Air valve device for stretching experiment

A kind of technology for experiment and air valve, which is applied in the direction of measuring device, applying stable tension/pressure to test the strength of materials, instruments, etc. It can solve problems such as mis-launch, eccentric loading of samples, complicated operation, etc., so as to avoid eccentric loading, The effect of high reliability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

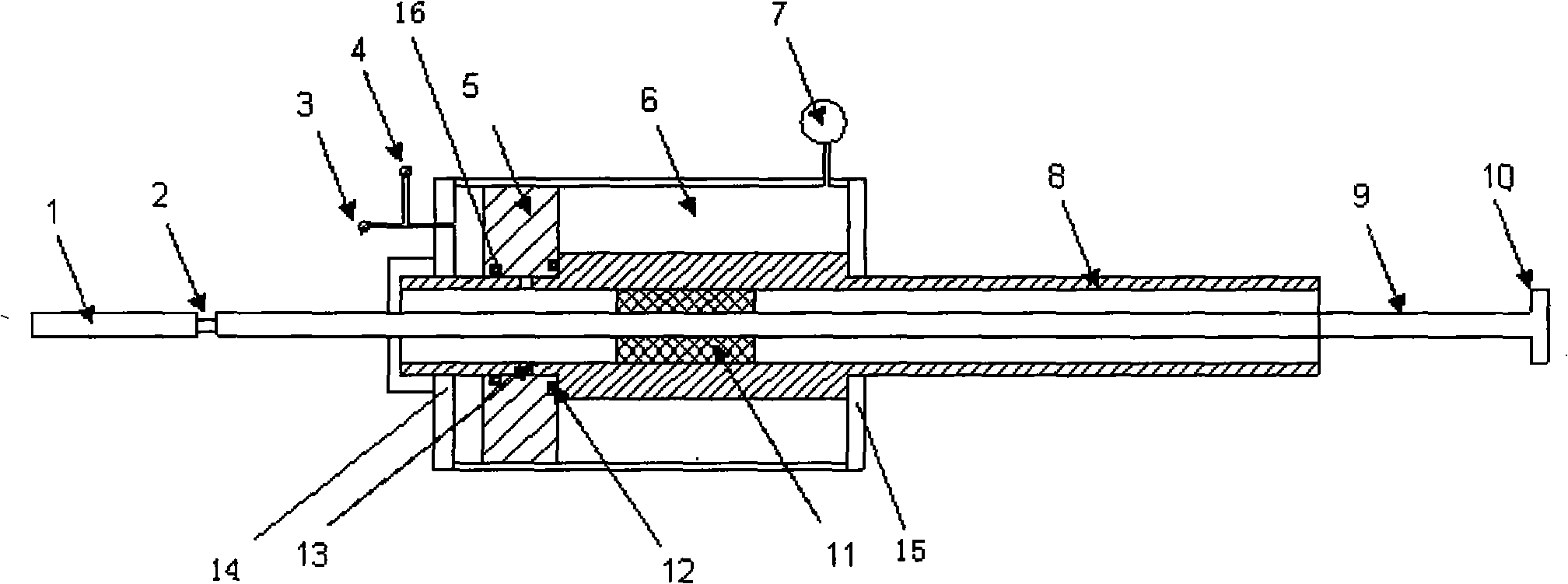

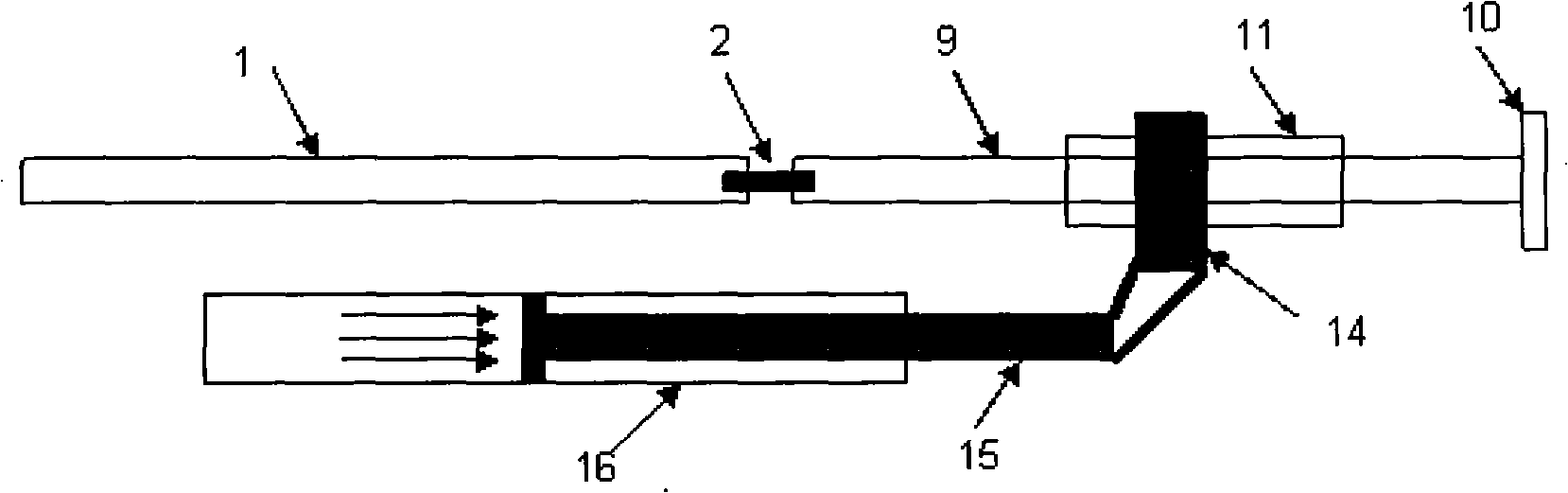

[0011] refer to figure 1 . The air valve device for tensile experiment includes transmission rod 1, launch valve 3, intake valve 4, sliding block 5, air chamber cavity 6, pressure gauge 7, gun barrel 8, incident rod 9, flange 10, loading cylinder 11 And the second O-ring 12. The air chamber cavity 6 is cylindrical and made of steel, with both ends sealed by a left end cover 14 and a right end cover 15, forming an air chamber together with the gun barrel 8. Half of the length of the gun barrel 8 is in the air chamber cavity 6, and is coaxial with the air chamber cavity 6. The left end of the gun barrel 8 passes through the left end cover 14 of the air chamber cavity 6, and is connected with the left end cover 14 with a soft rubber ring Sealing, the other half of the length of the gun barrel 8 passes through the right end cover 15 of the air chamber cavity 6, and relies on the boss on the gun barrel 8 and the right end cover 15 to seal with a soft rubber ring. The sliding blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com