Liquid level anti-blocking device for chilling chamber of gasification furnace

A technology for a chilling chamber and a gasifier, which is applied in the field of liquid level anti-blocking devices in the chilling chamber of a gasifier, can solve problems such as hidden dangers in production safety, oil leakage and damage to the membrane box, and achieves without affecting the measurement accuracy and equipment. The effect of small load influence and improved flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings.

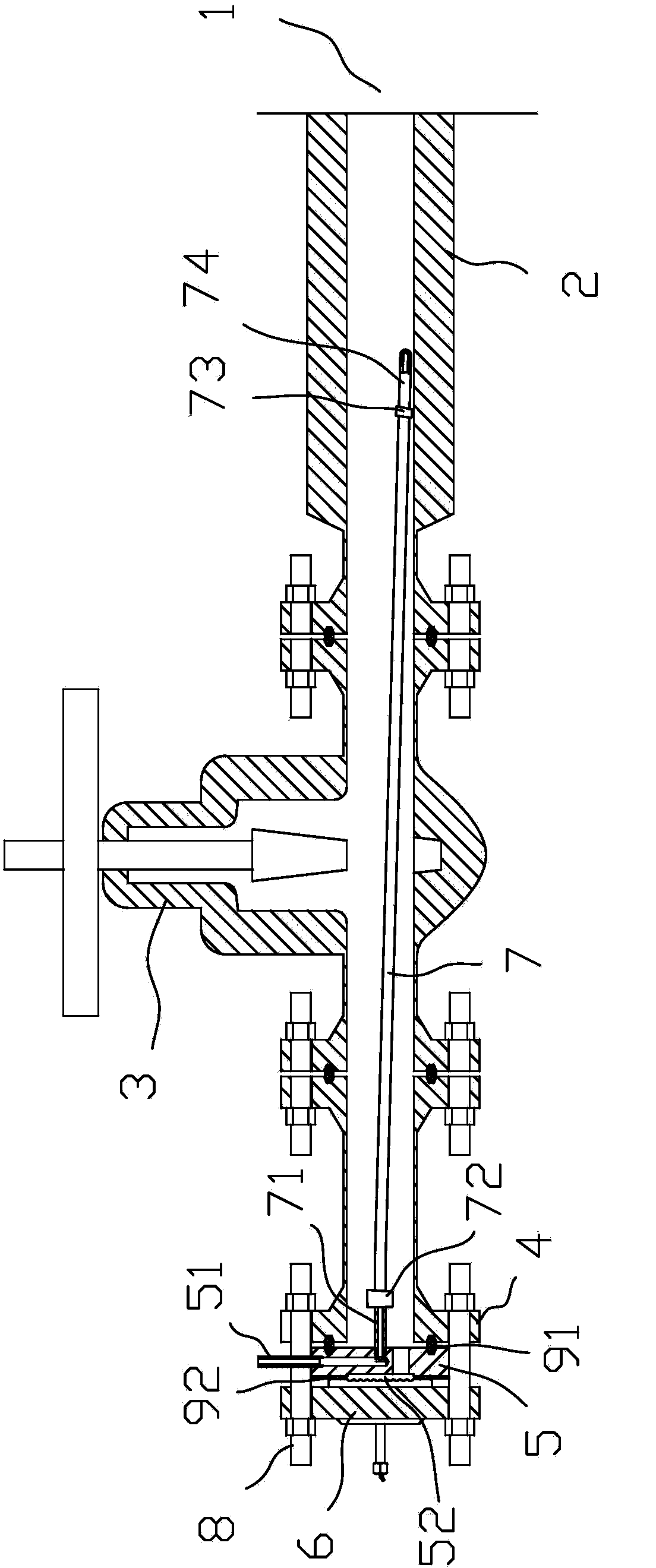

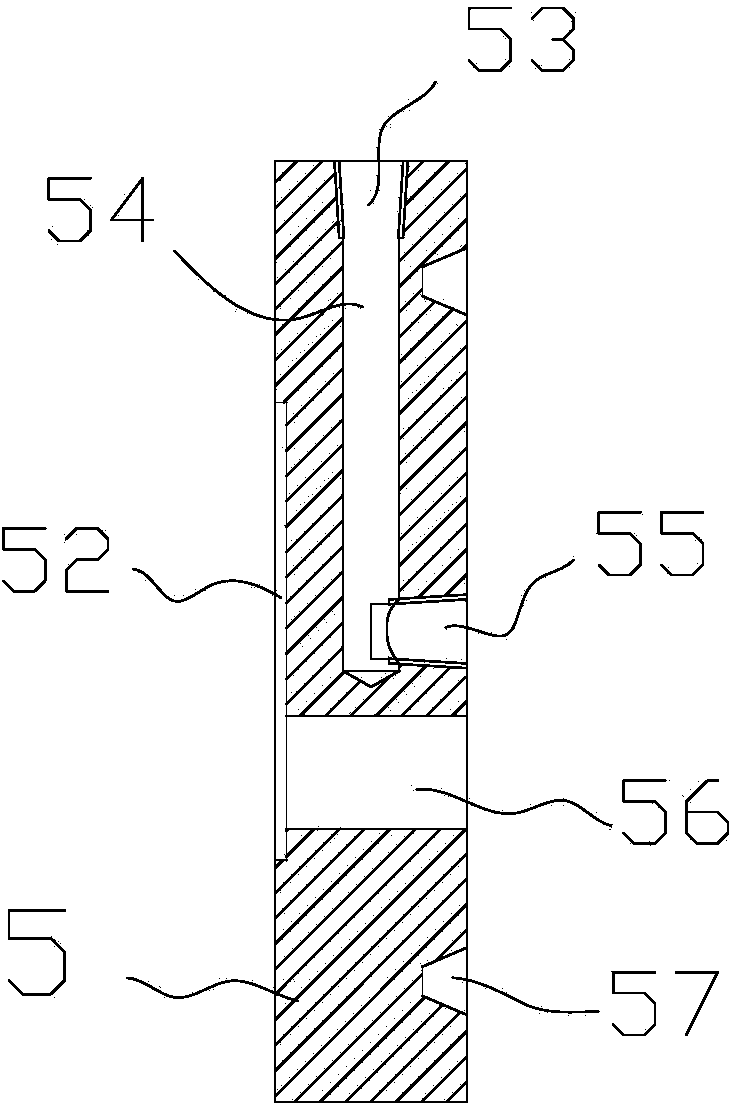

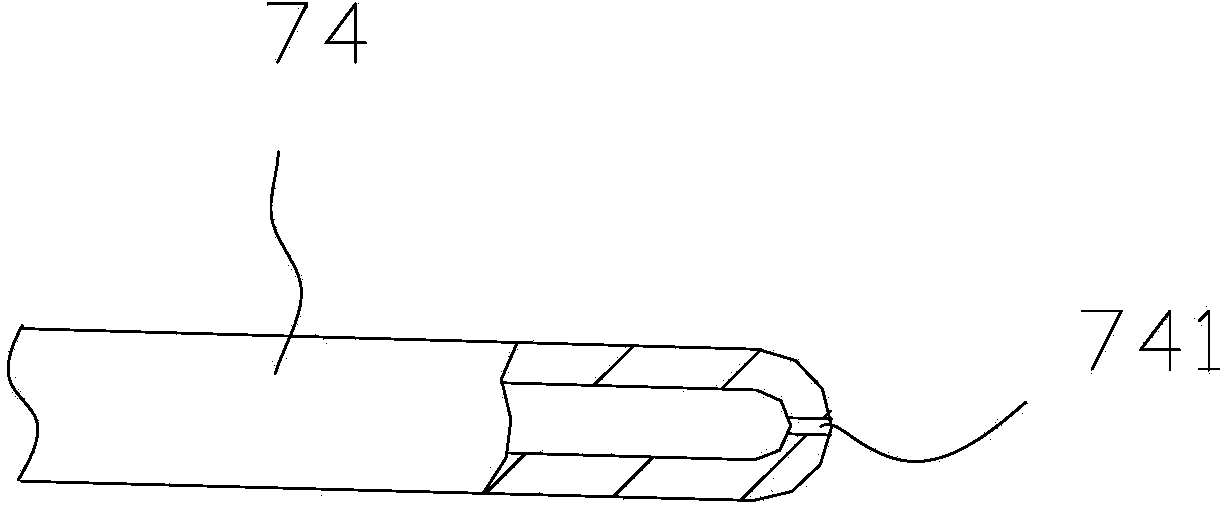

[0019] Such as figure 1 , figure 2 As shown, the right end of the pressure-taking pipe 2 communicates with the quenching chamber 1, a stop valve 3 is installed in the middle, and the left end is connected to the flanged pressure transmitter 6 through the flange 4 and the bolt 8. A flushing water ring 5 is provided between the flange 4 of the pressure taking pipe 2 and the pressure transmitter 6, and seals 91 and 92 are provided between the two end faces of the flushing water ring 5 and the corresponding flanges. An annular installation groove 57 for installing the sealing member 91 is opened on one end surface of the pressure pipe flange 4 . In the middle of the flushing water ring 5, there is a through hole 56 that connects the surface of the pressure transmitter 6 capsule with the pressure taking pipe 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com