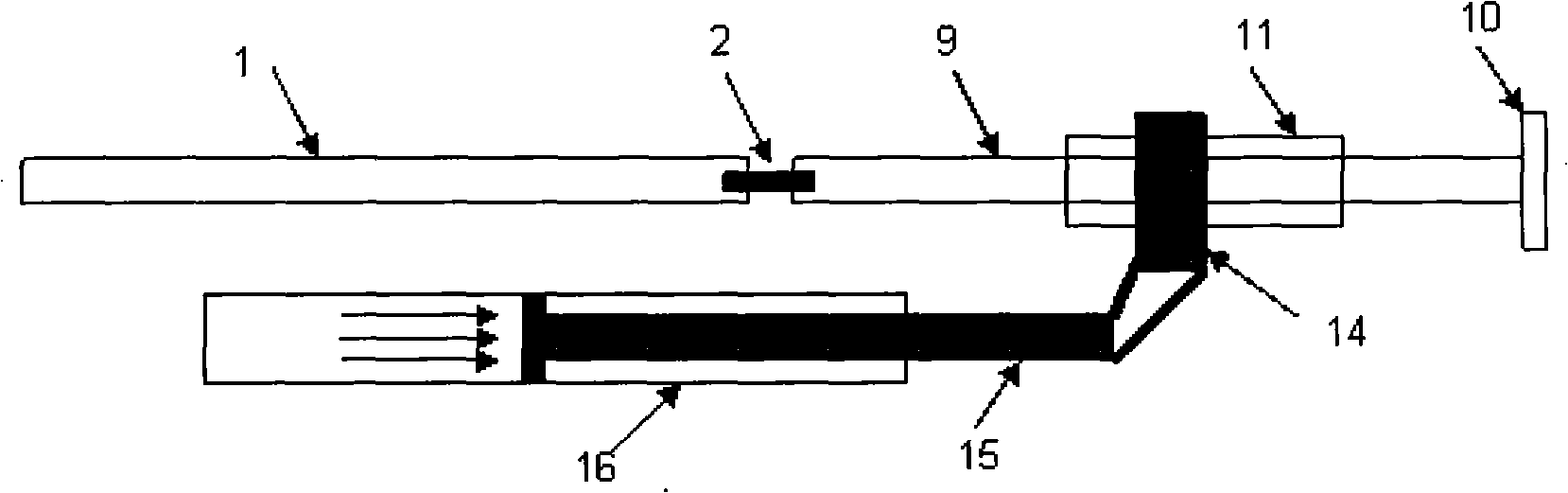

Fatigue testing device and fatigue testing method for traction connecting rod system of single-rail cart

ActiveCN102829985ARemove loadImprove test accuracyMachine part testingRailway vehicle testingBogieEngineering

Disclosed are a fatigue testing device and a fatigue testing method for a traction connecting rod system of a single-rail cart. The fatigue testing method for the traction connecting rod system of the single-rail cart includes disposing the traction connecting rod system on a simulated cart body and a bogie system and mounting the same on a testing platform horizontally integrally, jointly loading on the traction connecting rod system from the vertical and lateral (horizontal) direction via a loading oil cylinder and a testing tooling, fixing ball hinges at the upper ends of four traction rods of the traction connecting rod system on a carrying platform of the simulated cart body via bolts to form a double-torsion rod mechanism with internal force of four connecting rods balanced, and mounting a hinge device at a position deviated from the center of the carrying platform by a certain distance, wherein the hinge device penetrates through four guide seats in a parallel manner and is connected with a vertical loading oil cylinder through a loading crossbeam, and the vertical loading oil cylinder applies traction force on the upper group and the lower group of traction rods in an eccentric loading manner, so that deviation angle generated makes runout actions around a rotary shaft via the hinge device, runout loading is eliminated, and accordingly, vertical loading on the traction connecting rod system is realized.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

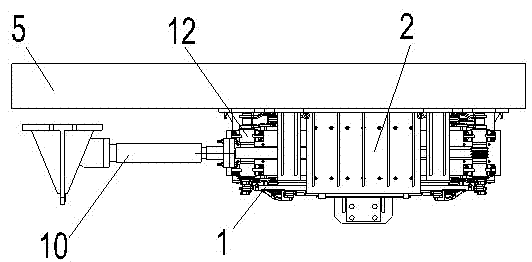

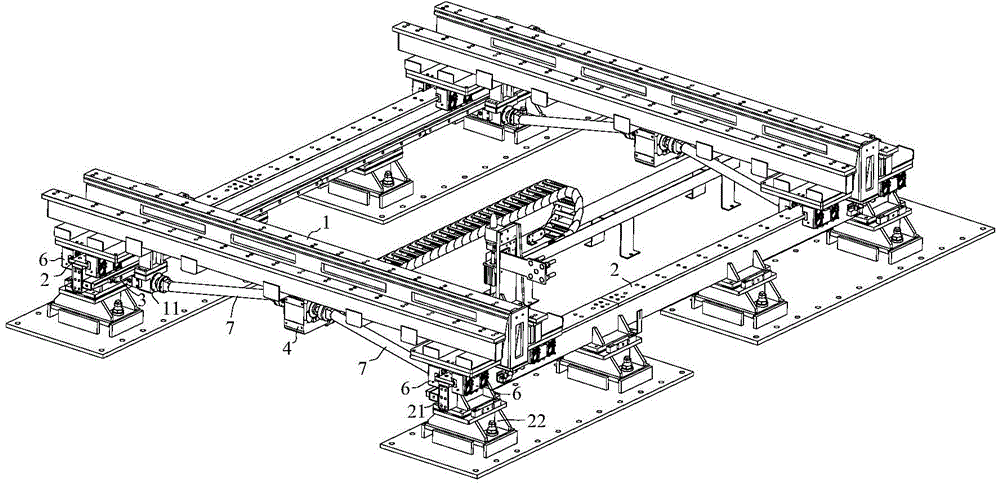

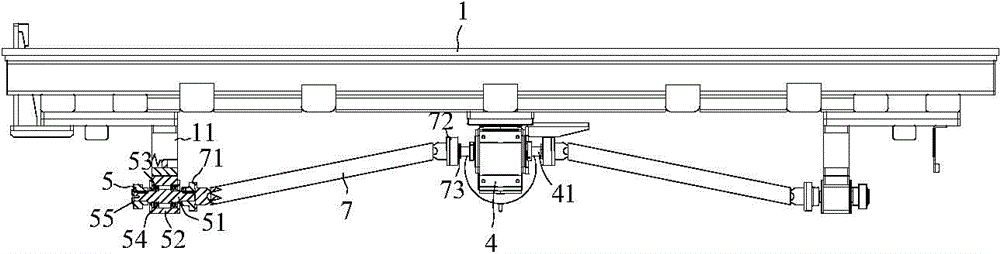

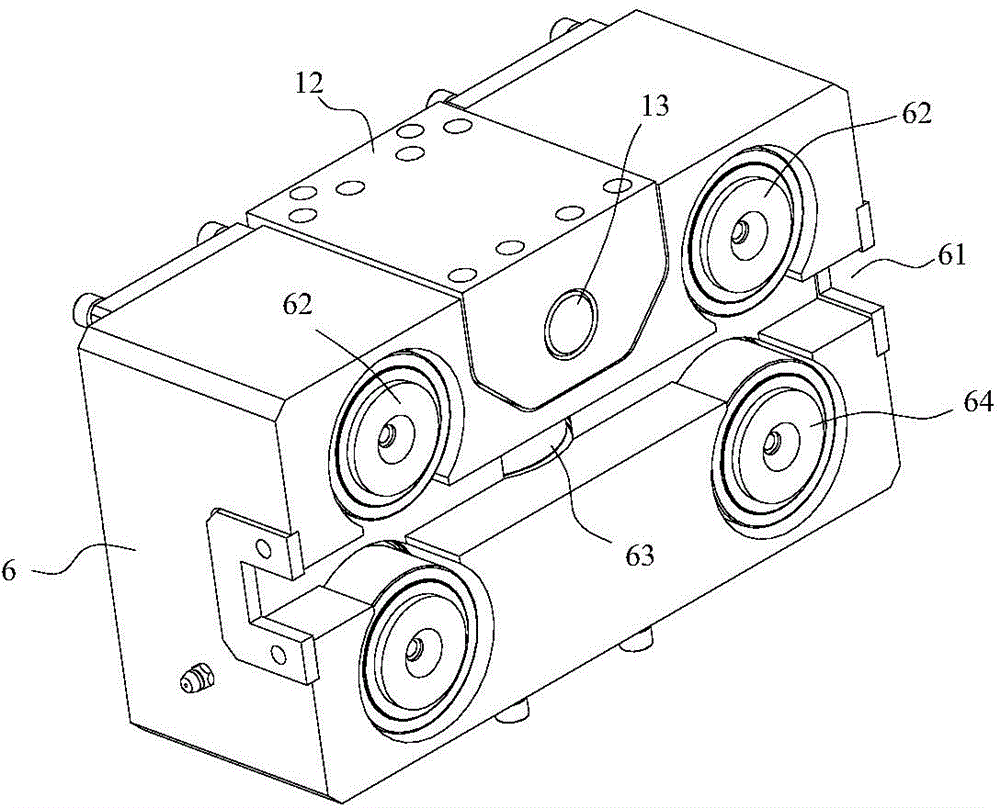

Double side drive transport system

The invention discloses a double side drive transport system. The double side drive transport system comprises a guide rail support and two parallel guide rails, wherein the guide rail support is transversely erected on the two guide rails through a guiding device, racks are arranged along each guide rail, a motor is arranged on the guide rail support and between the two guide rails, drives seats corresponding to the racks on two sides of the guide rail support are installed on two sides of the motor, located on the guide rail support, gears respectively meshed with the racks on the corresponding sides and driven by a motor are installed on the drive seats, the guiding device comprises a wheel group installation seat, and a wheel group matched with the guide rails is installed on the wheel group installation seat. The double side drive transport system reduces accuracy requirements for the guide rails by using the wheel group on the wheel group installation seat and the guide rails to cooperatively guide, and improves transmission accuracy due to the fact that intervals among idler wheels and the guide rails are adjustable. The double side drive transport system solves the problem that an existing double side drive transport system is unstable in running due to the fact that an eccentric load easily rocks under high speed work conditions through double side drive of the motor. By adopting the above design, the double side drive transport system can reduce cost, is reliable in performance and convenient to install, and meets material conveying demands of an industrial automatic production line.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD +1

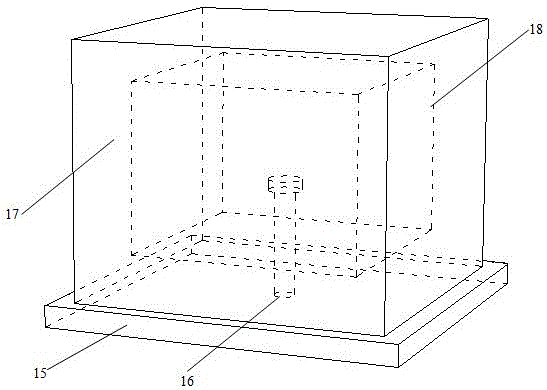

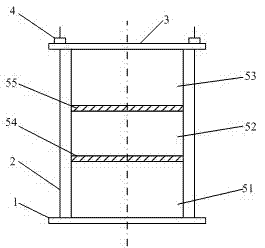

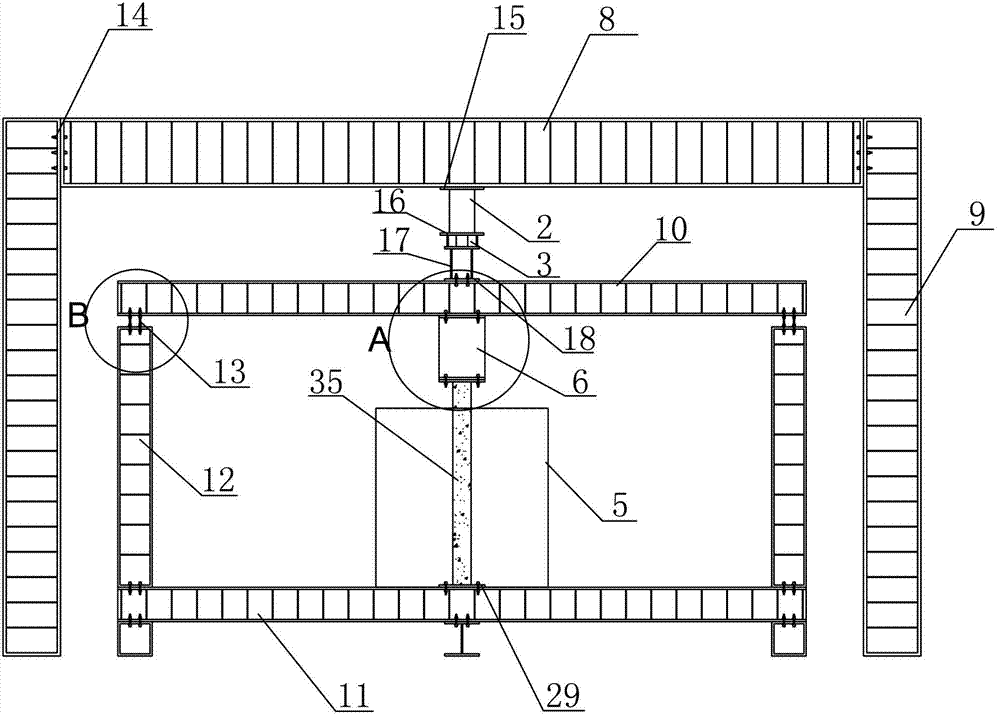

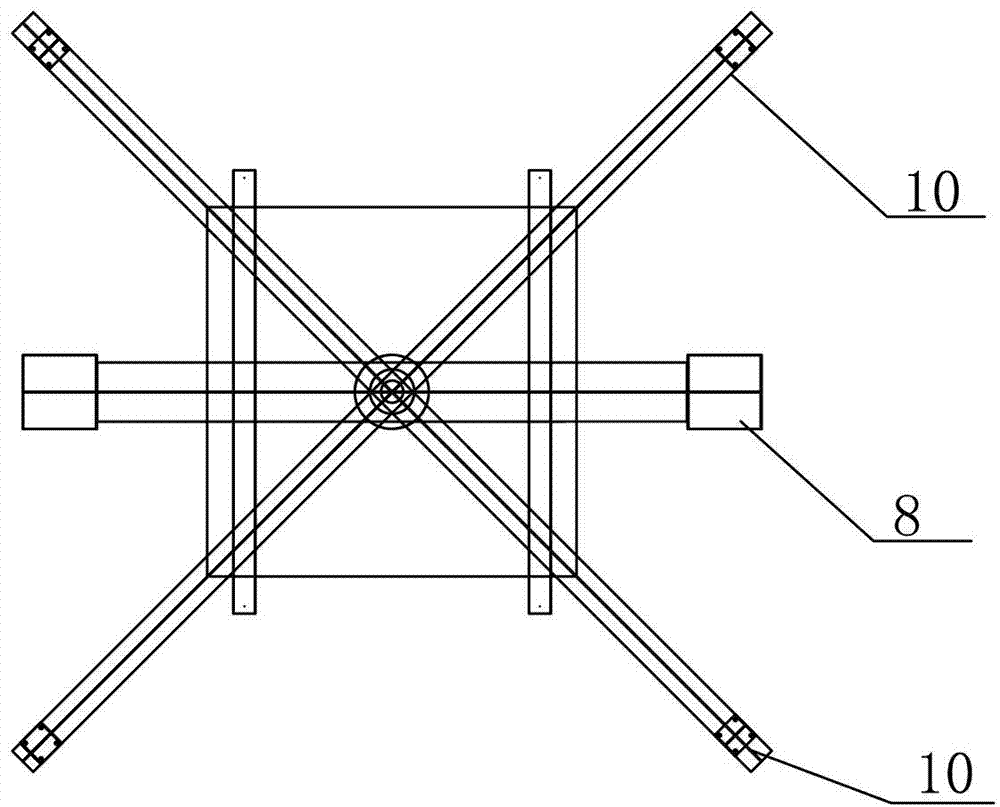

Restraint device for column fire resisting test

ActiveCN102901648AFlexible adjustment of floor areaFlexible size adjustmentStructural/machines measurementSmall footprintEngineering

The invention discloses a restraint device for a column fire resisting test. The device comprises a loading counter-force rack, a lifting jack, a load sensor, a restraint framework, a heating stove, a measured column generating constraint force device and a plurality of displacement meters. The device is characterized in that the restraint framework includes two rectangular frameworks which are mutually crossed and fixedly connected through a bolt pair, each rectangular framework comprises an upper restrained beam, a lower restrained beam and a restrained column, the upper and lower restrained beams are horizontally arranged, the upper restrained beams are located at the lower end of a steel beam, the lifting jack and the load sensor are sequentially disposed between the steel beam and the upper restrained beams, the measured column generating constraint force device and the heating stove are sequentially mounted between the upper restrained beams and the lower restrained beams, a testing column is mounted in the heating stove, the upper end of the testing column penetrates through the heating stove to be connected with the measured column generating constraint force device, and the lower end of the testing column penetrates through the heating stove to be connected with the lower restrained beams. The restraint device for the column fire resisting test has the advantages that the floor space is small, the manufacture is easy, the usage is convenient and flexible, the operability is high, the device is safe and reliable, simultaneously the stiffness out of plane can be effectively provided, and the experimental study can be achieved under the action of eccentric loading.

Owner:NINGBO UNIV

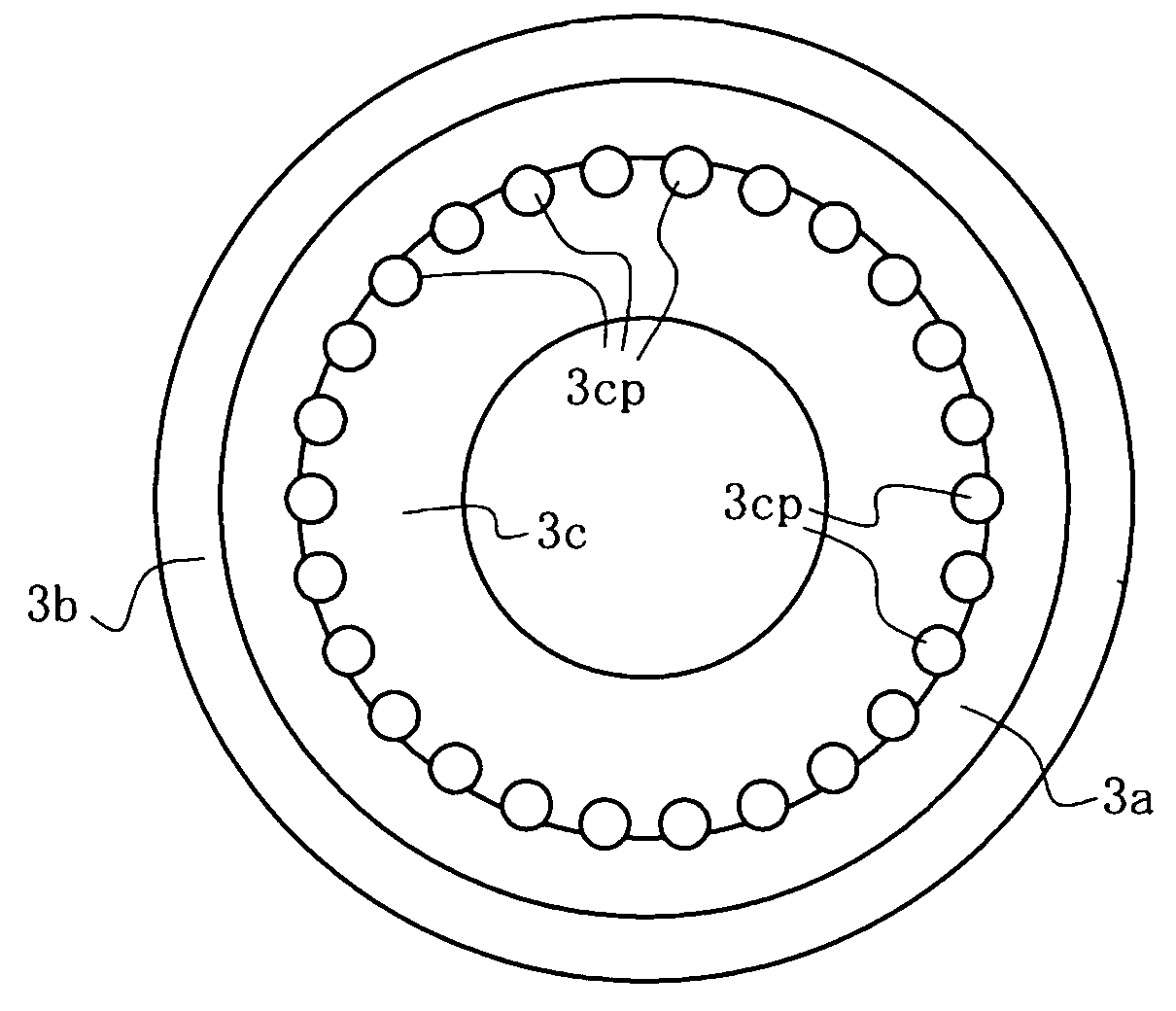

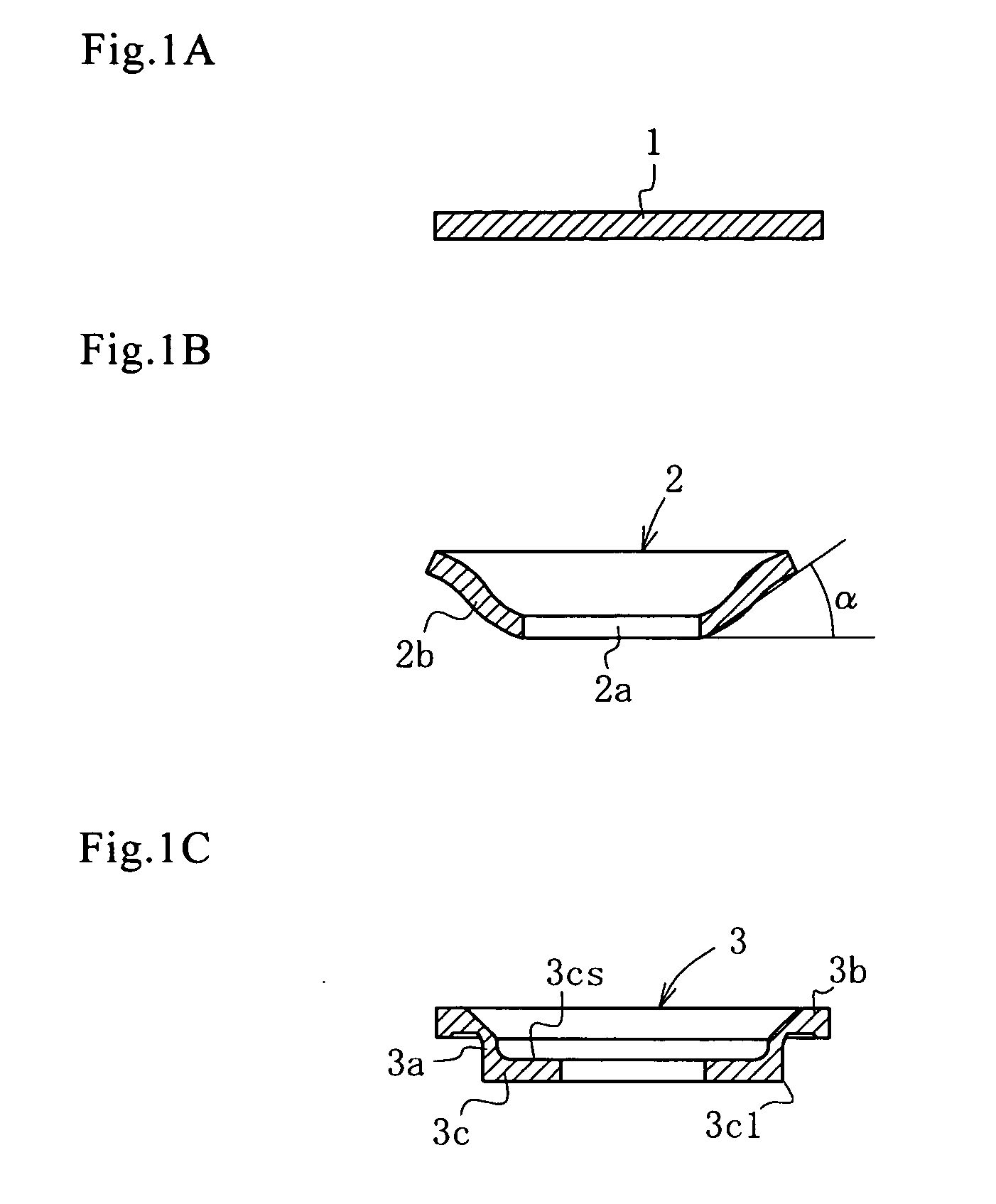

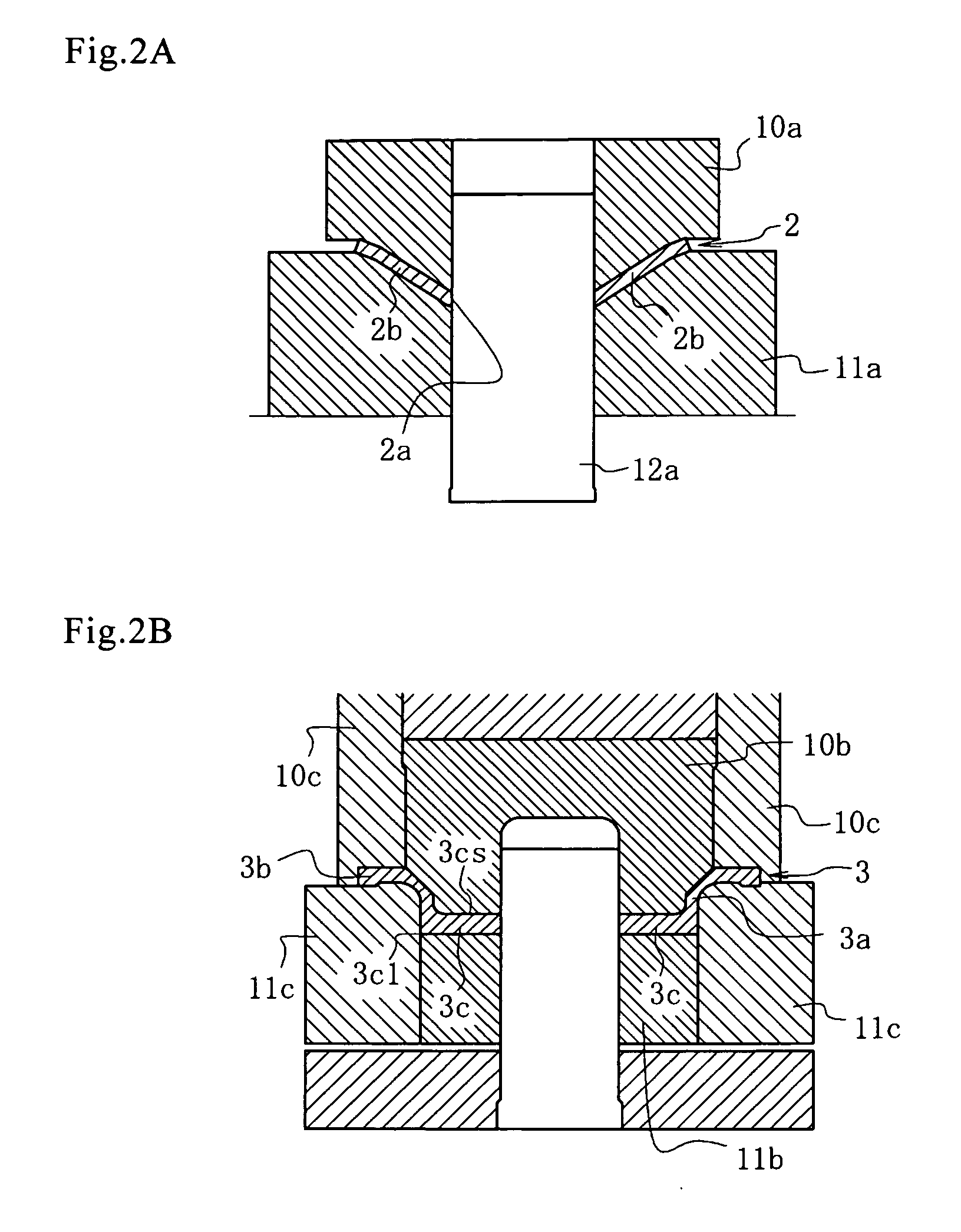

Method of forming spring washer blind-holes into a piston for an automobile transmission

InactiveUS20090282885A1Long enduranceIncrease speedMetal-working apparatusPistonsEngineeringEccentric loading

The problem to be solved by the present invention is to clear up an eccentric load onto a pin and a problem of deformation and cavity due to flowing material during extrusion when spring washer blind-holes in a piston for an automobile transmission is formed by extrusion with a pin. After an annular region along the peripheral edge portion on the back of an end plate 3c of a secondary workpiece 3 is flattened, the secondary workpiece 3 is set on a lower die 11f. Further, while the lower die is pressed with upper dies 10f, 10g and cushion pressure is applied on the lower die 11f, pins 13, 13 . . . for piercing the spring washer blind-holes are made to perform an extrusion operation onto the end plate 3c of the secondary workpiece 3 from the backside of said end plate. The extruded material is made to flow into recess holes 10f1, 10f1 . . . of the upper die 10f and thus spring washer blind-holes 5, 5 . . . are formed. Then, projections 3cp which have flowed and protruded on the front side are removed by turning with a lathe.

Owner:IBARAKI STEEL CENT +1

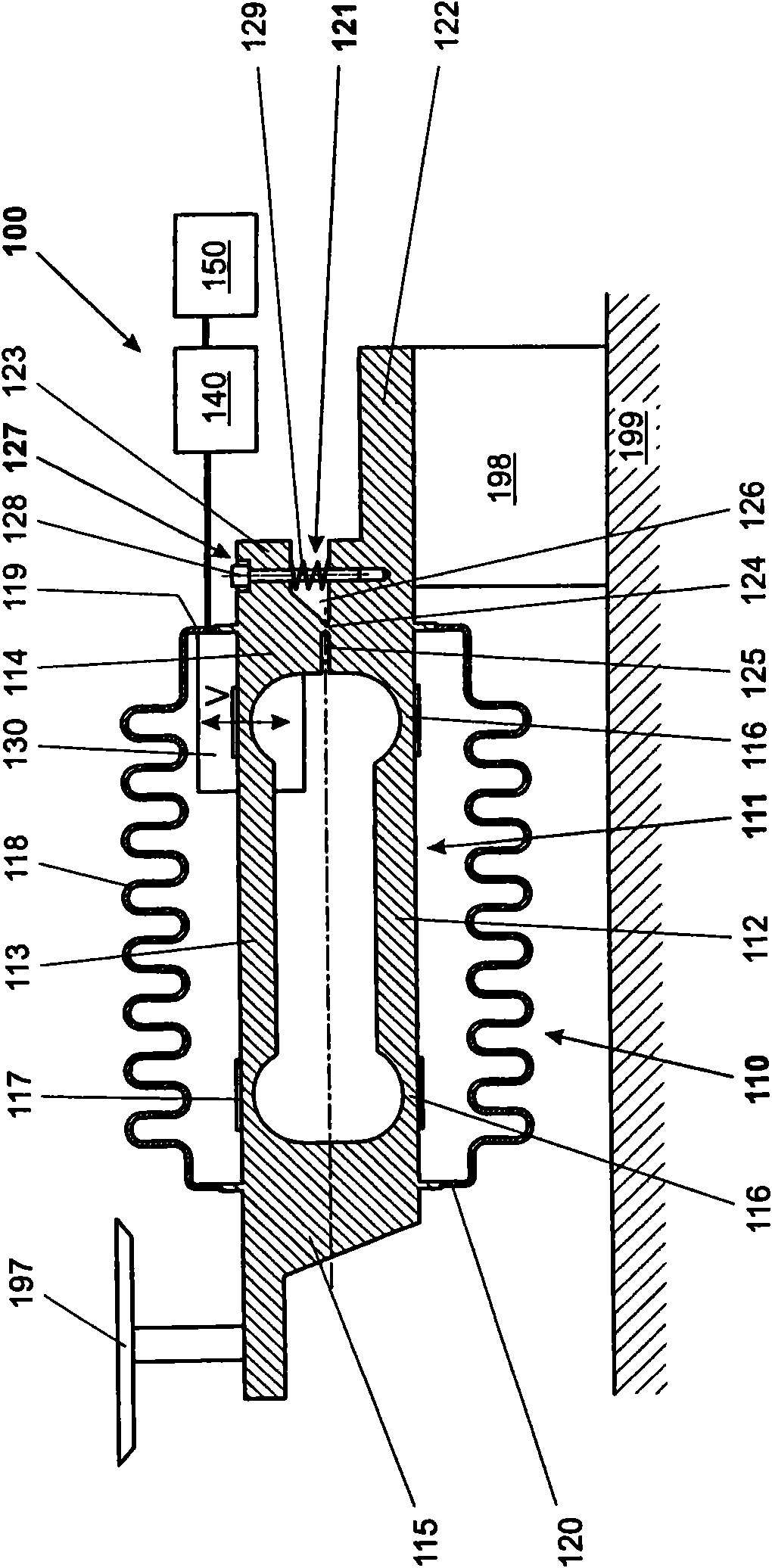

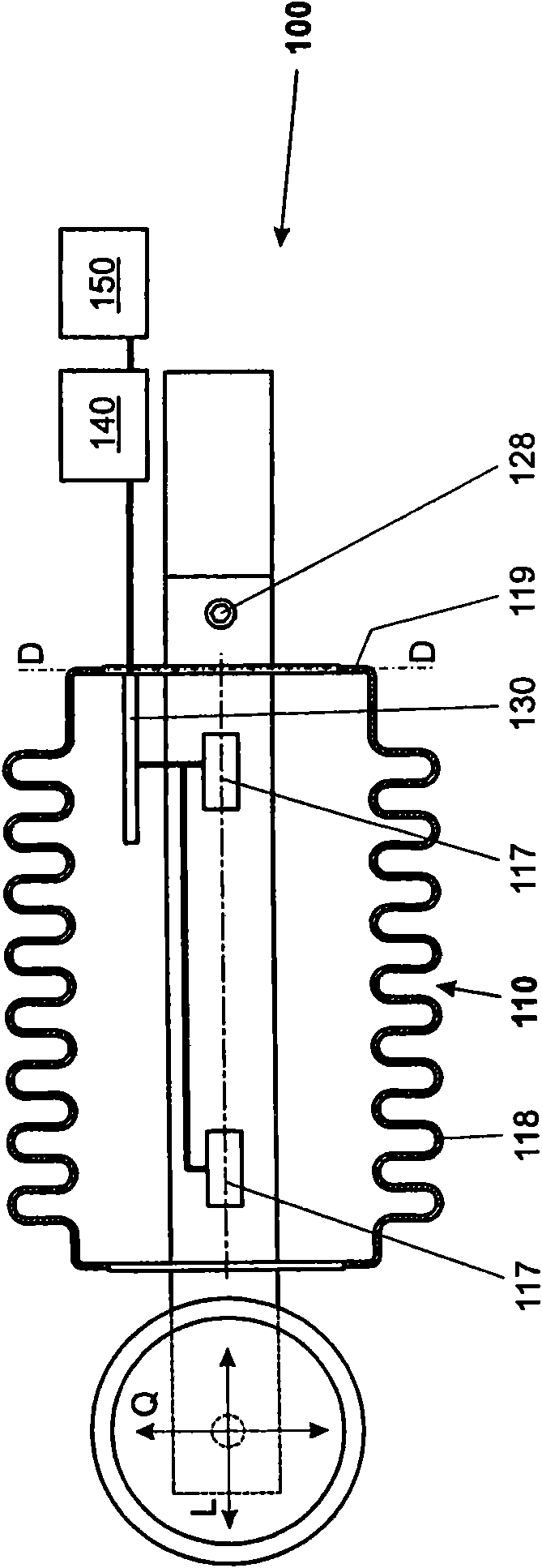

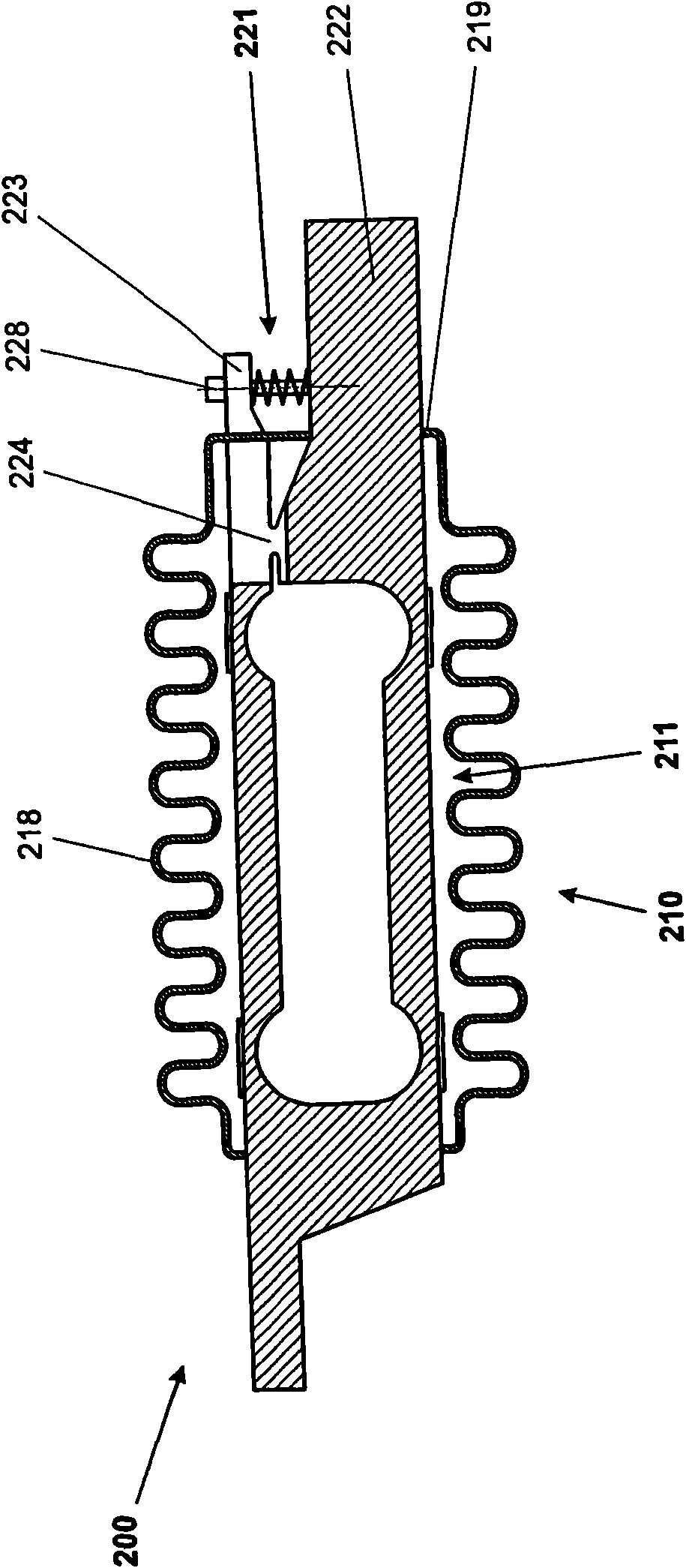

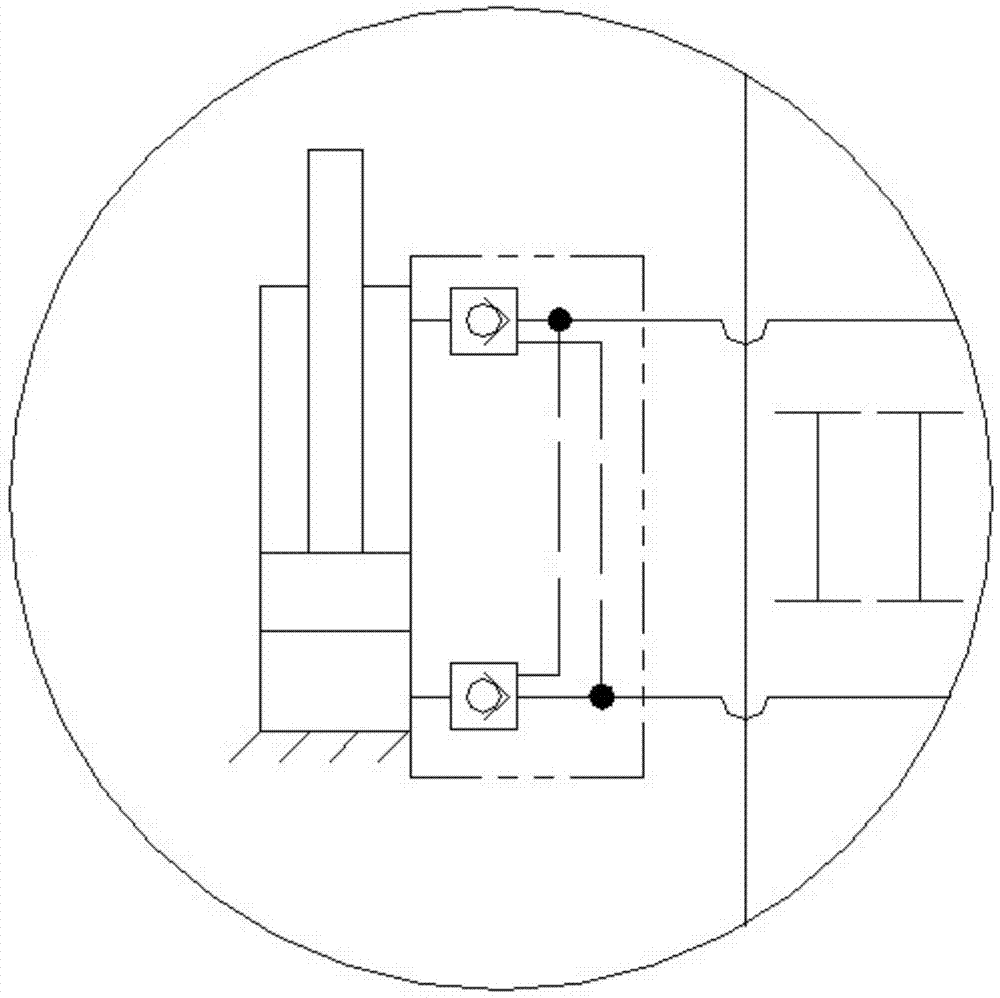

Encapsulated weighing cell with eccentric load error adjustment

ActiveCN101581600AWeighing apparatus using elastically-deformable membersWeighing apparatus testing/calibrationMeasuring instrumentTransducer

A gravimetric measuring instrument has a weighing cell and a flexible, tubular-shaped encapsulation. The weighing cell has a parallel-guiding mechanism and at least one measurement transducer. The ends of the encapsulation are attached, respectively, to the stationary parallelogram leg and the movable parallelogram leg, so that at least the parallel-guiding mechanism and the measurement transducerare enclosed by the encapsulation, protecting them from dirt and humidity. In some aspects, the parallel-guiding mechanism has an adjustment region formed at one of the parallelogram legs which allows adjustment of the distance between at least one flexure pivot of the upper parallel-guiding member and a flexure pivot of the lower parallel-guiding member. This adjustment region is mechanically connected to at least one adjustment-setting area, which is arranged outside the encapsulation and allows changes to be made to the adjustment region.

Owner:METTLER TOLEDO (CHANGZHOU) PRECISION INSTR CO LTD

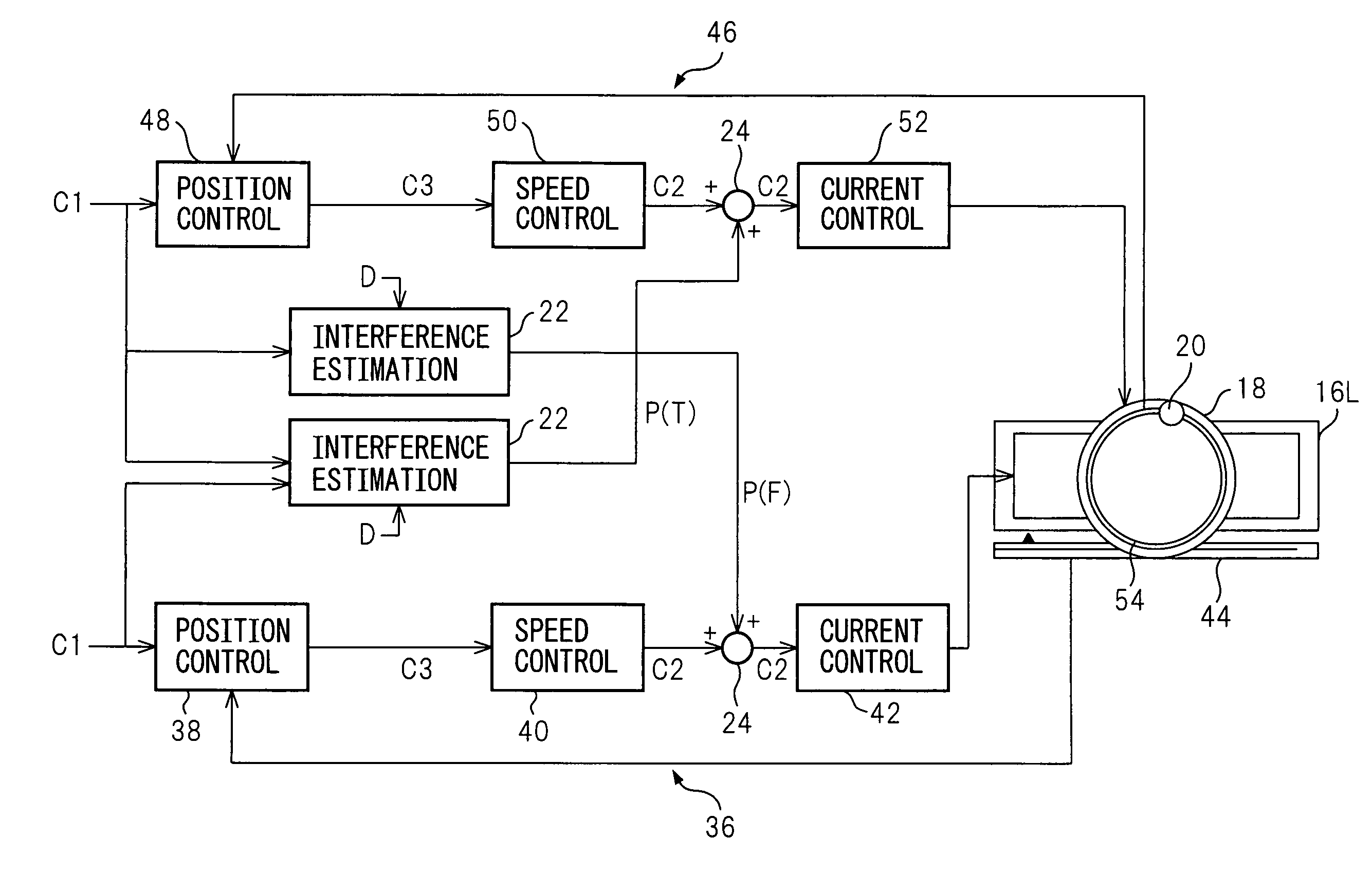

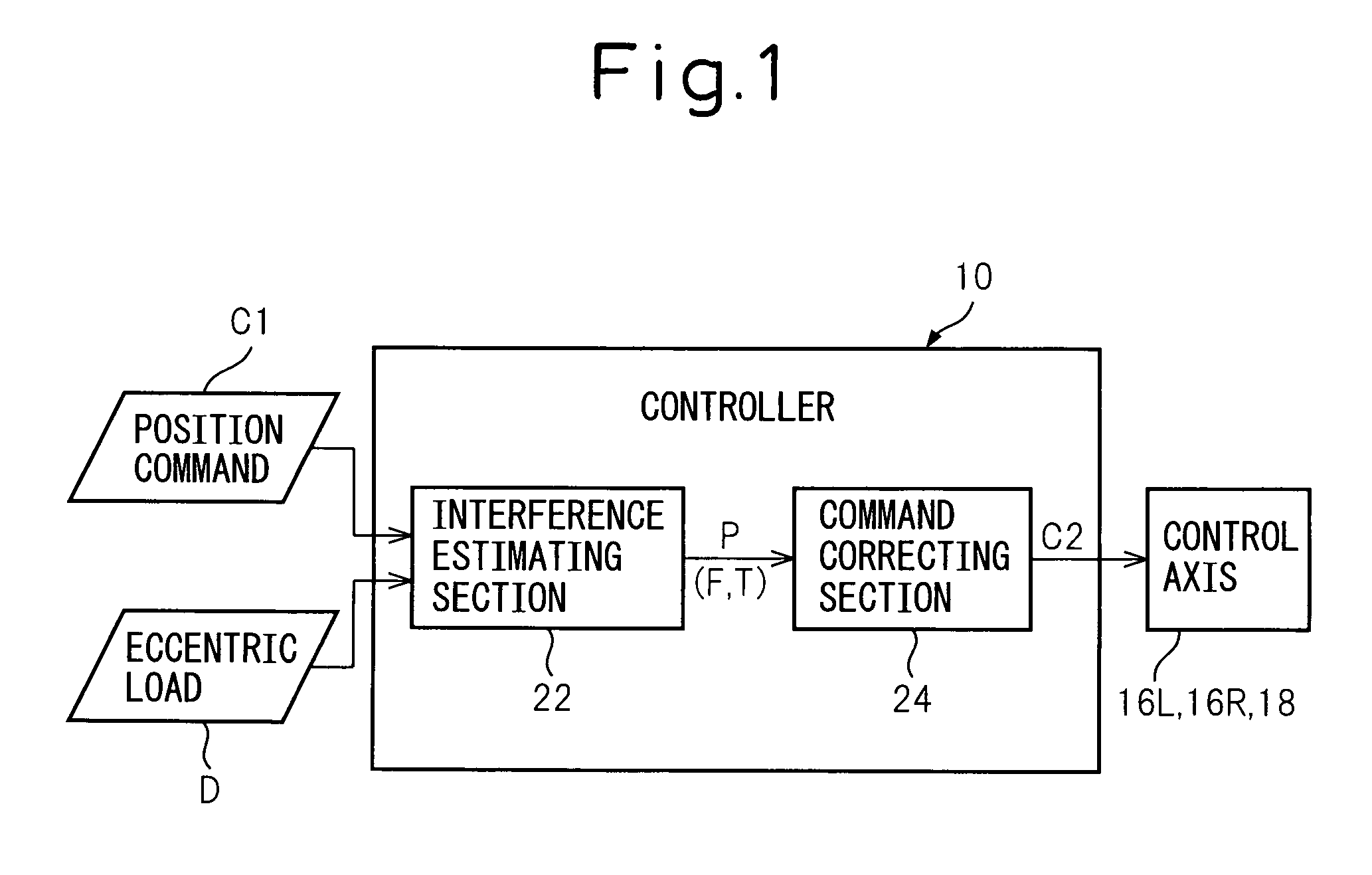

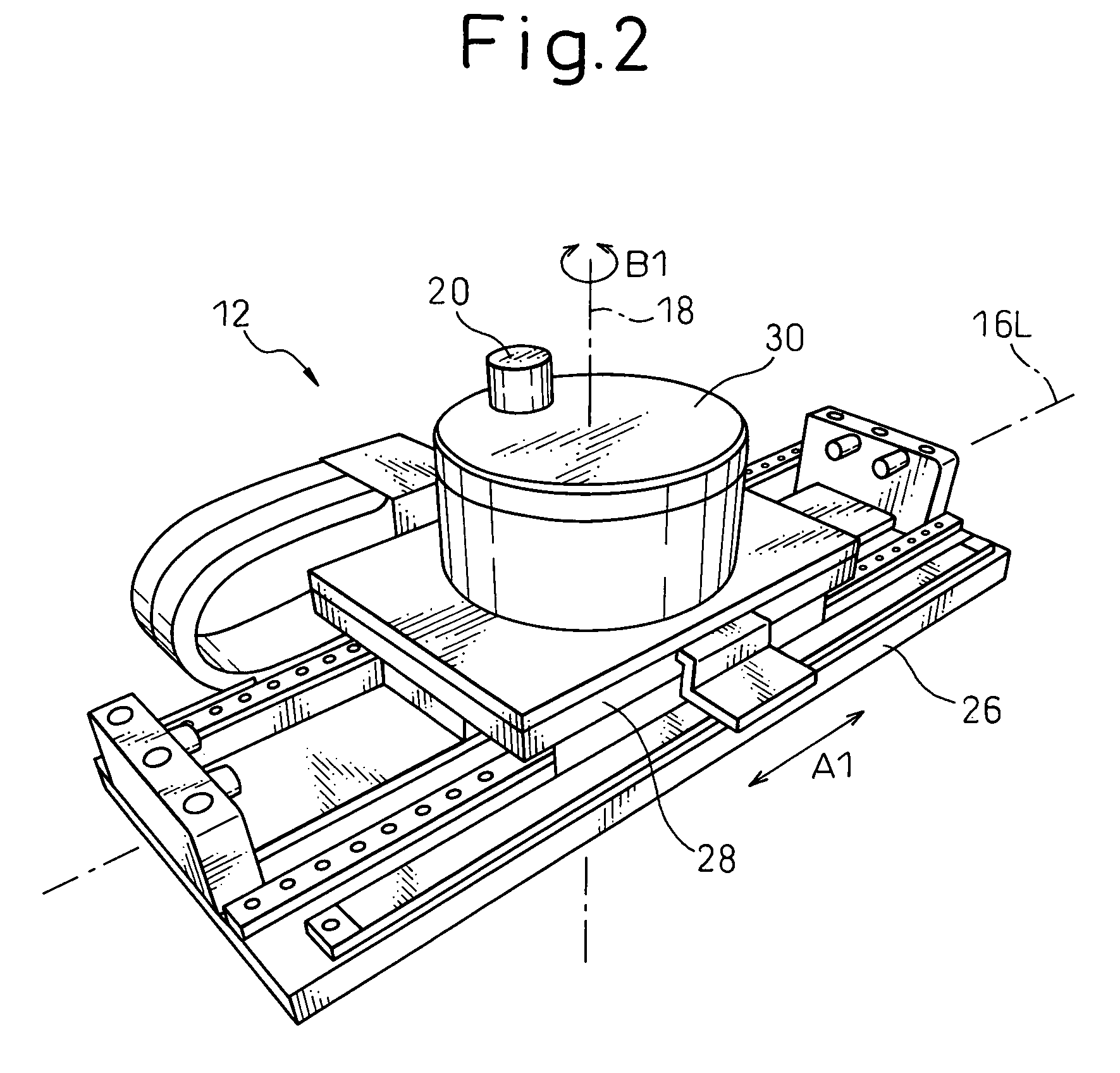

Device and method for controlling machine tool

ActiveUS7847502B2Eliminate distractionsStable and accurate motion control of controlComputer controlTemperatue controlEccentric loadingControl theory

A device for controlling a feed motion of a feed control axis and a rotary motion of a rotary control axis, both axes being provided in a machine tool so that the rotary control axis is fed along the feed control axis. The device includes an interference estimating section estimating an interference generated between the feed control axis and the rotary control axis, based on a position command instructed to at least one of the feed control axis and the rotary control axis and a position and mass information of an eccentric load carried by the rotary control axis; and a command correcting section correcting a current command given to at least one of the feed control axis and the rotary control axis, based on the interference estimated by the interference estimating section.

Owner:FANUC LTD

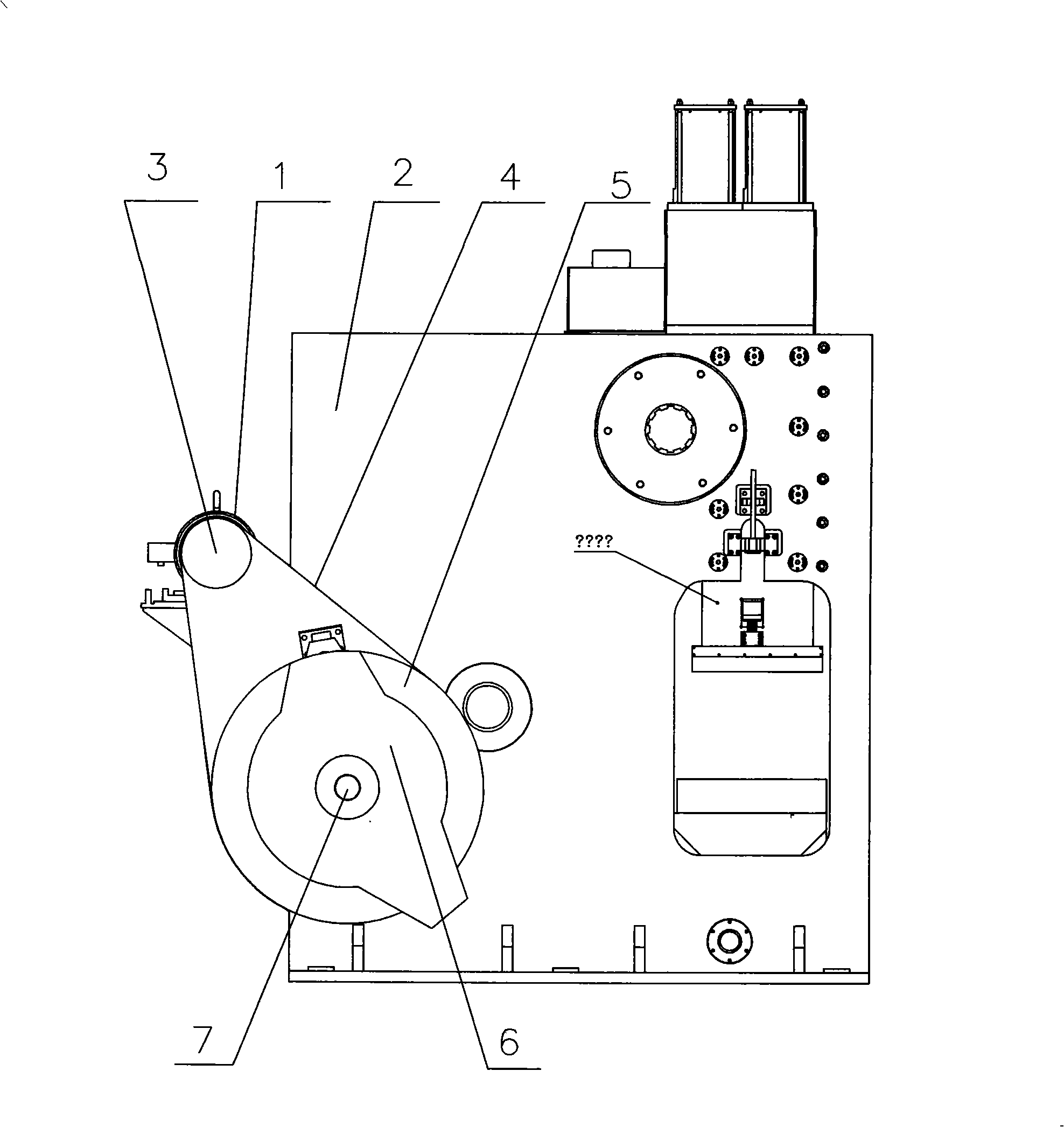

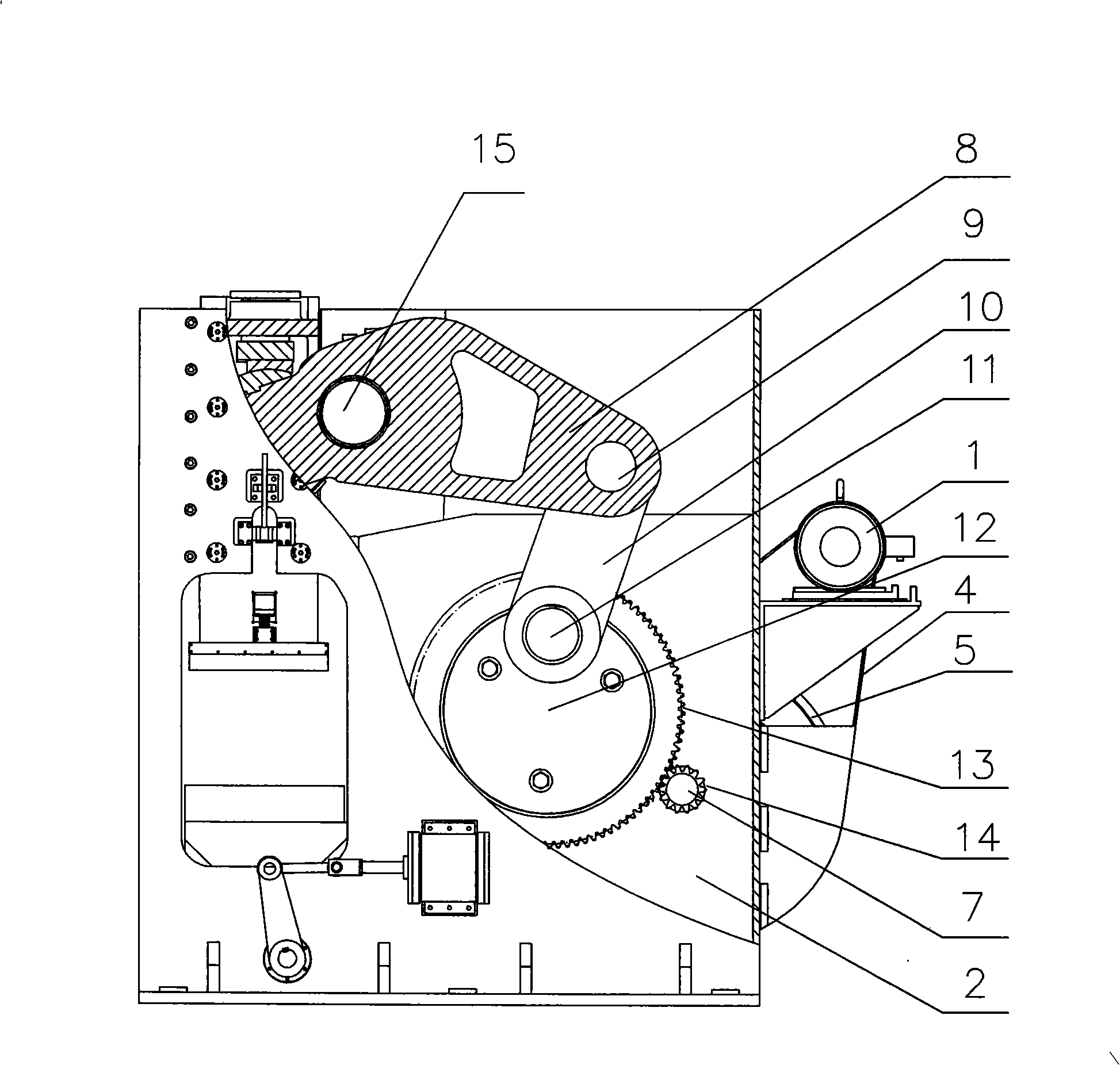

Sliding block driving mechanism of multiple slide rod press machine

The invention relates to a slide block driving device for multi-connecting-rod press machine. The slide block driving device comprises a frame, a motor, a fly wheel, a drive shaft, a transmission member, a slide block and a slide block lead rail. One end of the drive knuckle-lever of the transmission member is connected with and drives a connecting rod by a connection shaft and the other end of which is arranged on the side leg of a crank shaft. The coaxial deceleration gear of the crank shaft gears into a transmission gear arranged on the drive shaft. The slide block driving device is characterized in that the drive shaft is supported below one side of the frame by a bearing; the drive knuckle-lever is supported against the frame by the bearing in the manner of mismatched length; a drive tee is arranged at the other end; an upper fixed block and a lower fixed block are arranged in the drive chamber of the slide block; an upper rubbing block and a lower rubbing block are arranged between the drive tee and two fixed blocks respectively; the sphere of the drive tee is matched with two rubbing blocks and the drive tee can relatively slide between the running-in surfaces of two rubbing blocks; the upper fixed block is assembled by an adjustment bolt that is against the upper fixed block; and the lower fixed block is supported by a strut member that is against the lower fixed block. The slide block driving device has the advantages of stable running, small eccentric load and quick clearance adjustment, and thus is suitable for the such technologies as precise cold forging, cold warm forging, etc.

Owner:SHANDONG JINCHEN MACHINERY CORP LTD LTD

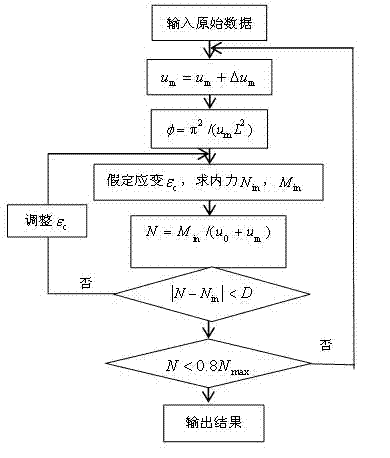

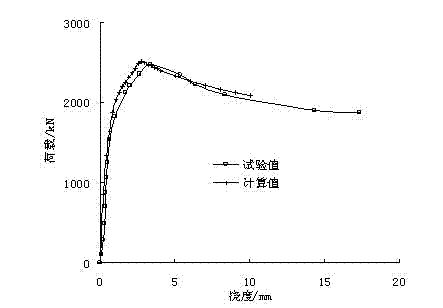

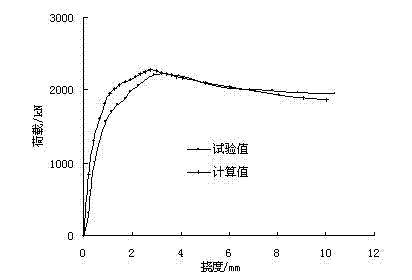

Method for performing stimulation test on stress of glass fiber reinforced plastic (GFRP) pipe steel reinforced high-strength concrete eccentric loading column

InactiveCN102305739AImprove ductilityFit closelyMaterial strength using tensile/compressive forcesHigh strength concreteStimulation tests

The invention discloses a method for performing stimulation test on the stress of a glass fiber reinforced plastic (GFRP) pipe steel reinforced high-strength concrete eccentric loading column, and relates to a method for testing a building member. The method is characterized by comprising the steps of: analyzing the whole stress process under the action of an eccentric compressive load; establishing a bearing capacity calculation program of the GFRP pipe steel reinforced high-strength concrete eccentric loading column on the basis of a finite strip method with assumed plane sections; and calculating to obtain a load and deformation relation curve and a curve of the influence of the concrete strength, slenderness ratio, eccentricity and steel ratio on load-deformation by using the program, and performing test analysis. The test analysis shows that: the ultimate bearing capacity of a member is decreased along with the increase of the slenderness ratio, the elastic stage of a member curve is gradually shortened, and the rigidity is gradually lost; the ultimate bearing capacity of the member is decreased along with the increase of the eccentricity; the ductility of the member is improved; and the ultimate bearing capacity of the member is improved along with the improvement of the strength of concrete. In the method, a test analysis result and a test result are consistent, and a basis is provided for the actual design.

Owner:SHENYANG UNIV

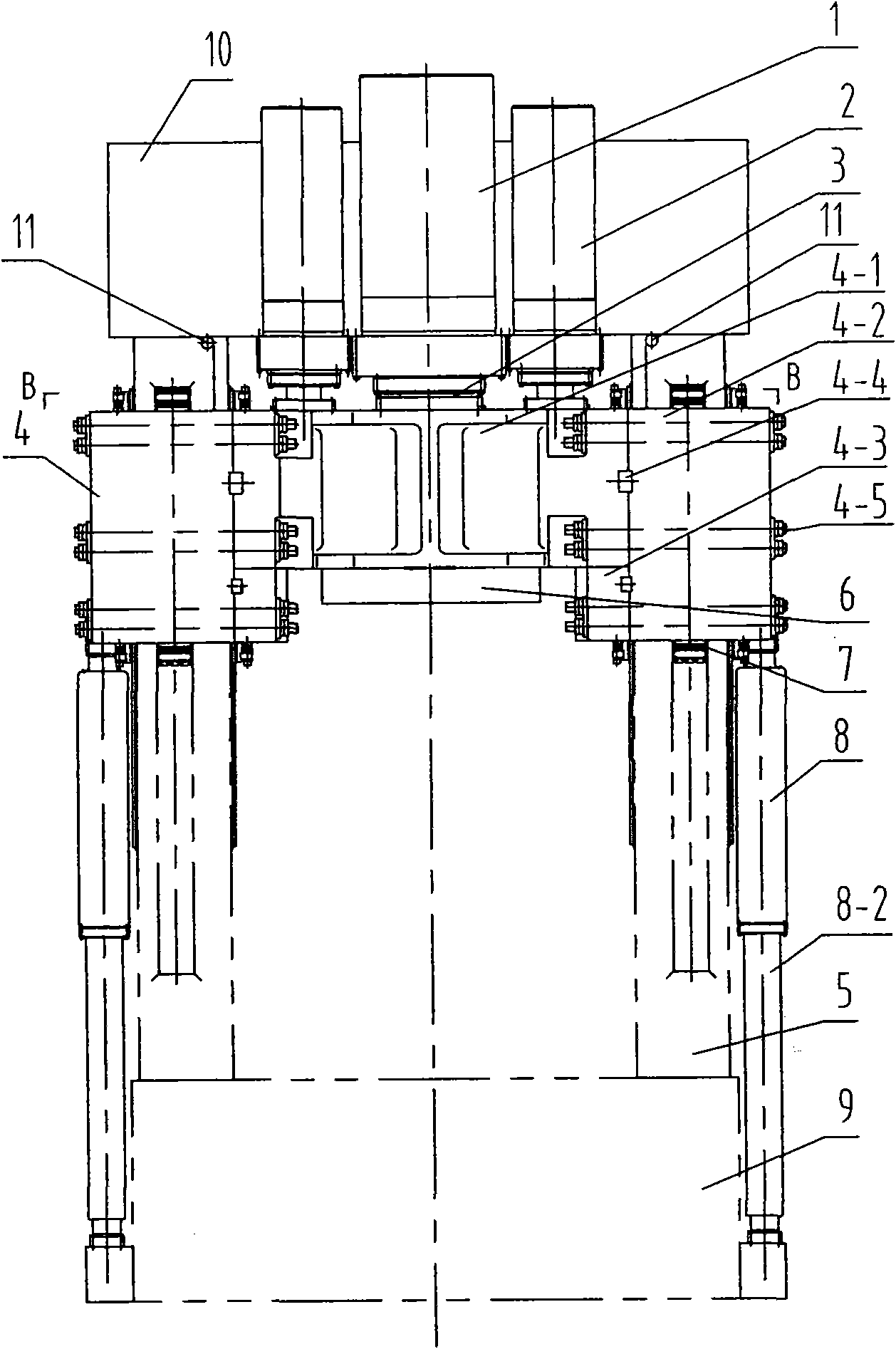

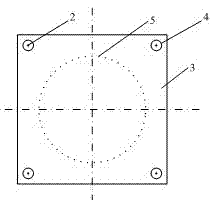

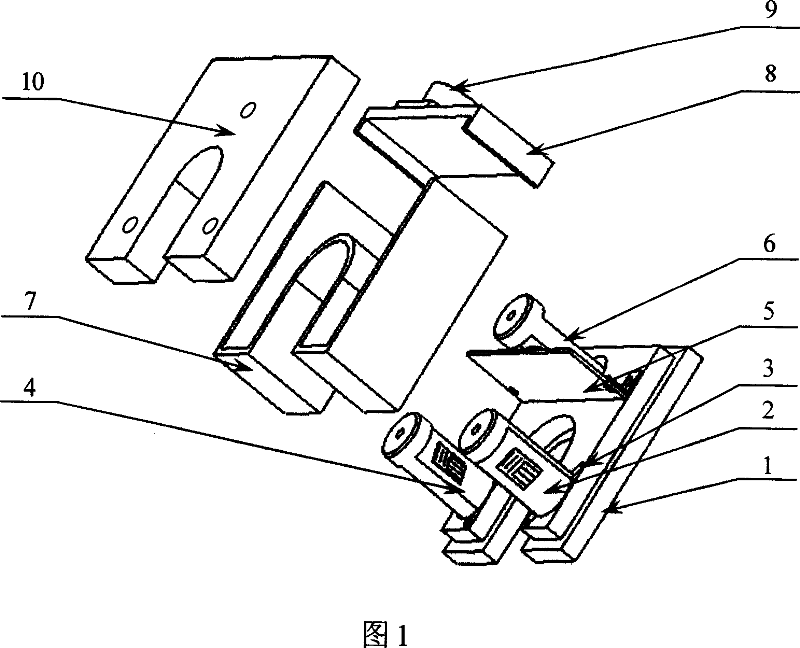

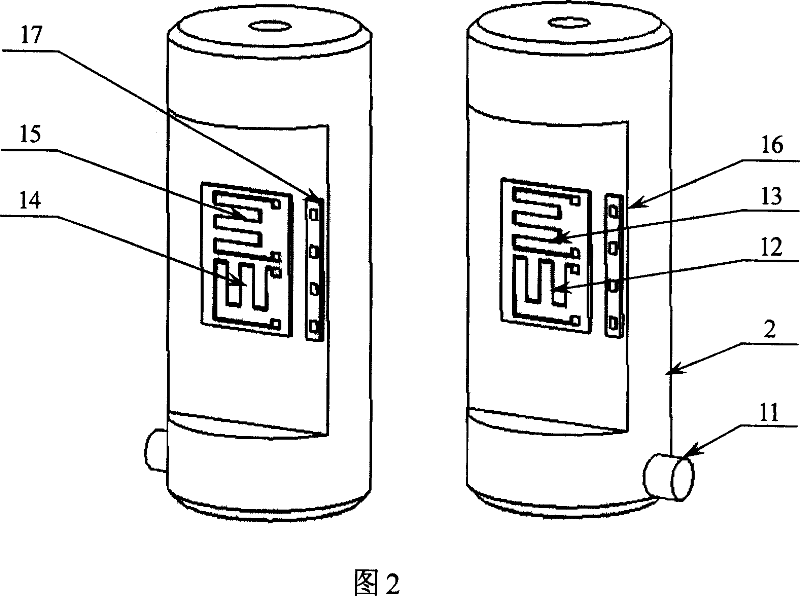

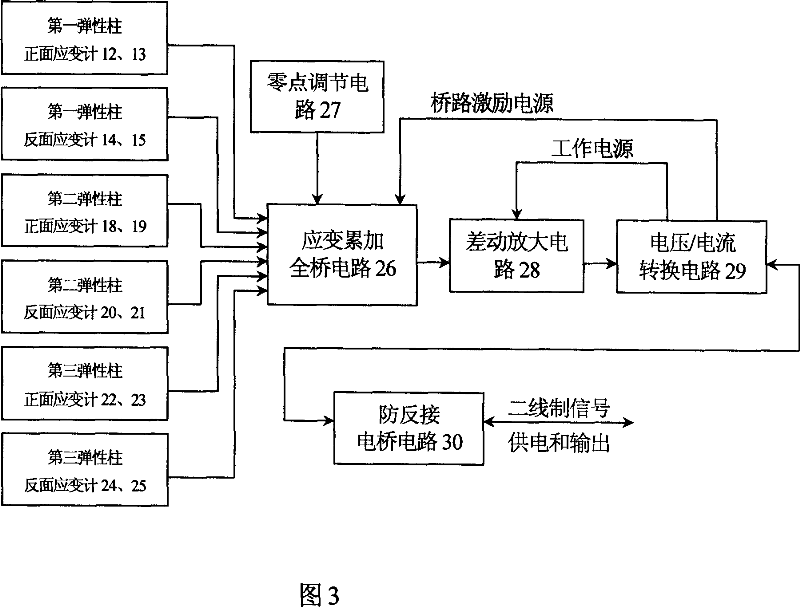

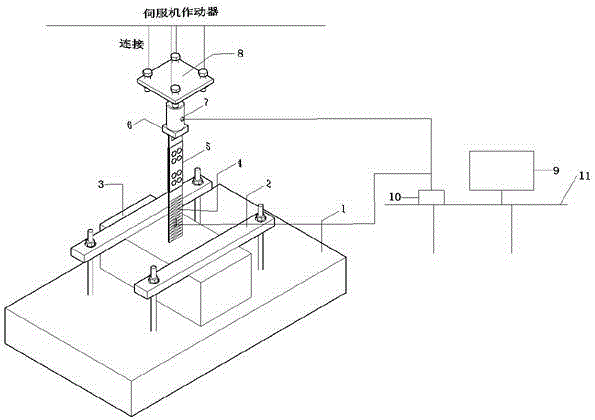

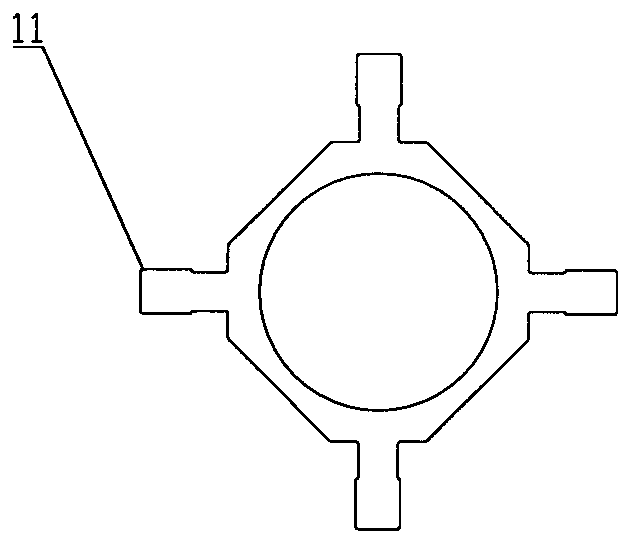

Opening type anti-eccentric-loading three elastic cylinders load cell

InactiveCN101033999ADoes not affect measurement accuracyAccurate Load SignalWeighing apparatus using electromagnetic balancingTransducerEccentric loading

This invention relates to a load transducer of open type, resisting eccentricity loaded and three elastic posts. Connect three selfsame elastic posts on the open type lower loading plate; built-in amplifying circuit board attach with three elastic posts; lower loading plate's side connect with curve type shell and strap; Upper end of three elastic posts attach upper loading plate; pros and cons of elastic post middlepiece all paste two piece strain gauge and connector; strain gauge's led feet monogamy connect with connector, connector by wire join to amplifying circuit board; this invention adopt open type low-short structure, via amplifying circuit board built-in load transducer to realize three elastic post's strain signal summation, even if load eccentricity will not impact accuracy of measurement. amplifying circuit panel gain precise load signal by amplify cumulative strain signal, and translate these signal into two-wire channel current signal to make remote transmission.

Owner:XI AN JIAOTONG UNIV

Protective coating adhesion effect test device and test method under action of uniaxial tension

InactiveCN105388107AChange sizeRealize the effect of cohesionUsing mechanical meansMaterial analysisEngineeringEccentric loading

The invention is suitable for the technical field of bridge anti-corrosion engineering coating performance tests, and discloses a protective coating adhesion effect test device under the action of uniaxial tension. The test device comprises test pieces, a fixation system, a loading system and a recording system, and the test device needs to be matched with a large hydraulic servo structure tester for use. The test pieces are composed of a concrete block and steel plates with holes; the fixation system comprises a concrete counter-force foundation and a fixture used for fixing the experimental test pieces; the loading system comprises clamping plates, bolts, a lower connector and an upper connector; the recording system comprises a strain gauge and a pressure sensor. According to the protective coating adhesion effect test device under the action of the uniaxial tension, operation is flexible, and fixation is simple; by means of the method of adjusting the loading system, changing the sizes of the test pieces, changing the loading mode and the like, the tests of the bond value, protective coating damage and the like of the protective coating and the concrete and protective components under the action of axial loading, the action of eccentric loading, the size effect of the test pieces and the action of vibration fatigue are achieved.

Owner:XUZHOU UNIV OF TECH

Novel lift well

ActiveCN105883549AEliminates increased wearImprove stabilityElevatorsBuilding liftsEngineeringEccentric loading

The invention relates to a novel lift well. The novel lift well comprises polyhedral upright columns, a base plate, a top plate, a lift car frame and a counterweight housing. The lift car frame comprises an upper beam, lift car upright columns and a base beam. Guide shoes are arranged on the lift car upright columns. The counterweight housing comprises counterweight beams and counterweight upright columns. At least four hollow polyhedral upright columns are arranged in the lift well. Column piles are further arranged in the lift well and connected to the two end faces of the polyhedral upright columns in a threaded mode. The base plate and the top plate are placed at the two ends of the polyhedral upright columns correspondingly and connected with the column piles in a threaded mode. The polyhedral upright columns are arranged to be used in cooperation with the guide shoes arranged on a lift car through rectangular protrusions arranged on the polyhedral upright columns so that car guide rails can be formed. Further, the four-guide-rail structure is adopted, each polyhedral upright column is matched with the two guide shoes arranged at the corresponding apex angle of the lift car, the phenomenon of severe abrasion of the guide shoes caused by lift car eccentric loading is eliminated, and therefore, the stability of lift operation is enhanced, installation cost is lowered, installation precision is improved, and lift space occupation is reduced at the same time.

Owner:NINGBO GUDA MECHANICAL & ELECTRICAL

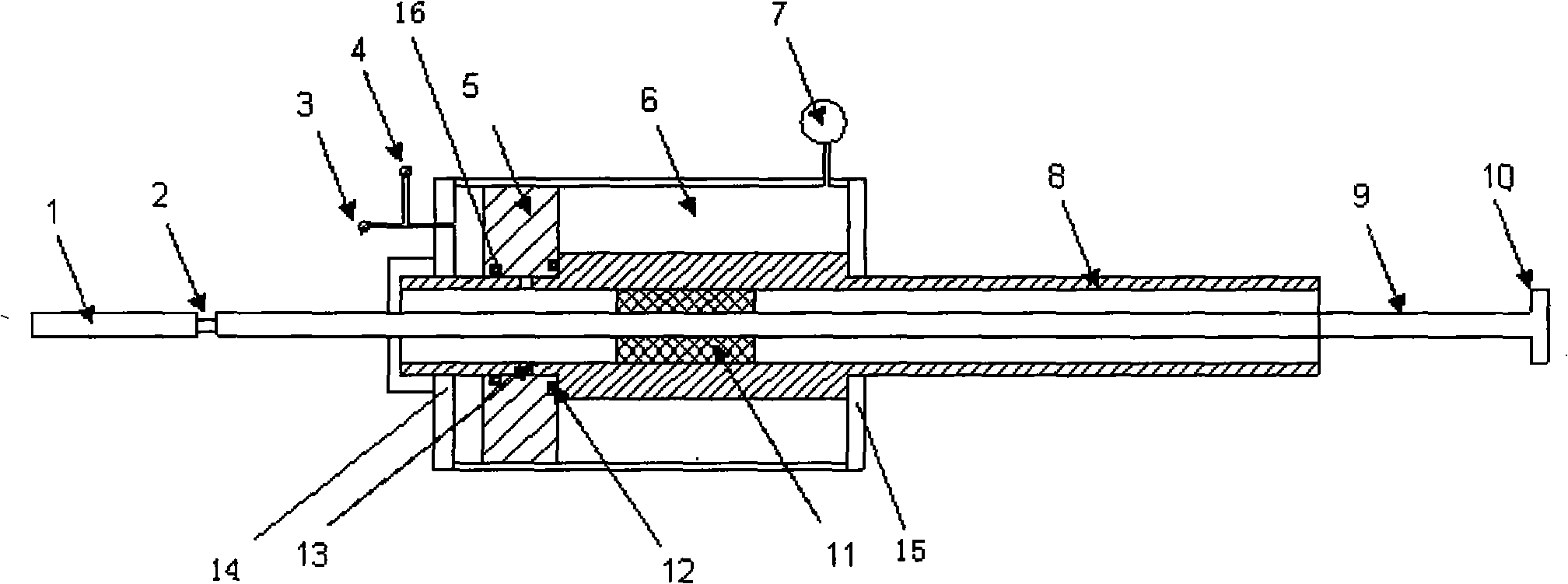

Air valve device for stretching experiment

InactiveCN101339108AMove quicklyEasy to operateMaterial strength using tensile/compressive forcesInlet valvePush pull

The invention discloses a valve device which is used in a tensile test and which comprises a transmission rod, an incidence rod, a flange, a loading cylinder, a connecting sleeve, a push-pull rod and an accelerating cylinder. The valve device is characterized by comprising an emitting valve, an inlet valve, a sliding block, an air-chamber cavity and a gun tube. The air-chamber cavity is cylindrical; two ends of the air-chamber cavity are sealed by an end cap and form an air chamber with the gun tube; a half of the gun tube is arranged in the air-chamber cavity and the other half extends out of the right end cap of the air-chamber cavity; the sliding block is arranged at the left end of the air-chamber cavity and is sleeved on the gun tube; thus part of the sliding block can move leftwards and rightwards along the periphery of the gun tube; the radial center of the sliding block on the gun tube is provided with an air intake; the loading cylinder is arranged in the gun tube; the internal circle of the loading cylinder matches the incidence rod in a sliding way; the external circle of the loading cylinder matches the gun tube in a sliding way. Because of the arrangement of the sliding block, the pressure difference on two sides of the sliding block can be applied to the experiment; the sliding block moves coaxially along the incidence rod and the gun tube; the valve device has the advantages of simple operation and high reliability, and prevents the problem of eccentric loading.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

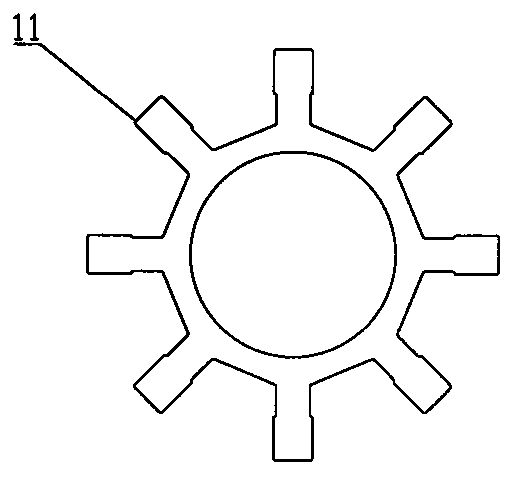

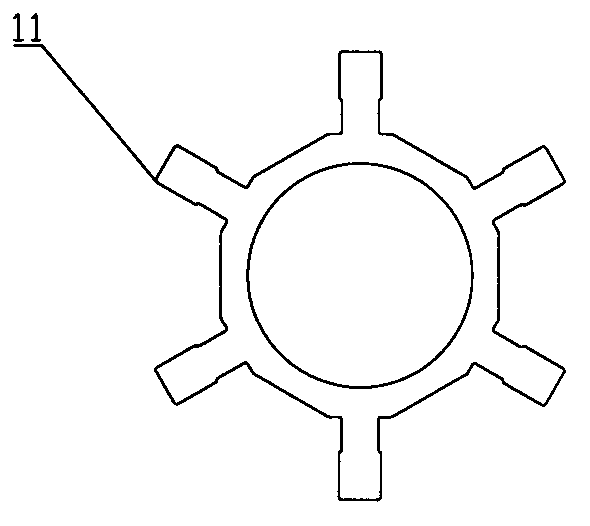

Aeroengine ratchet impact intensity testing device

The invention relates to an aeroengine ratchet impact intensity testing device, which comprises an impact testing machine, an impact hammer, a ratchet fixing holder, a connecting pin and an acceleration sensor. The impact testing machine is provided with a base and a hammer head holder. The impact hammer is fixed to the hammer head holder. The ratchet is fixed on the ratchet fixing holder through the connecting pin and the ratchet fixing holder is fixed to the base. The acceleration sensor is used to monitor the speed variation during an impact process. The aeroengine ratchet impact intensity testing device of the invention can complete the test on the impact intensity of an engine ratchet, and can accurately measure the impact intensity and a breaking process. When some connecting parts of the device are replaced, it can be applied to the tests on the impact intensity of various eccentric loadings. The device is also advantageous in that its structure is simple, its manufacturing cost is low and its application is wide.

Owner:AECC SHENYANG ENGINE RES INST

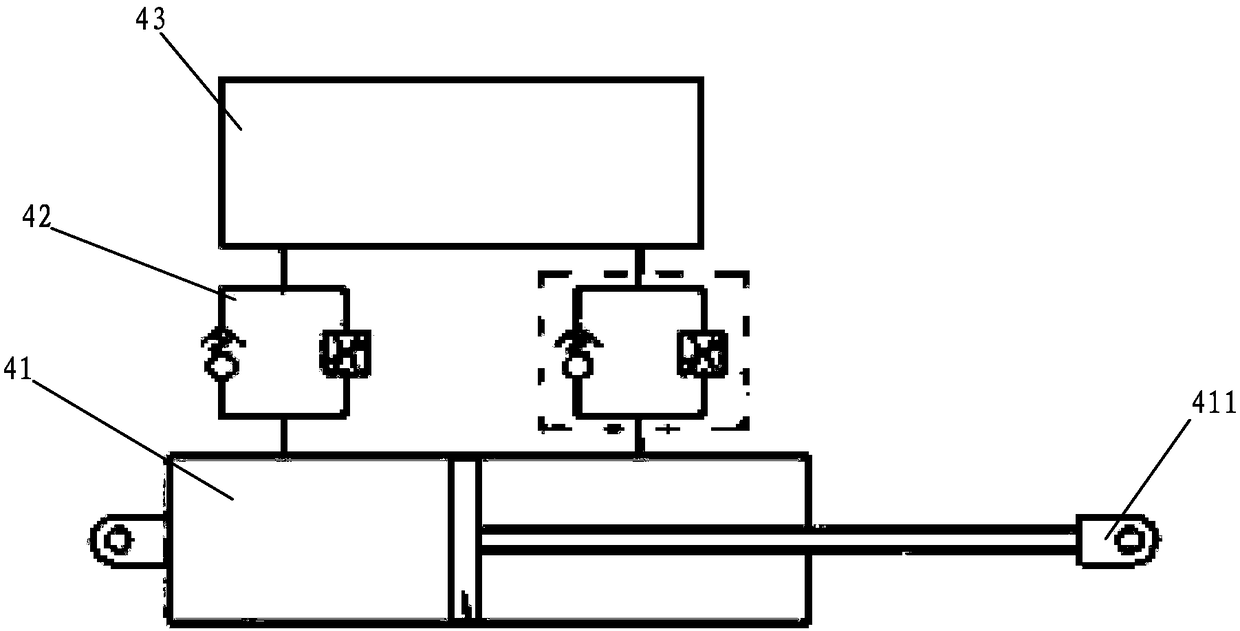

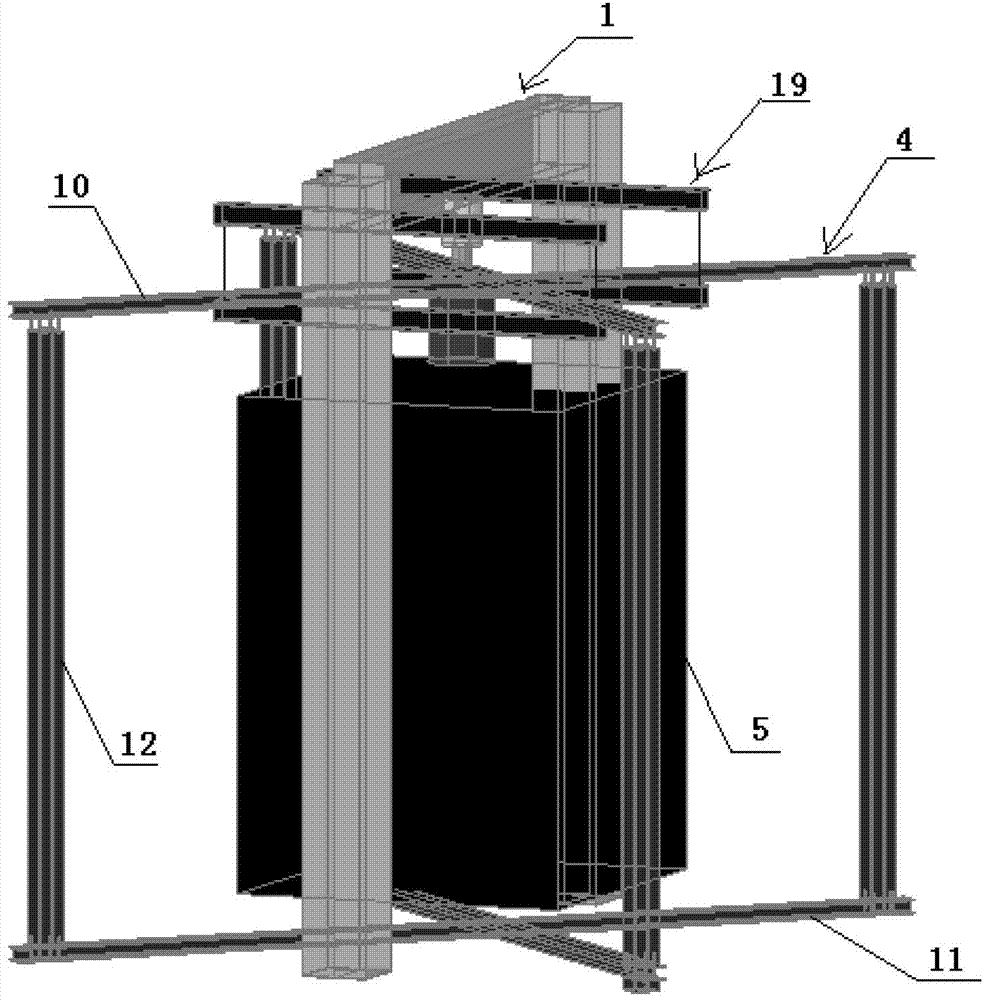

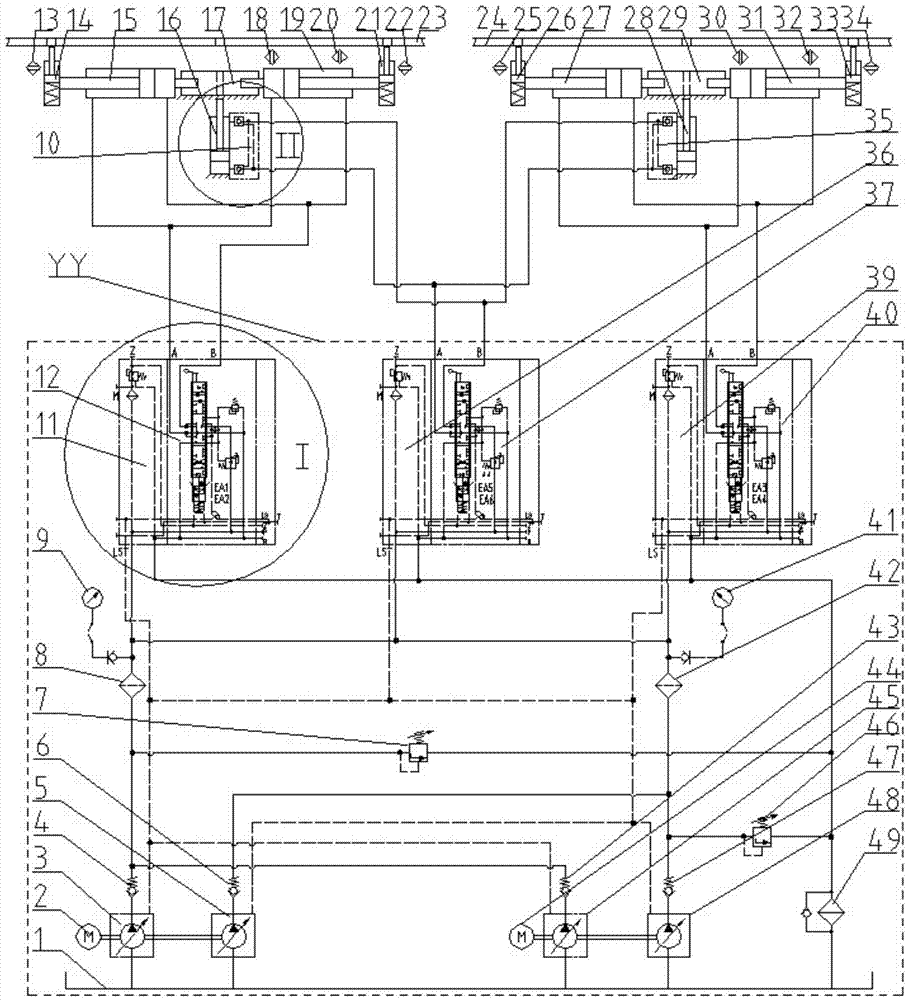

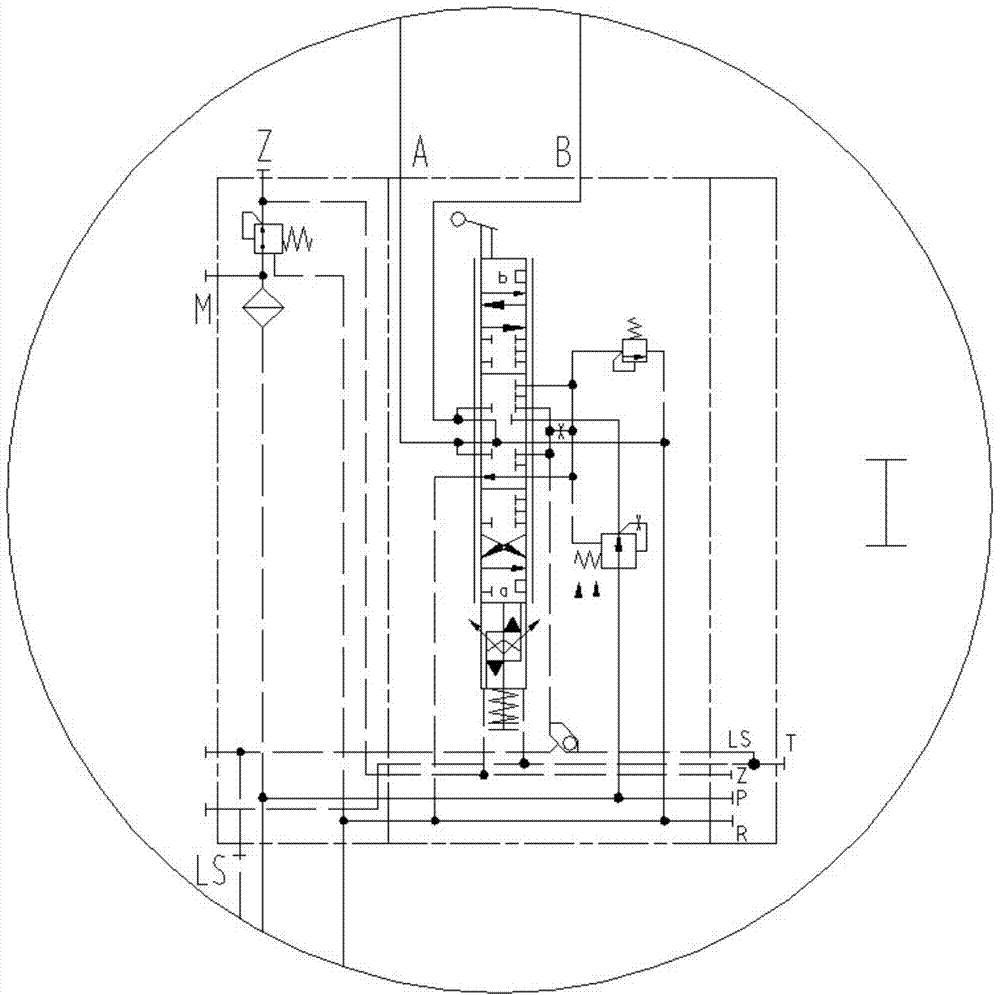

Cantilever beam slippage system for self-elevating drilling platform

ActiveCN103882843ASmooth back and forthQuickly handle emergencies such as damageArtificial islandsUnderwater structuresCantilevered beamLine tubing

The invention discloses a cantilever beam slippage system for a self-elevating drilling platform. The cantilever beam slippage system comprises at least two hydraulic execution components distributed at the symmetric positions of the two sides of a cantilever beam, control valve sets matched with the hydraulic execution components and connected with the corresponding hydraulic execution components, a hydraulic pipeline assembly connected with the hydraulic execution components and the control valve sets, a power unit, a valve, an instrument and an oil source, wherein the power unit, the valve, the instrument and the oil source are installed in the hydraulic pipeline assembly and used for controlling and achieving work of the hydraulic execution components. The power unit comprises at least two double pump sets, and the double pump sets are backups for each other. According to the cantilever beam slippage system, eccentric loading of the execution components on the two sides of the cantilever beam does not occur, the cantilever beam moves, returns and slips smoothly, the phenomenon that the cantilever beam is twisted and getting stuck due to eccentric loading and can not be compensated does not occur, and the double pump sets can be started to drive the cantilever beam to slip and be started under the condition of the maximum starting static friction force .

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

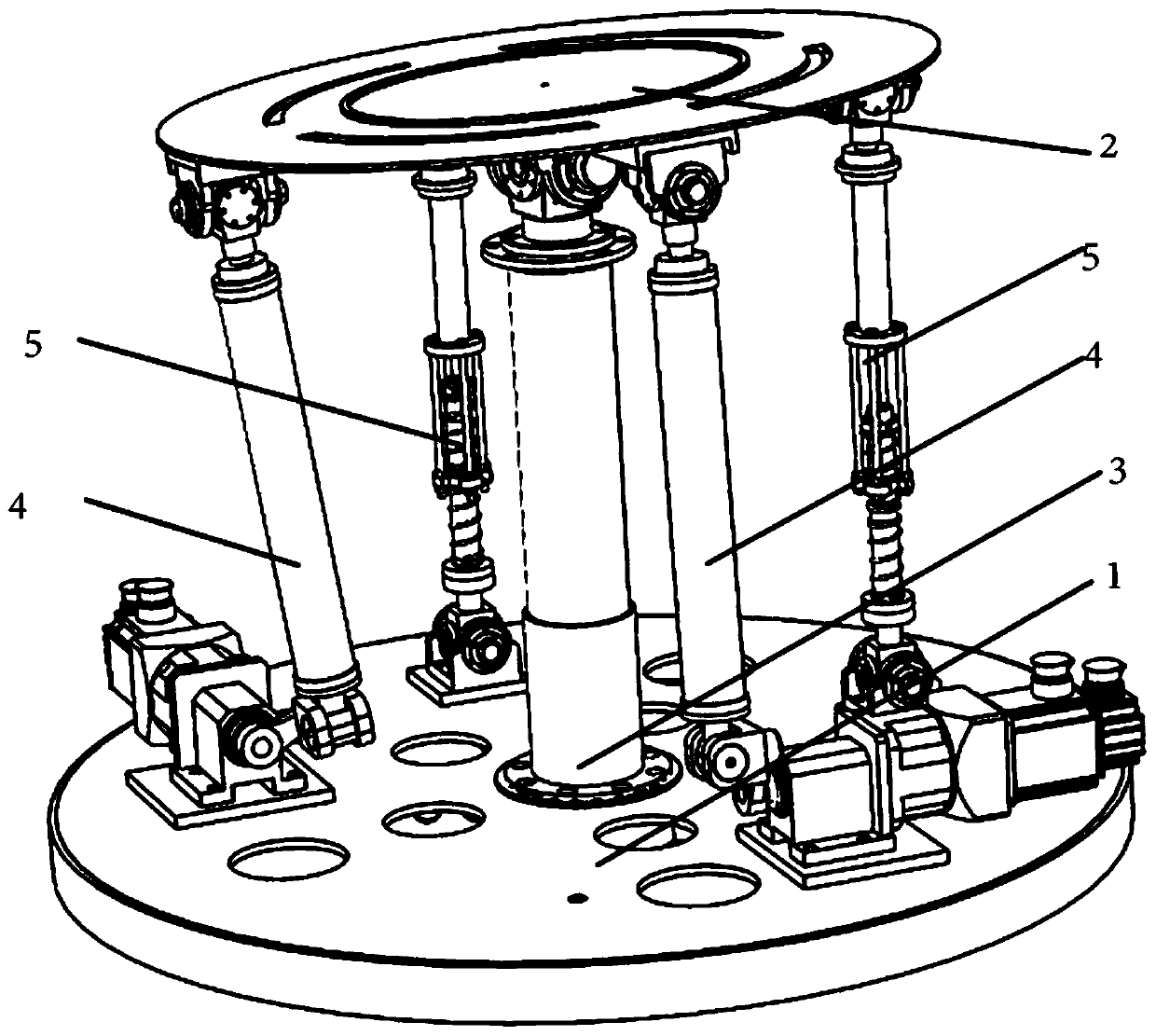

Two-degree-of-freedom parallel-connection rotating platform with eccentric torque unloading device

ActiveCN111059431AImprove carrying capacityReduce eccentric loadStands/trestlesClassical mechanicsEngineering

The invention discloses a two-degree-of-freedom parallel-connection rotating platform with an eccentric torque unloading device. The platform comprises a fixed platform, a movable platform, a supporting branch chain, a driving branch chain and an auxiliary branch chain, wherein the auxiliary branch chain comprises a tension-compression spring device, the tension-compression spring device comprisesa lower supporting rod, the bottom end of the lower supporting rod is hinged to the fixed platform, the lower supporting rod is sleeved with an annular sleeve movably connected with the lower supporting rod, a radial locking nut is fixed to the top of the lower supporting rod, an upper compressed spring is installed between the radial locking nut and the annular sleeve, a lower compressed springis arranged between the annular sleeve and the bottom of the lower supporting rod, the outer wall of the annular sleeve is fixedly connected with the bottom of an upper supporting rod arranged above the lower supporting rod through a plurality of connecting columns, and the top of the upper supporting rod is hinged to the movable platform. According to the platform, on the basis of a traditional rotating platform, the auxiliary branch chain is additionally arranged, eccentric loads can be effectively reduced through tension-compression spring device of the auxiliary branch chain, and the bearing capacity of the rotating platform is greatly improved.

Owner:YANSHAN UNIV

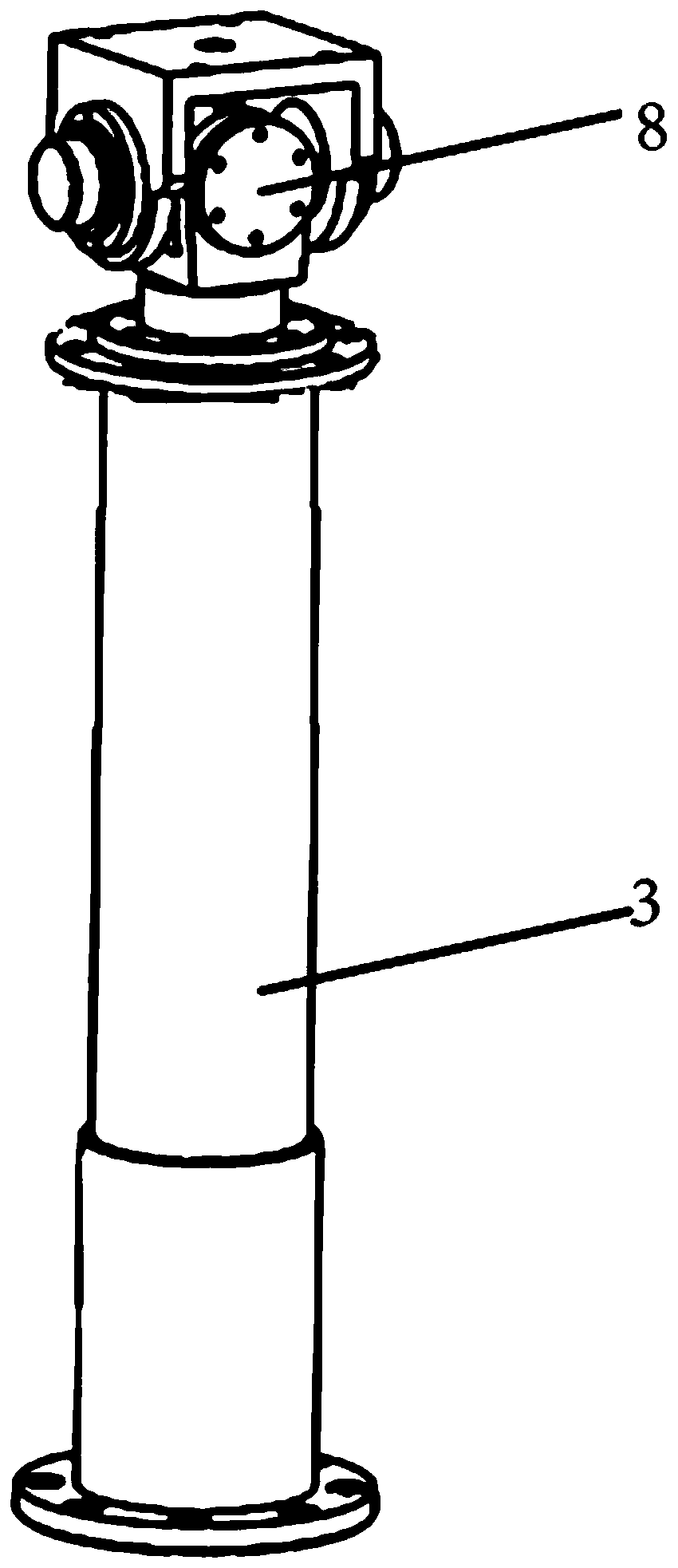

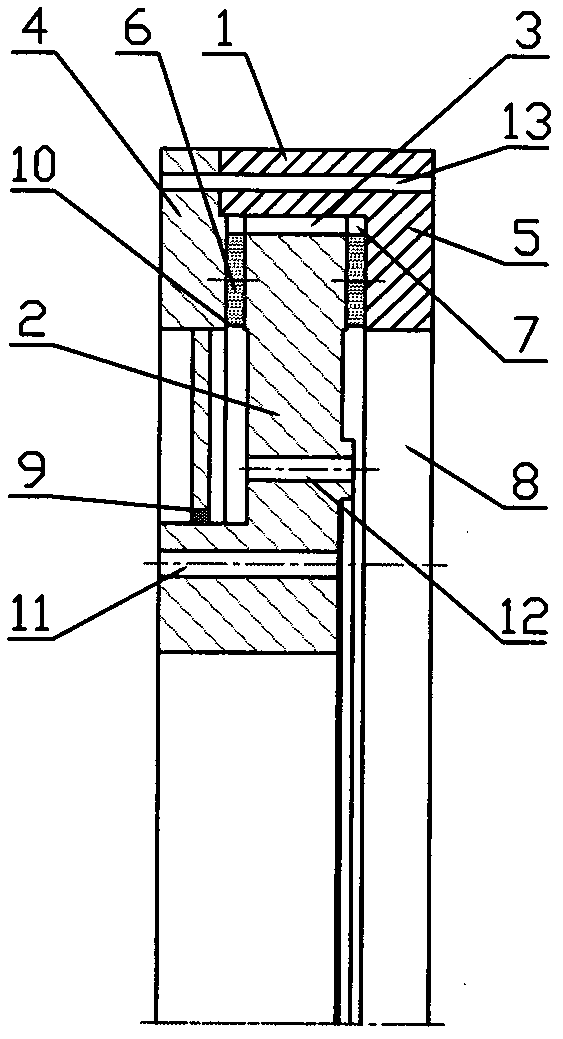

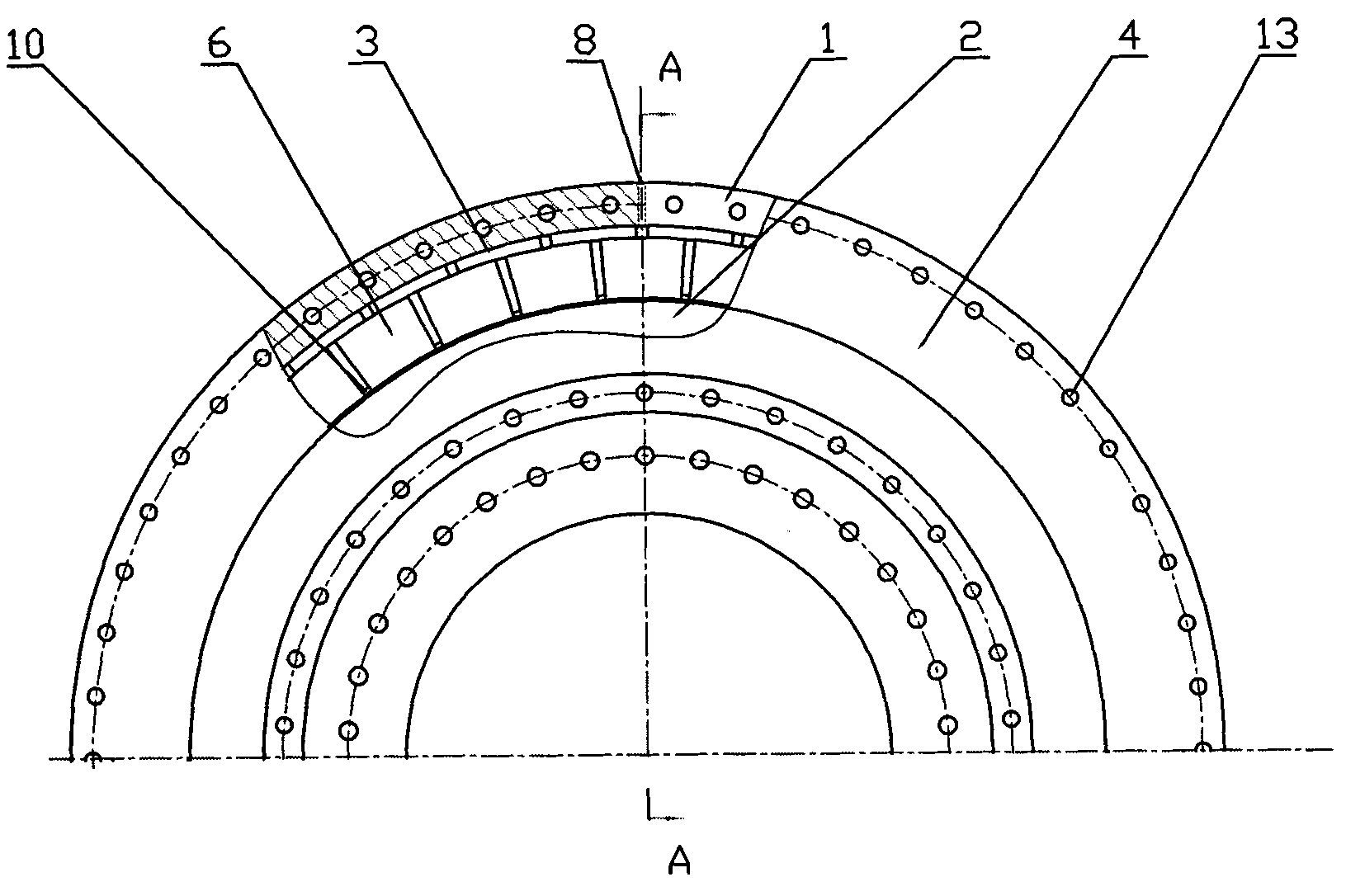

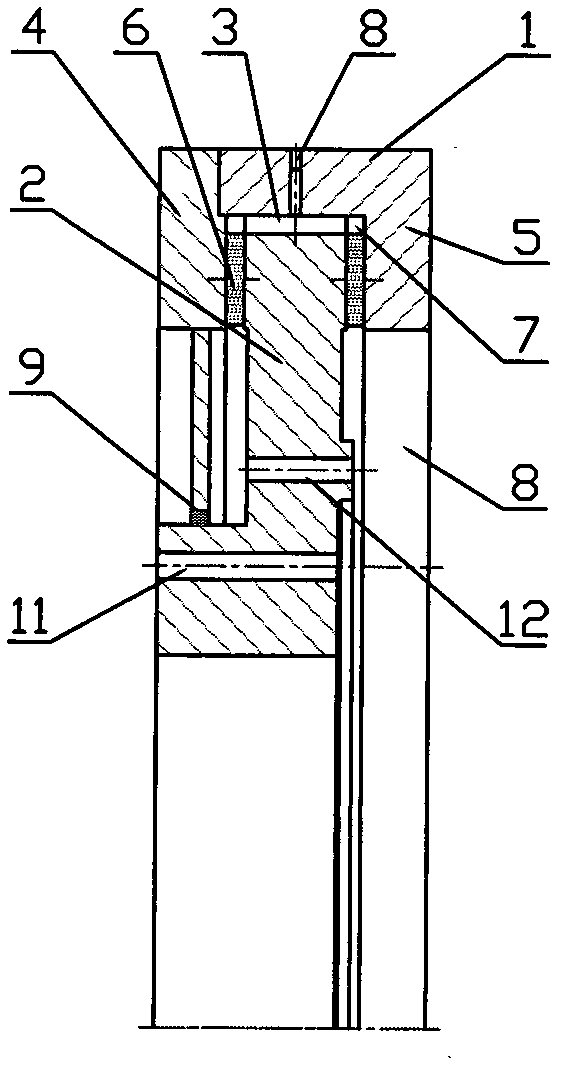

Three-directional composite self-lubricating sliding bearing for main shaft of wind turbine set

ActiveCN101963188AAutomatically adjusts for uneven loadsImprove the state of stressBearing componentsSliding contact bearingsAxial thrustEccentric loading

The invention discloses a three-directional composite self-lubricating sliding bearing for a main shaft of a wind turbine set, which has simple structure, convenient installation and disassembly and low cost, can avoid eccentric loading, can bear larger and multi-directional loads, is safe and reliable, has long service life and is provided with an outer ring (1) and an inner ring (2). A plurality of uniformly-distributed radial pads (3) are arranged between the outer ring (1) and the inner ring (2), an inward left thrust ring (4) is connected with the axial left side of the outer ring (1), an inward right thrust ring (5) is connected with the axial right side of the outer ring (1), a plurality of uniformly-distributed axial thrust pads (6) are respectively arranged between the left thrust ring (4) and the inner ring (2) and between the right thrust ring (5) and the inner ring (2), the radial pads (3) and the axial thrust pads (6) are provided with communicated lubricating passages (7), and the lubricating passages (7) are communicated with an oil filling hole (8).

Owner:DALIAN SANHUAN COMPOSITE MATERIAL TECH DEV +1

Dynamic tensile test fixture for test specimen and test method thereof

InactiveCN109738280AFully contactedGuaranteed coincidenceMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesJackscrewEngineering

The invention discloses a dynamic tensile test fixture for a test specimen. The dynamic tensile test fixture for the test specimen comprises an upper part and a lower part; the upper part and the lower part are separately arranged at both ends of the test specimen and are arranged symmetrically up and down, and the upper part and the lower part have the same structure; the upper part comprises a main fixture and an assistant fixture; the central part of the lower end of the main fixture is provided with a through groove; screw holes are arranged on both sides of the through groove; fixed filler sheets are arranged on both sides of the main fixture; the fixed filler sheet is connected to the main fixture through bolts and nuts; the main fixture and the assistant fixture are fixed through the fixed filler sheets; the middle part of the upper end of the assistant fixture is provided with a jackscrew through hole, and the middle part of the lower end is provided with a sample groove; the test specimen is arranged in the sample groove; and the assistant fixture and the test specimen are fixed through a jackscrew adapted to the jackscrew through hole. During the test, the test specimen,the assistant fixture and the main fixture are fixed through the jackscrew and the fixed filler sheets, so as to ensure that the tensile force applied by the testing machine coincides with the axis ofthe test specimen, thereby preventing eccentric loading from adversely affecting the test.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com