Restraint device for column fire resisting test

A technology of restraint device and restraint beam, which is applied in the direction of measuring device, machine/structural component test, instrument, etc., can solve the problems of test device damage, temperature stress, inaccurate test results, etc., to provide in-plane rigidity, improve Safety factor, effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

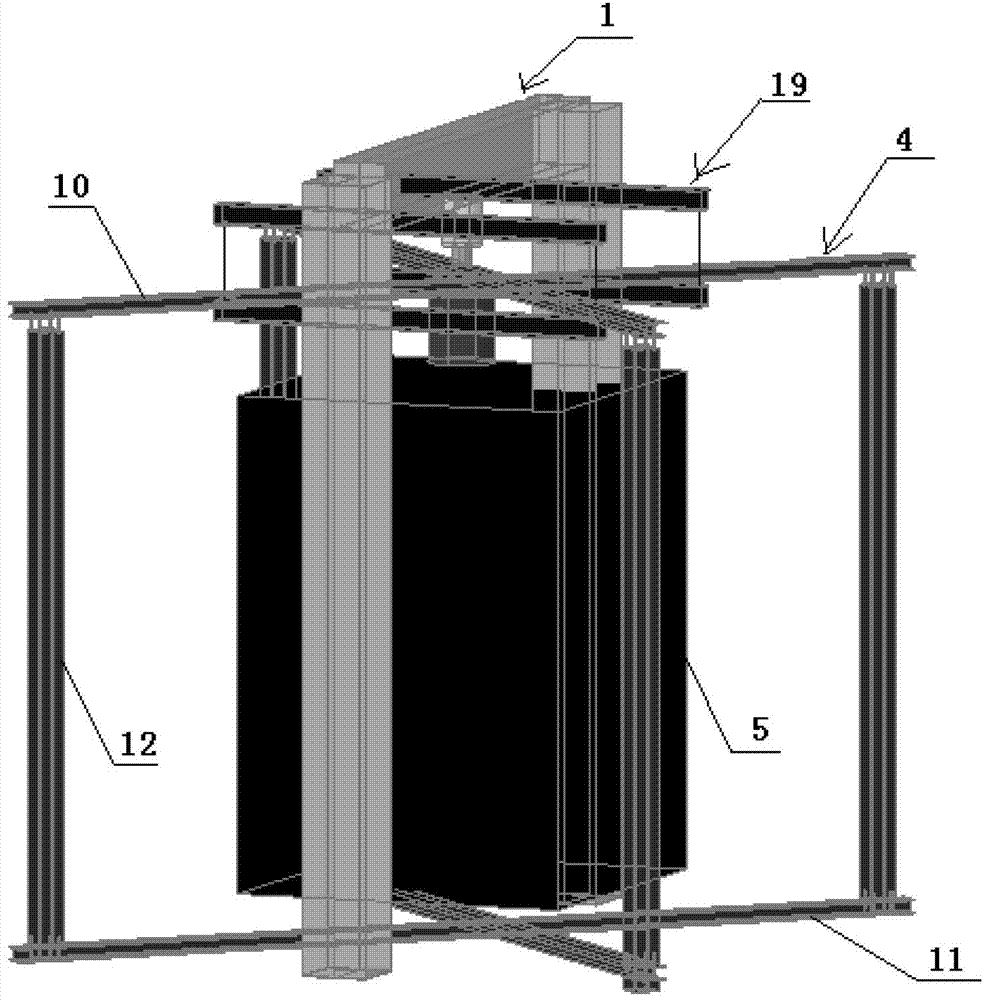

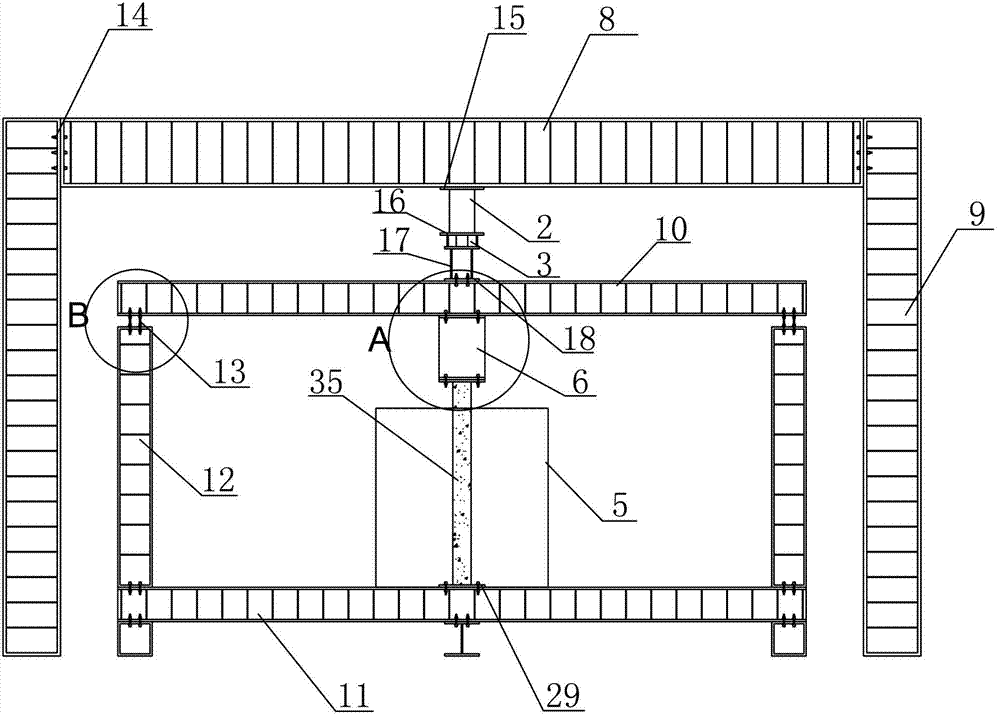

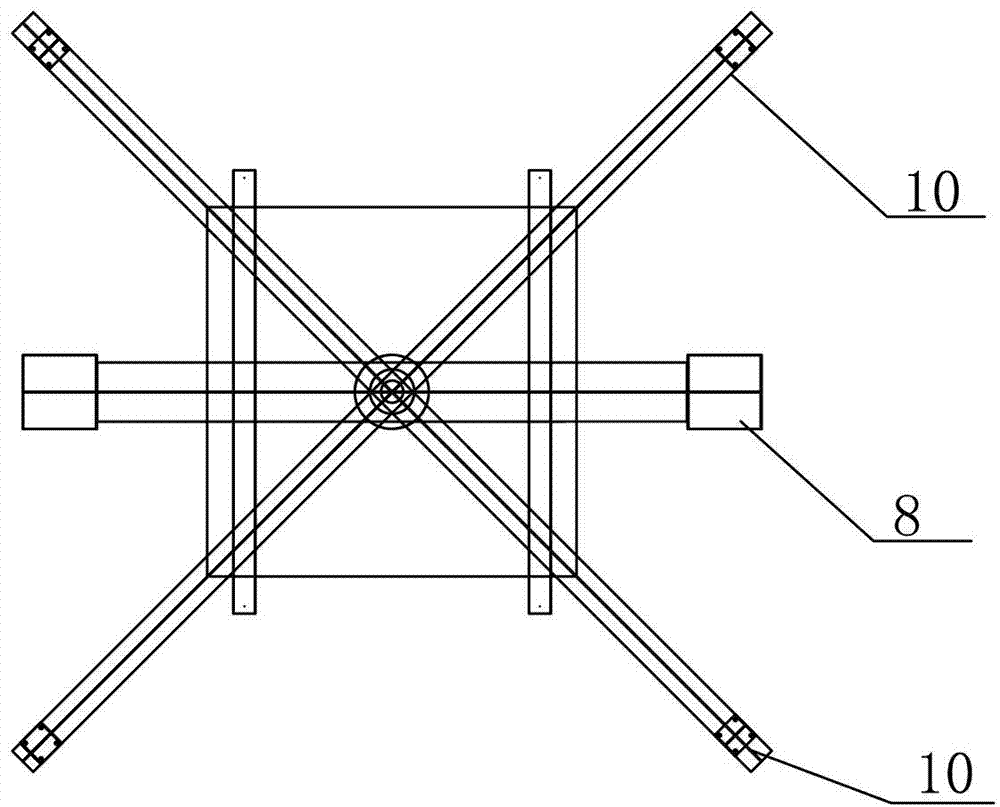

[0031] The present invention is a restraint device for column fire resistance test, such as figure 1 and figure 2 As shown, it includes a loading reaction frame 1, a jack 2, a load sensor 3, a constraint frame 4, a heating furnace 5, a measuring column generating a constraint force device 6, and several displacement gauges 7 (see Figure 4 shown), the loading reaction frame 1 is mainly surrounded by a steel beam 8 arranged horizontally and two steel columns 9 arranged vertically. not shown in ) fixedly connected rectangular frame, the rectangular frame includes a horizontally arranged upper restraint beam 10, a lower restraint beam 11 and two vertically arranged restraint columns 12, the upper restraint beam 10 is located at the lower end of the steel beam 8, the jack 2 and the load sensor 3. Arranged sequentially from top to bottom between the steel beam 8 and the upper constraining beam 10. The measuring column generating constraining force device 6 and the heating furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com