Novel lift well

A new type of technology for elevator shafts, which is applied to elevators, lifts, transportation and packaging in buildings, can solve the problems of increasing energy consumption, installing elevators, and long construction periods, so as to save space, improve installation accuracy, and reduce The effect of installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Such as Figure 6-7 As shown in the figure, the structure of four polygonal columns is pre-installed in the workshop by installing the traction machine on the top plate 9 and the buffer on the bottom plate 7. Install the bottom plate 7 on the bottom of the hoistway, and fix the column pile 2 and the bottom plate 7 by screws. Place the car frame 5 above the bottom plate 7, thread the polygonal column 1 and the column pile 2 through screws, place the counterweight frame 4 between the two polygonal columns 1, and the top plate 9 and the upper end surface of the polygonal column 1 The column pile 2 is threaded, and the counterweight frame 4 and the car frame 5 are connected through the suspension device on the traction machine.

Embodiment 2

[0026] Such as Figure 8-9 As shown, eight polygonal column structures, compared with Embodiment 1, the present embodiment adopts eight polygonal columns 1, connects them two by two end to end, and by installing connecting shaft 8 at the docking position, the connecting shaft 8 Placed in the inner cavity of the two polygonal columns 1, the connecting shaft 8 is respectively fixedly connected to the two polygonal columns 1 by bolts, so as to meet the requirement of extension height. In order to ensure the stability of the assembled polygonal columns 1 , crossbeams 10 are installed between the polygonal columns 1 . The structure is simple, the installation is convenient, and the stability of the overall structure can be effectively improved.

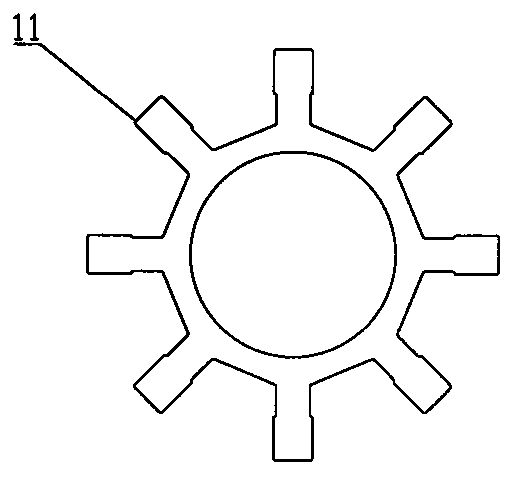

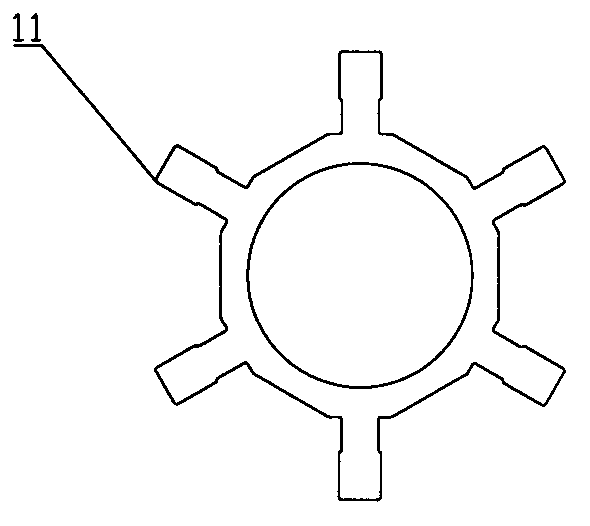

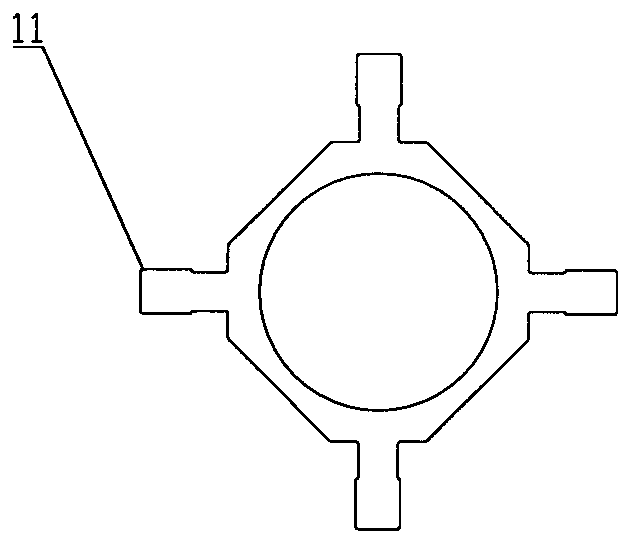

[0027] Compared with the prior art, the present invention has the advantages of: the polygonal column 1 is arranged, and the rectangular protrusion 11 on the polygonal column 1 cooperates with the guide shoe on the car to form the car gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com