Verticality error measurement method used for orthogonal guide rail platform

A rail platform, error measurement technology, applied in the field of precision measurement, can solve the problems of analysis and introduction, and achieve the effect of simple and clear measurement process, high precision, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

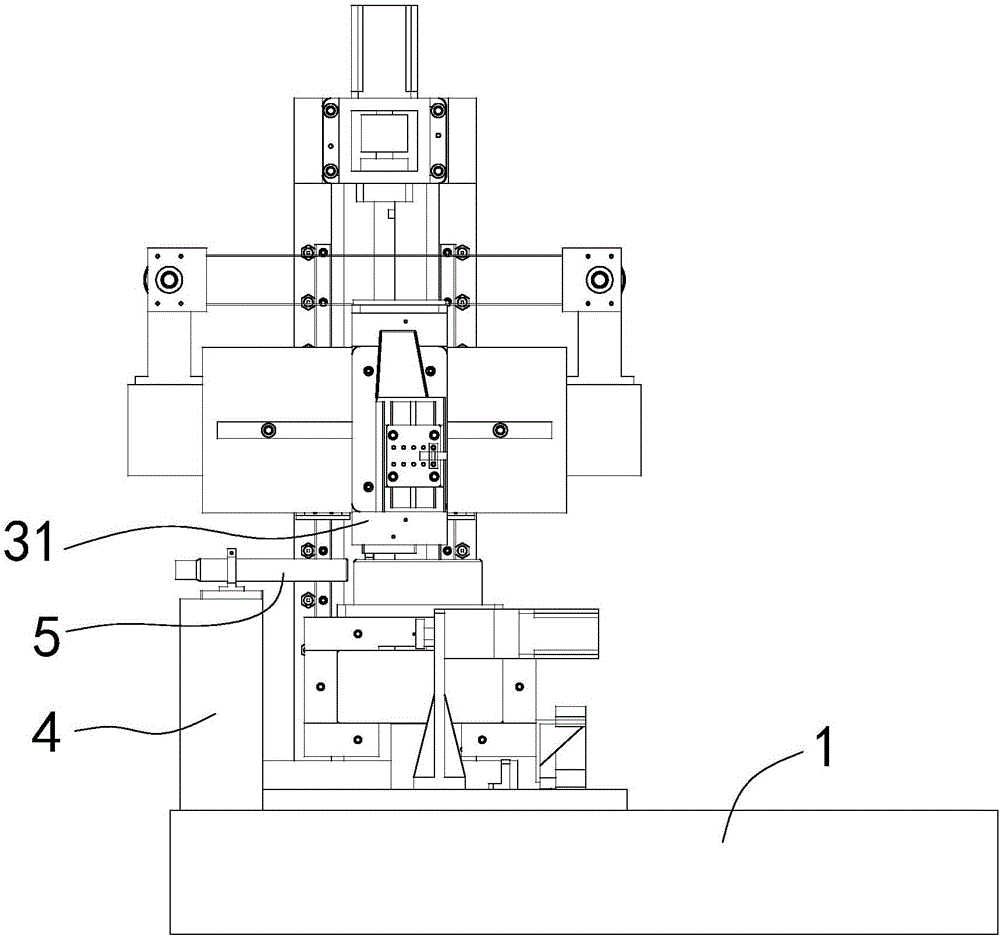

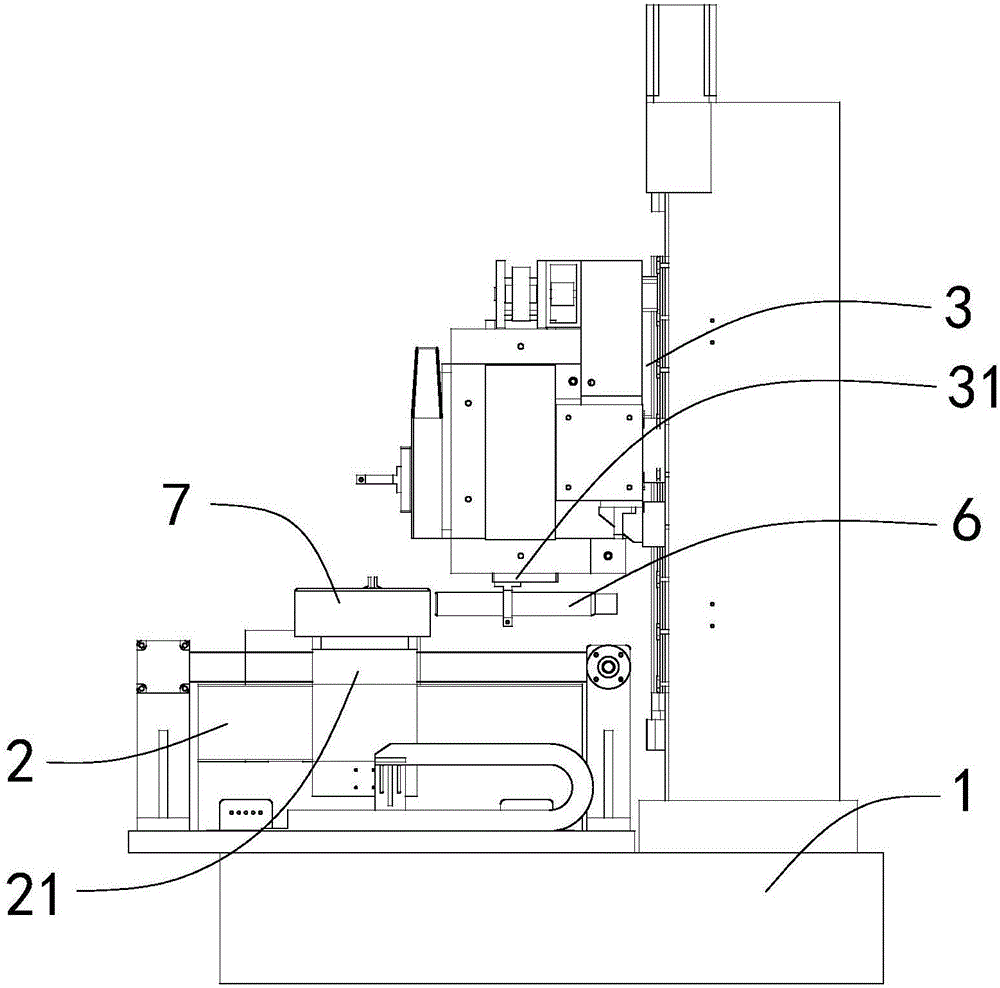

[0035] The core idea of the method for measuring the verticality error of the orthogonal guide rail platform in the present invention is to use the sum of the inner angles of the optical brick to be 2π, and to measure the angles between the four cylindrical surfaces of the optical brick and the guide rail through four rotations to calculate the perpendicularity of the guide rail. A research conclusion, by controlling the details of the measurement process to achieve high-precision verticality measurement. Hereinafter, taking a certain orthogonal guide rail platform as an example, the method for measuring the perpendicularity error of the present invention for the orthogonal guide rail platform will be further described in detail.

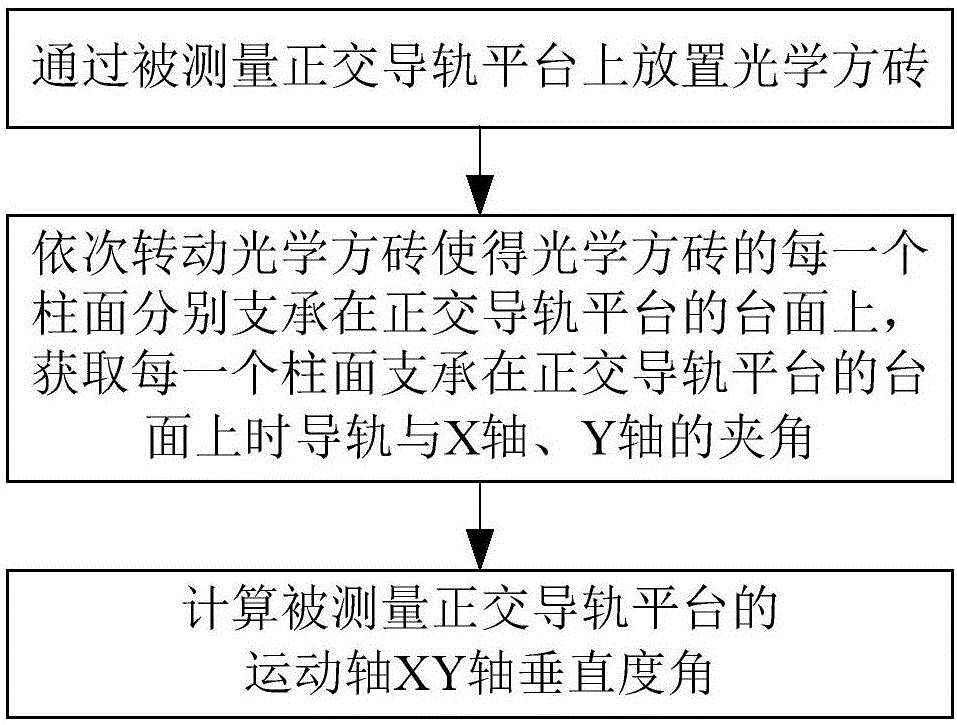

[0036] like figure 1 As shown, the steps of the method for measuring the perpendicularity error of the orthogonal guide rail platform in this embodiment include:

[0037] 1) Place the optical tiles on the X-axis slider of the X-axis slide rail of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com