Protective coating adhesion effect test device and test method under action of uniaxial tension

A technology of protective coating and test device, which is applied in the field of testing, can solve problems such as performance degradation, concrete damage, and poor corrosion resistance of foam-like materials, and achieve the effect of flexible operation and simple fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

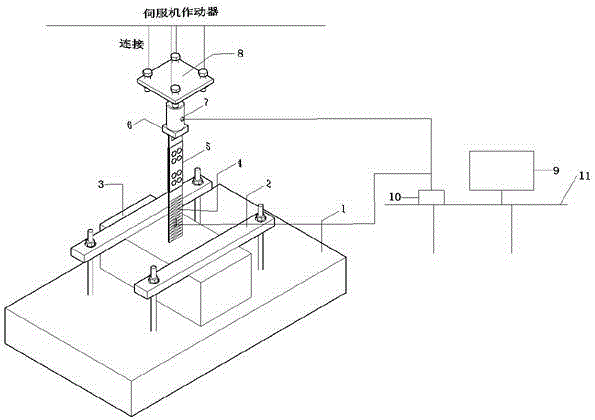

[0017] The present invention will be further described below in conjunction with accompanying drawing.

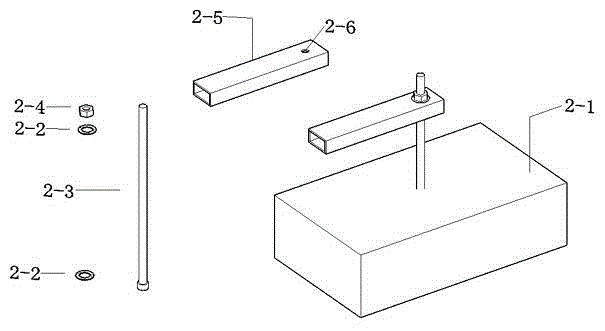

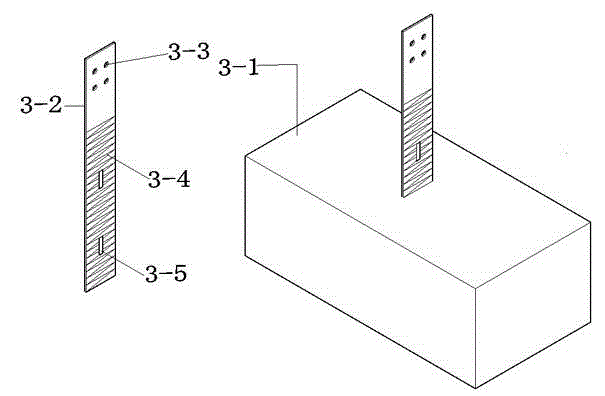

[0018] The test device includes a test piece; a fixing system, a loading system and a recording system; the test piece includes a concrete block 2-1, a steel plate with holes 2-2, and a protective coating 2-3; the fixing system includes a concrete reaction foundation 3-1, pad Sheet 3-2, screw rod 3-3, nut 3-4 and box pad 3-5; the loading system includes splint 4-2, and the lower link 6 includes rib plate 4-3, rigid screw head 4-4, Pad block 4-5 and steel plate with holes 4-6, upper connector 8 includes steel plate with holes 5-1, steel cylinder 5-3 and steel screw head 5-4; recording system includes strain gauges 3-5 and pressure sensor7.

[0019] When doing the axial tensile test, the micro-adjustment part 3-1 is required to prevent eccentric loading.

[0020] The protective coating 3-4 of different materials and the protective coating 3-4 of different thicknesses can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com