Clamping device and method for anti-eccentric loading of double-shearing experiment

A technology of eccentric loading and clamping devices, which is applied to measuring devices, using stable shear force to test the strength of materials, instruments, etc., can solve the problems of eccentric bending moment, easy to generate torque, misalignment of test pieces, etc., and achieve reduction Effects of size, space saving, and loading space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

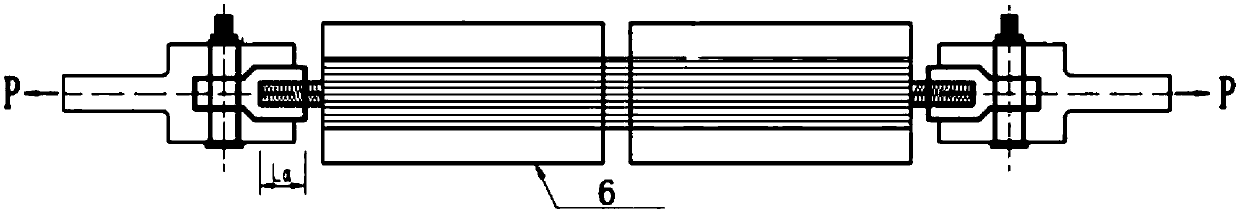

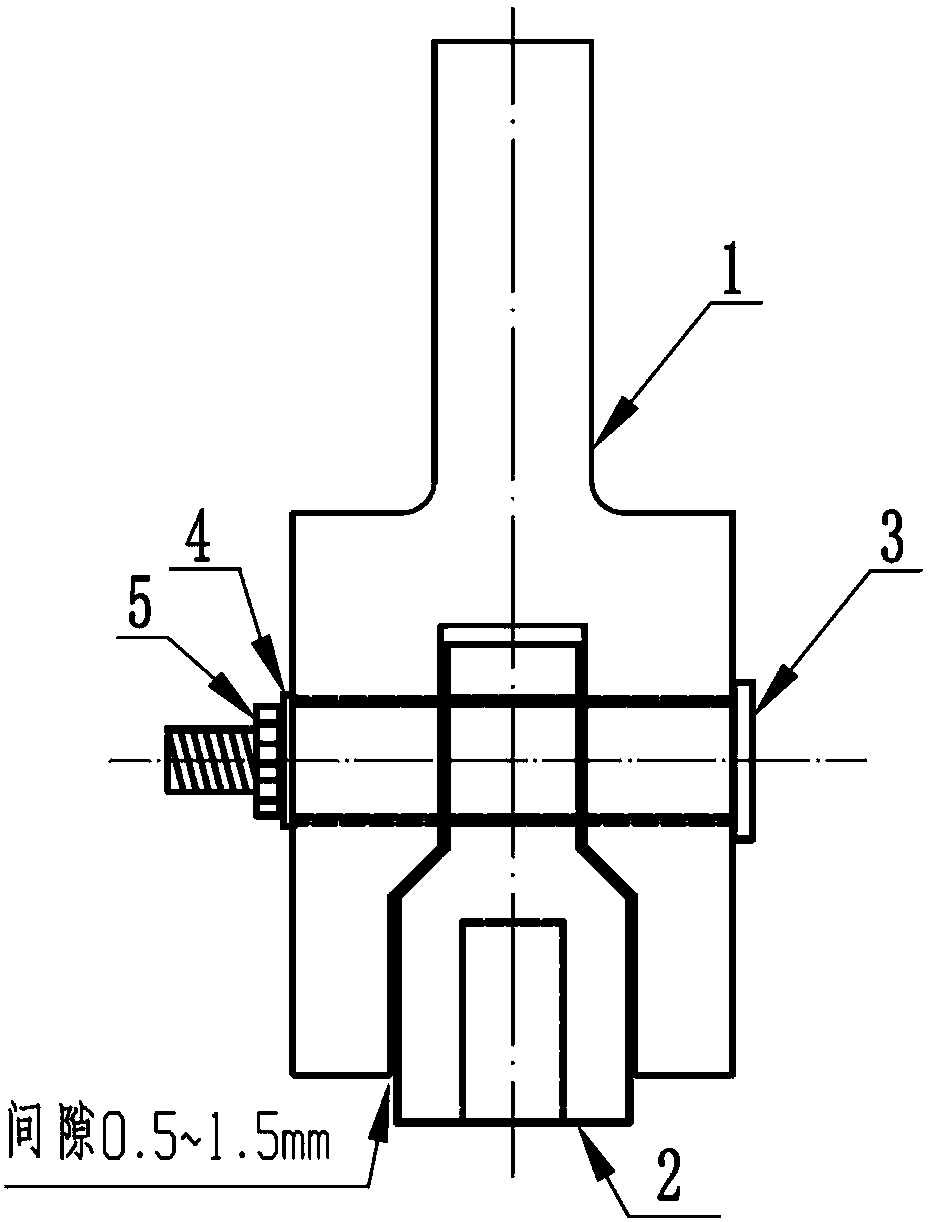

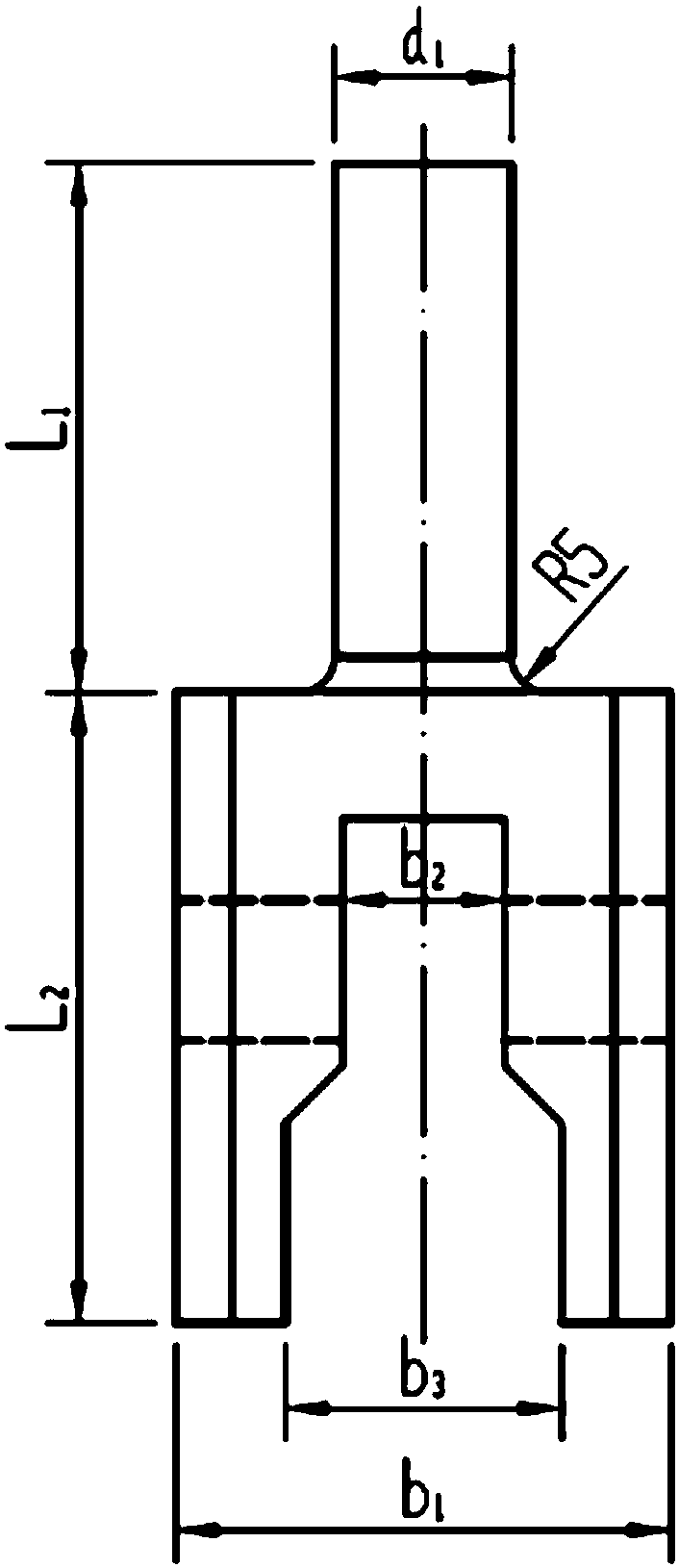

[0036] Such as Figure 1 to Figure 7 As shown, a double shear experiment anti-eccentric loading clamping device is used in the double shear experiment of the FRP-concrete interface under static load and fatigue load, and is connected between the testing machine and the threaded rods at the upper and lower ends of the concrete specimen. During the period, in order to eliminate the adverse effects of the torque and eccentric bending moment on the specimen during the installation and clamping process, a clamping device connected to both ends of the specimen 6 was adopted, including two combined loading heads with the same structure. The combined loading head includes a fork fixture 1, a suspension ring 2, and a pin connection device. One end of the fork fixture 1 is provided with a straight rod part clamped by the testing machine, and the other end is centered along the axis of the fork fixture 1. An open slot matching the shape of the suspension ring is provided, and one end of ...

Embodiment 2

[0071] In this embodiment, a clamping method for anti-eccentric loading in a double shear experiment based on the device,

[0072] Include the following steps:

[0073] 1) Make a double-shear test piece, and process the external thread at the leaky end of the ribbed steel bar that will be pre-embedded in test piece 6 for loading. The length of the external thread is ≥ 5d, and d is the diameter of the steel bar. The end of the steel bar for processing the external thread is closed; prevent the mortar from filling the thread in the process of making the test piece, and at the same time prevent the steel bar from rusting and making it difficult to connect.

[0074] 2) Connect the lifting ring with the test piece. After the double-shear test piece is made, remove the scotch tape at the end of the steel bar, clean it up, and screw the lifting ring into the external threaded part of the steel bar end at both ends of the test piece to realize When connecting with the test piece, pay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com