Device and measuring method for measuring direct stretching mechanical parameter of rock

A mechanical parameter and direct technology, applied in the field of rock tensile test, can solve problems such as easy eccentric loading, difficult to implement, difficult to process rock samples, etc., achieve deflection and rotation sensitivity, improve work efficiency, and have great practical significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

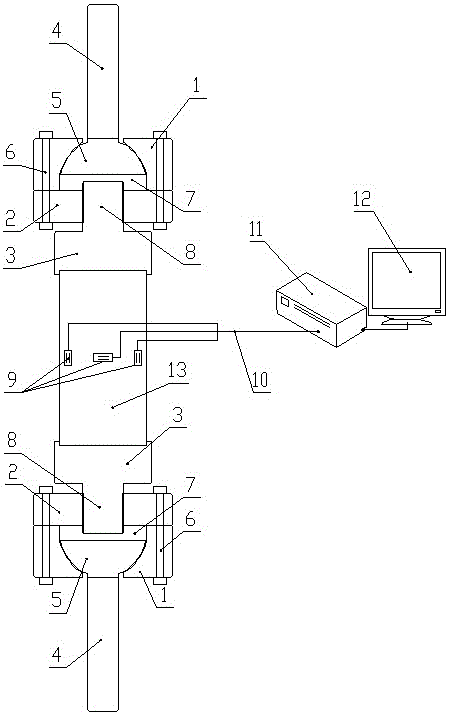

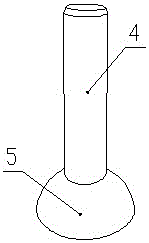

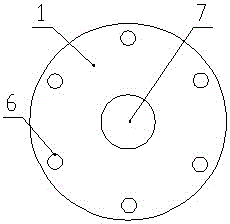

[0028] Such as Figure 1-5 As shown, a kind of device of the present invention measures the mechanical parameter of rock direct tension, comprises strain gage 9, resistance strain gauge 11, computer 12 and two groups of structure identical upper rod assembly and lower rod assembly, upper rod assembly and lower rod The components are symmetrically arranged up and down; the upper tie rod assembly includes a spherical hinge tie rod, an upper connecting seat 1, a lower connecting seat 2 and a clamping sleeve 3, and the spherical hinge tie rod includes a connecting rod 4 and a connecting head 5 fixedly connected to the lower end of the connecting rod 4, and the connecting head 5 is a hemispherical structure; the upper connecting seat 1 and the lower connecting seat 2 are both disc-shaped structures, the upper connecting seat 1 and the lower connecting seat 2 are connected by connecting bolts 6, and the center of the upper connecting seat 1 is provided with a mounting hole 7, The di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com