Modeling method for realizing structural mechanical performance of pipe segment three-dimensional loading

A technology of structural mechanics and modeling methods, applied in 3D modeling, image data processing, special data processing applications, etc., can solve problems such as simplification of mechanical models, idealization of segment stress environment, and inability to obtain limit boundary conditions, etc. achieve the effect of overcoming interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific implementation process, the embodiment of the present invention is described further:

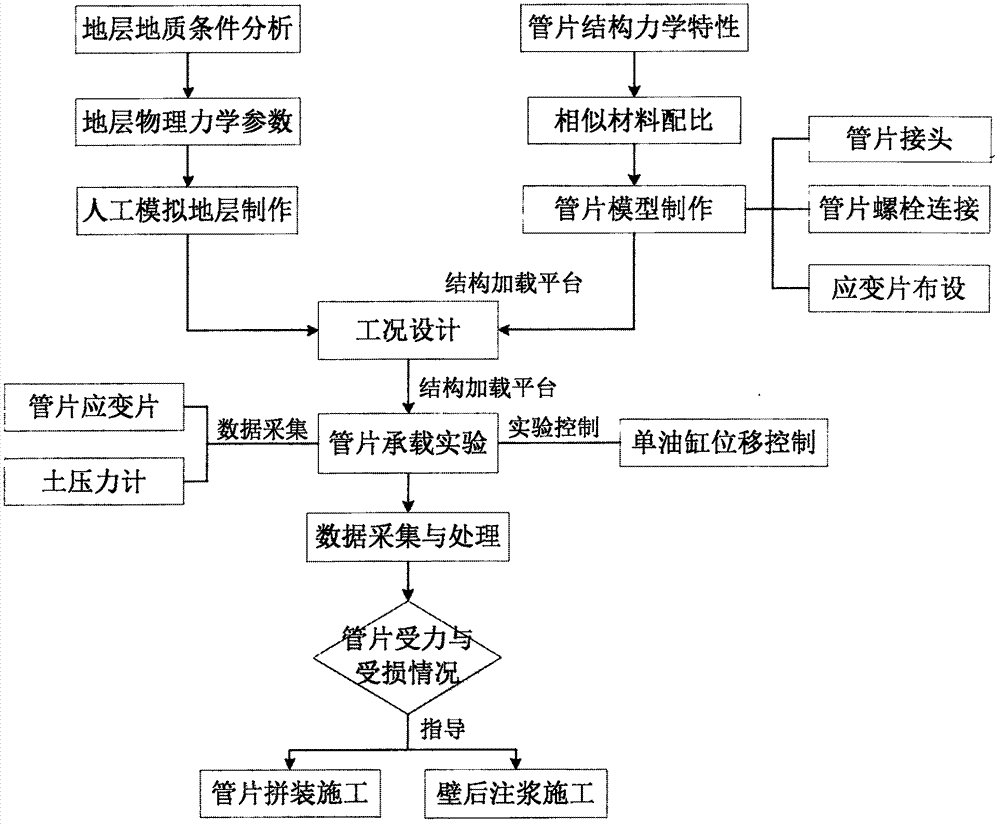

[0021] Such as figure 1 As shown, the modeling of structural mechanical properties of three-dimensional loaded segments includes stratum remodeling and fabrication, scaled segment model making, segment monitoring system design, realization of different segment load model experiments, and data collection and analysis.

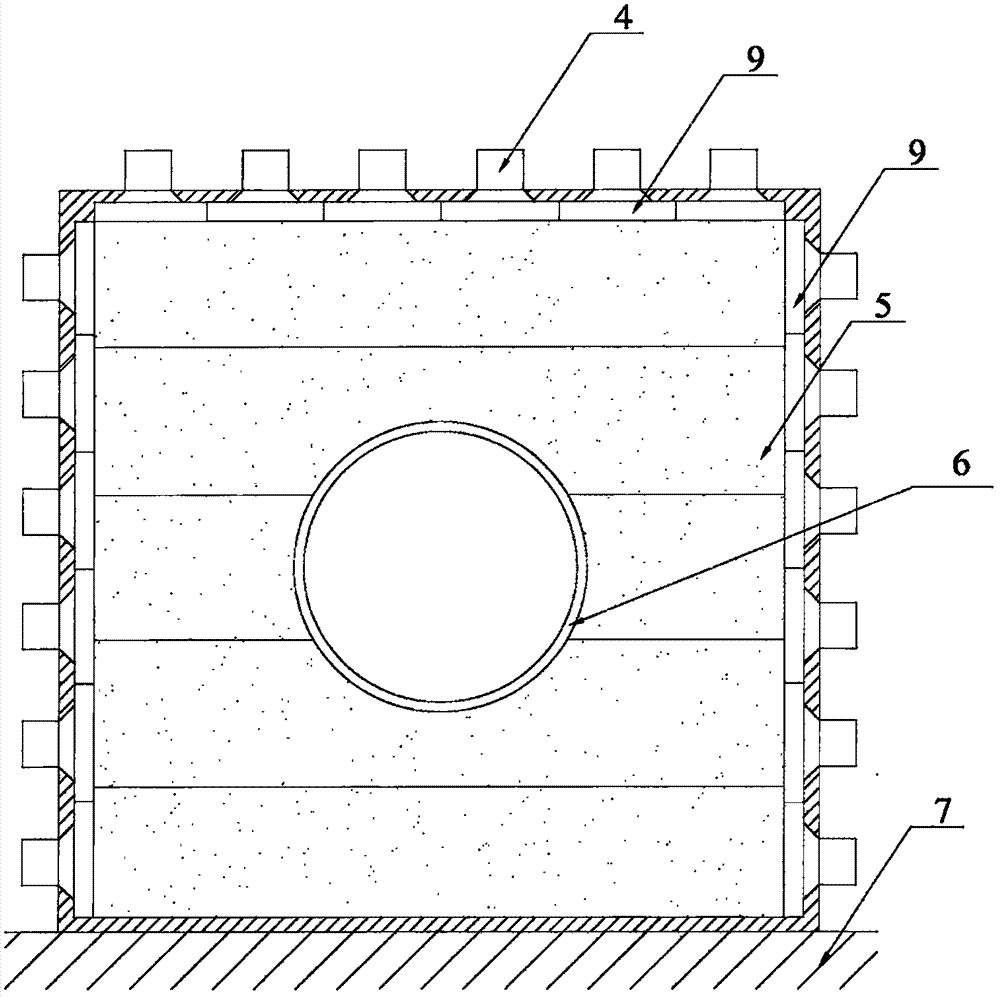

[0022] Such as image 3 , 4 As shown, a loading platform is first established, and the loading platform is a hexahedron structure, including left and right sides, front and rear sides, an upper cover surface, a bottom surface, the left and right sides and the upper cover surface The inner layer is provided with a push plate 9, and the push plate is composed of several push plate units arranged in an array, and a propulsion oil cylinder 4 is vertically arranged on the outside of each push plate unit passing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com