Encapsulated weighing cell with eccentric load error adjustment

A weighing sensor and error technology, applied in the field of weight measuring instruments, to achieve the effect of avoiding temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

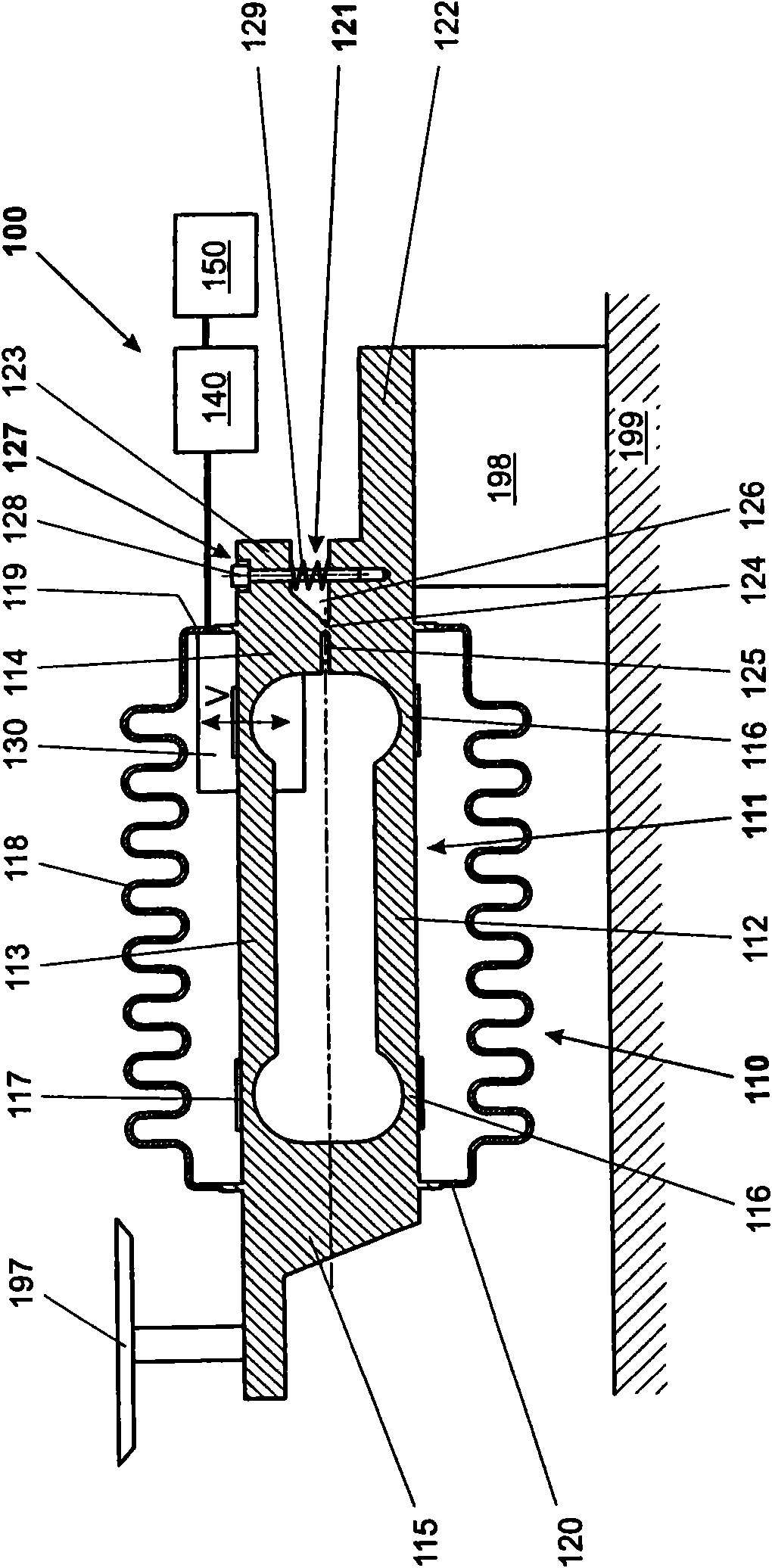

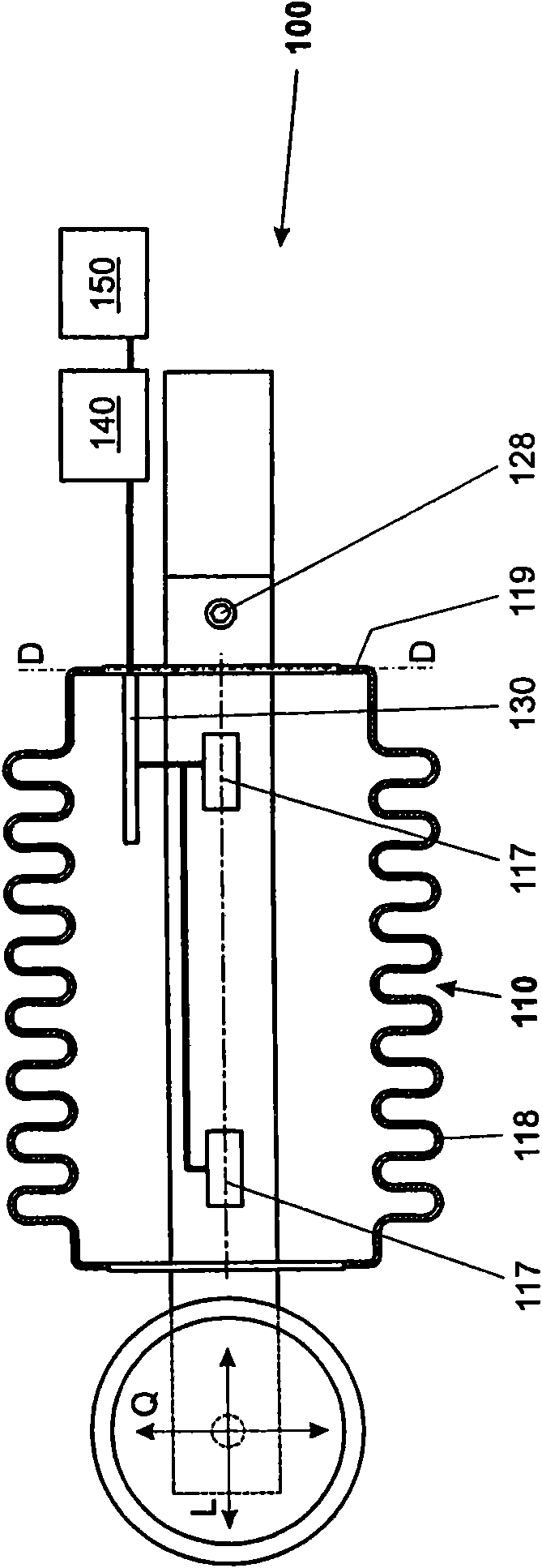

[0050] Figure 1A The gravimetric measuring instrument 100 in the first embodiment is shown in a sectional view seen from the side. The weight measuring instrument 100 includes a load cell 110 , a circuit module 130 , a processor module 140 and an input / output unit 150 . The load cell 110 has a parallel guide 111 whose fixed parallelogram legs 114 are mounted on a solid ground 199 via a support 198 . The load cell 110 also includes a movable parallelogram leg 115, which is connected to a load receiver 197, for example to a load pan. The movable parallelogram leg 115 is guided in vertical movement and is connected to the fixed parallelogram leg 114 by means of an upper parallelogram guide mechanism 113 and a lower parallelogram guide member 112 . A flexible pivot 116 is formed in the connection area between the parallel guide members 112 , 113 and the parallelogram legs 114 , 115 . Measurement transducers, more particularly strain gauges 117 , are arranged in each connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com