Bidirectional eccentric loading device for bamboo bending members, and installation method

An eccentric loading and component technology, which is applied in the field of bamboo and wood structures, can solve the problems that the additional corbels are not easy to connect components, and the research method has not been reported, and achieves the effect of clear force transmission, wide applicability, and clear force transmission path.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

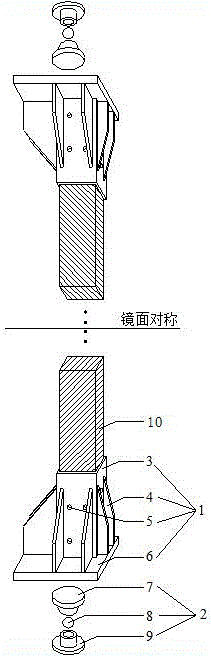

[0033] Such as figure 1 Shown: the wall thickness of the hollow steel cylinder of the steel column sleeve is 5mm, the section of the inner wall is 102mm×102mm, the height of the steel cylinder is 200mm, the diameter of the bolt hole on the steel cylinder is 12mm; the thickness of the steel rib is 8mm, the height is 180mm, and it is welded to the outer surface of the steel cylinder , the spacing is 80mm; the thickness of the steel backing plate is 20mm, and the length × width is 200mm × 200mm. The thickness of the cylindrical base of the connecting platform of the spherical hinge support and the pressure bearing platform is 20mm, the diameter is 100mm, the height of the protruding part of the groove is 8mm, and the inner diameter of the groove is 30mm; the diameter of the steel ball is 30mm. The thickness of the steel filler is 1mm, the length × width is 200mm × 100mm, and the bolt hole diameter on the steel filler corresponds to the bolt hole on the steel cylinder.

[0034] w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com