Multi-channel easy-open lid automatic stamping engineering design scheme and production line

An engineering design, easy-opening technology, applied in other home appliances, home appliances, applications, etc., can solve the problems of unbalanced punching force, easy-opening element molding cannot be produced at high speed and stable, and reduce downtime and operation. Maintenance cost, effect of reducing reactive load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

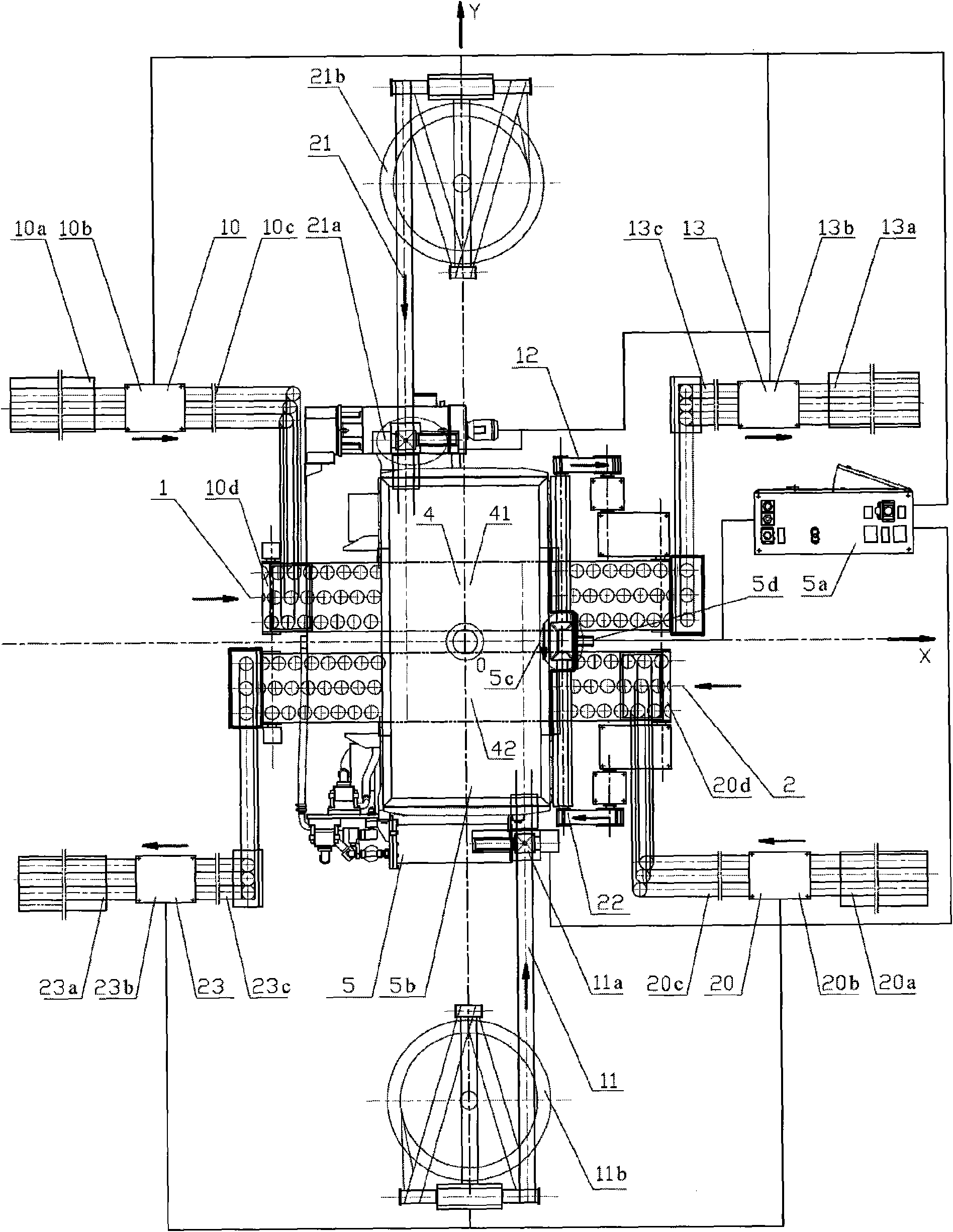

[0047] A 6-channel easy-open end stamping production line is built on a horizontal-axis high-speed punching machine as an example, and the implementation plan is described in detail with reference to the attached drawings.

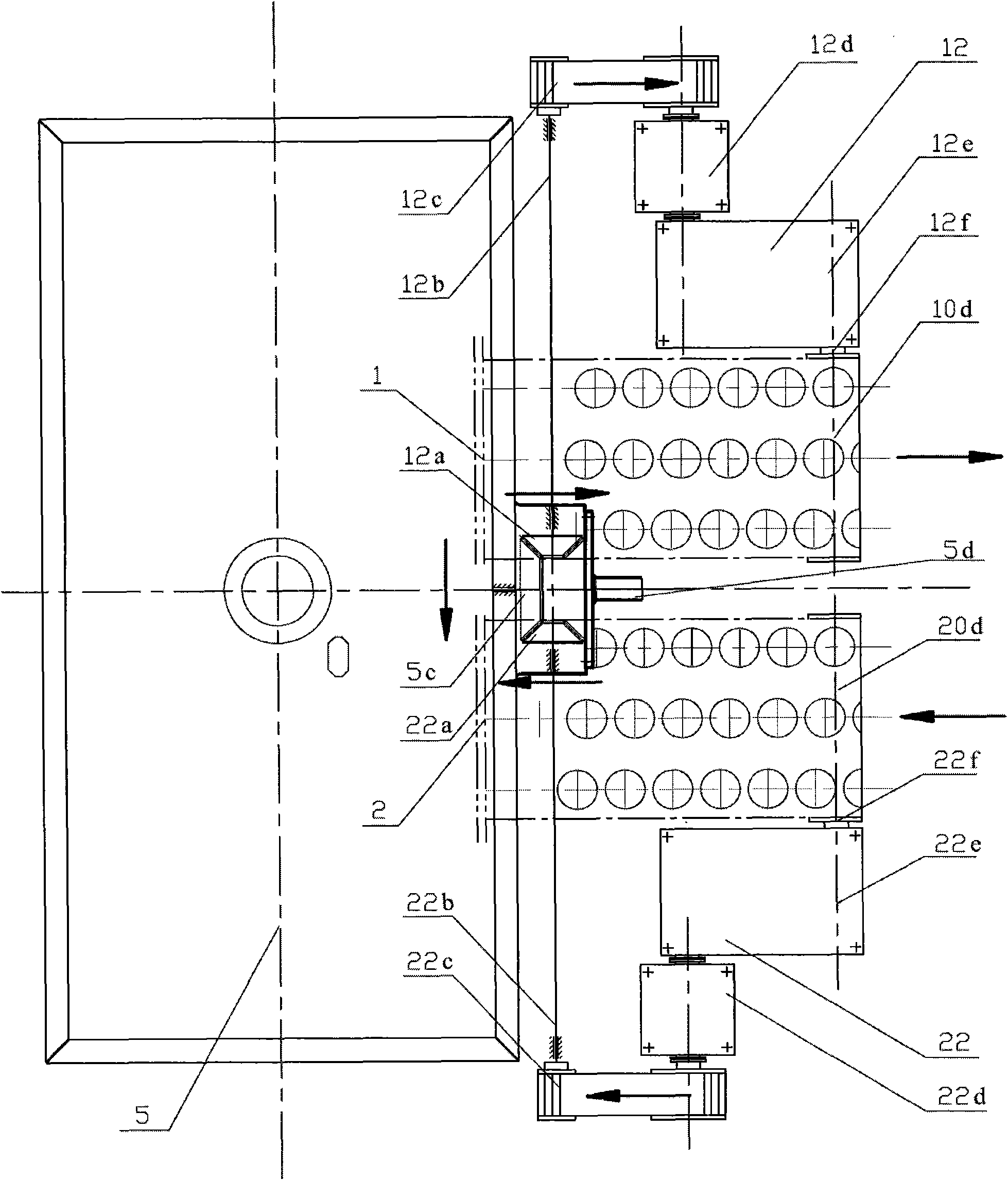

[0048] Such as figure 1 with figure 2 As shown, the 6-channel easy-open end automatic stamping production line described in Example 1 is composed of a high-speed punch 5, a channel group A and a channel group B, wherein the channel group A is composed of a basic cap feeding system 10, a tab feeding system 11, Transmission system 12, easy open end finished product conveying system 13 and channel group A combined progressive mold 41; channel group B consists of basic cover feeding system 20, pull ring material belt feeding system 21, transmission system 22, easy open end finished product conveying system 23 and channel group B combined progressive die 42 to form. Channel group A and channel group B are arranged in parallel and have opposite progressive di...

Embodiment 2

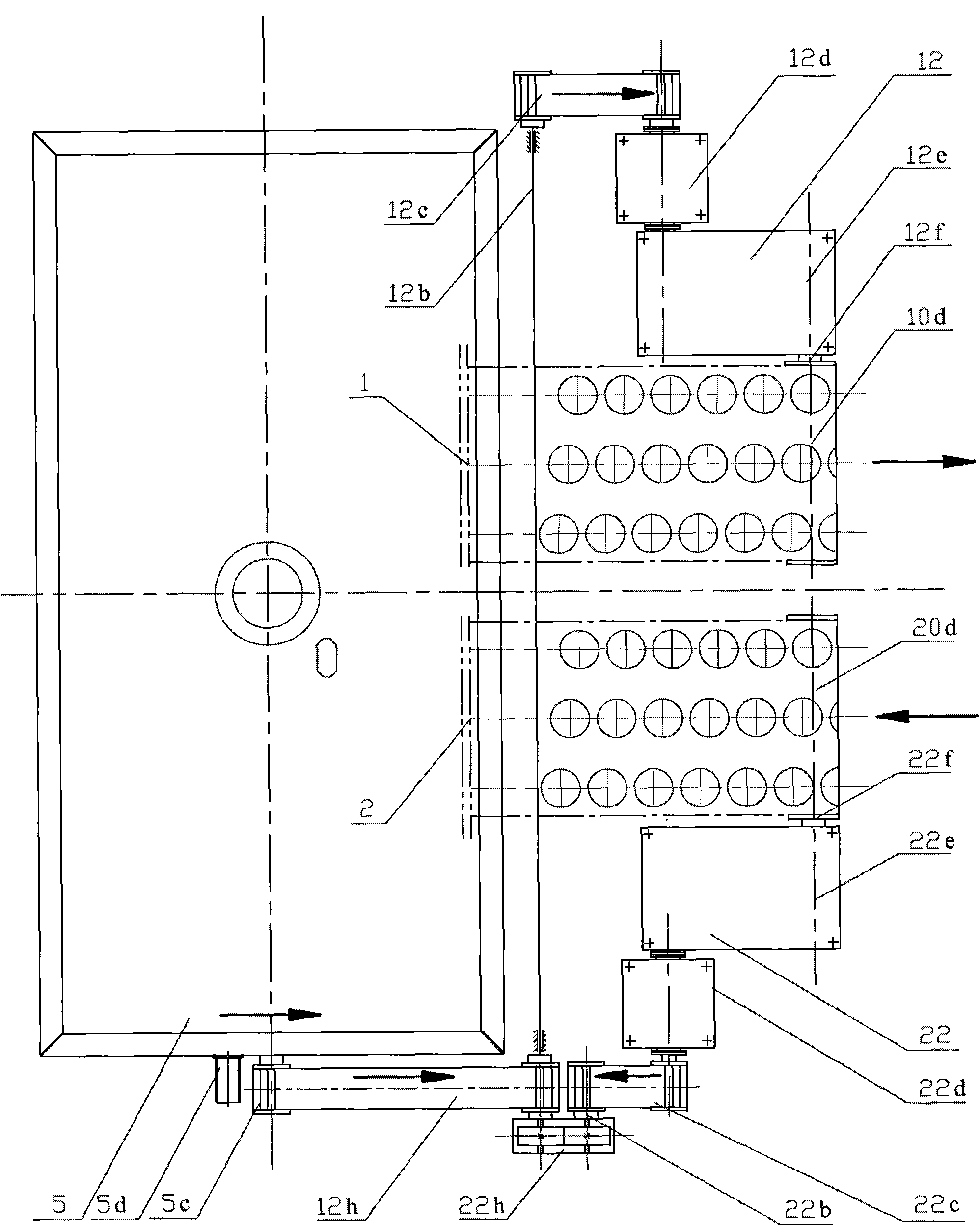

[0061] Build a 6-channel easy-open end stamping production line on a vertical-axis high-speed punching machine and illustrate the implementation plan with reference to the drawings. The composition of building a 6-channel easy-open end stamping production line on a vertical-axis high-speed punching machine and Example 1 building a 6-channel easy-open end stamping production line on a horizontal-axis high-speed punching machine: basic cover feeding system, pull ring belt feeding system, transmission system, easy open end finished product conveying system and combined progressive die have exactly the same composition, structure and layout; the only difference is that the transmission system of the basic cap feeding system built on the vertical axis high speed punching machine is relatively complicated, the following is the vertical axis high speed The transmission system of the basic cover feeding system built on the punching machine is described in detail in the embodiment.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com