Opening type anti-eccentric-loading three elastic cylinders load cell

A load sensor and eccentric loading technology, which is applied to the weighing equipment and measuring devices using electromagnetic balance, and can solve the problems such as the inability to guarantee the measurement accuracy of the sensor and the difficulty of on-site installation of the hollow cylindrical sensor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

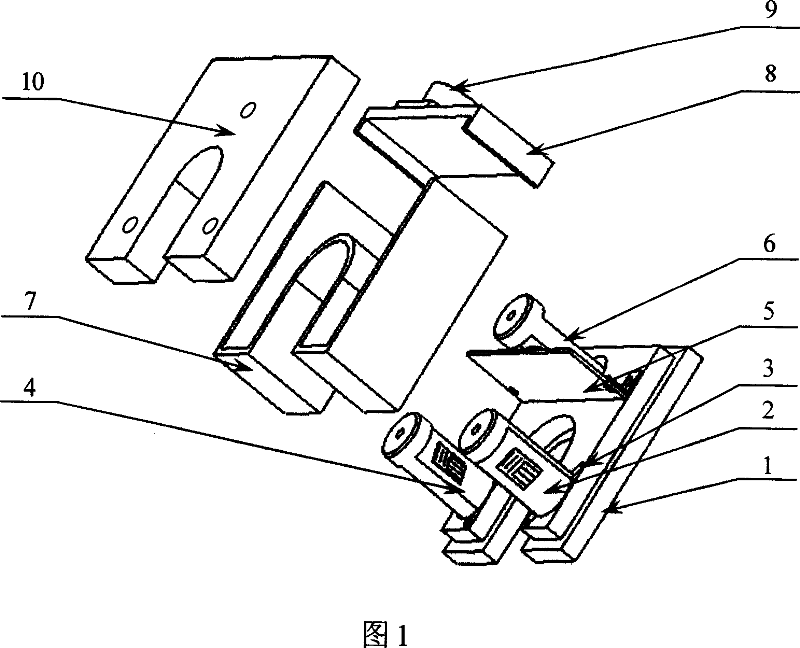

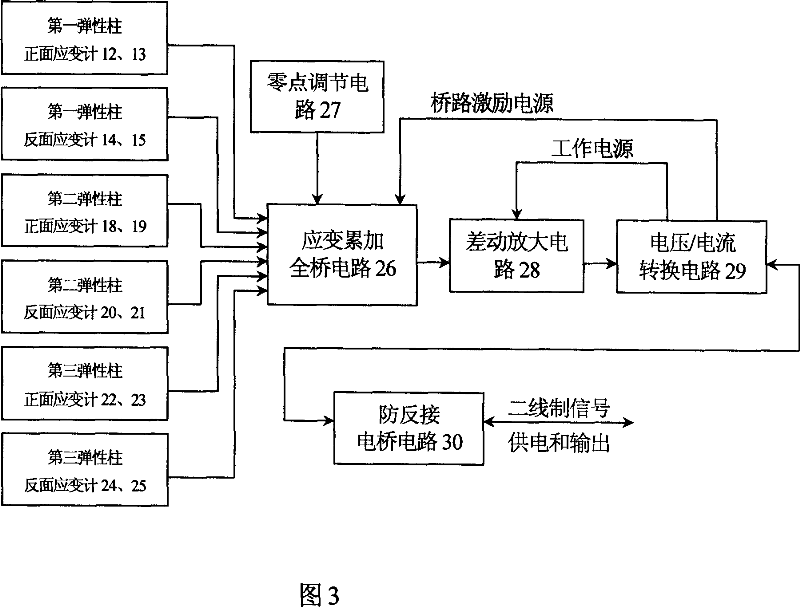

[0012] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

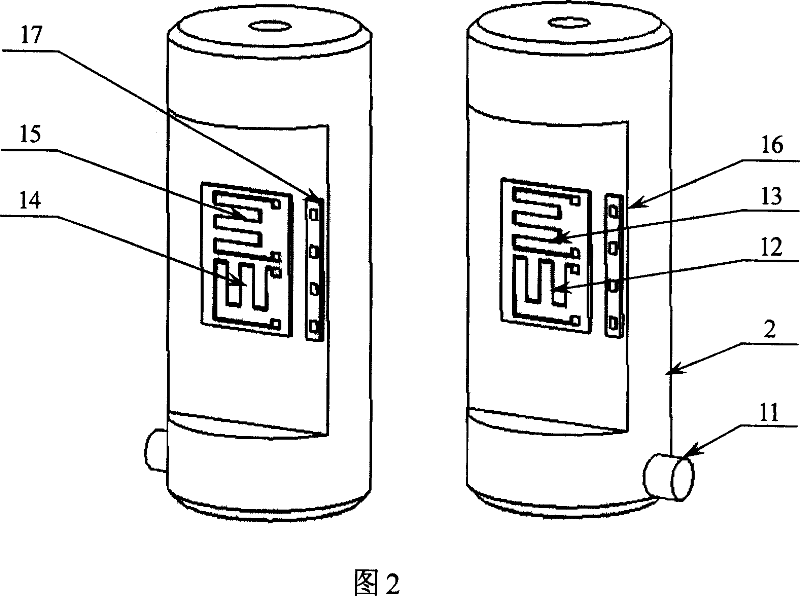

[0013] Referring to Fig. 1, the present invention includes an open-type lower bearing plate 1, three identical high-strength manganese steel elastic columns 2, 4 and 6 are arranged on the lower bearing plate 1 and a positioning groove 3 is provided at the installation position of each elastic column , the three elastic columns 2, 4 and 6 are distributed in an equilateral triangle on the lower bearing plate 1, the amplifying circuit board 5 is vertically fixed on the lower bearing plate 1, and the side of the lower bearing plate 1 is connected to the curved housing 7 and has a fixed socket 9 The upper end of the three elastic columns 2, 4 and 6 is connected to the upper bearing plate 8, because the elastic columns 2, 4 and 6 will be slightly deformed after being loaded, the upper bearing plate 10 and the curved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com