Patents

Literature

104results about How to "Guaranteed punching accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

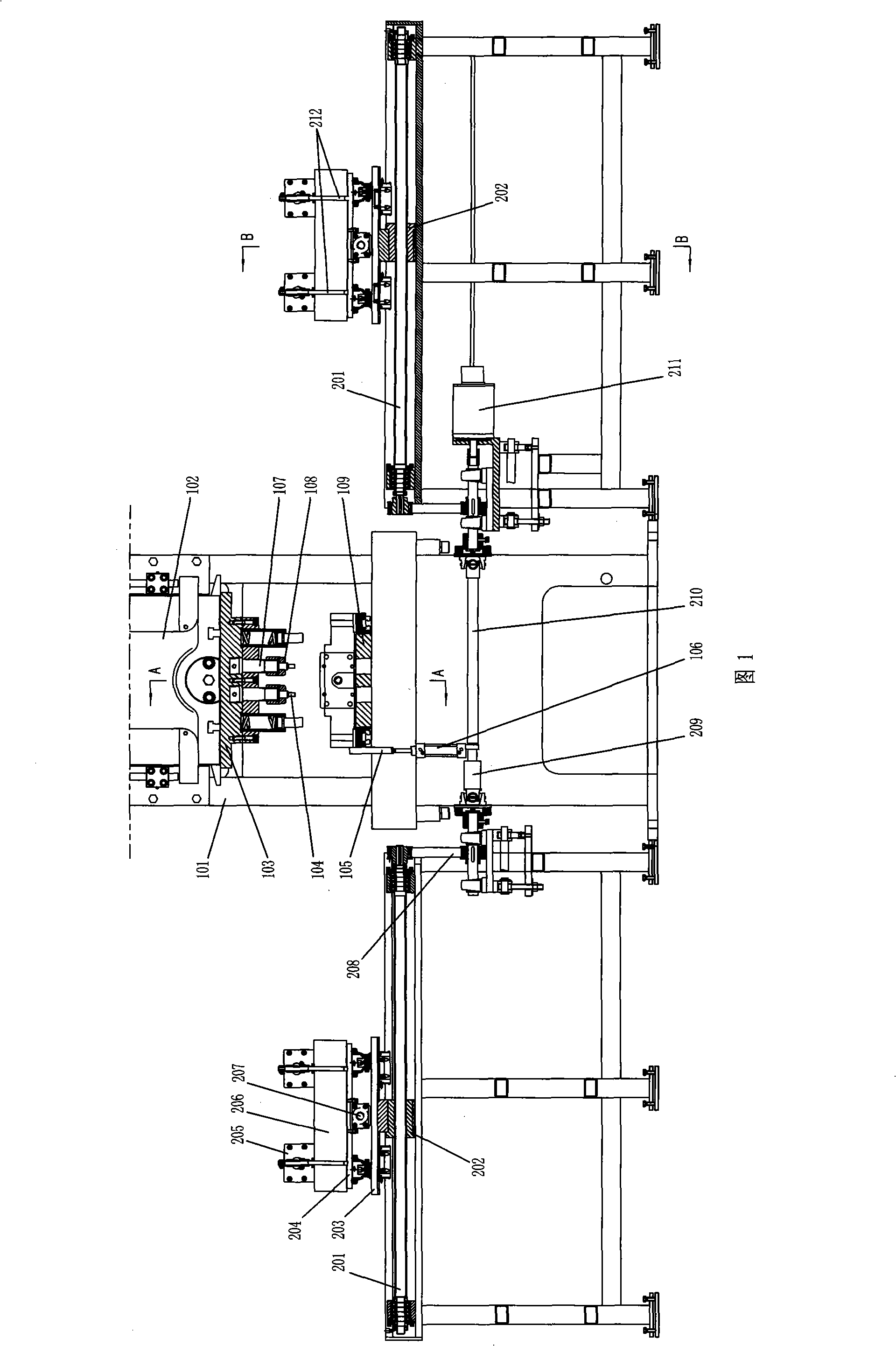

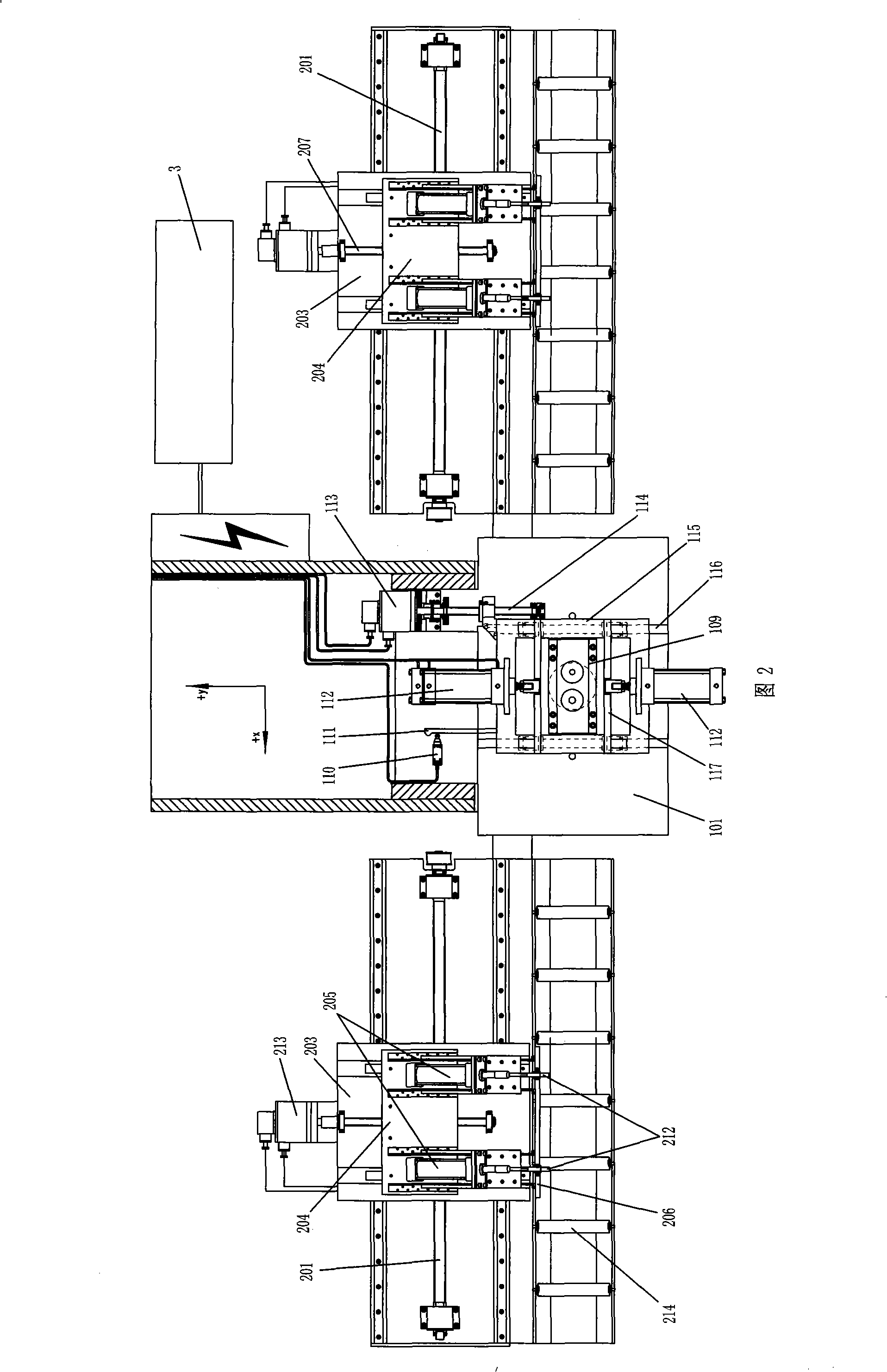

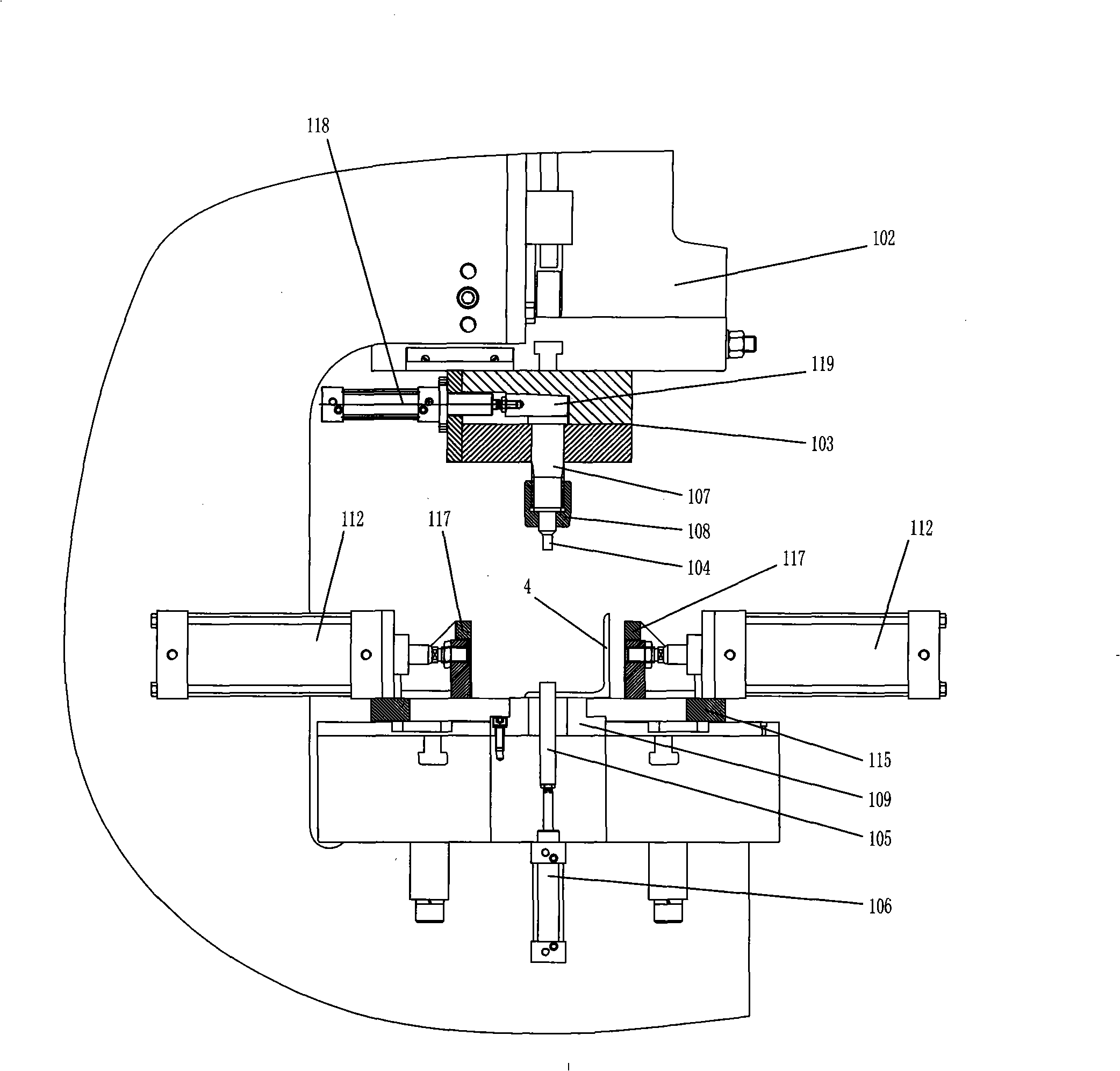

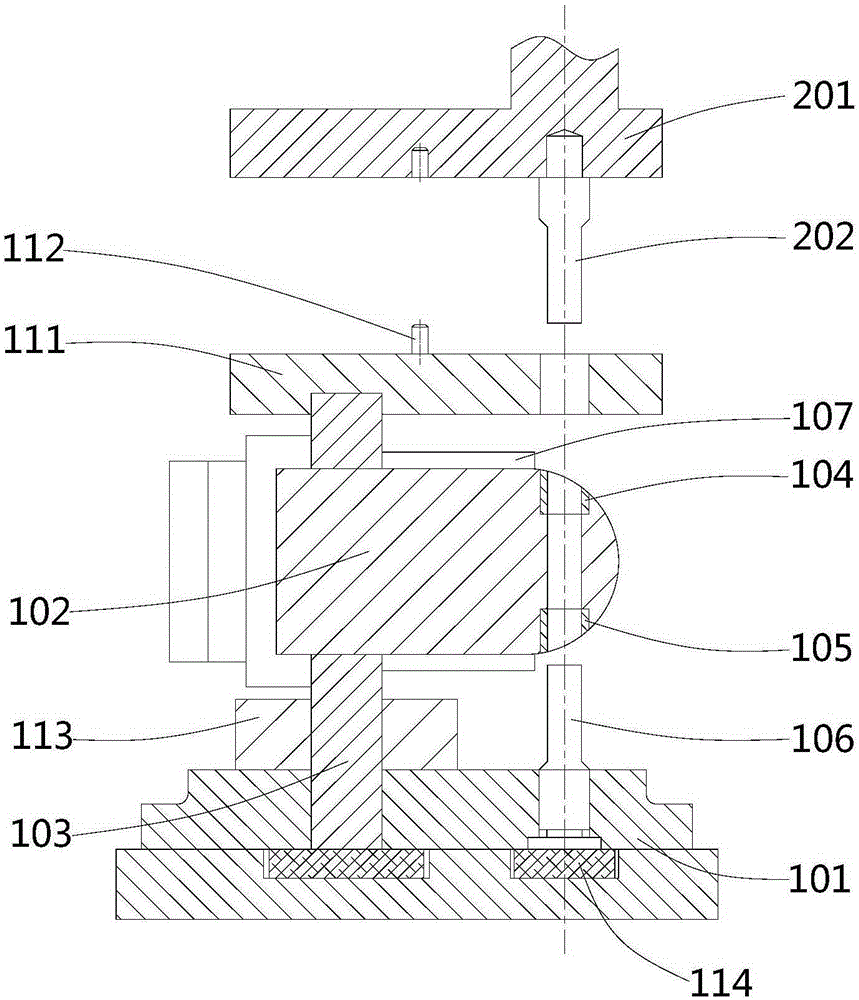

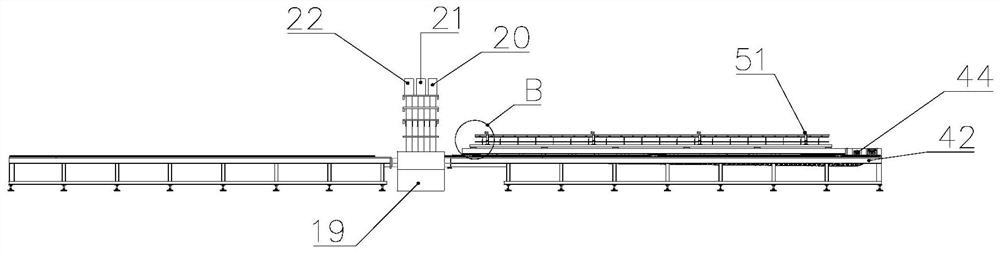

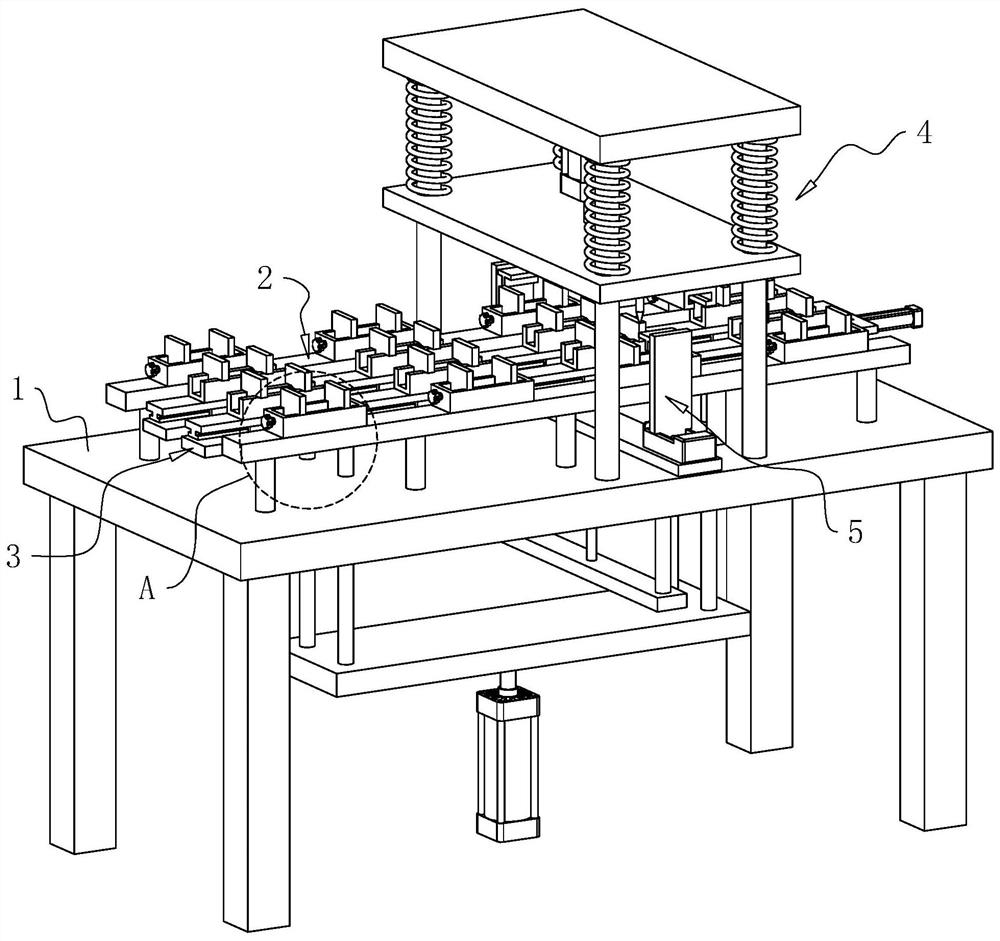

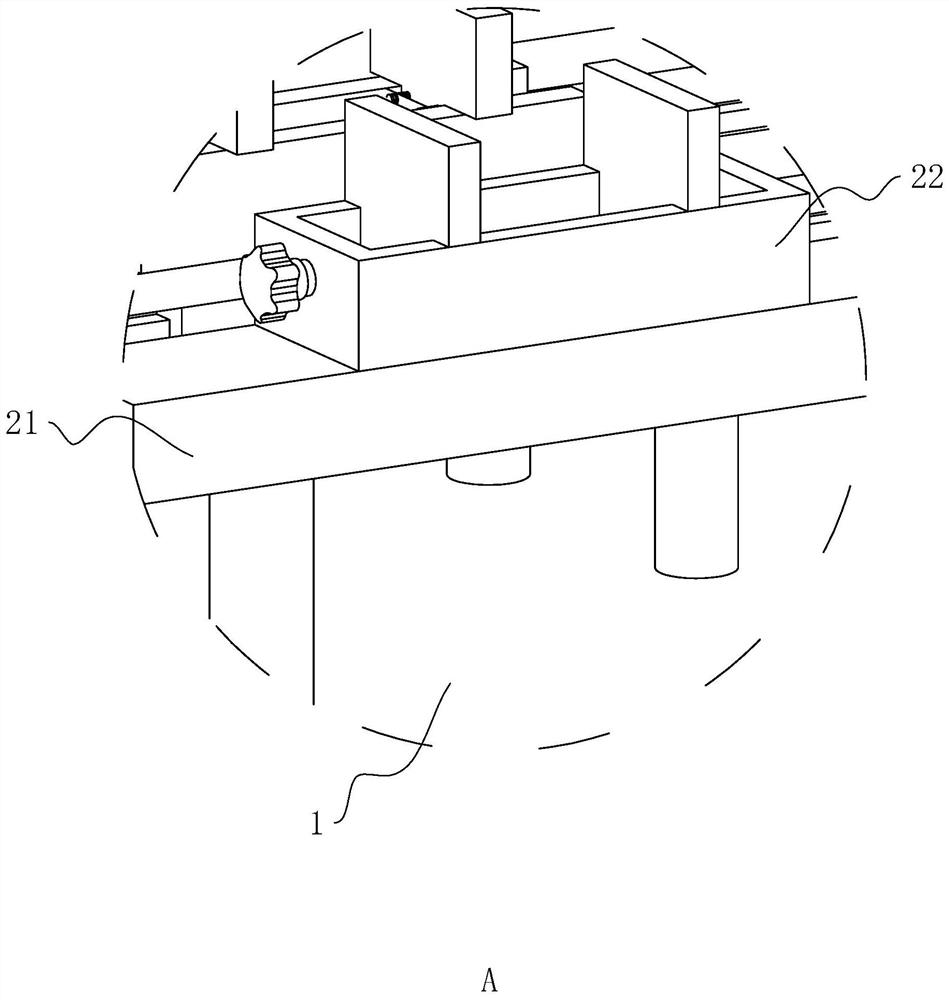

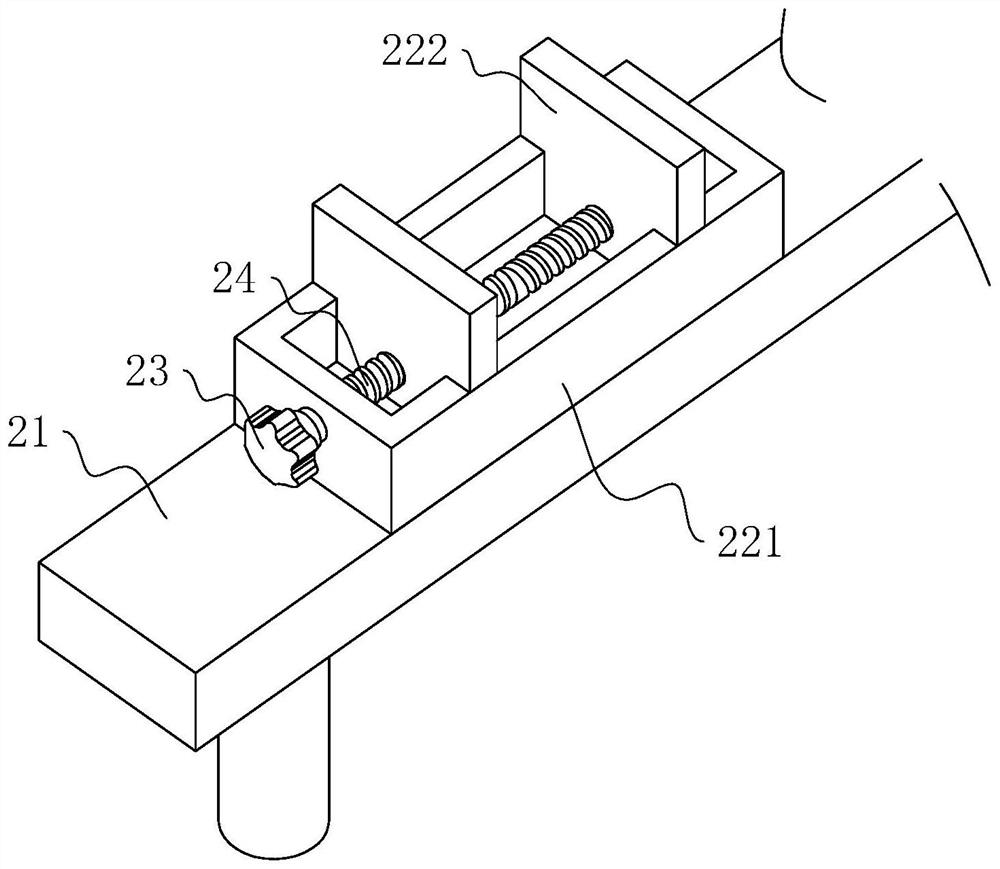

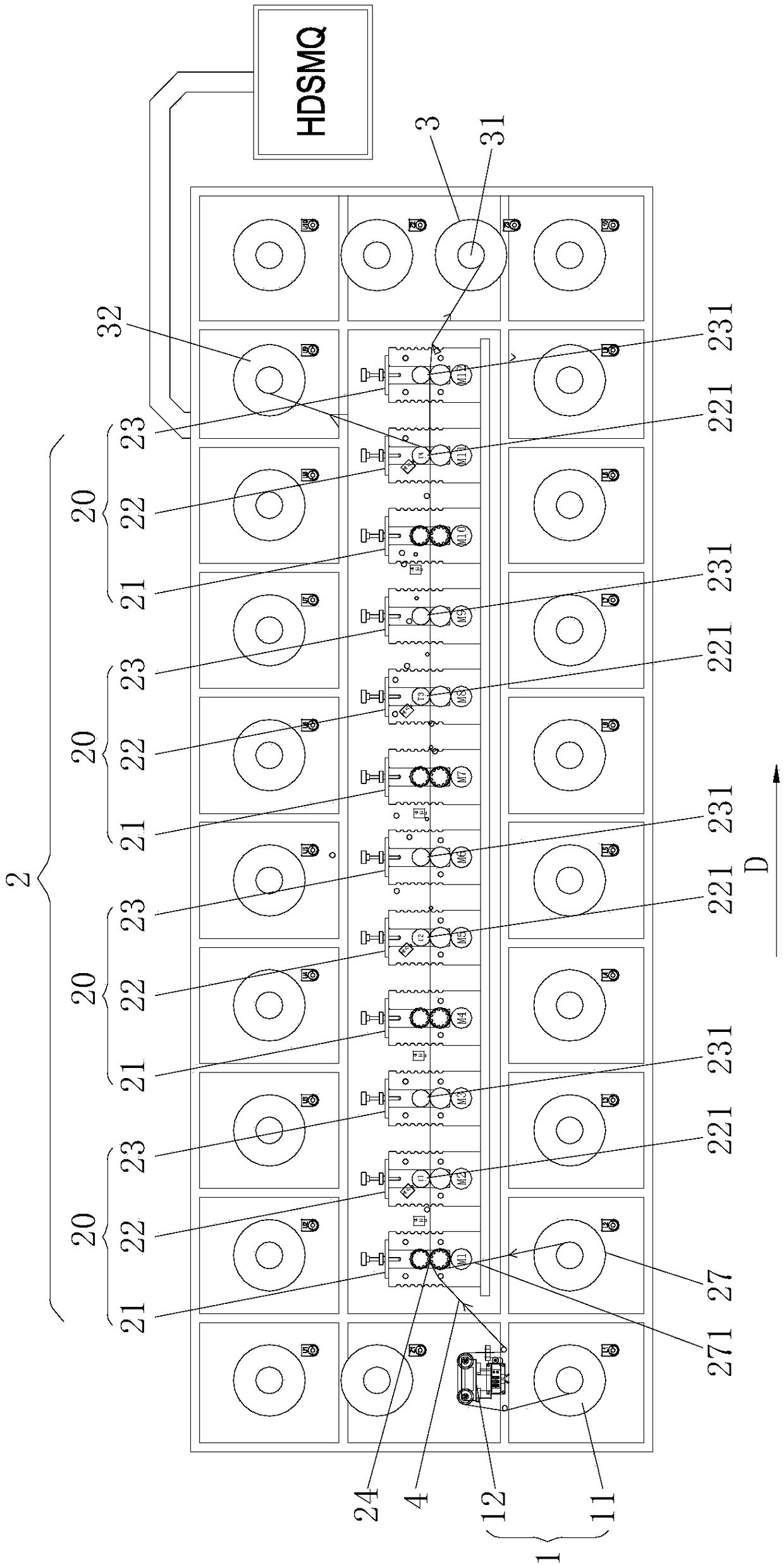

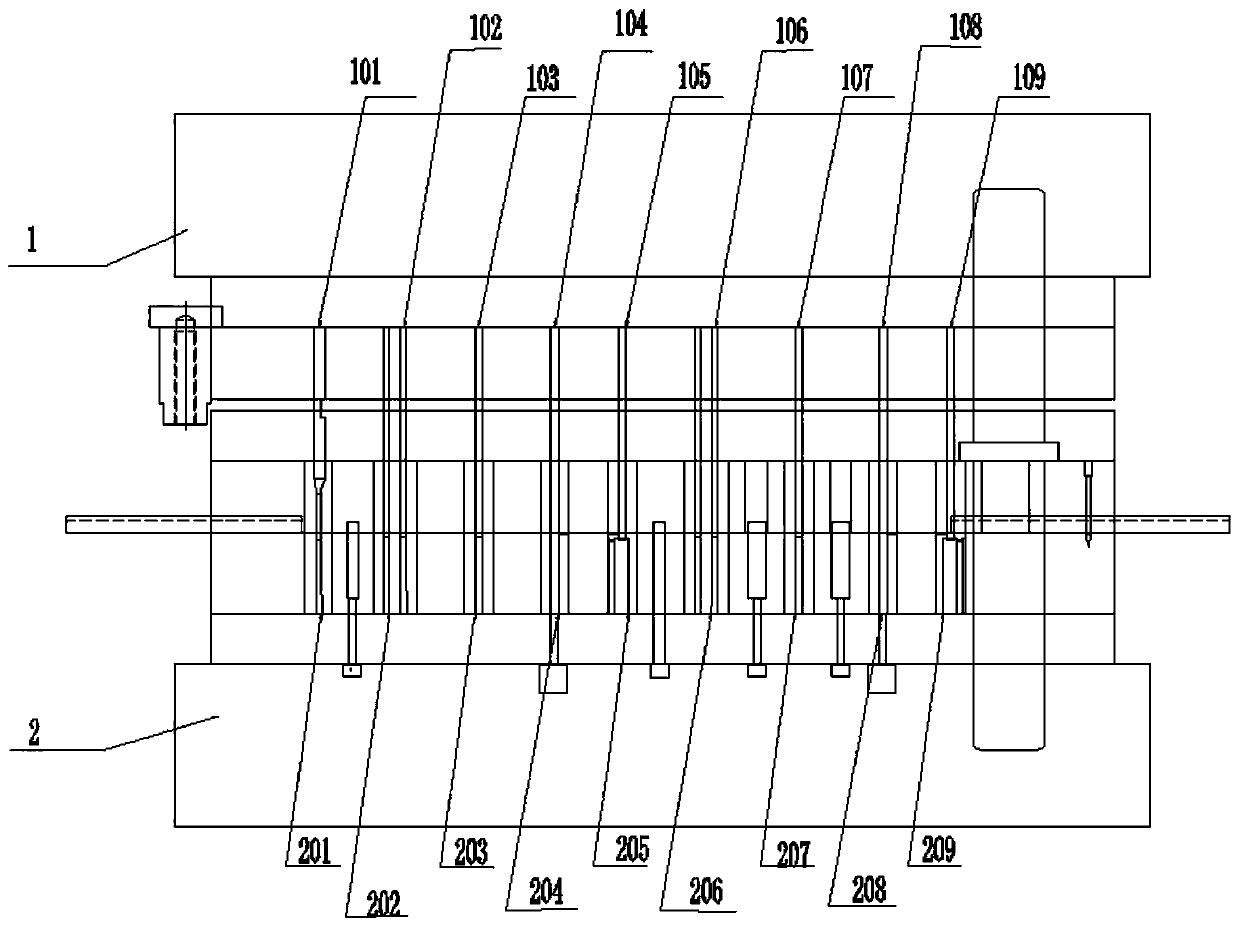

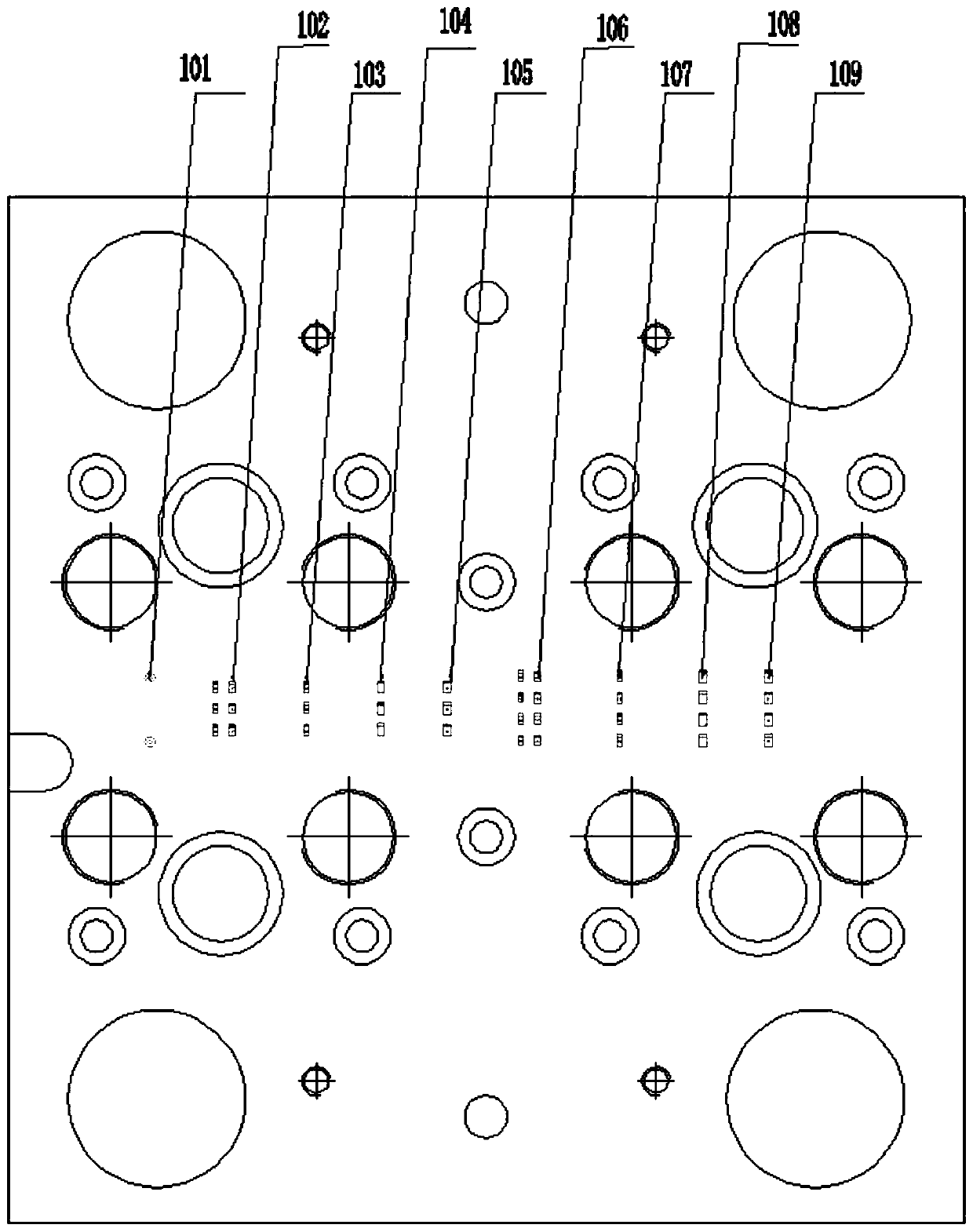

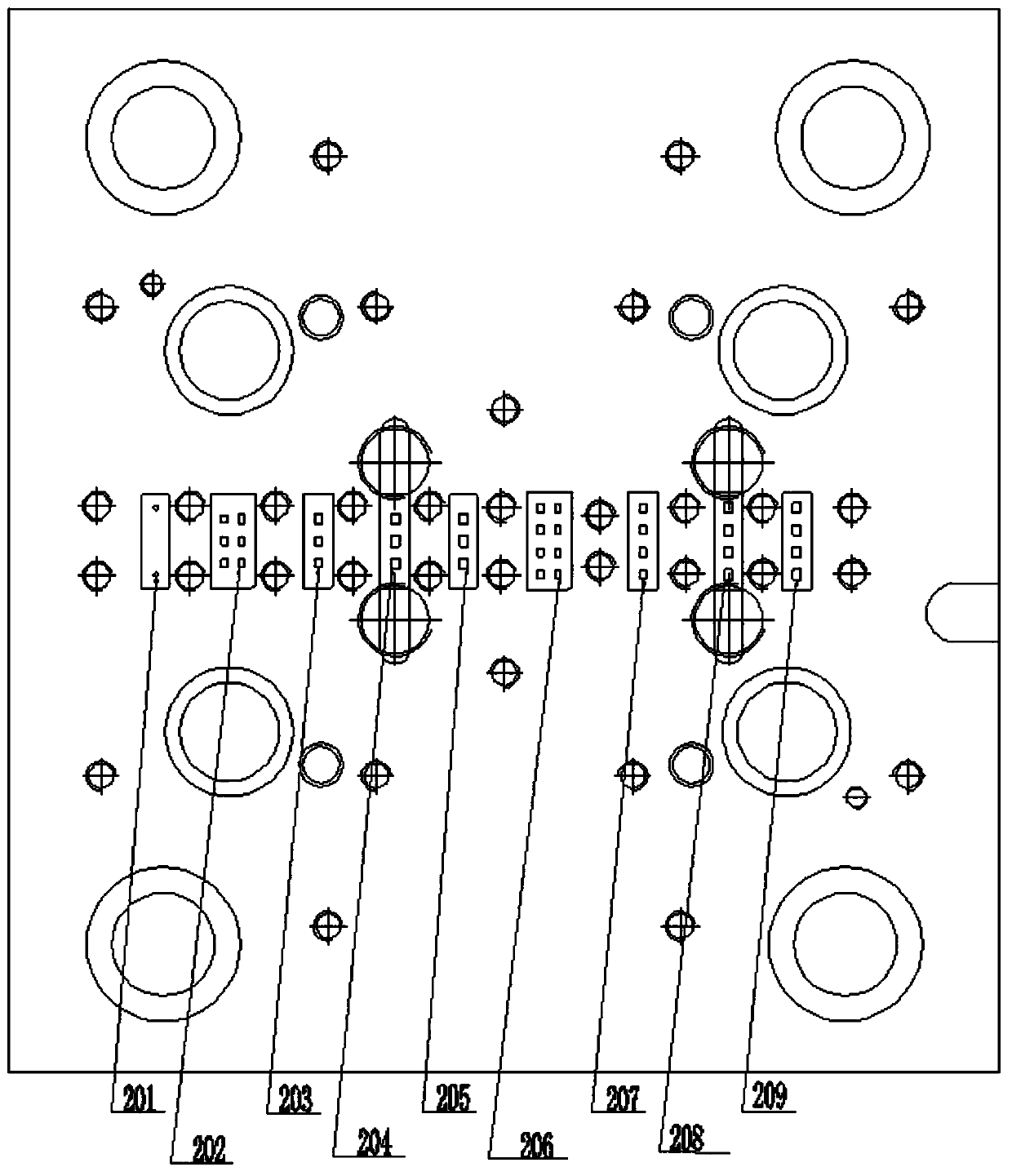

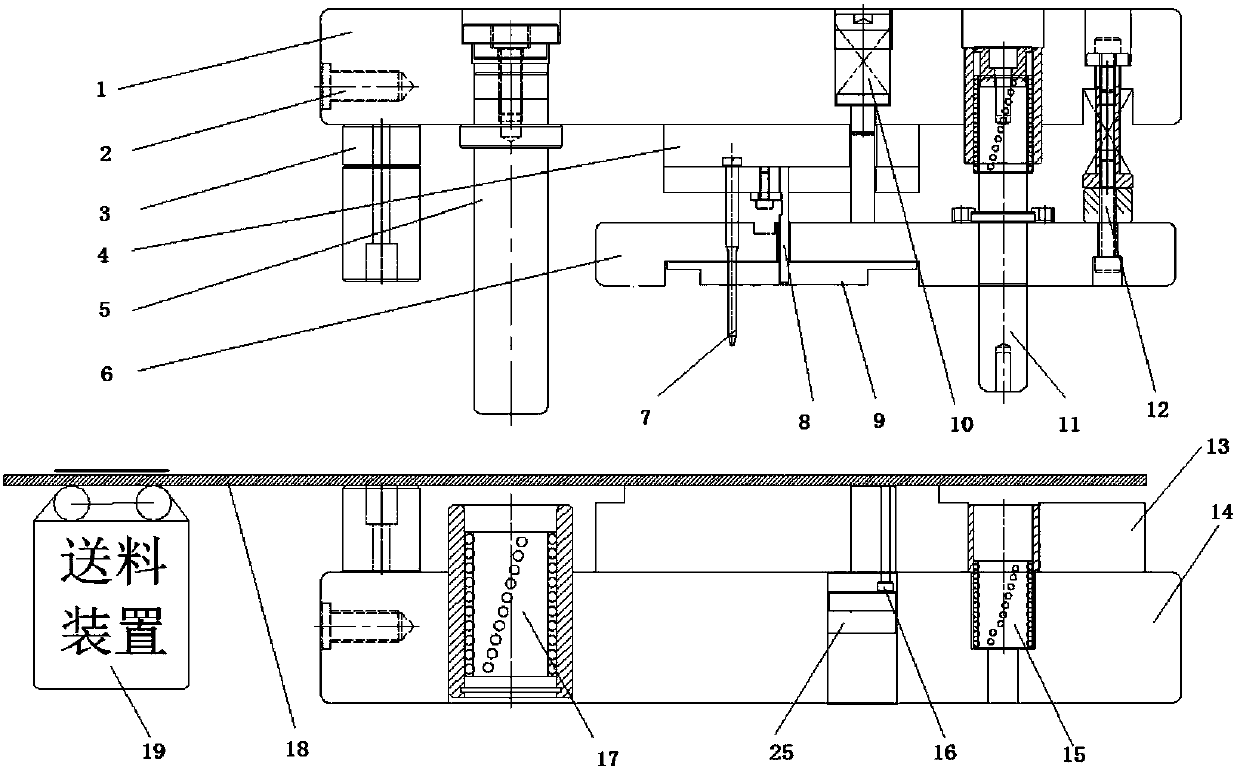

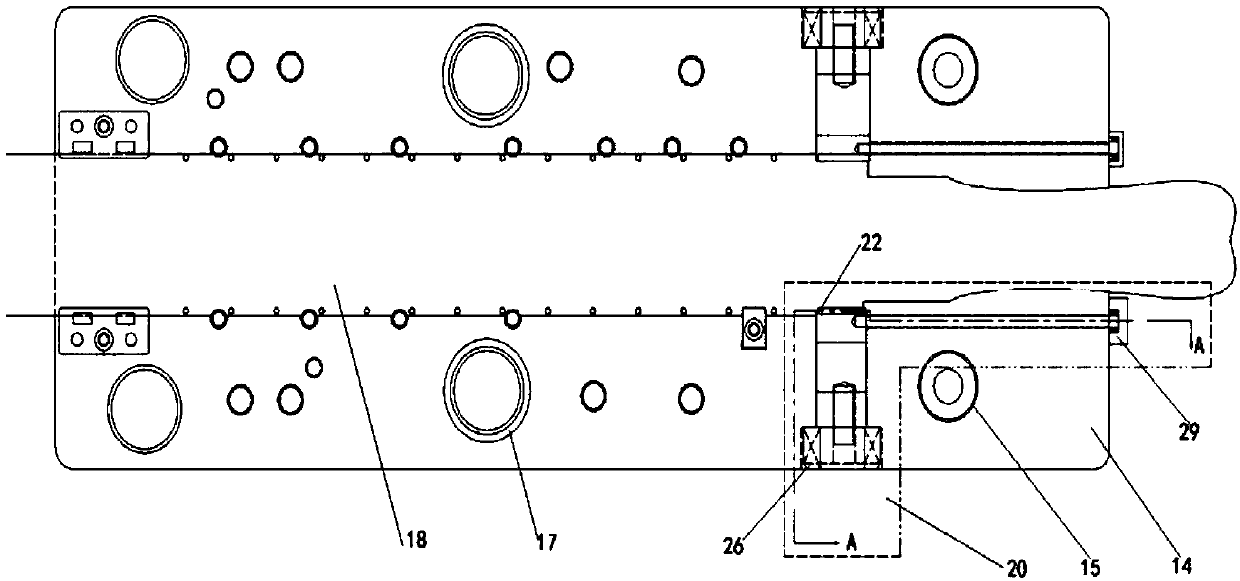

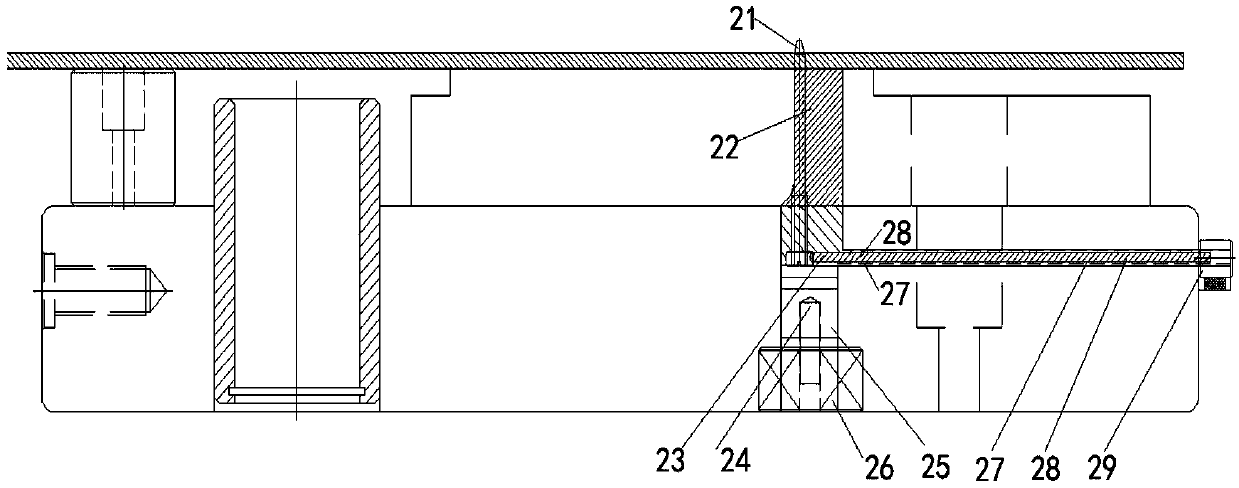

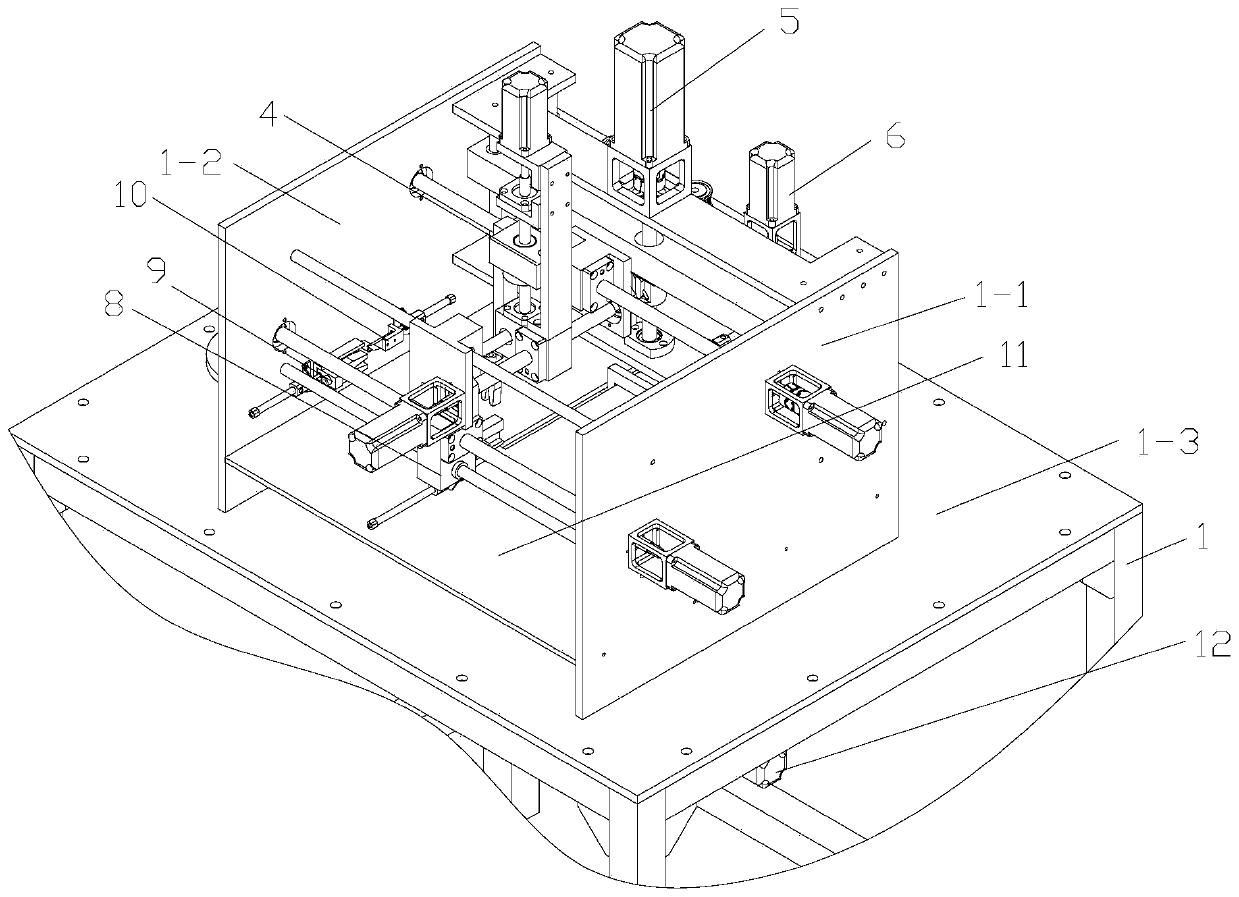

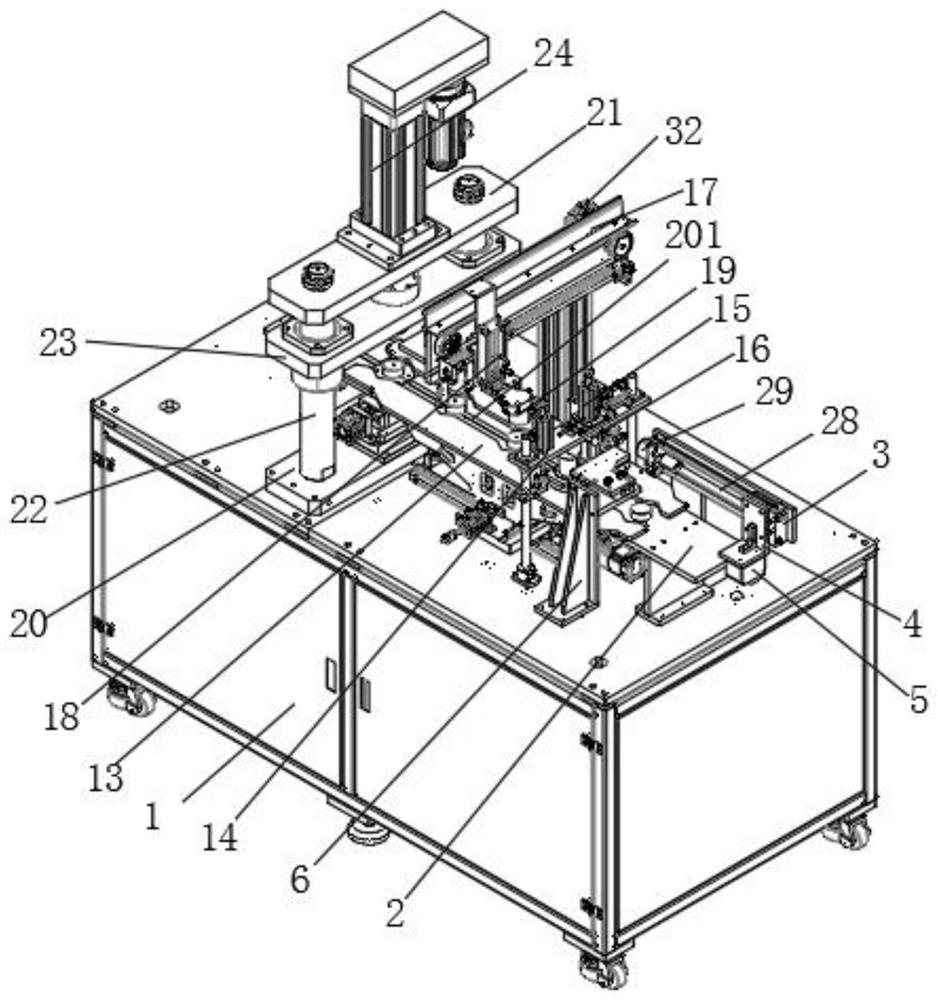

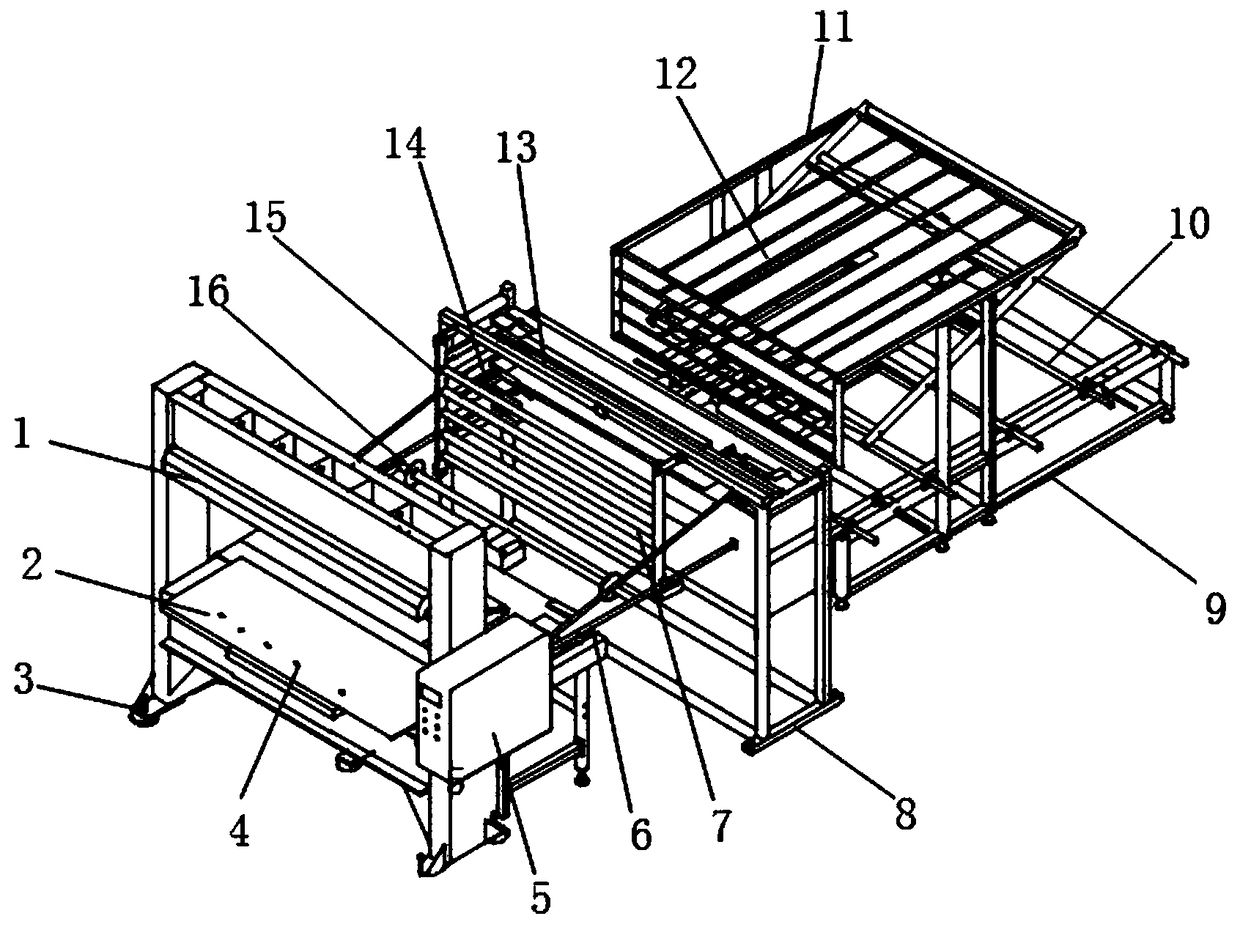

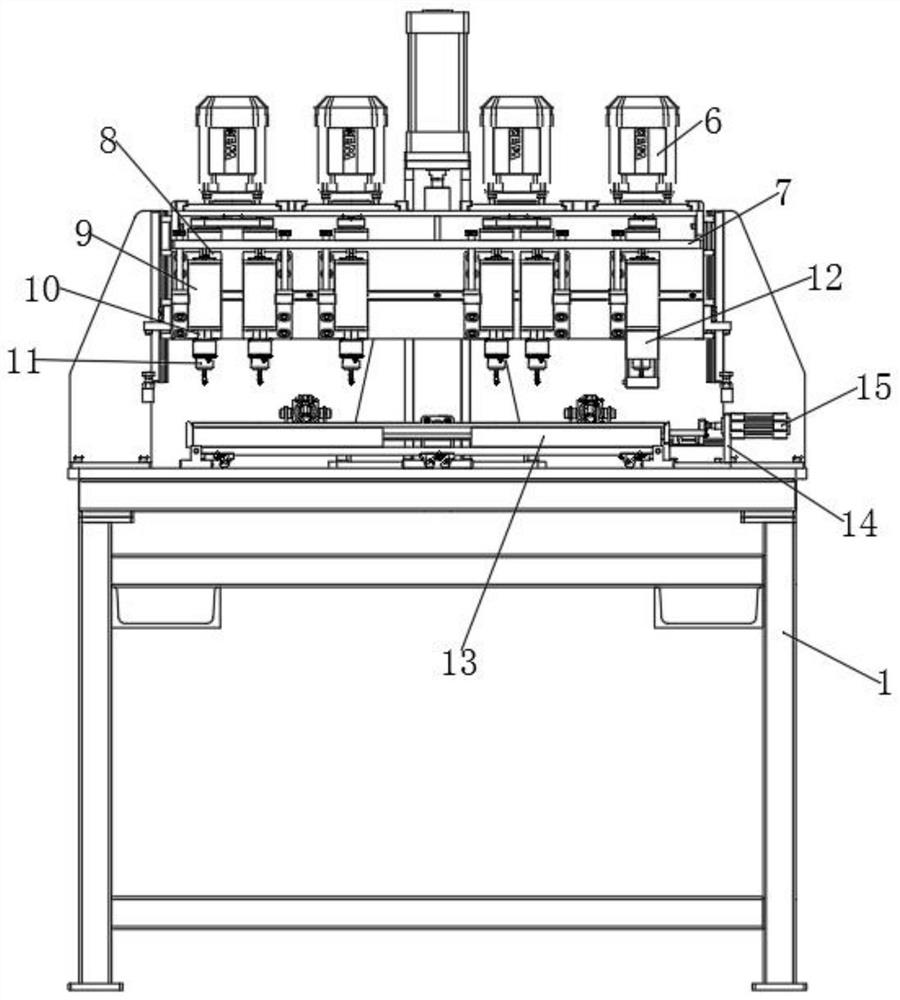

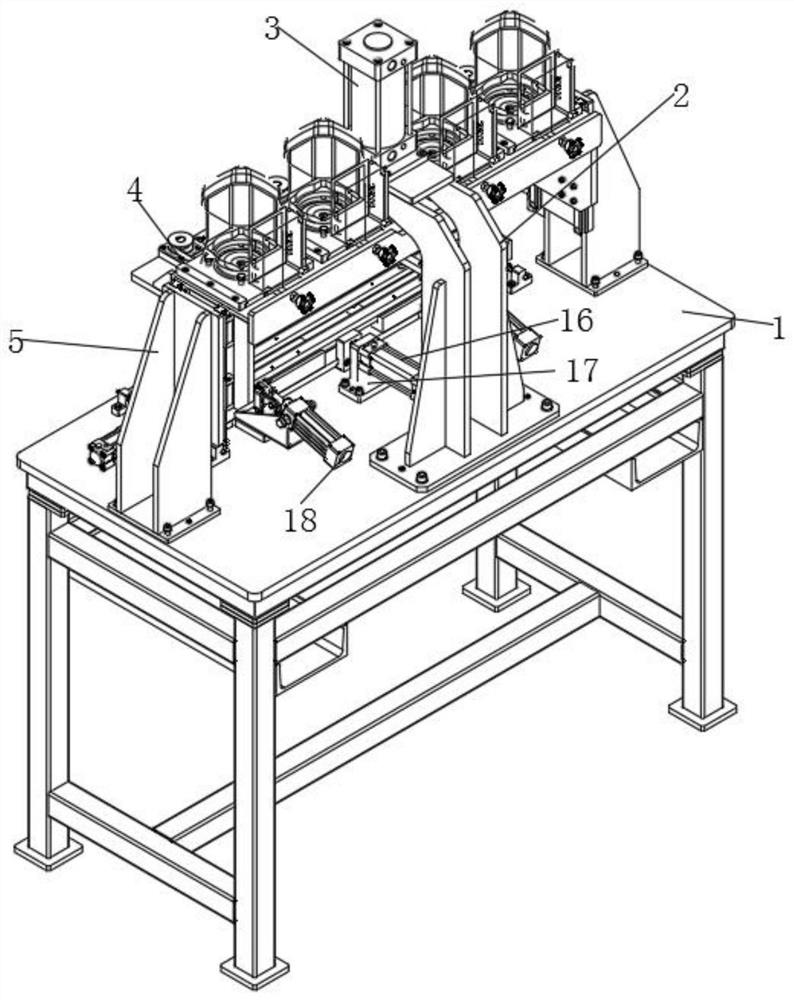

Angle steel eyelet work product line

InactiveCN101402118ARealize automatic clampingAchieve positioningPerforating toolsMetal-working feeding devicesProduction linePunching

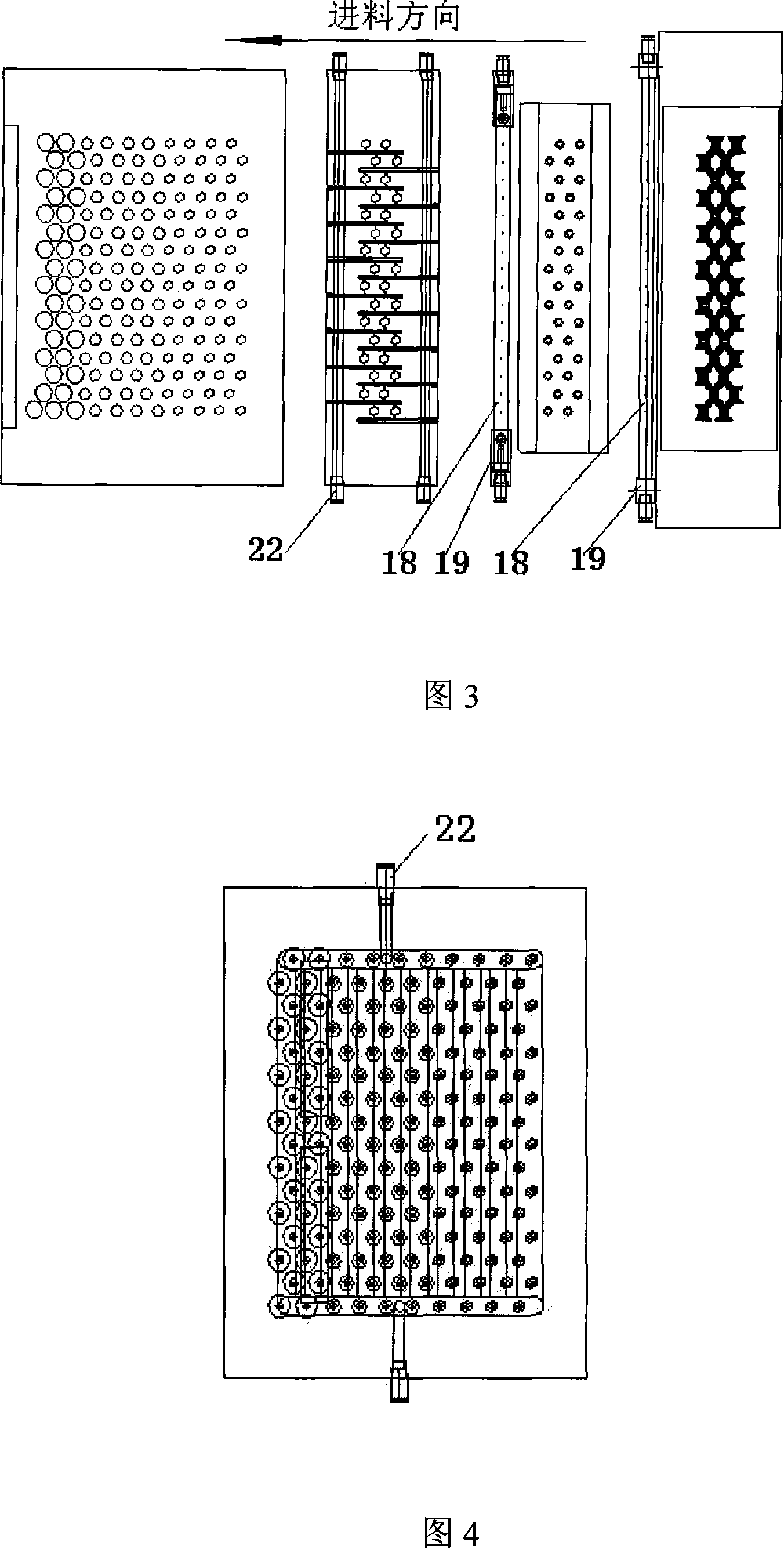

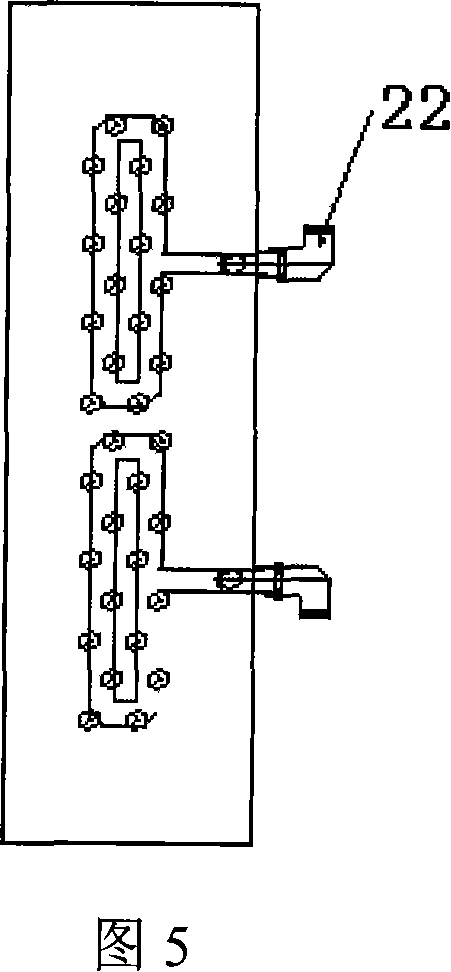

The invention discloses a production line for punching angle iron. A transverse feed device and a transverse positioning device are used to realize the feed displacement and the positioning of an angle iron work piece along the transverse direction(the X axis); a vertical feed device, a vertical displacement device and a vertical positioning device which are matched with each other are used to realize the displacement and the positioning of the angle iron work piece along the vertical direction(the Y axis); and in the whole process of punching, after the angle iron work piece is put on the production line for punching, the clipping, feed, displacement, accurate positioning and punching are automatically realized, thereby not only realizing the automatic accurate positioning and continuous punching on any position of a punching face of the angle iron along the X and the Y axes, but also greatly improving the punching accuracy, production efficiency and processing stability and reliability.

Owner:浙江博雷重型机床制造有限公司

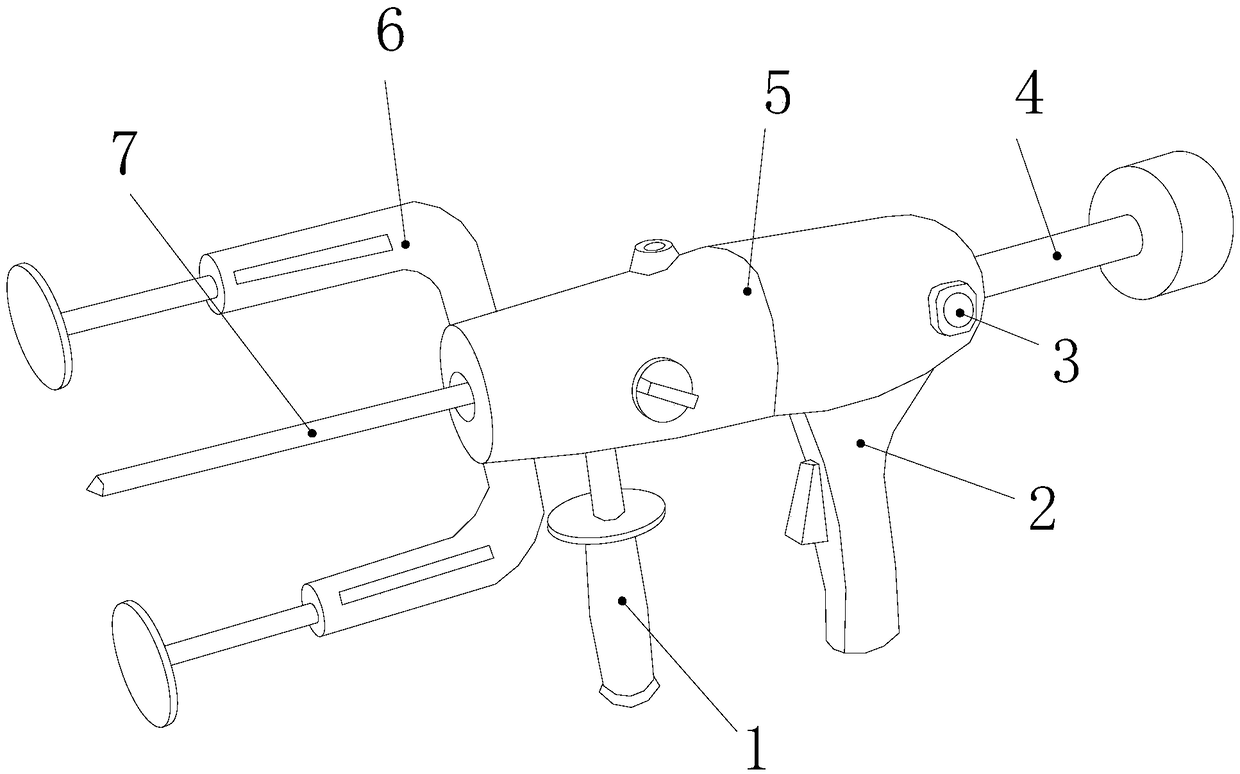

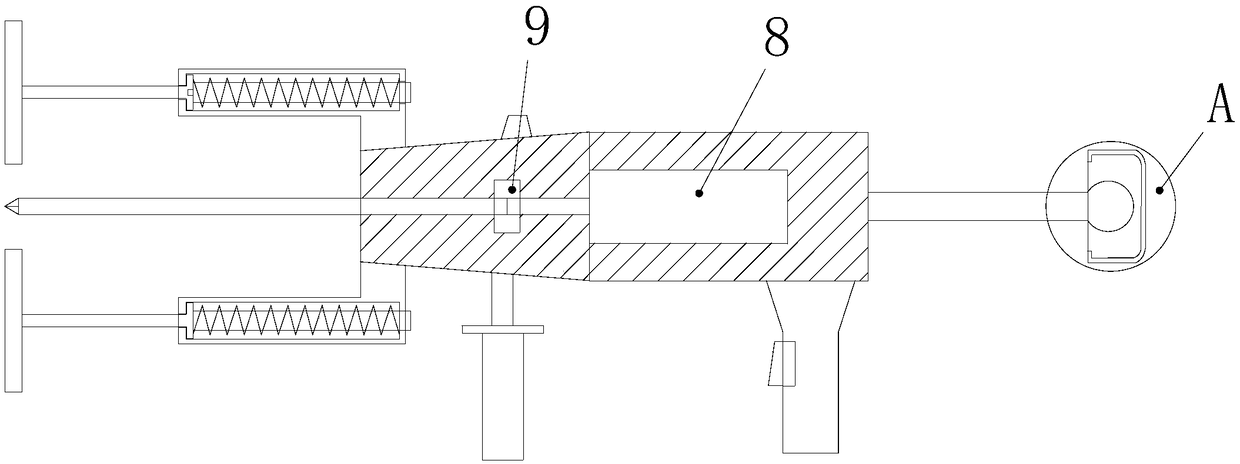

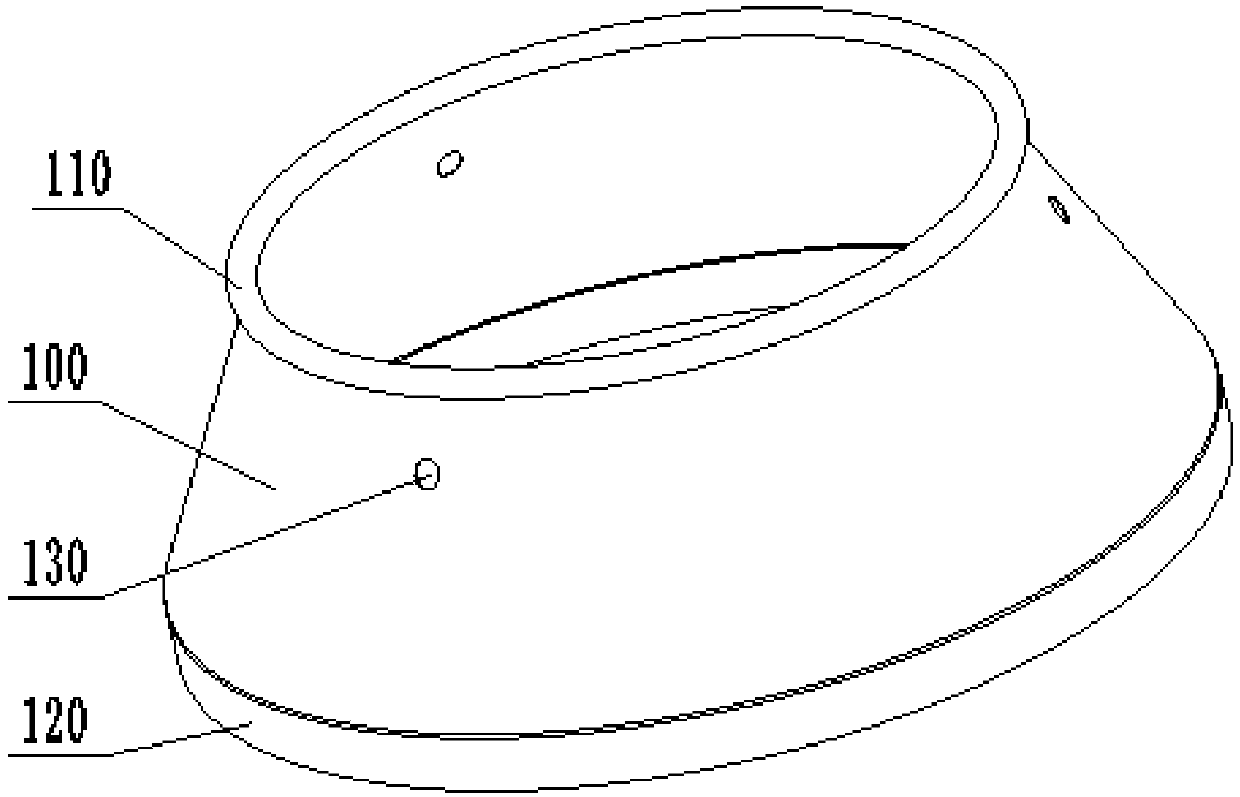

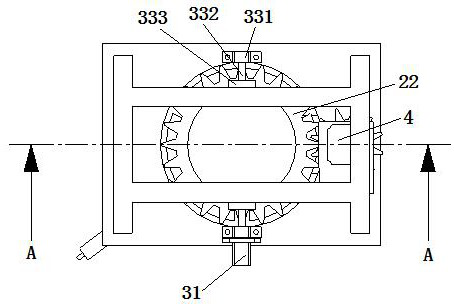

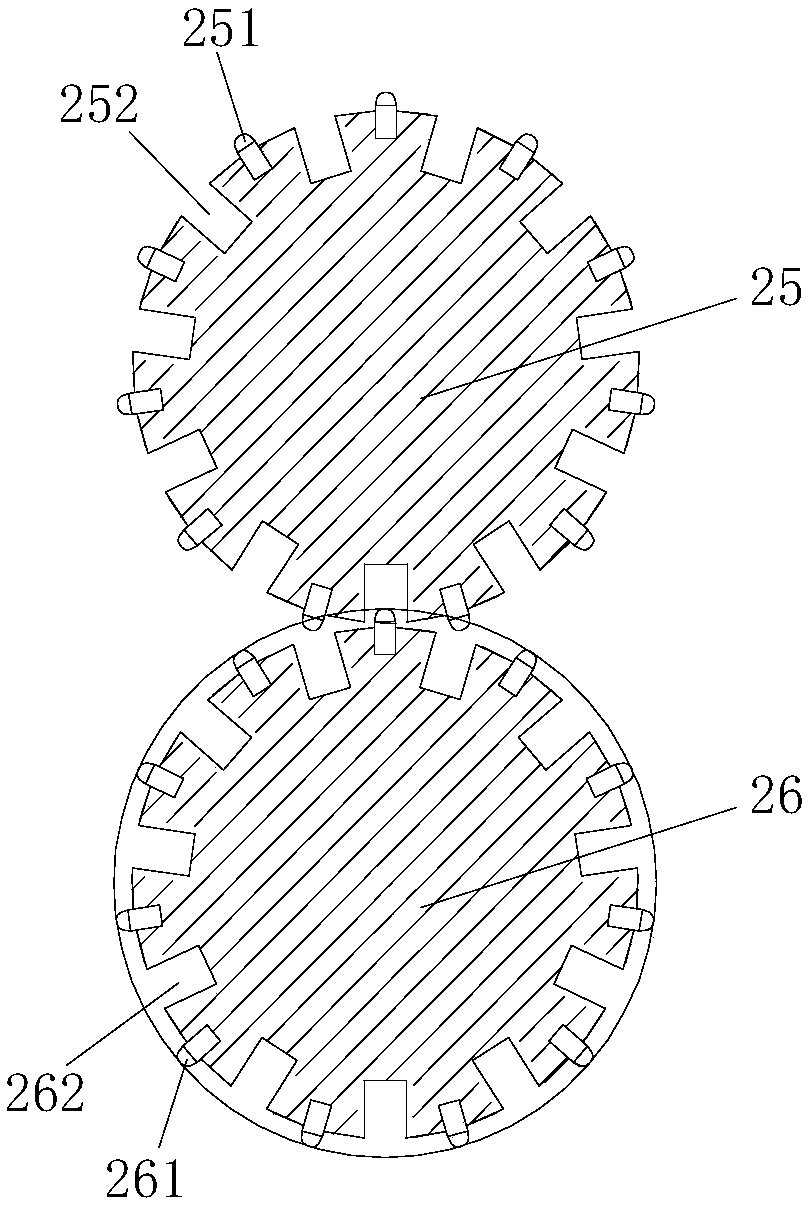

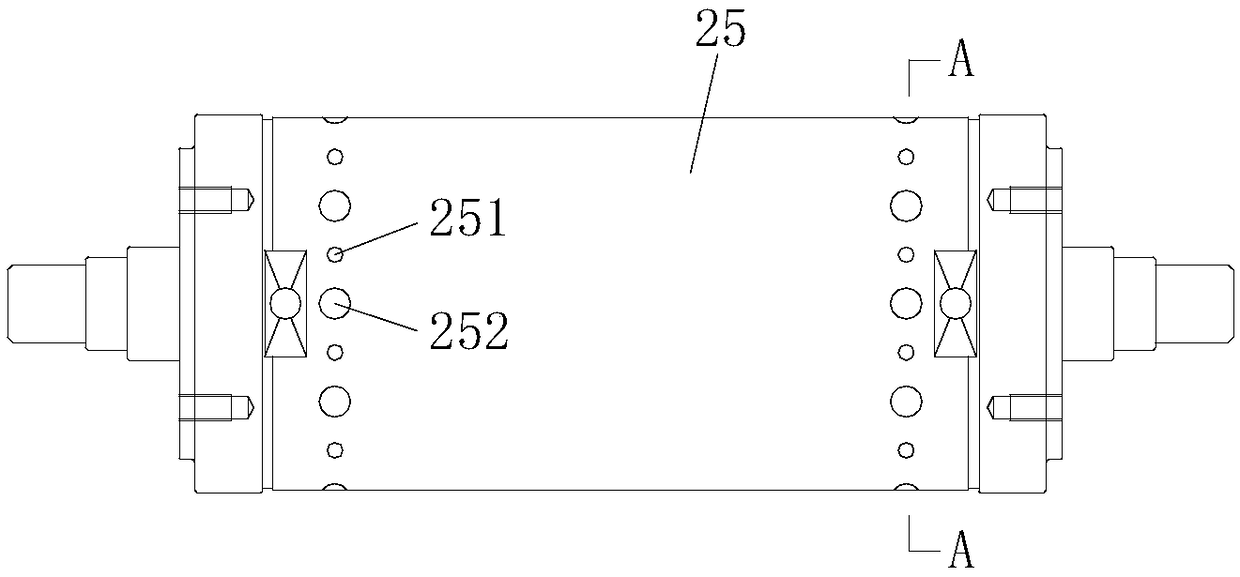

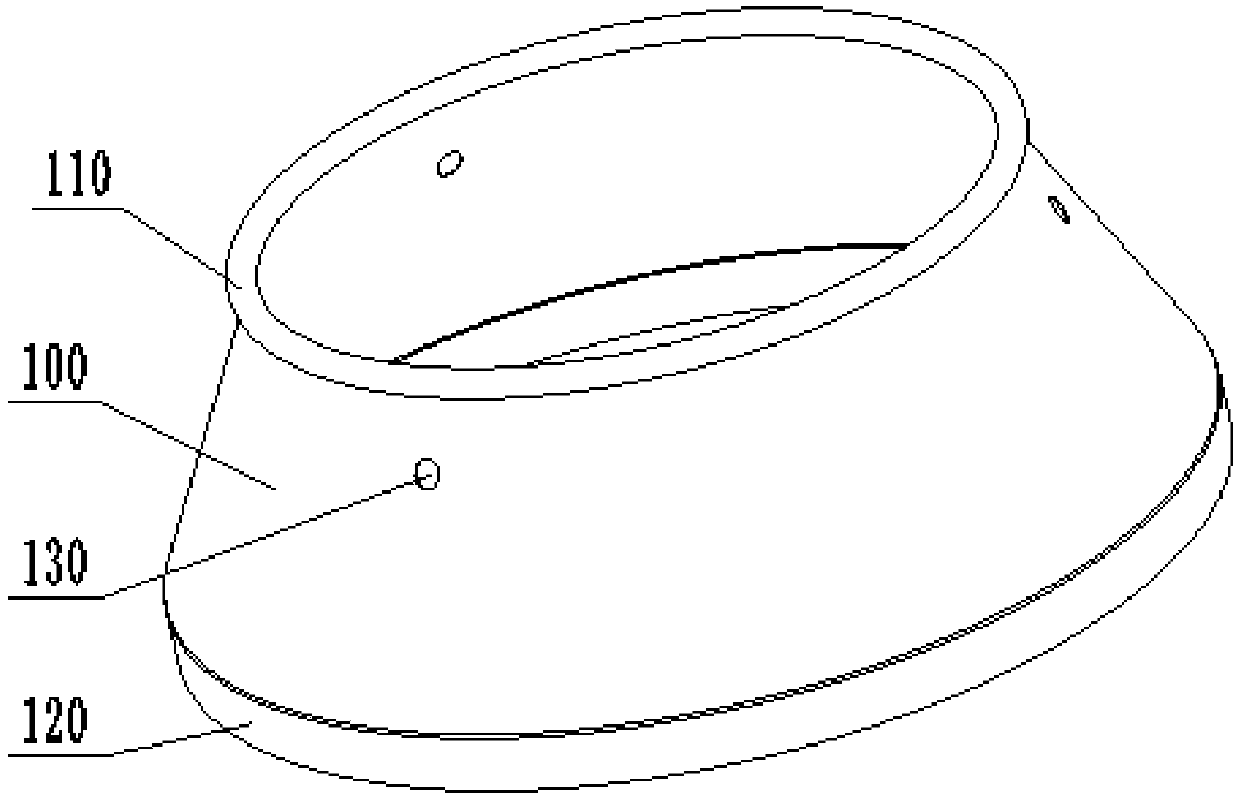

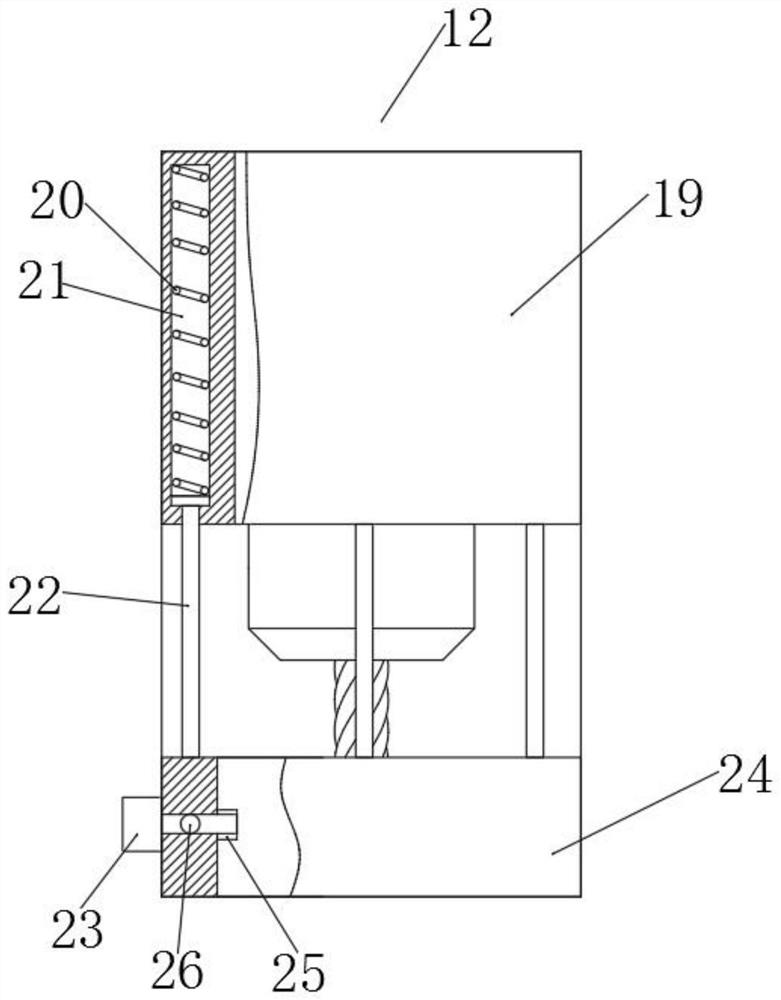

Spherical surface cantilever type bi-directional punching die

ActiveCN105215149AEasy to fixGuaranteed to proceed normallyPerforating toolsMetal-working feeding devicesPunchingSpherical shaped

The invention provides a spherical surface cantilever type bi-directional punching die and belongs to the field of punching dies. The punching die comprises a lower die base and an upper die base. The lower die base is provided with a cantilever part. One end of the cantilever part is connected with the lower die base through a female die fixing base. The other end of the cantilever part serves as a working end. The working end is provided with a spherical surface. The spherical surface is provided with an upper female die body and a lower female die body in a vertically opposite mode. The upper die base is provided with an upper male die body. The lower die base is provided with a lower male die body. The upper male die body corresponds to the upper female die body. The lower male die body corresponds to the lower female die body. Clamping blocks are arranged at the positions, close to the left side and the right side of the working end, of the lower die base respectively. The clamping blocks are detachably connected with the lower die base. The spherical surface cantilever type bi-directional punching die can punch spherical surface work-pieces synchronously in two directions, the work-pieces do not need to be punched one by one, machining efficiency is improved, punching precision is greatly improved, deformation of the spherical surface work-pieces in the punching process is reduced, and the machining quality of the manufactured work-pieces is ensured.

Owner:启东市鸿洋润滑产品有限公司

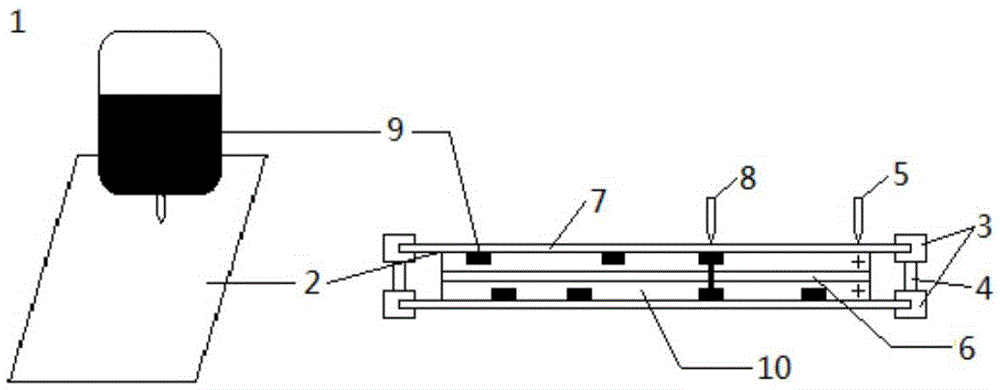

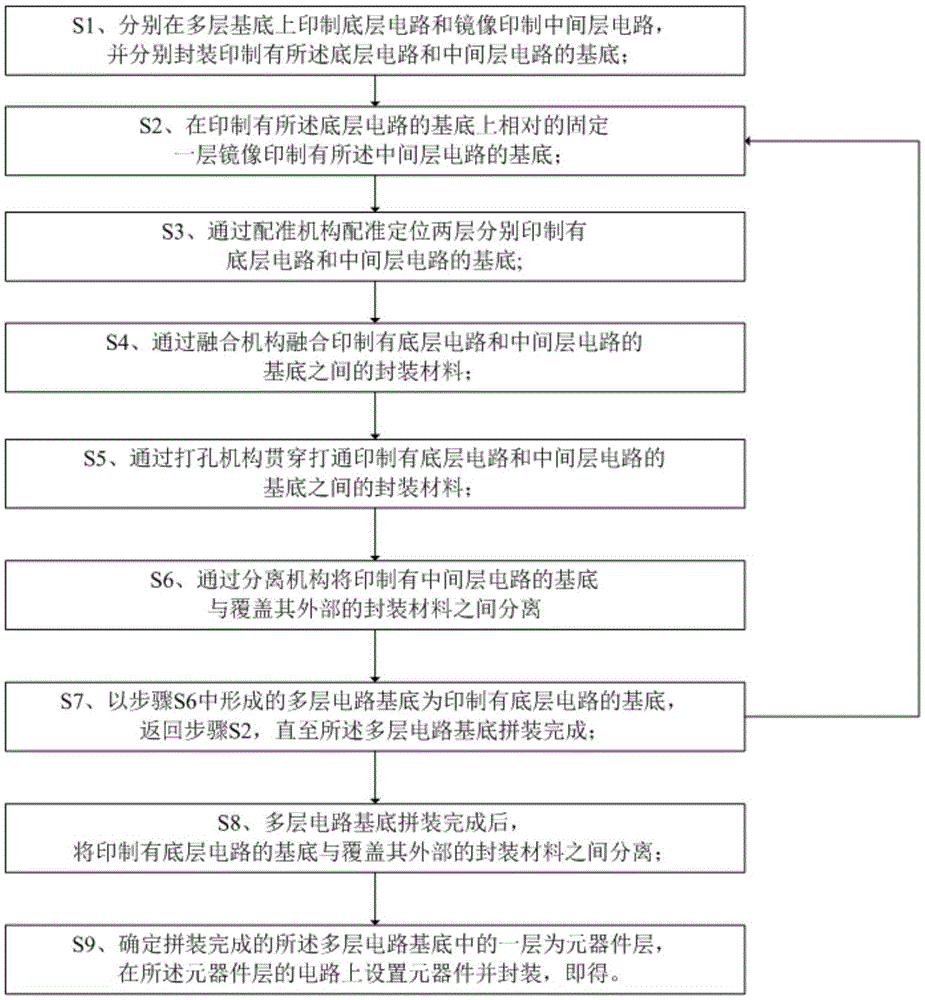

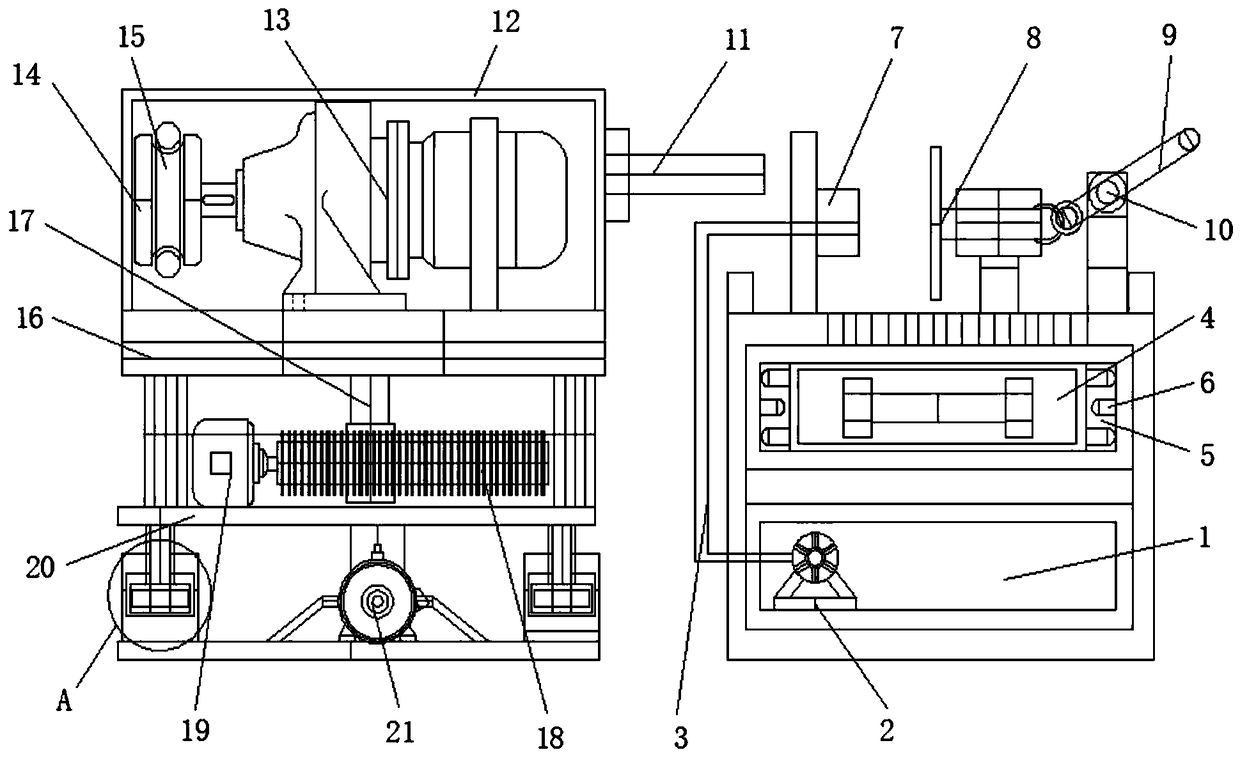

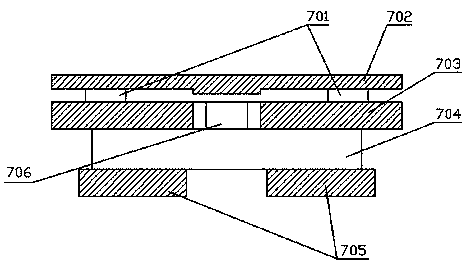

Manufacturing method and apparatus for liquid metal multilayer circuit

ActiveCN105611753AAvoid the problem of fragile linesMade preciselyMultilayer circuit manufacturePunchingFlexible circuits

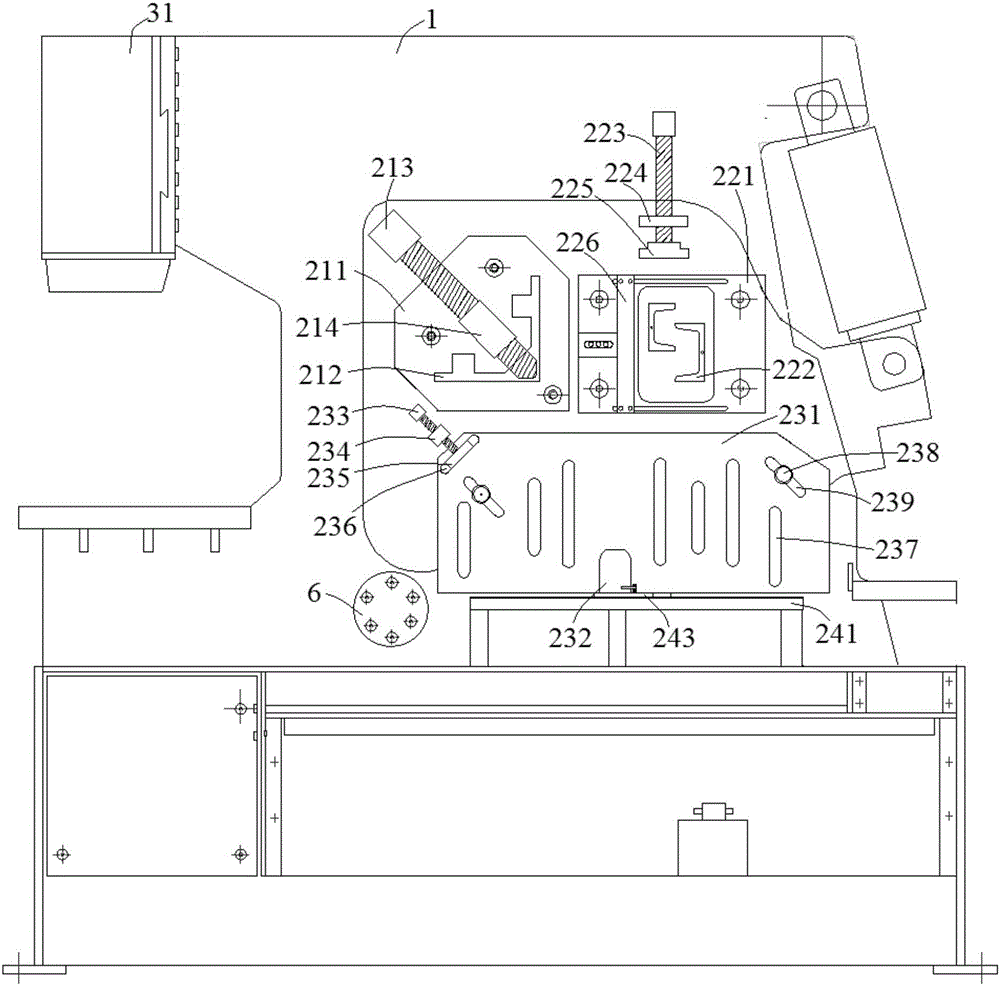

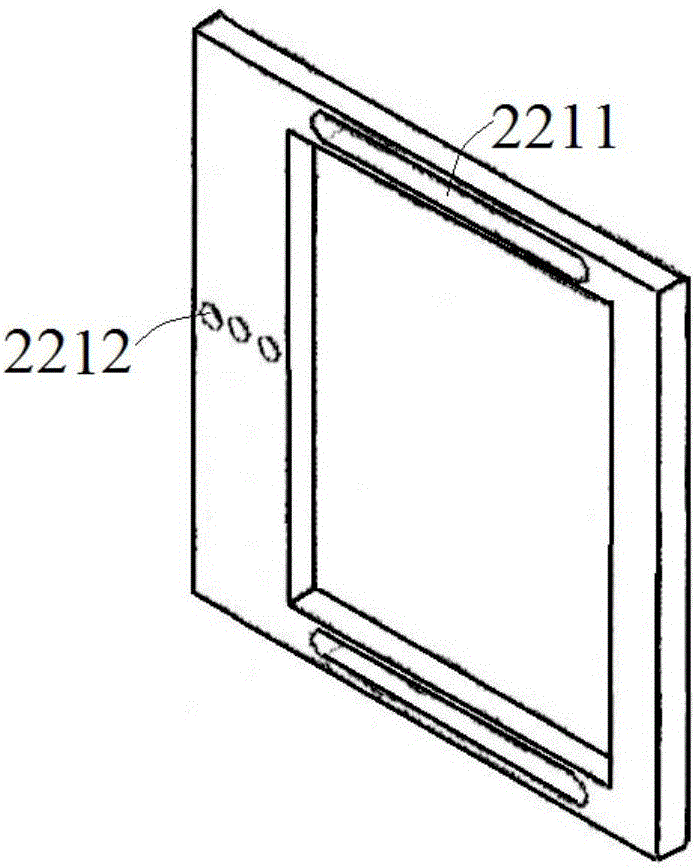

The invention relates to the manufacturing technical field of a flexible circuit, and particularly to a manufacturing method and apparatus for a liquid metal multilayer circuit. According to the manufacturing method and apparatus for the liquid metal multilayer circuit, the circuit can be printed and packaged in different layers; after the circuits in different layers are registered and aligned through a registering mechanism, the packaging materials among the circuits in different layers are fused through a fusion mechanism; the circuits in different layers are punched and connected through a punching mechanism according to requirements; the problem of frequent damage to circuits caused by directly turning over or stacking the liquid metal circuit is avoided; the multilayer liquid metal circuit can be manufactured accurately and effectively, so that the applicable range of the liquid metal circuit is greatly expanded; the packaging thickness, the alignment precision, and the punching accuracy can be effectively ensured; the problems of circuit mismatch, wrong connections, or punched circuits due to carelessness, and the like are avoided; and in addition, the manufacturing method is simple to use, and the manufacturing apparatus has the advantages of simple assembling, low cost, no pollution, and the like.

Owner:BEIJING DREAM INK TECH CO LTD

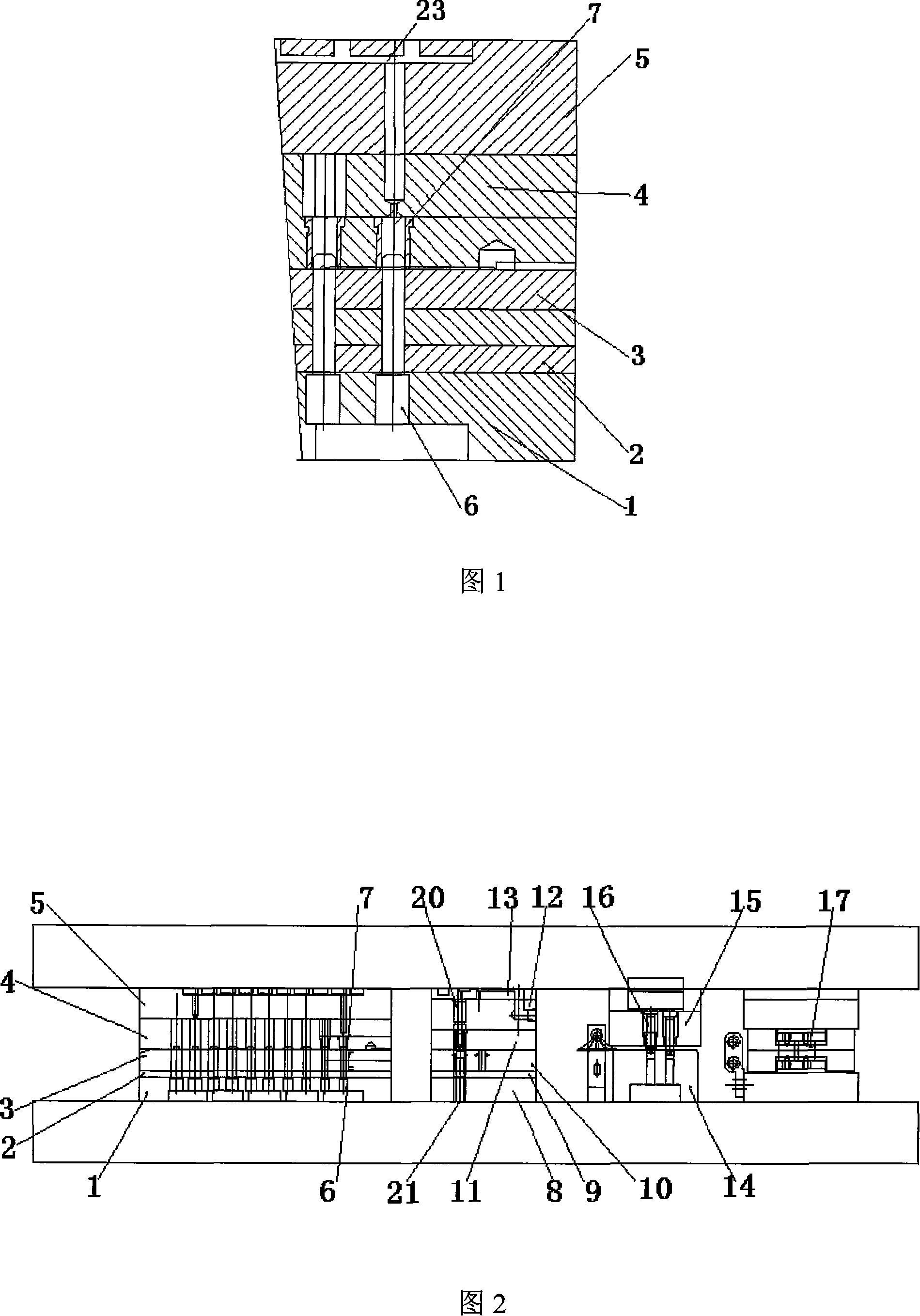

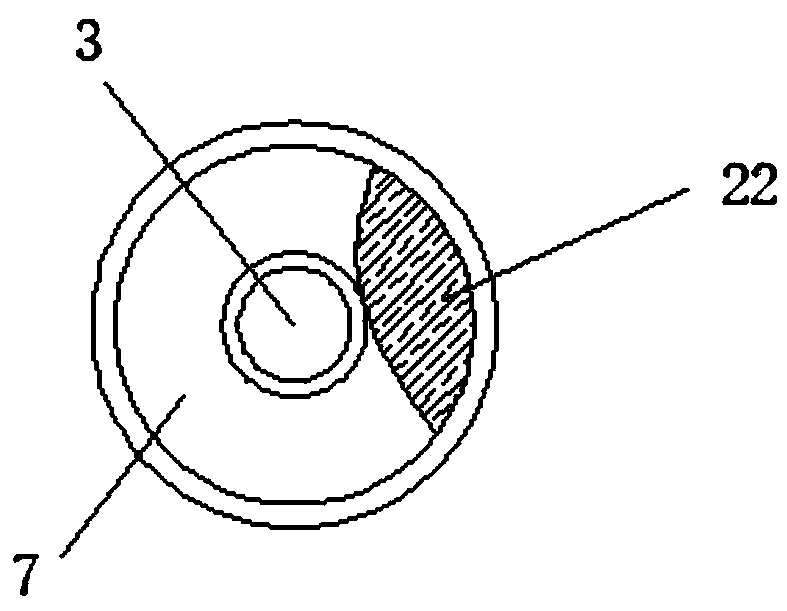

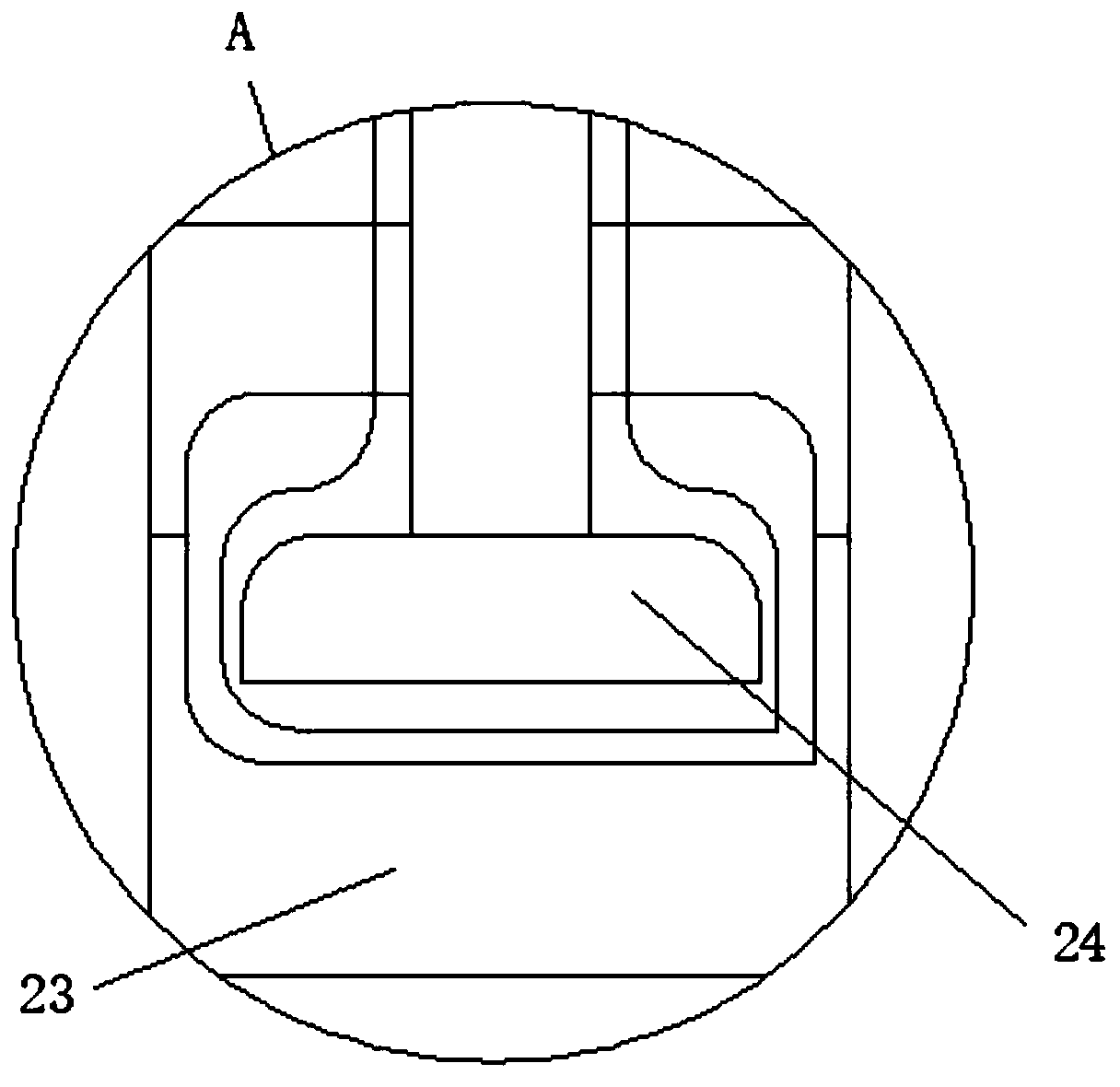

Thin band high speed stamping die and method for controlling oil-gas jetting

InactiveCN101121187AFast punching speedImprove securityShaping toolsStripping-off devicesPunch pressControl system

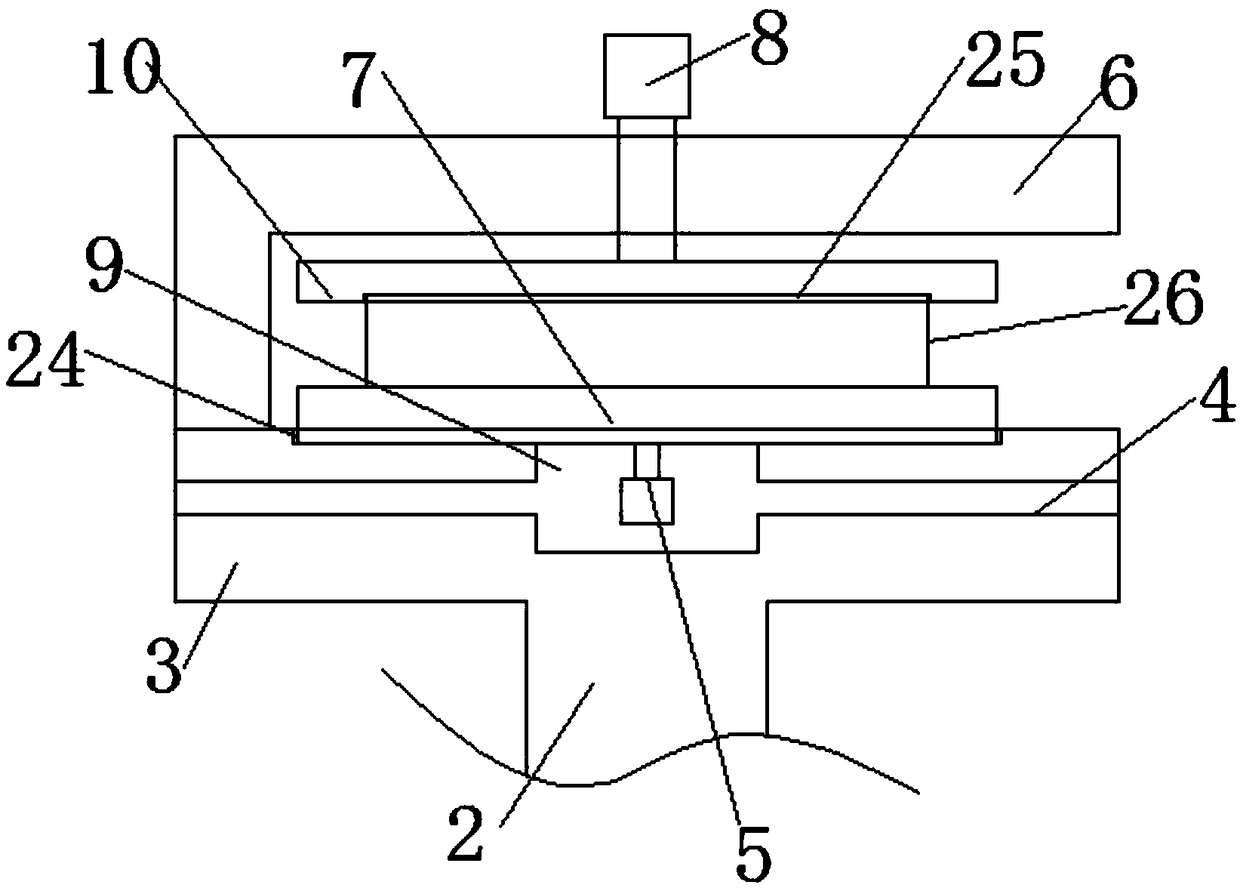

The present invention discloses a thin belting high-speed die; every submodule in the thin belting high-speed die is equipped with a high-pressure oil gas supply closed path (23) and connected with an oil gas supply control system of a high-speed punch. An elongated die air supply supporting block (5) is equipped between an elongated concave die fixing plate (4) and a mold frame which are equipped on an elongated submodule; the elongated concave die fixing plate (4), elongated air supply supporting block (5) and elongated concave dies (7) are equipped with communicated oil gas closed paths; oil gas closed path of every concave die is gathered to an elongated common path equipped on the elongated die air supply supporting block (5) and the elongated common path is communicated with the high-pressure oil gas supply closed path 23 of the high-speed punch high-pressure oil gas supply control system. By adopting the technical proposal mentioned above, the punching speed of the thin belting is increased in the process of high-speed punching and the punching precision is ensured; the safety performance of the die is excellent which prevents the cutting edge of the punch-die from being damaged by the punching waste material.

Owner:黄山三佳谊华精密机械有限公司

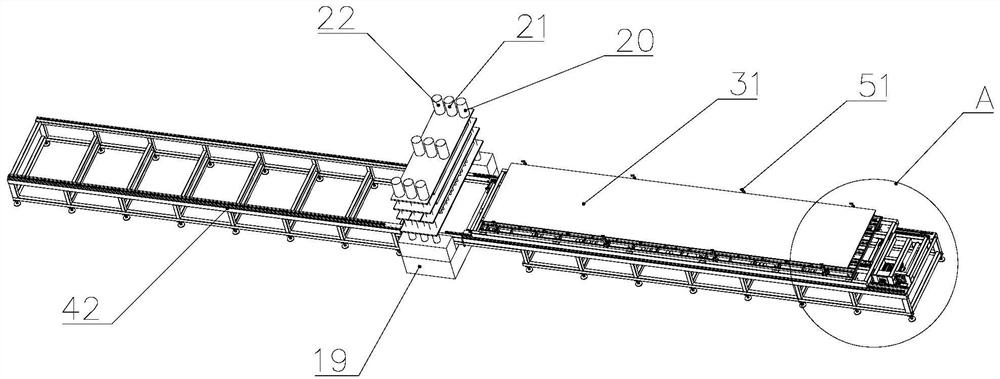

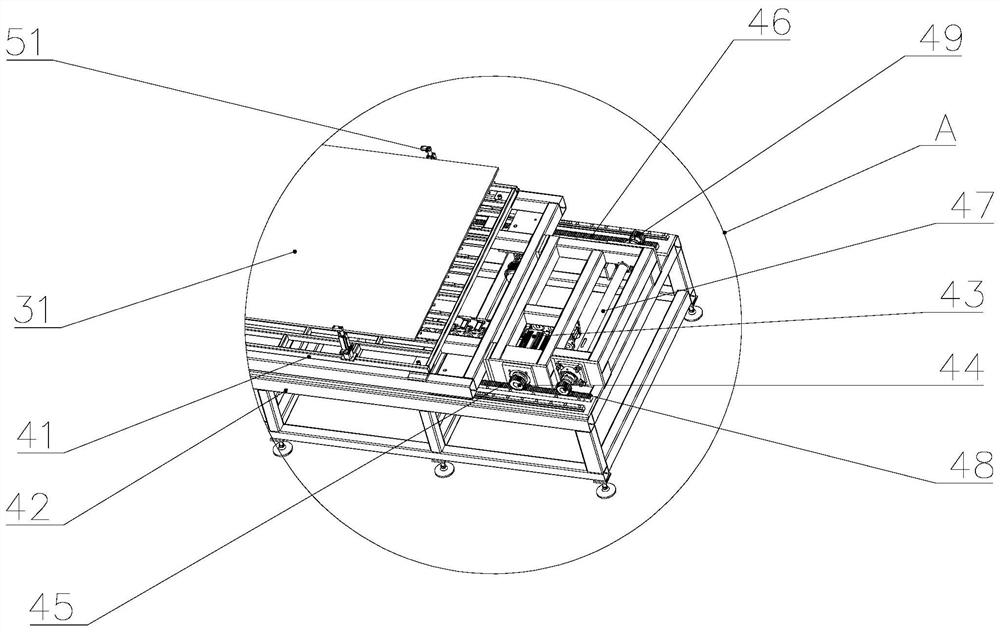

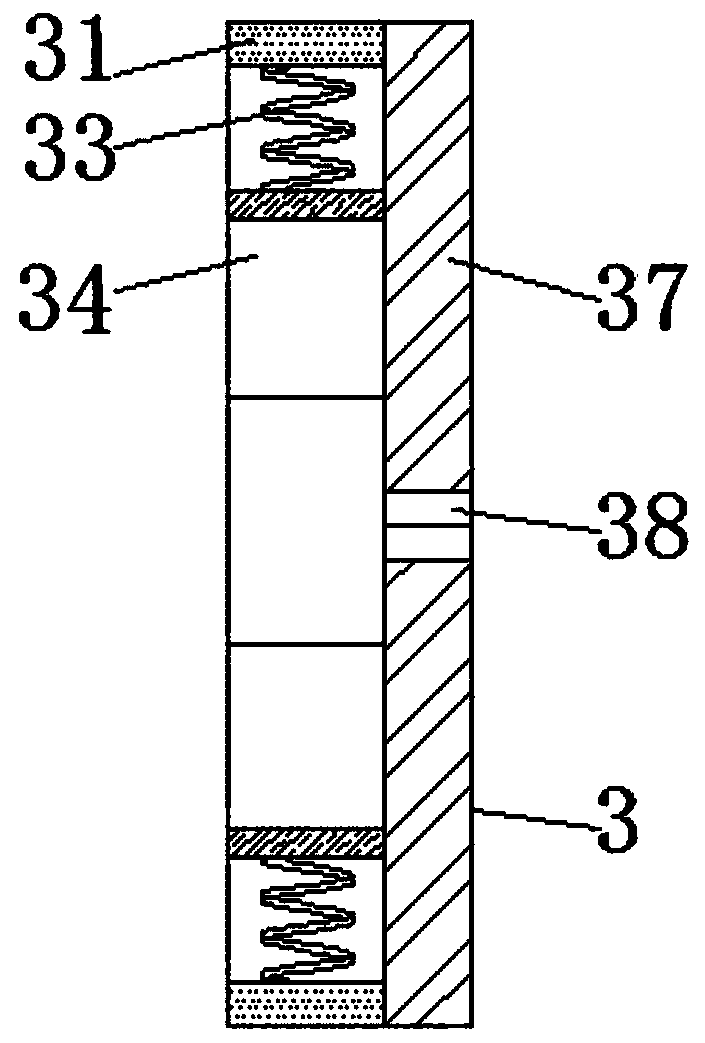

Truss 3D floor plate perforating machine

ActiveCN113020653AReduce damageReduce the breakage rateMetal working apparatusStone-like material working toolsFloor levelFloor plate

The invention discloses a truss 3D floor plate perforating machine, and belongs to the field of floor plate production equipment. The perforating machine comprises a screw feeding mechanism, wherein the screw feeding mechanism comprises a first perforating assembly, a second perforating assembly and a screw feeding assembly, the first perforating assembly comprises a plurality of first perforating drill bits, and the first perforating drill bits are used for perforating a first workpiece; the second perforating assembly comprises a plurality of second perforating drill bits, and the second perforating drill bits are used for perforating a second workpiece; the screw feeding assembly comprises a plurality of screw feeding heads, and the screw feeding heads are used for fastening the first workpiece and the second workpiece; and under the action of a conveying mechanism, the first perforating assembly is used for perforating the first workpiece to form a first hole, the second perforating assembly is used for continuously perforating the second workpiece along the first hole to form a second hole, and then the second workpiece is conveyed to the screw feeding assembly to connect the first hole with the second hole.

Owner:山东七星绿色建筑科技有限公司

Mechanical drilling machine capable of realizing ergonomic hole depth adjustment and deflection prevention

ActiveCN109304502AGuaranteed accuracyGuaranteed punching efficiencyPortable drilling machinesCouplingPush pull

The invention discloses a mechanical drilling machine capable of realizing ergonomic hole depth adjustment and deflection prevention. The mechanical drilling machine capable of realizing ergonomic hole depth adjustment and deflection prevention structurally comprises a grip, a handle, a carbon brush cover, an ergonomic shouldering device, a device main body, a location and hole depth adjustment device, a drill rod, a drive motor and a shaft coupling, wherein the grip is fixed to the left side of the lower end of the device main body through a screw; and the handle is connected to the right side of the lower end of the device main body through glue. According to the mechanical drilling machine capable of realizing ergonomic hole depth adjustment and deflection prevention, the ergonomic shouldering device is arranged, and a spherical inner groove, a rolling ball and a ball body slide head are mutually cooperated, so that a rubber cover and the soft tissues of the shoulders of a human body are mutually bonded, the comfort is improved, and the transversal impact force is reduced; the location and hole depth adjustment device is arranged, and a deflection prevention plate and an inner rod are mutually cooperated, so that a correct drilling angle is ensured, and the occurrence of waste holes is reduced; and a stop block, a depth gauge and a push-pull location structure are mutually cooperated, so that the accuracy of a hole depth, and the drilling efficiency are ensured.

Owner:浙江黎盛新材料科技有限公司

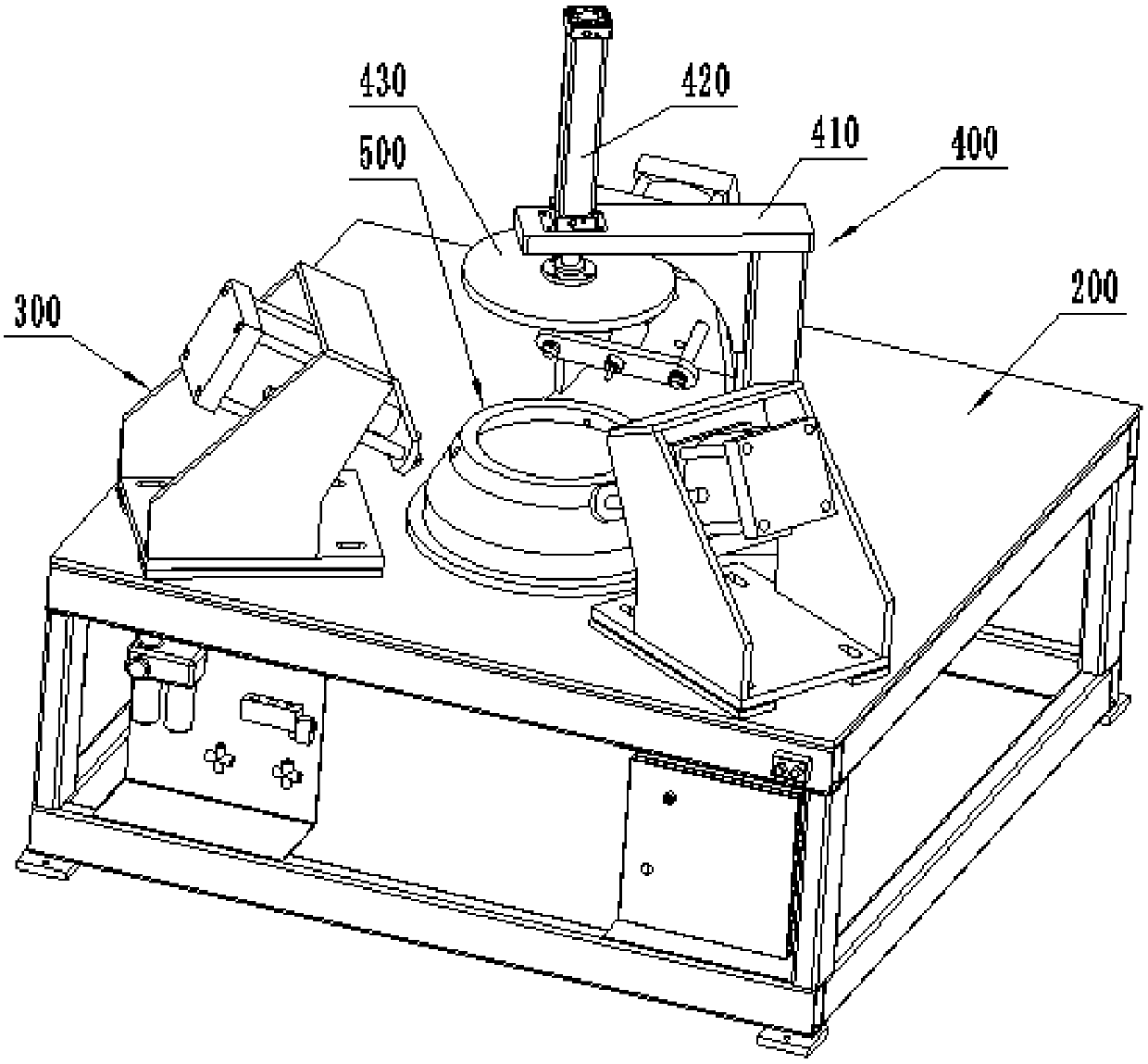

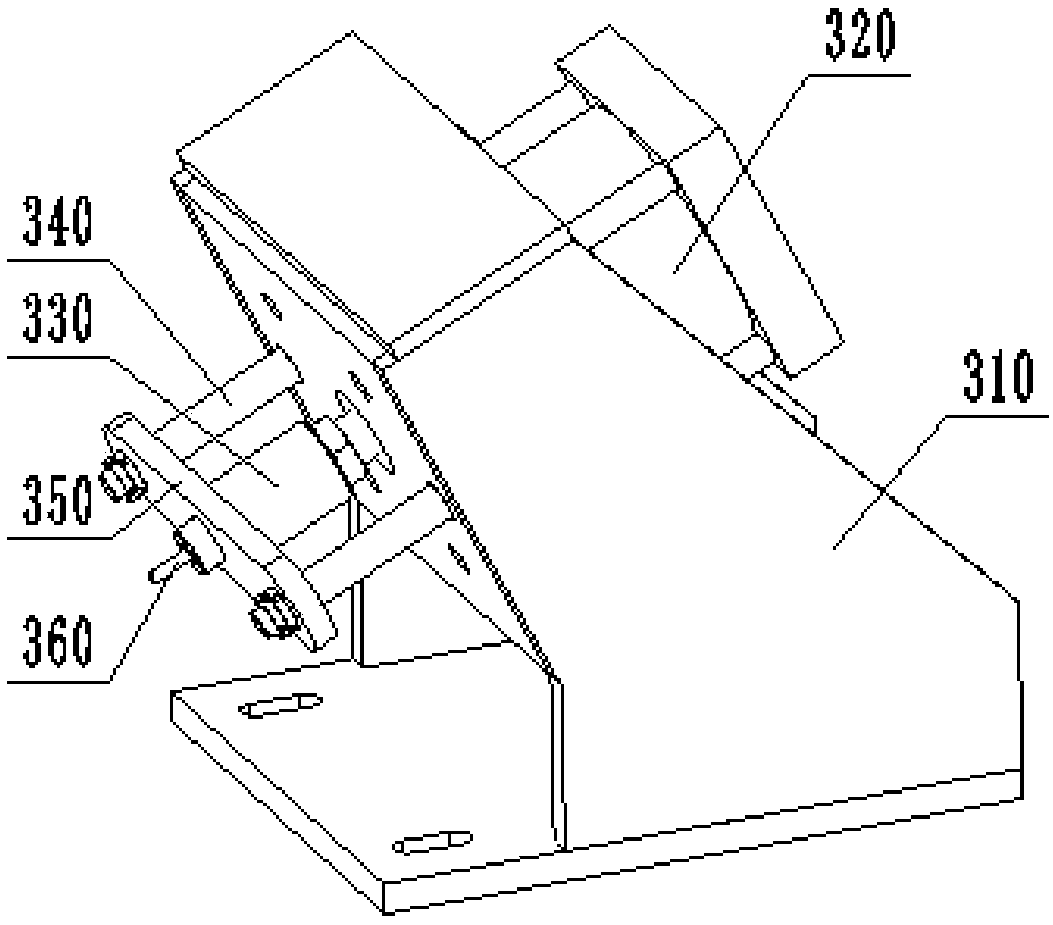

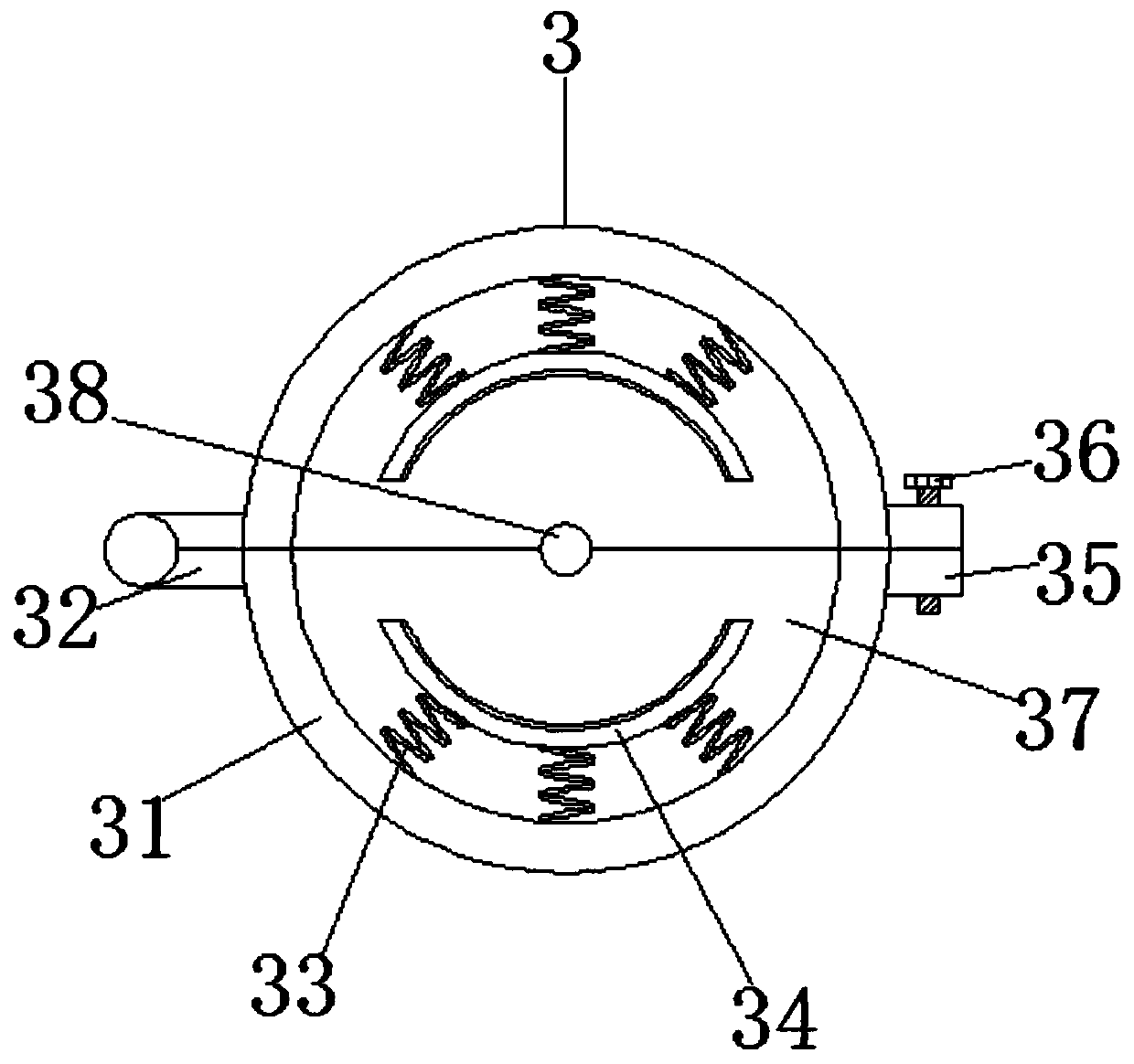

Punching and edge cutting method of conic cylindrical workpiece

ActiveCN107900189ASimple processGuaranteed punching accuracyPerforating toolsMetal-working feeding devicesPunchingLocking mechanism

The invention discloses a punching and edge cutting method of a conic cylindrical workpiece and belongs to the technical field of machining assistance. According to the punching operation in the method, alignment of a punch to a mold sleeve is ensured, a locking mechanism locks a rotating disc, a pressing mechanism presses the conic cylindrical workpiece sleeving a material carrying mold, a punching assembly drives the punch to punch a hole in a cylinder body of the conic cylindrical workpiece, and the punching operation is completed. According to edge cutting operation, the locking mechanismloosens the rotating disc, a rotating disc mechanism drives the rotating disc to drive the material carrying mold to rotate, the edge cutting assembly drives a cutter to get close to the conic cylindrical workpiece and make contact with the conic cylindrical workpiece, the cutter cuts the circular ring edge of the conic cylindrical workpiece, and the edge cutting operation is completed. Accordingto the punching and edge cutting method, punching can be carried out on the cylinder body of the conic cylindrical workpiece conveniently and fast, and edge cutting can be carried out on the circularring edge conveniently and fast.

Owner:安徽省华夏机床制造有限公司

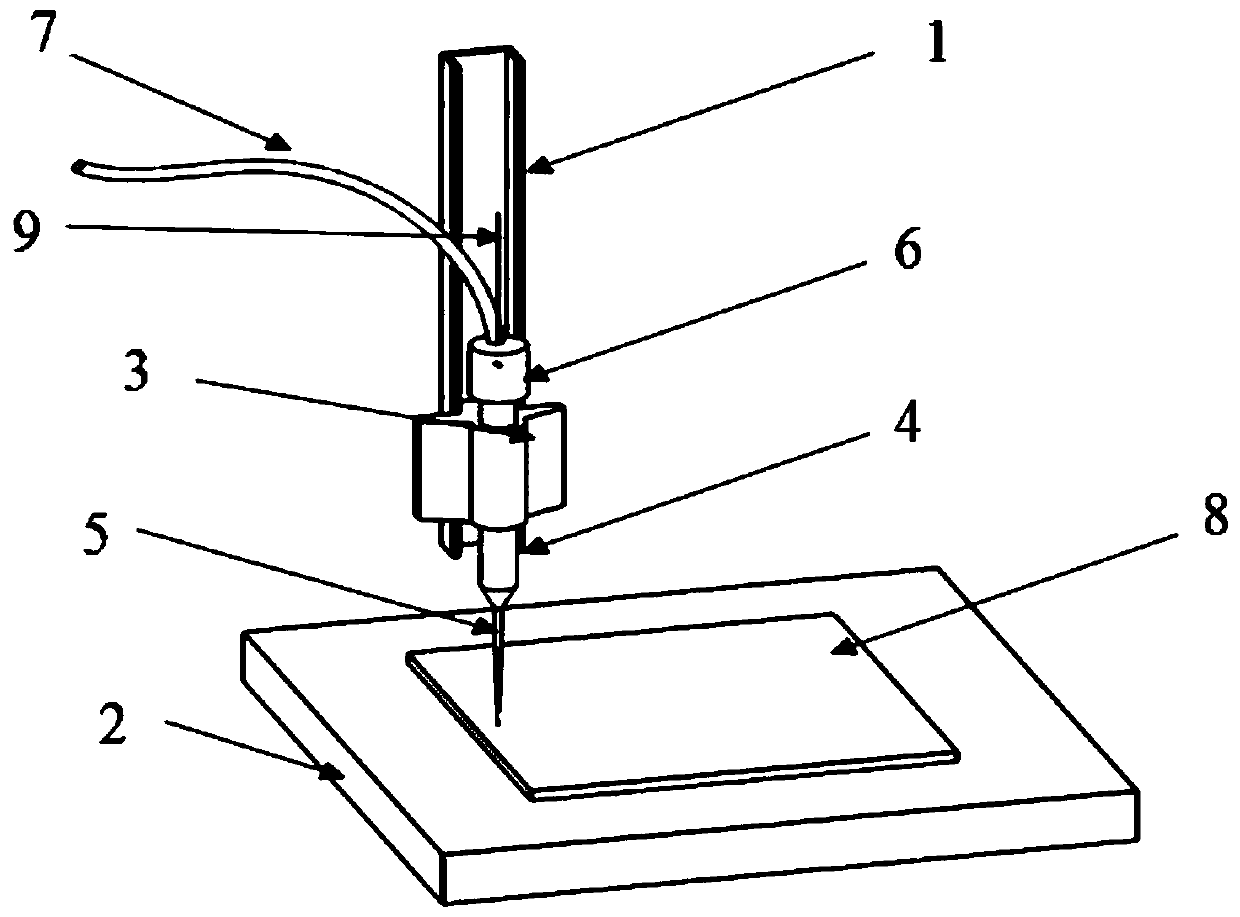

Laser drilling method for miniature loudspeaker brackets

InactiveCN102756396AReduce processing stepsSave labor hoursMetal working apparatusLaser beam welding apparatusLoudspeakerDrill hole

The invention discloses a laser drilling method for miniature loudspeaker brackets. The method is characterized in that through drilling holes on a miniature loudspeaker bracket by using laser, the required basic unit air flow quantity of a loudspeaker vibrating plate in the process of vibrating is adjusted, and then the tone quality is regulated. According to the invention, through creatively using the cooperation of a laser drilling machine and an automatic feeding machine, micropores are drilled on a miniature loudspeaker bracket, so that compared with the traditional loudspeaker bracket drilling process which is implemented through using mechanical processing or die forming, so that the pore diameter is overlarge, and then manually coating glue for adhering damping materials so as to adjust the sound effect of a loudspeaker, the method disclosed by the invention can be used for reducing the application of raw materials such as loudspeaker glue and damping materials, reducing the processing process, and saving the artificial time; and under the condition of guaranteeing the accuracy of drilling through a laser drilling machine, an effect of batch production is achieved, the production efficiency is obviously improved, and the stability and consistency of frequency response characteristics and tone quality performances of a loudspeaker are ensured, thereby significantly reducing the processing cost of the loudspeaker.

Owner:刘天镐

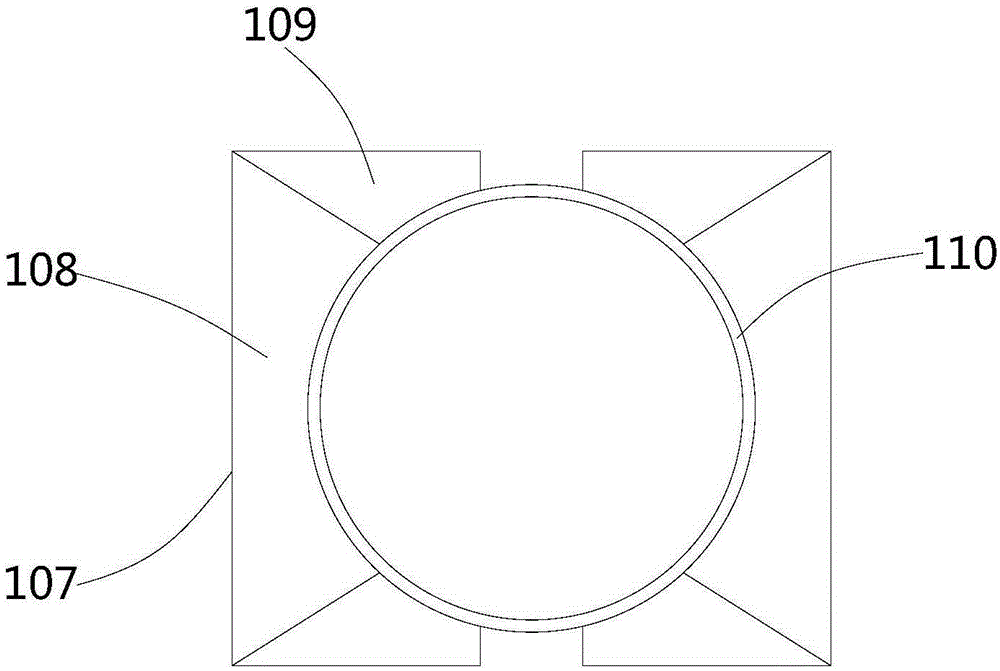

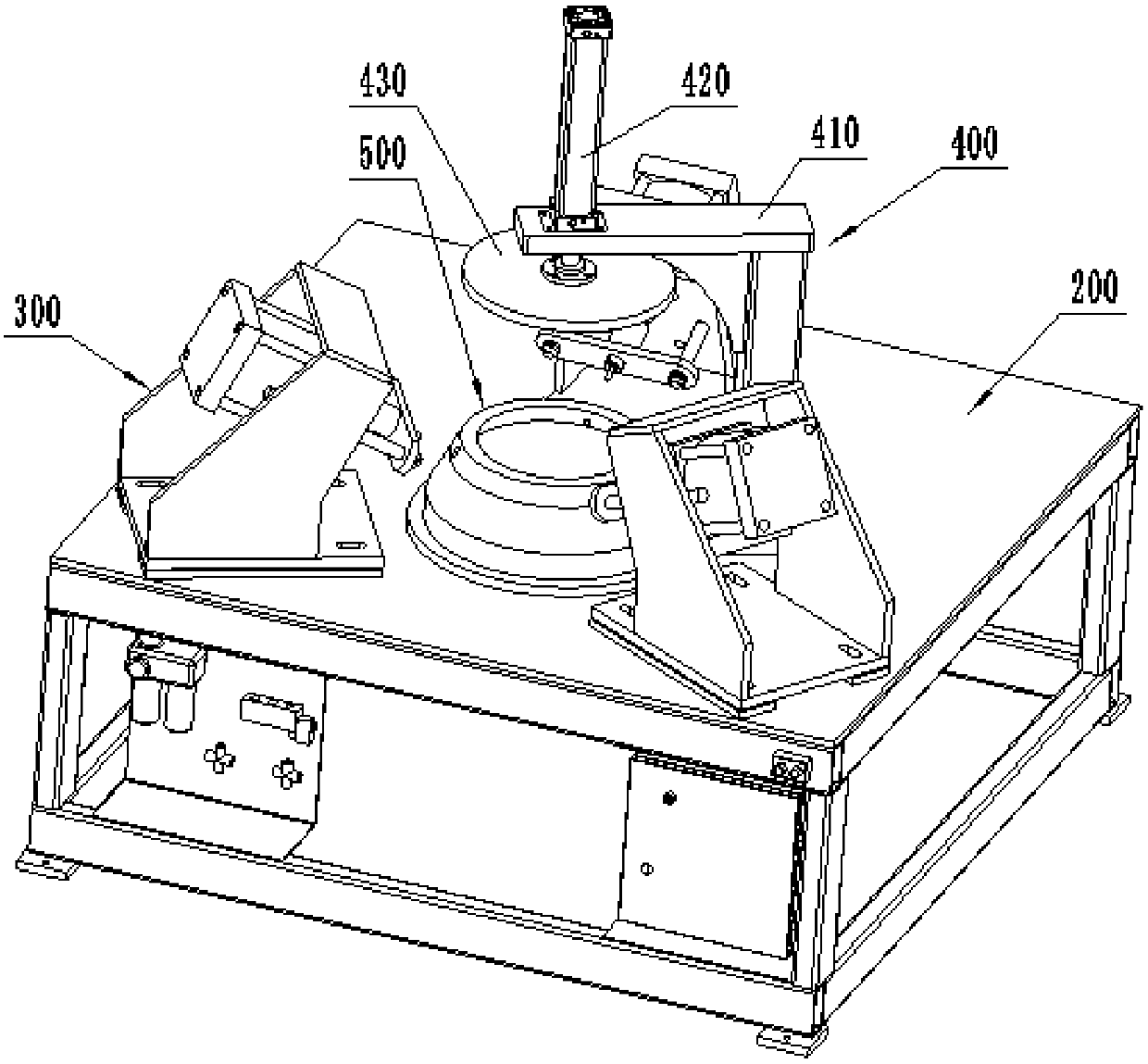

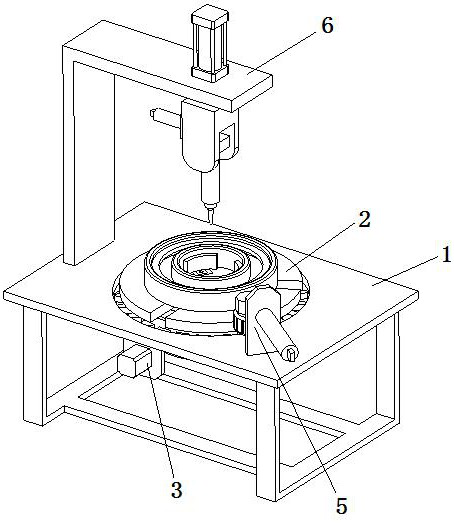

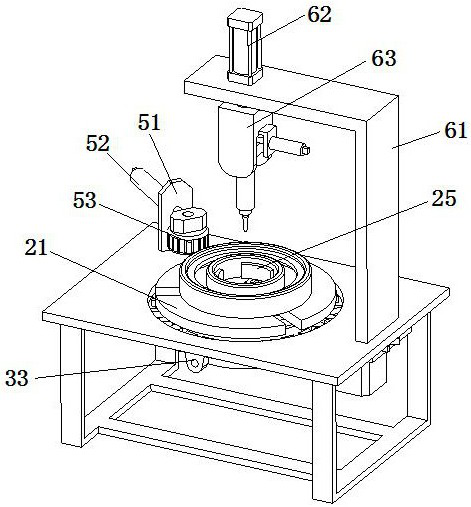

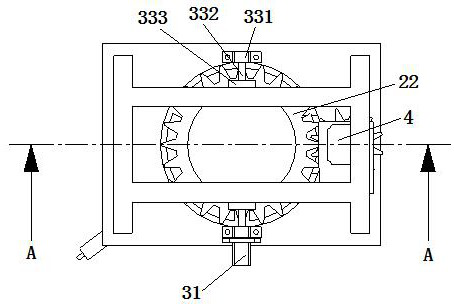

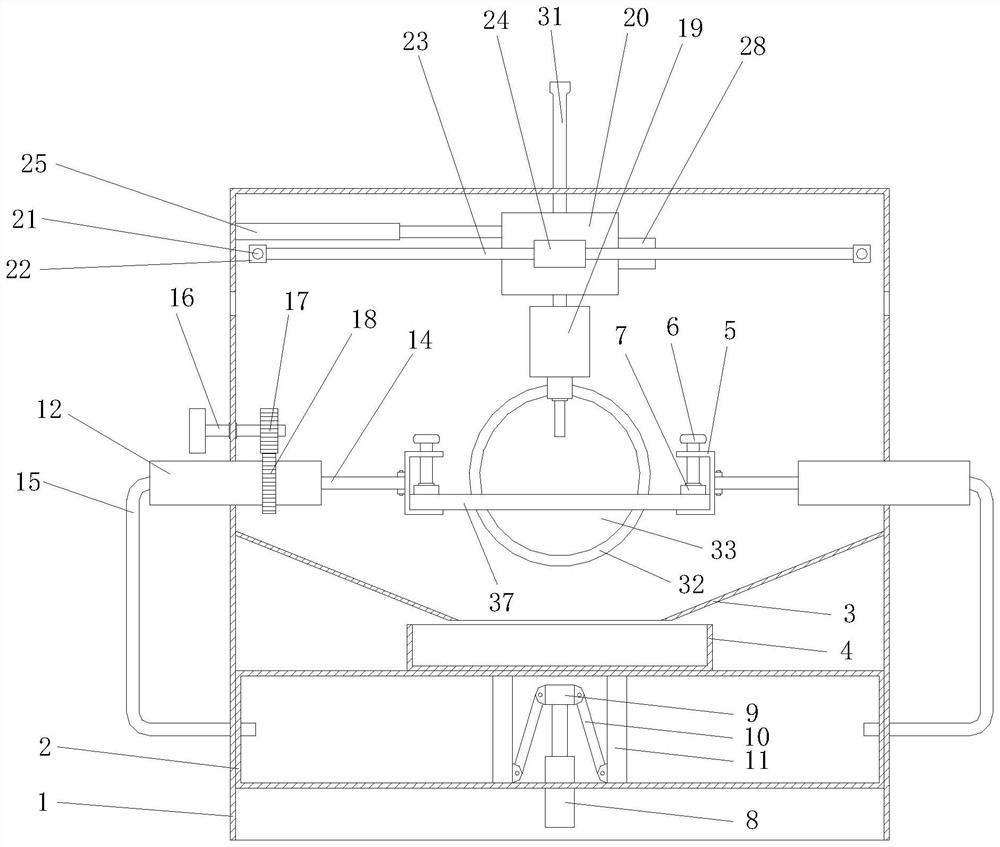

Automatic punching device for tire mold

ActiveCN113246212ARapid positioningMeet the positioning needsMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic punching device for a tire mold, and relates to the technical field of punching devices. The automatic punching device for the tire mold comprises a workbench, a positioning mechanism, a rotating mechanism, a linkage mechanism, an abutting mechanism and a punching mechanism; the rotating mechanism is installed at the bottom of the workbench; a circular groove is formed in the workbench, and the positioning mechanism is installed on the rotating mechanism and located in the circular groove; and the positioning mechanism comprises a base disc, a bottom disc, driving assemblies and three driven assemblies, the bottom disc is installed at the bottom of the base disc, a cavity used for containing the three driven assemblies is formed between the bottom disc and the base disc, and each driving assembly is provided with a limiting assembly connected with the driving assembly. According to the automatic punching device for the tire mold, the tire mold can be quickly positioned, the positioning requirements of various tire molds with different sizes can be met, the automation degree is high, and the production efficiency and the product quality are improved; and multi-direction and multi-angle punching operation of the tire mold can be completed, and the overall machining efficiency and the practical performance are further improved.

Owner:山东新豪克轮胎有限公司

High-precision and low-resistance alloy chip resistor efficiently resistance-regulating technique

InactiveCN109494037ASimple requirementsNo chemical pollutionResistor manufactureNon-adjustable resistorsElectrical resistance and conductancePunch press

The invention aims at providing a high-precision and low-resistance alloy chip resistor efficiently resistance-regulating technique. The high-precision and low-resistance alloy chip resistor efficiently resistance-regulating technique comprises 2) punching a raw material belt through a punch press or die into alloy chip resistors; 2) testing the resistance of every alloy chip resistor, and classifying the alloy chip resistor; 3) for the alloy chip resistors in different resistance ranges, adjusting the position of every product during every feeding, punching out notches in the alloy chip resistors; 4) after the products are conveyed to a punching position, limiting the short side of every product through a feeding groove of a lower die; 5) measuring the resistance of the resistance-regulated resistor and re-classifying the resistors; 6) on different levels punching the alloy chip resistors with the resistance offset ranging between 1% and 5% until reaching within a target resistance range so as to improve the resistance qualification rate of the resistors. The high-precision and low-resistance alloy chip resistor efficiently resistance-regulating technique is low in requirements onequipment, only requires the die, the punching press and a feeding device, and is free from chemical pollution, applicable to continuous operation and high in operation efficiency.

Owner:SHENZHEN YEZHAN ELECTRONICS

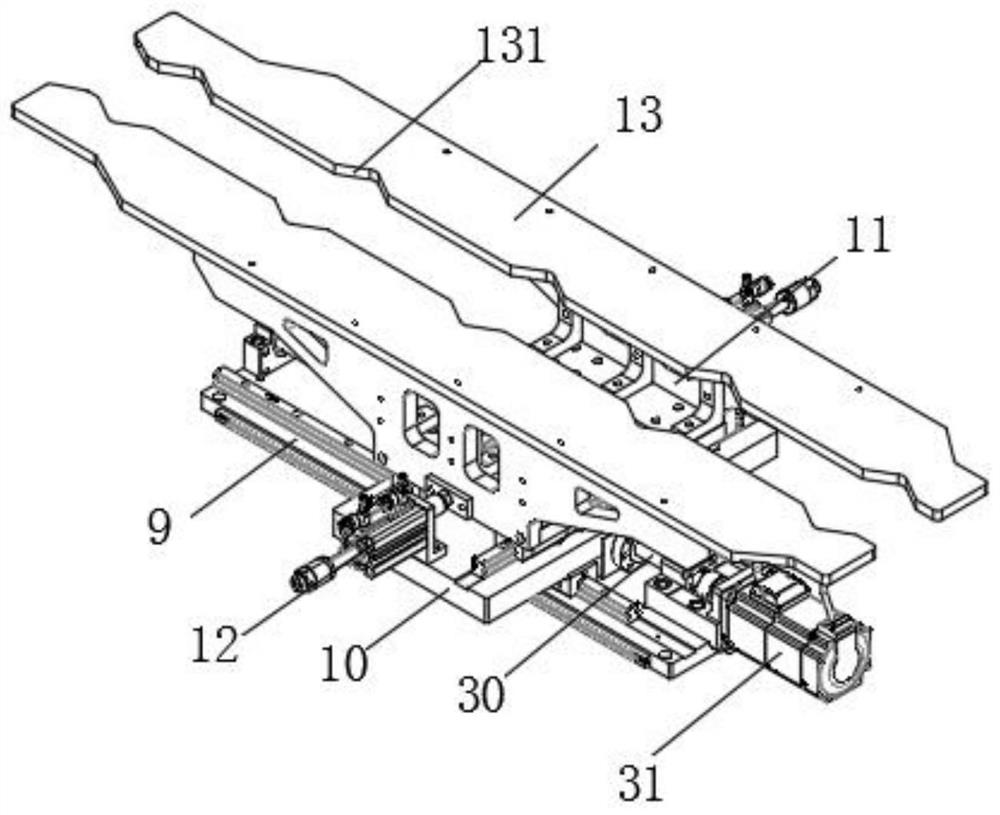

Punching equipment for machining solar frames

InactiveCN112588938AAvoid clampingGuaranteed punching accuracyMetal-working feeding devicesPositioning devicesPunchingStructural engineering

The invention relates to the field of punching equipment, in particular to punching equipment for machining solar frames. The punching equipment comprises a rack; a supporting device for bearing workpieces, a feeding device for driving the workpieces to transfer and a punching device for punching the workpieces are arranged on the rack; the rack is further provided with a clamping device used forclamping the workpieces, and the clamping device is arranged below the punching device; and the clamping device comprises two sets of clamping arms connected with the rack in a sliding mode, and the two sets of clamping arms are fixedly connected with clamping plates clamped to the ends of each workpiece. Through cooperation of the supporting device, the feeding device and the clamping device, synchronous conveying of the multiple workpieces is achieved, repeated clamping of the workpieces by workers is avoided, manual errors are also avoided, and the punching efficiency and the punching precision in the solar frame assembly machining process are guaranteed.

Owner:江阴市钰满金属制品有限公司

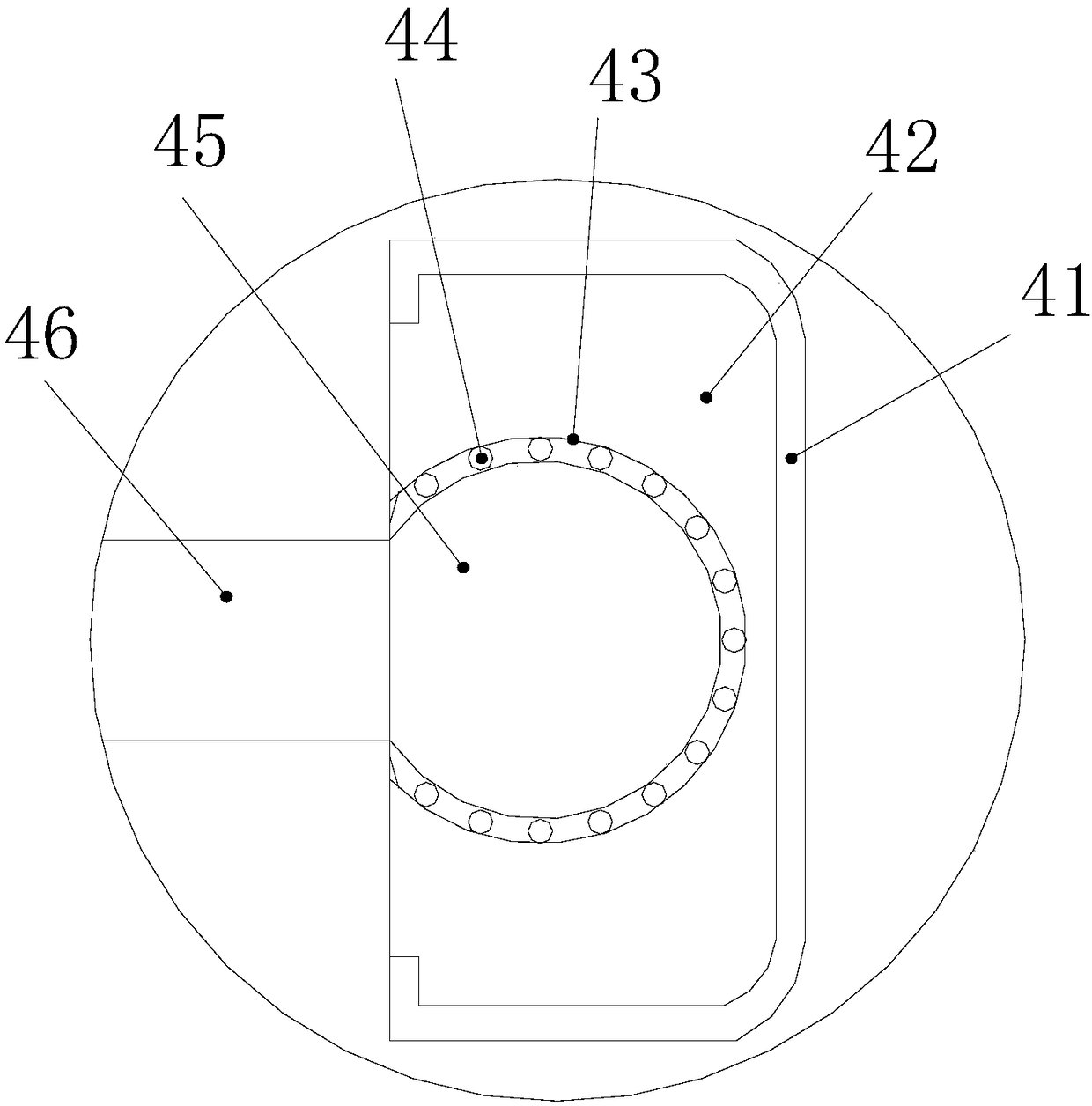

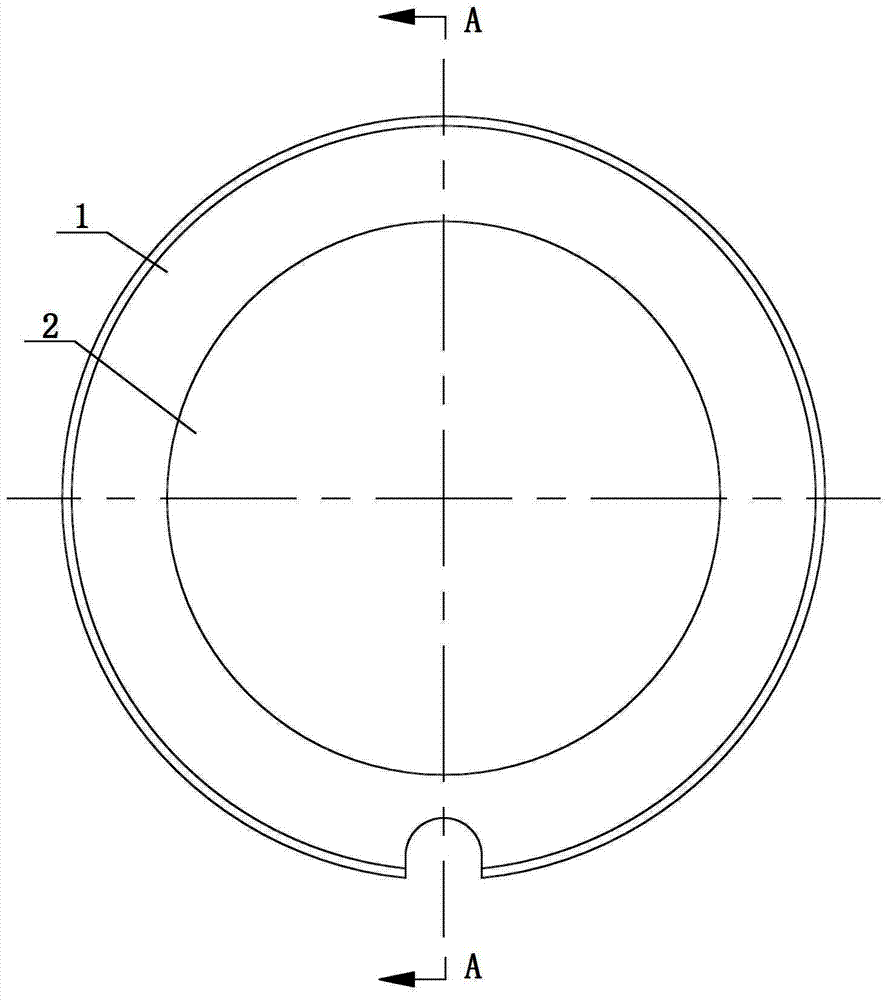

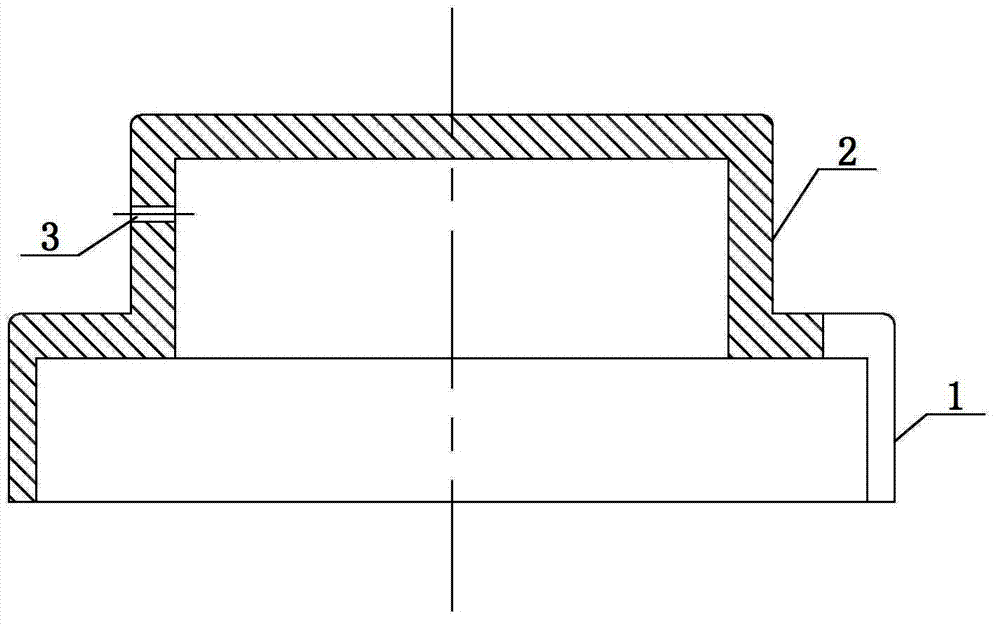

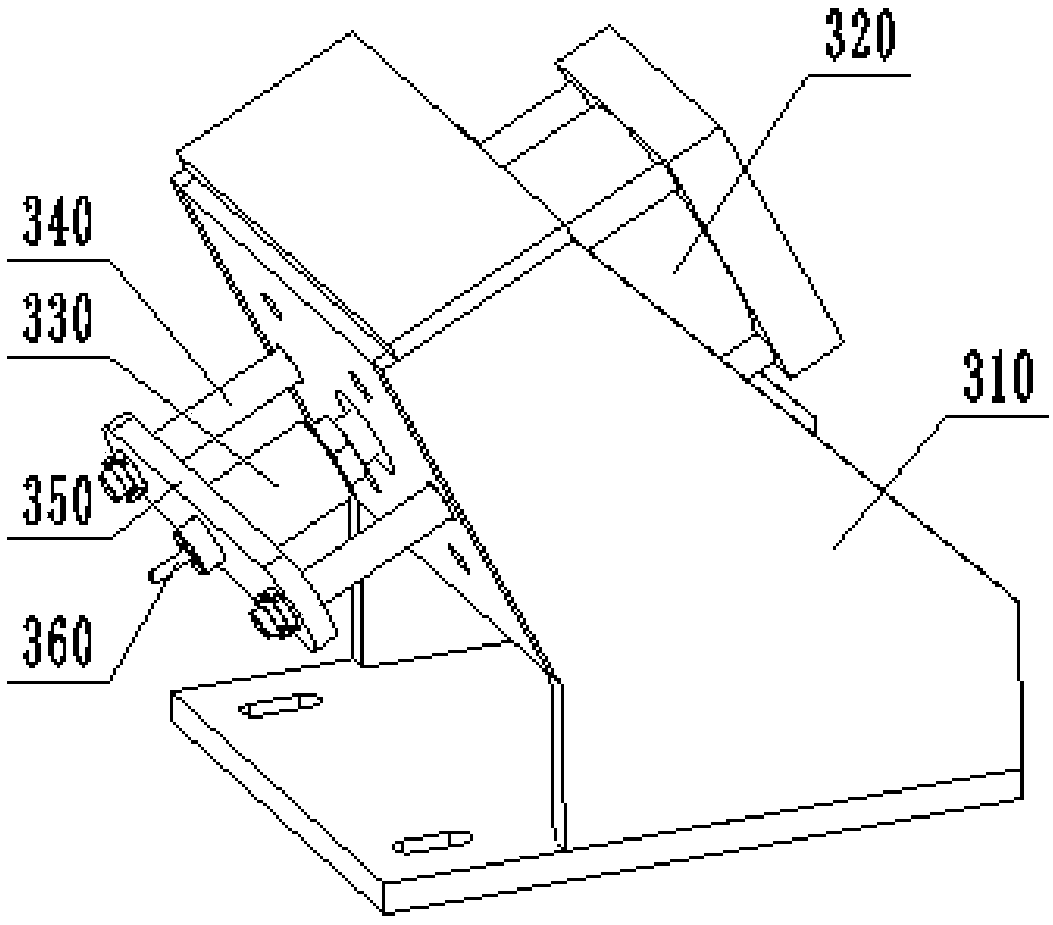

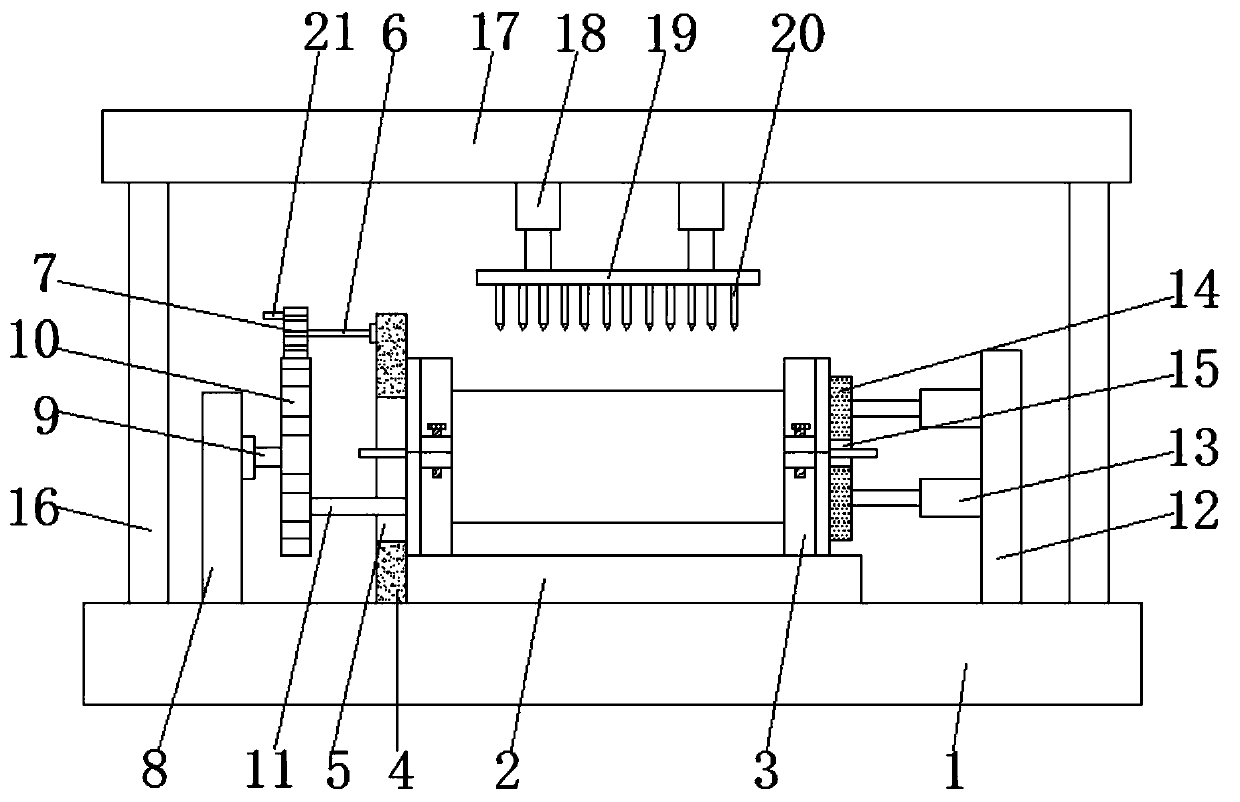

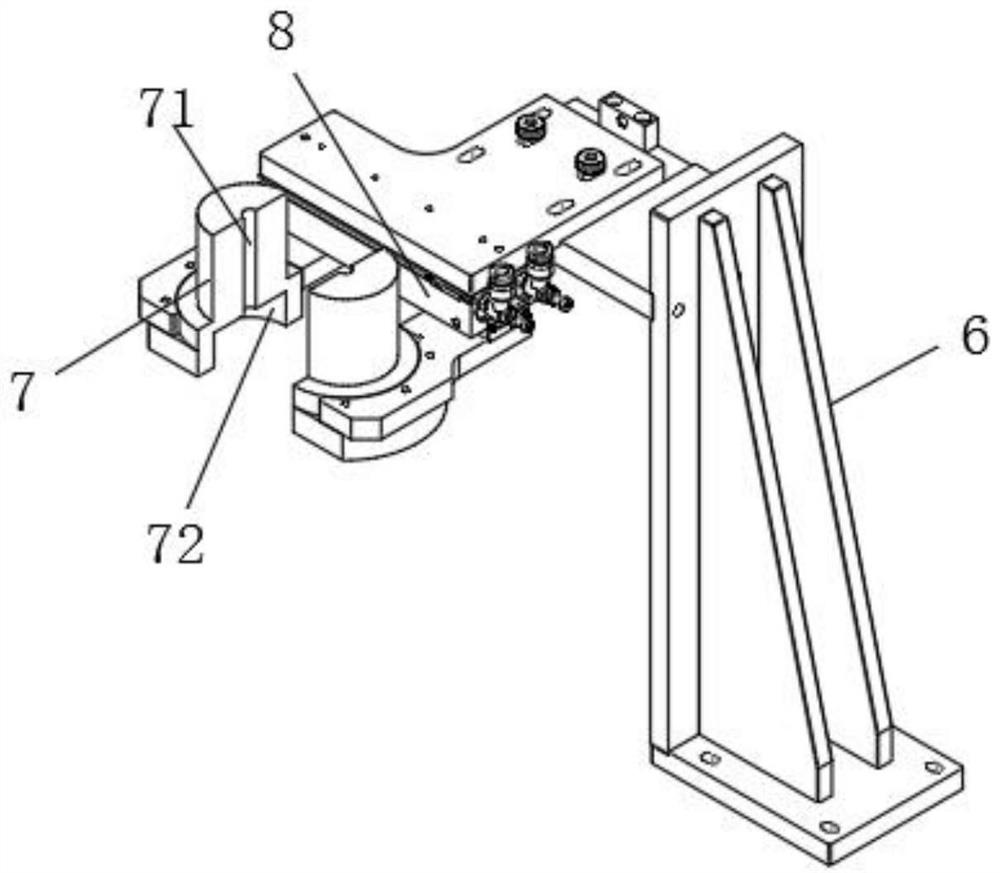

Punching device and punching process for bearing retainer processing

PendingCN108405715AQuality improvementGuaranteed punching accuracyPerforating toolsEngineeringPunching

The invention discloses a punching device for bearing retainer processing. The punching device for bearing retainer processing comprises a base, wherein a clamping and fixing mechanism and a punchingmechanism are arranged on the base; the clamping and fixing mechanism comprises a support pillar fixed onto the base; a first installation seat is arranged at the top end of the support pillar; a rotating disk installation groove is formed in the upper surface of the first installation seat; a rotating disk driven by a motor is embedded into the rotating disk installation groove; a support fixed to the first installation seat is arranged above the rotating disk; a pressing disk driven by a pressing air cylinder is arranged on the support; the punching mechanism comprises a bottom plate capableof sliding along the base; a second installation seat is connected onto the bottom plate through a support rod; and a puncher driven by an air cylinder is horizontally arranged on the second installation seat. According to the punching device for bearing retainer processing provided by the invention, a retainer can be clamped and is prevented from deviating during a punching process, the punchingaccuracy is ensured, and the retainer quality is good.

Owner:ANHUI BUERYUE BEARING

Multifunctional hydraulic combined punching and shearing machine and punching and shearing method thereof

ActiveCN106217058AAvoid deformationImprove punching accuracy and service lifeMetal-working feeding devicesShearing machinesEconomic returnEngineering

The invention discloses a multifunctional hydraulic combined punching and shearing machine and a punching and shearing method thereof, and belongs to the technical field of mechanical processing equipment. The multifunctional hydraulic combined punching and shearing machine comprises a material pressing mechanism, a lower die base pressing mechanism, a rear material blocking mechanism, an oil cylinder fixing mechanism and a cutter plate matching mechanism, wherein a hydraulic oil cylinder in the oil cylinder fixing mechanism is connected with a punching and shearing machine body through second fastening bolts; contact surfaces of the hydraulic oil cylinder and the punching and shearing machine body are oblique wedge surfaces that are matched pairwise; a cutter plate in the cutter plate matching mechanism is connected with an eccentric shaft; and by rotating the eccentric shaft, a moving cutter plate is matched with a static cutter plate. According to the multifunctional hydraulic combined punching and shearing machine and the punching and shearing method, the defects of the conventional punching and shearing machine are overcome, the use effect of the multifunctional hydraulic combined punching and shearing machine is improved, the modification cost of the conventional punching and shearing machine is low, and economic returns are good.

Owner:ANHUI ZHONGYI MACHINE TOOL MFG

External molding equipment for flexible circuit board for automobile and process thereof

ActiveCN109049131APrecise positioningRealize guided feedingFlexible printed circuitsPrinted circuit manufacturePunch pressFlexible circuits

The invention relates to external molding equipment for a flexible circuit board for an automobile and a process thereof. The external molding equipment comprises a feeding mechanism, a die cutting mechanism and a receiving mechanism which are arranged on a rack, the die cutting mechanism comprises a plurality of punching groups, each of the punching groups is sequentially provided with guide roller stations, a die cutting station and a material pressing station, and a column pin roller is installed on each of the guide roller stations. According to the external molding equipment for the flexible circuit board for the automobile and the process thereof, the total length of the flexible circuit board punching function can be adjusted to be 2-3 meters is achieved, and the punching precisioncan be effectively guaranteed through accurate connection between adjacent punching groups; the automation production replacing the operation mode of the large punch press is realized, the labor is saved, and the safety risk of multi-person operation of the punch press is avoided; the external molding equipment is high in production efficiency and is particularly suitable for developing a high-precision automobile FPC.

Owner:MFLEX YANCHENG CO LTD

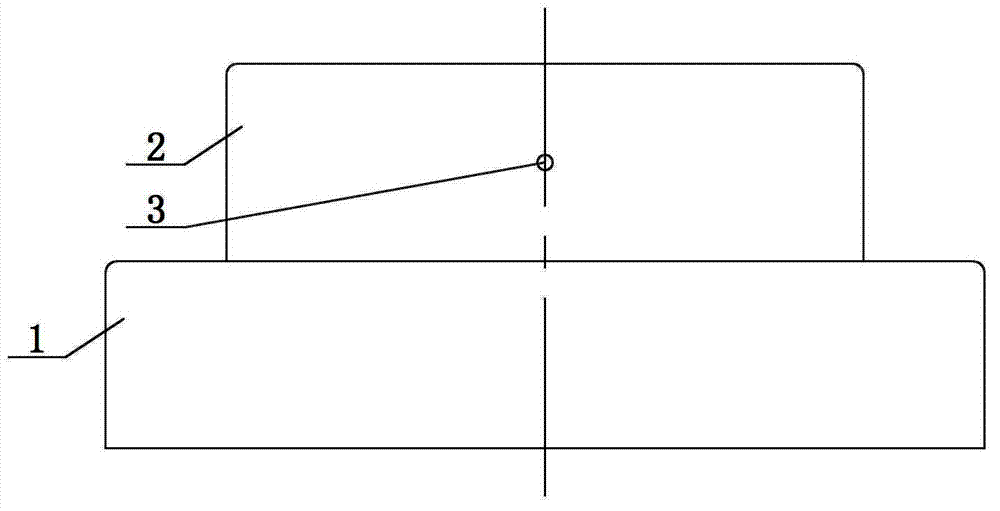

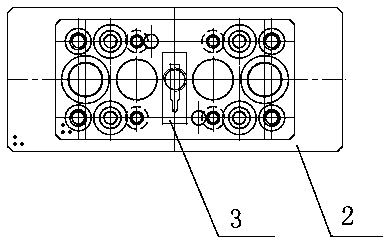

Manufacturing die for 3225 Kovar ring

The invention discloses a manufacturing die for a 3225 Kovar ring. The manufacturing die for the 3225 Kovar ring comprises a stepper die, wherein the stepper die comprises an upper die holder 1 and alower die plate 2, and the upper die holder is sequentially provided with a location convex die, a one-for-three convex die assembly and a one-for-four convex die assembly in the stepper direction ofthe stepper die; the one-for-three convex die assembly comprises three rows of one-for-three convex die insert groups, and the one-for-four convex die assembly comprises four rows of one-for-four convex die insert groups; the lower die plate is sequentially provided with a location concave die, a one-for-three concave die assembly and a one-for-four concave die assembly in the stepper direction ofthe stepper die, and the one-for-three concave die assembly comprises three rows of one-for-three concave die insert groups; and the one-for-four concave die assembly comprises four rows of one-for-four concave die insert groups. The die completes a one-for-seven yield in a one-for-three step and a one-for-four step, and completes production for seven products in one process and in a nine-stage stepper manner, so that the efficiency can be increased by 40%. During punching for an inner hole, the punching is carried out in twice, a part with a length of 0.05mm, of the periphery, is reserved after the first-time punching for the inner hole, and then the part with the length of 0.05mm is punched off, so that the punching accuracy of less than 0.005mm, for the inner hole, is ensured.

Owner:安徽晶赛科技股份有限公司

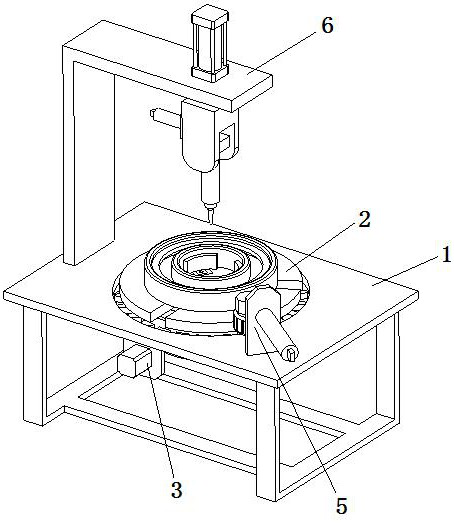

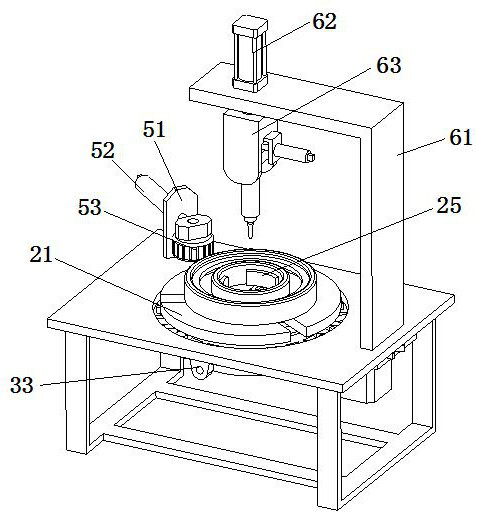

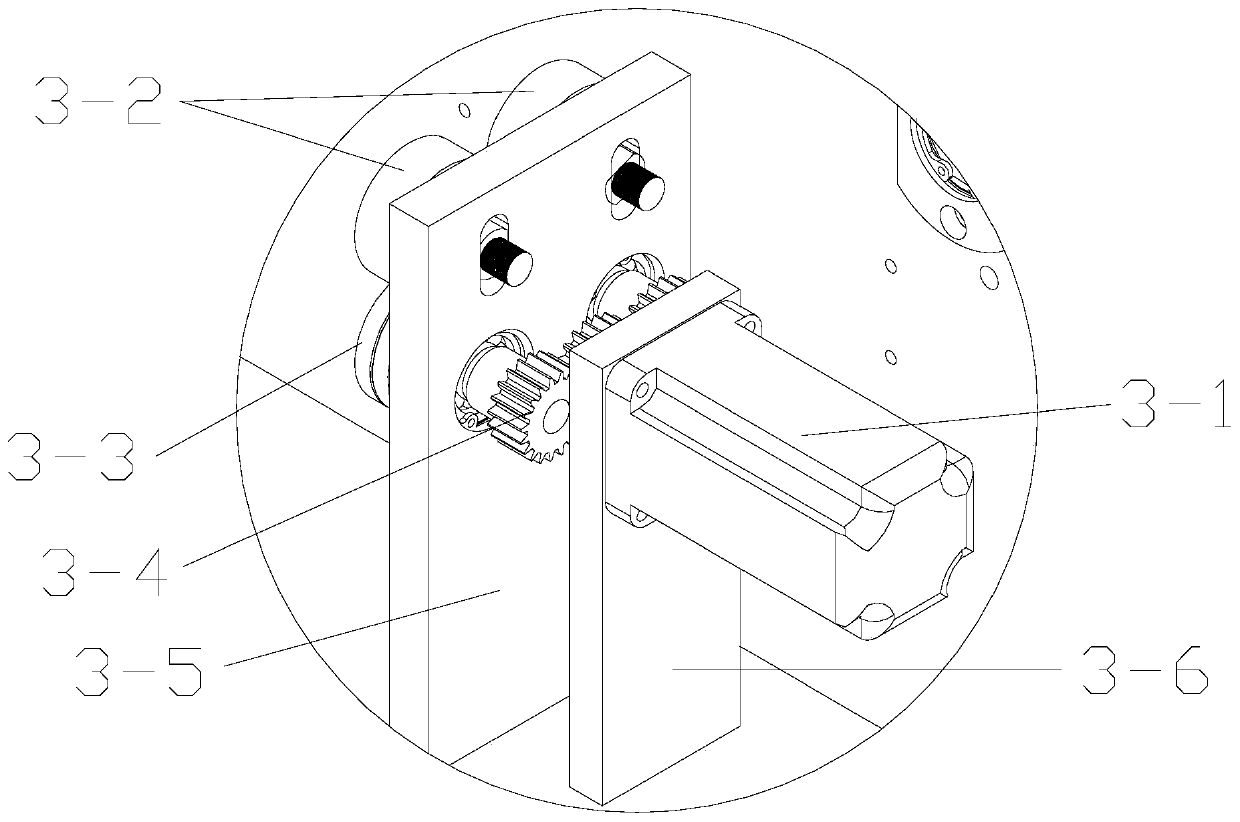

Machining equipment integrating punching and cutting

PendingCN107891087ASimple processGuaranteed punching accuracyPerforating toolsMetal-working feeding devicesPunchingLocking mechanism

The invention discloses machining equipment integrating punching and cutting and belongs to the field of machining assisting equipment. The machining equipment comprises punching assemblies, a material carrying mold, an edge cutting assembly, a rotating disc mechanism and a locking mechanism, wherein the edge cutting assembly is used for driving a cutter; the rotating disc mechanism is used for driving a rotating disc to rotate; and the locking mechanism is used for locking the position of the rotating disc. The material carrying mold is arranged on the rotating disc, and the shape of the material carrying mold is matched with the shape of an inner hole of a conical and cylindrical workpiece. The material carrying mold is provided with a conical face and a cylindrical face, wherein the conical face is attached to the inner surface of a barrel body, and the cylindrical face is attached to the inner surface of a ringlike edge. The conical face is provided with three mold holes, wherein the three mold holes correspond to three holes in the barrel body. Each mold hole is internally provided with a mold sleeve. The three punching assemblies are uniformly distributed around the materialcarrying mold and correspond to the three mold holes in the material carrying mold correspondingly. Each punching assembly is provided with a punch used for conducting punching. By means of the machining equipment, punching and edge cutting of the conical and cylindrical workpiece can be completed one time, and machining efficiency of the conical and cylindrical workpiece is greatly improved.

Owner:安徽省华夏机床制造有限公司

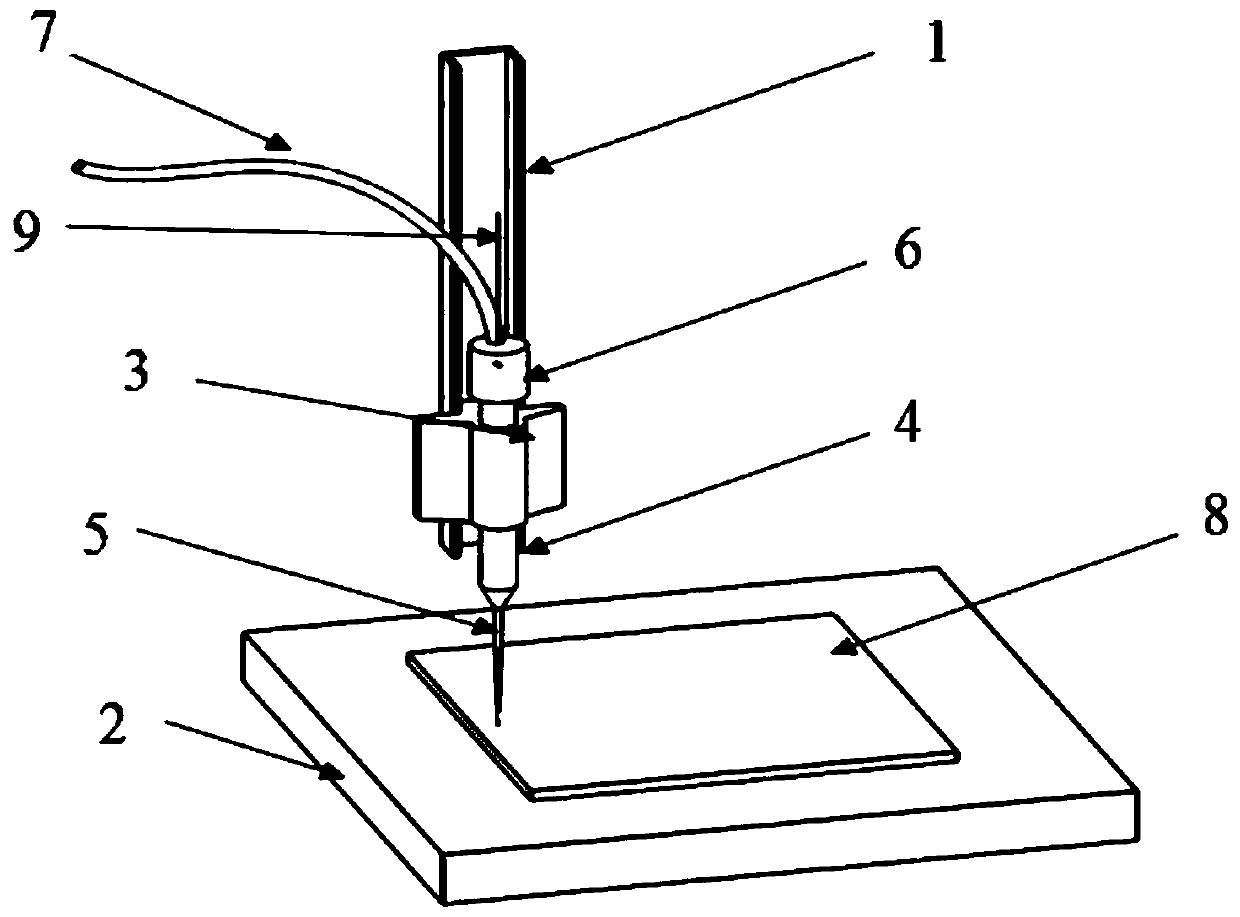

High-precision micro hole machining method and device

ActiveCN109909569AEnsuring the efficiency of the treatment processGuaranteed positioning accuracyPunchingMachining process

The invention discloses a high-precision micro hole machining method and device. The method comprises the following steps: (1) punching electrolyte is mixed; and the electrolyte is introduced into a needle through a pushing pump for positioning a punching position; (2) the electrolyte at the tip of the needle is controlled to form micro liquid beads to contact with the surfaces of materials; and the distances from the tip of the needle to the surfaces of the machined materials and the sizes of the micro liquid beads are adjusted to control the sizes of the contacted surfaces to be equal to thepunching sizes; (3) constant-current voltage is applied to two ends of the needle and the machined materials; and the contacted parts of the micro liquid beads with the machining materials are electrolytically corroded; and (4) along with increment of the corrosion depth, the distances from the tip of the needle to different corrosion layers are maintained invariable, and the pushing pump is adjusted to return and compensate the micro liquid beads, so that the internal concentration of the micro liquid balls is to be balanced, the sizes of the liquid beads are maintained stable, and the wholemicro hole machining process is finished. The punching mode belongs to normal-temperature punching without generating such problems as secondary crystallization and cracking; and the present punchingsizes can reach 10 microns.

Owner:CENT SOUTH UNIV

Cylinder inner inclined hole processing machine

PendingCN108941686AImprove practicalityImprove drilling efficiencyWork clamping meansPositioning apparatusPunchingPulp and paper industry

The invention discloses a cylinder inner inclined hole processing machine. The cylinder inner inclined hole processing machine comprises a cooling water tank, a storage box and a motor; a water pump is mounted in the cooling water tank; the left end of the water pump is connected with a water conveying pipe; the storage box is mounted above the cooling water tank; first chutes are formed in the left and right ends of the storage box; the motor is mounted in the fixed box; the left end of the motor is connected with a rotating wheel; the bottom end of the first motor is connected with a connecting base; a second motor is arranged under the connecting base; and support slide rails are mounted on the left and right sides of the second motor. Two fixed cylinders can be synchronously punched through two drill bits; four inclined holes are drilled, and the angles are about 40 degrees; and the operation method comprises the following steps: the two drill bits respectively drill two corresponding holes, that is, a spanner is opened, cylinder outer shells sleeve for fixation, and then, the corresponding drill bits move to align and drill two inclined holes; and the cylinder outer shells areunloaded to sleeve another fixed base to drill the other two inner holes. The punching efficiency of the device can be improved, and the punching precision of the device can be guaranteed; and the practicability of the cylinder inner inclined hole processing machine is greatly improved.

Owner:ZHEJIANG AOLI MACHINERY CO LTD

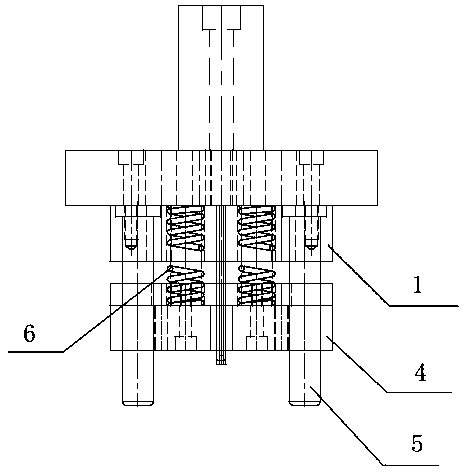

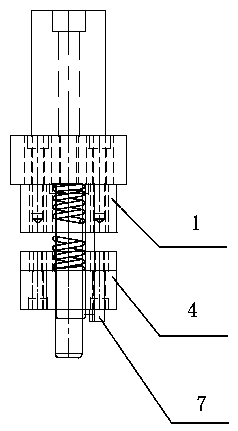

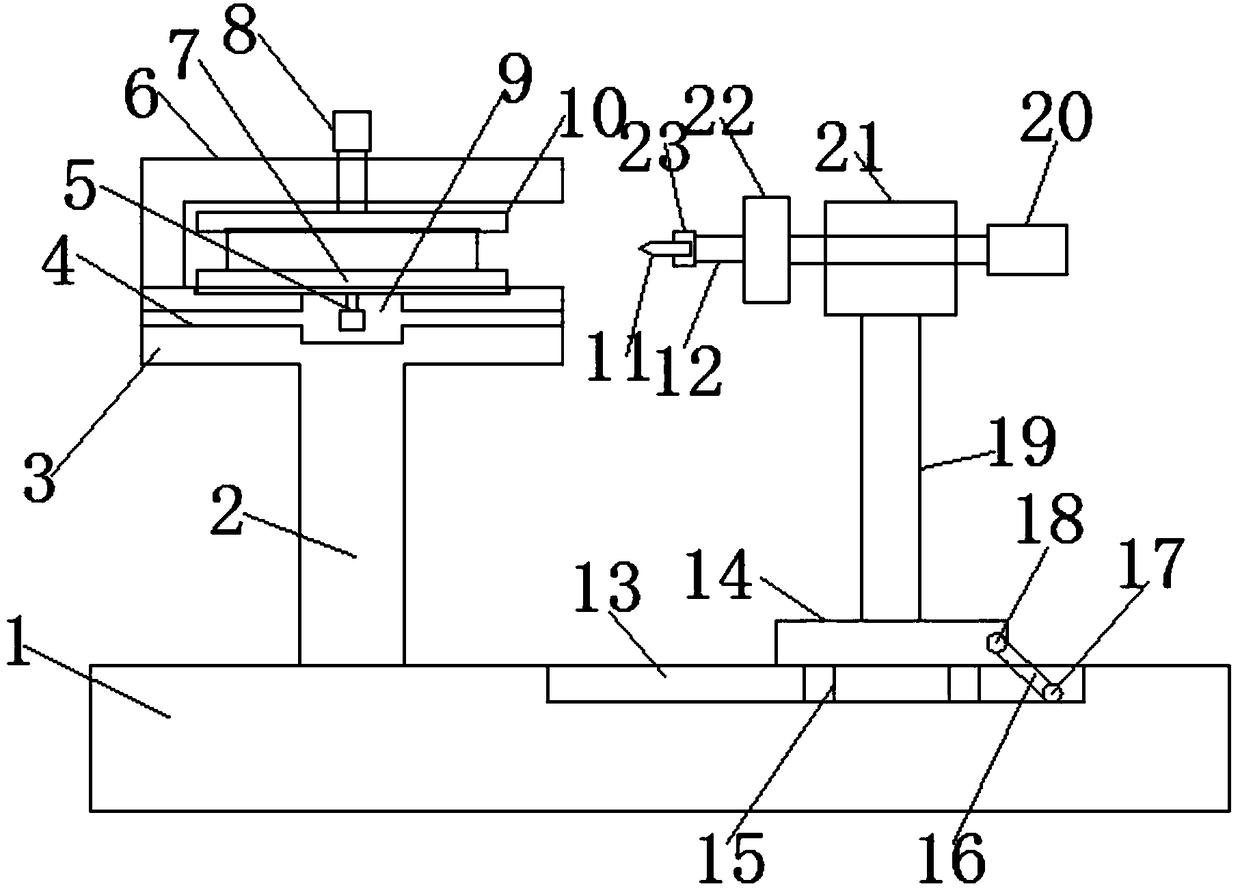

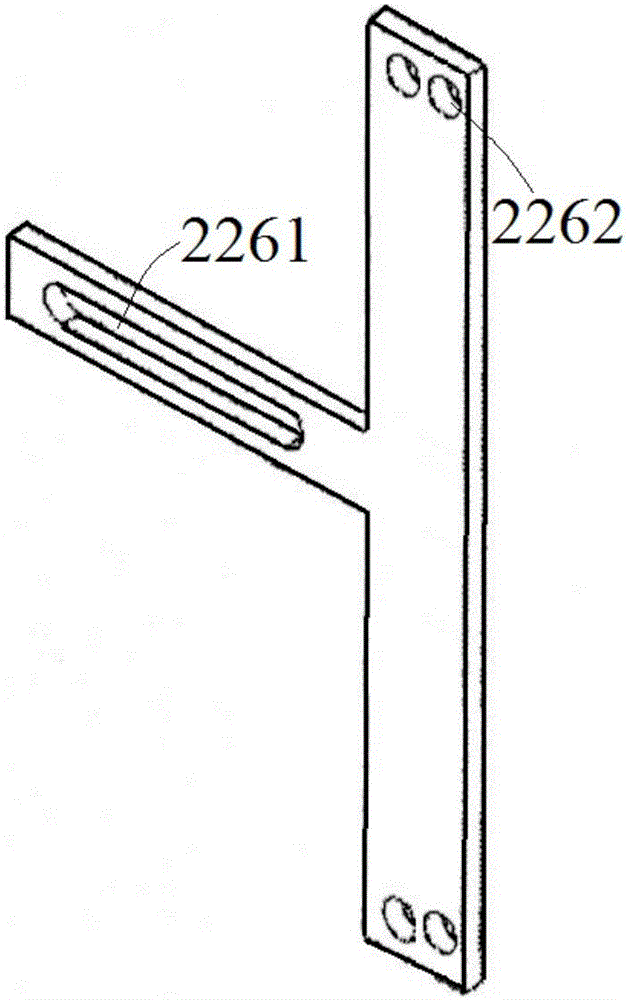

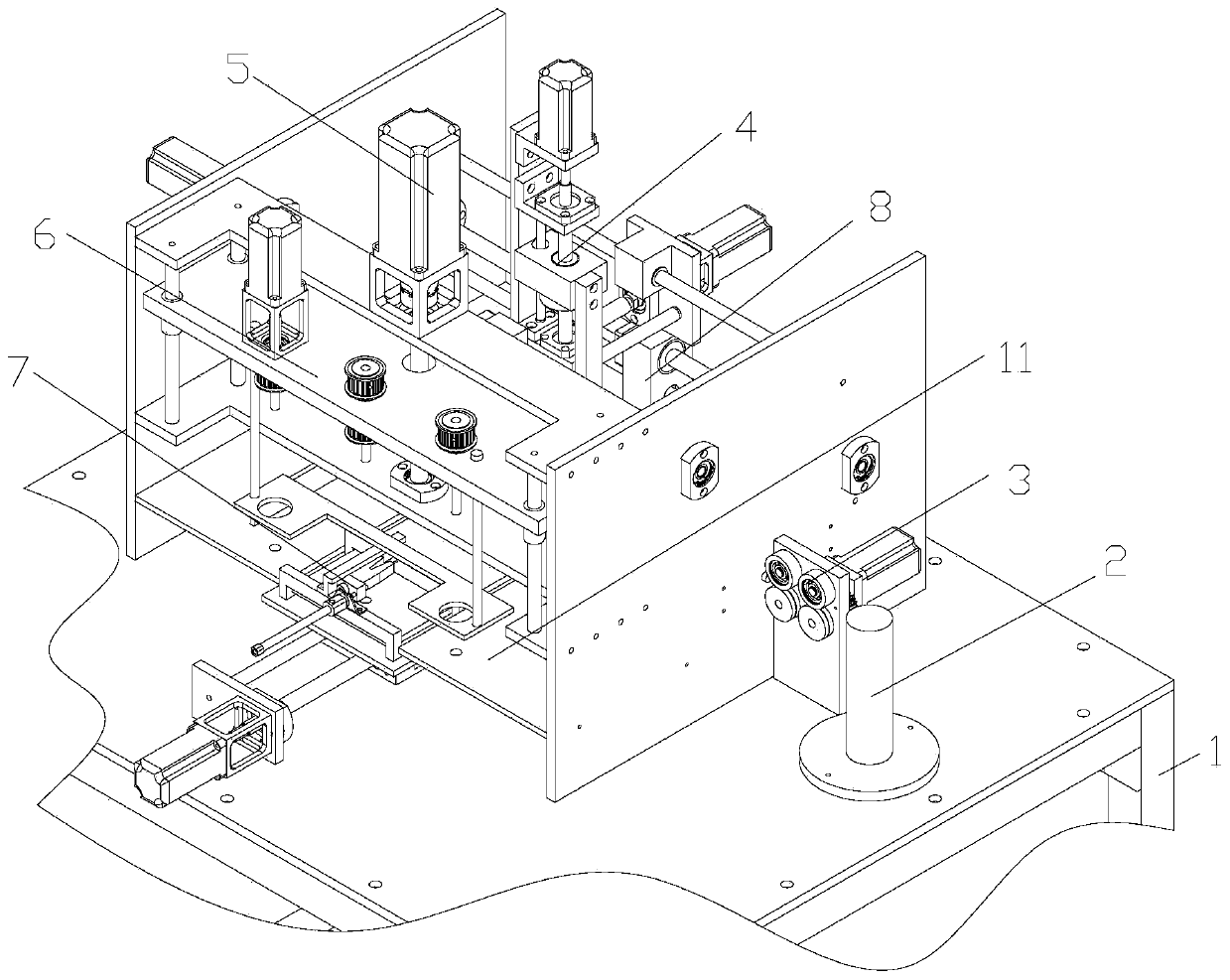

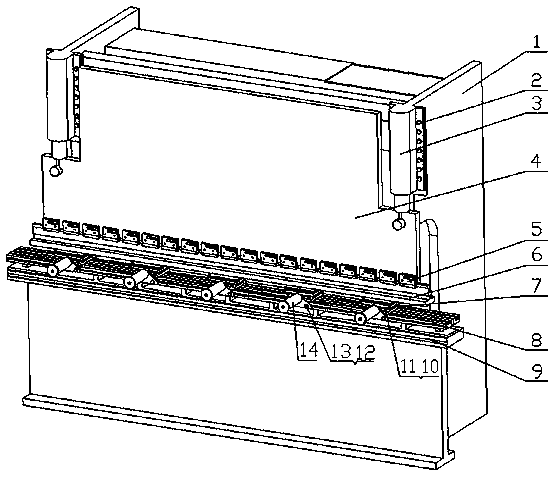

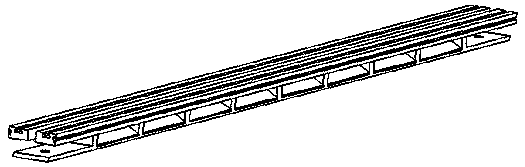

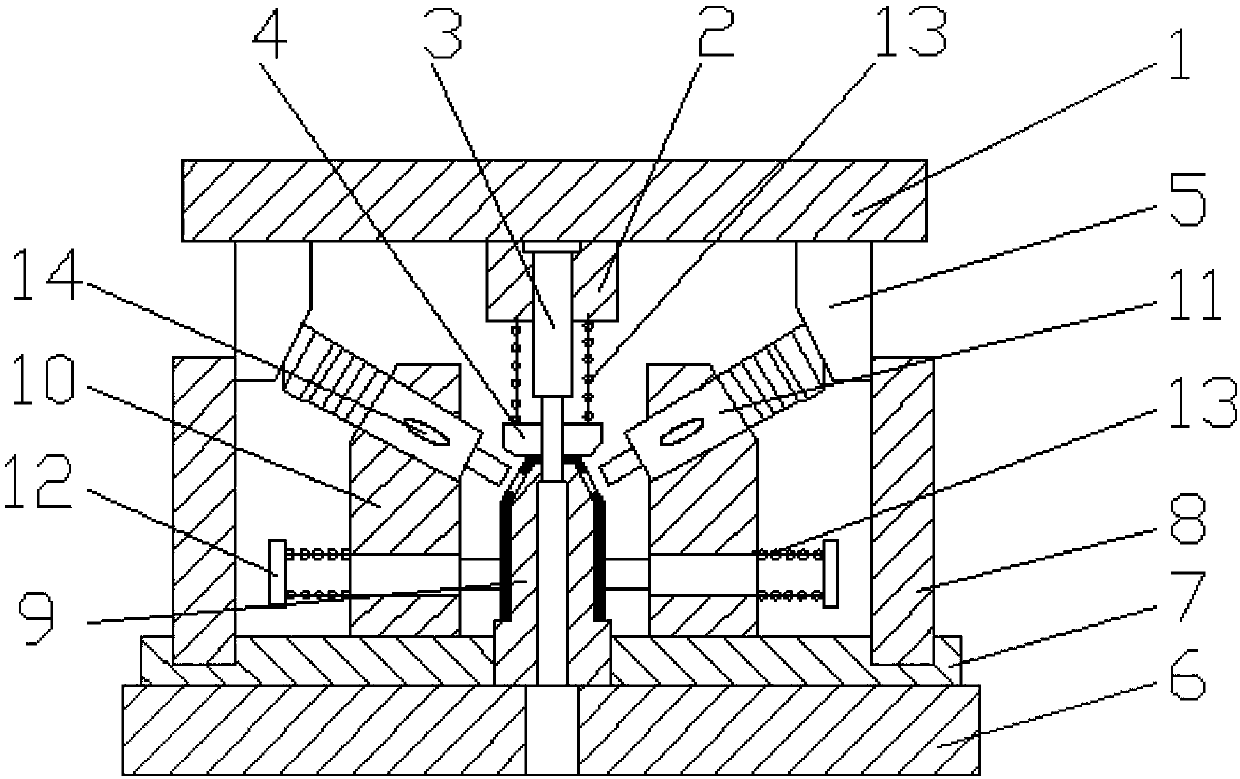

Tailing feeding device for multi-station progressive mould and working method for tailing feeding device

ActiveCN107695191AIncrease profitStable and reliable workShaping toolsMetal-working feeding devicesEngineeringTailings

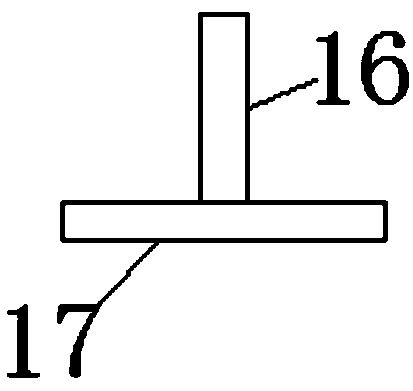

The invention provides a tailing feeding device for a multi-station progressive mould. The tailing feeding device comprises an upper mould part, an unloading part and a lower mould part. The tailing feeding device is characterized in that the upper mould structure comprises an upper mould base (1), a limiting post (3), an upper gasket (4), a first guide post (5), a convex mould (8) and an inner force transmission assembly (10); the unloading part comprises an unloading plate base (6), an aligning pin (7), a small unloading plate (9), an inner guide post (11) and an outer force transmission assembly (12); and the lower mould part comprises a concave molding board (13), a lower mould base (14), an inner guide post sleeve (15), an inverted aligning pin hole (16), and an outer guide post sleeve (17). The tailing feeding device can realize transmitting and processing utilization of residual tailings, ensures reliability and stability of a mould working process on the basis of guaranteeing strip stamping precision, and can be widely applied to follow-up processing utilization of residual tailings of various multi-station progressive moulds.

Owner:HUNAN UNIV

Automatic paper punching, threading and knotting machine

The invention relates to an automatic paper punching, threading and knotting machine comprising a rack, a work table surface arranged on the rack, left and right brackets fixedly arranged on the worktable surface and oppositely arranged, a paper containing plate horizontally mounted between the left bracket and the right bracket and threading and knotting assemblies mounted on the upper and lowersides of the paper containing plate and used for cooperating to achieve threading and knotting actions. According to the automatic paper punching, threading and knotting machine, an upper clamp mechanism and a lower clamp mechanism cooperate to complete threading work of a binding line, and the upper clamp mechanism cooperates with a front clamp mechanism and the lower clamp mechanism to completeknotting work of the binding line, so that the automation degree is high, the knotting speed is high, and the paper thread stitching efficiency is greatly improved.

Owner:WENZHOU ELECTRIC POWER BUREAU +2

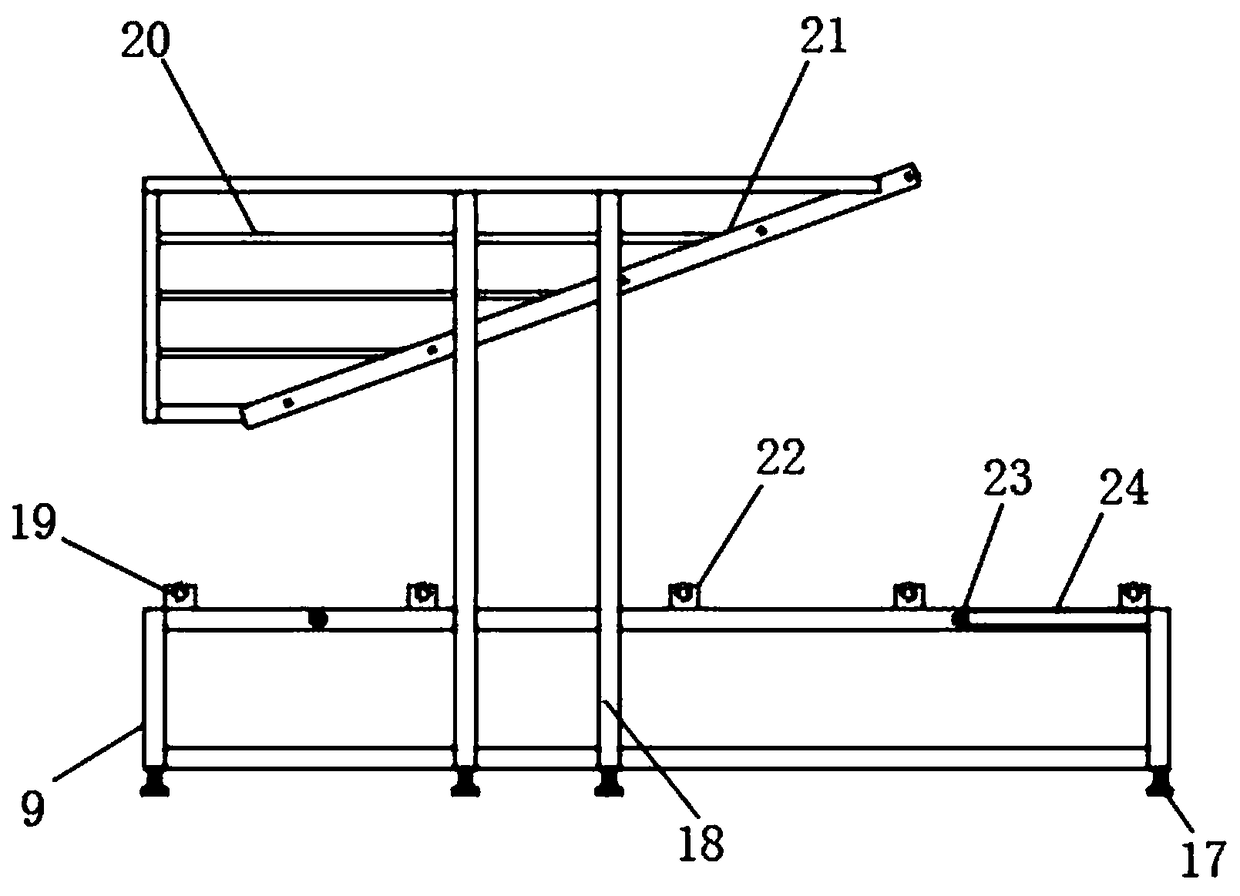

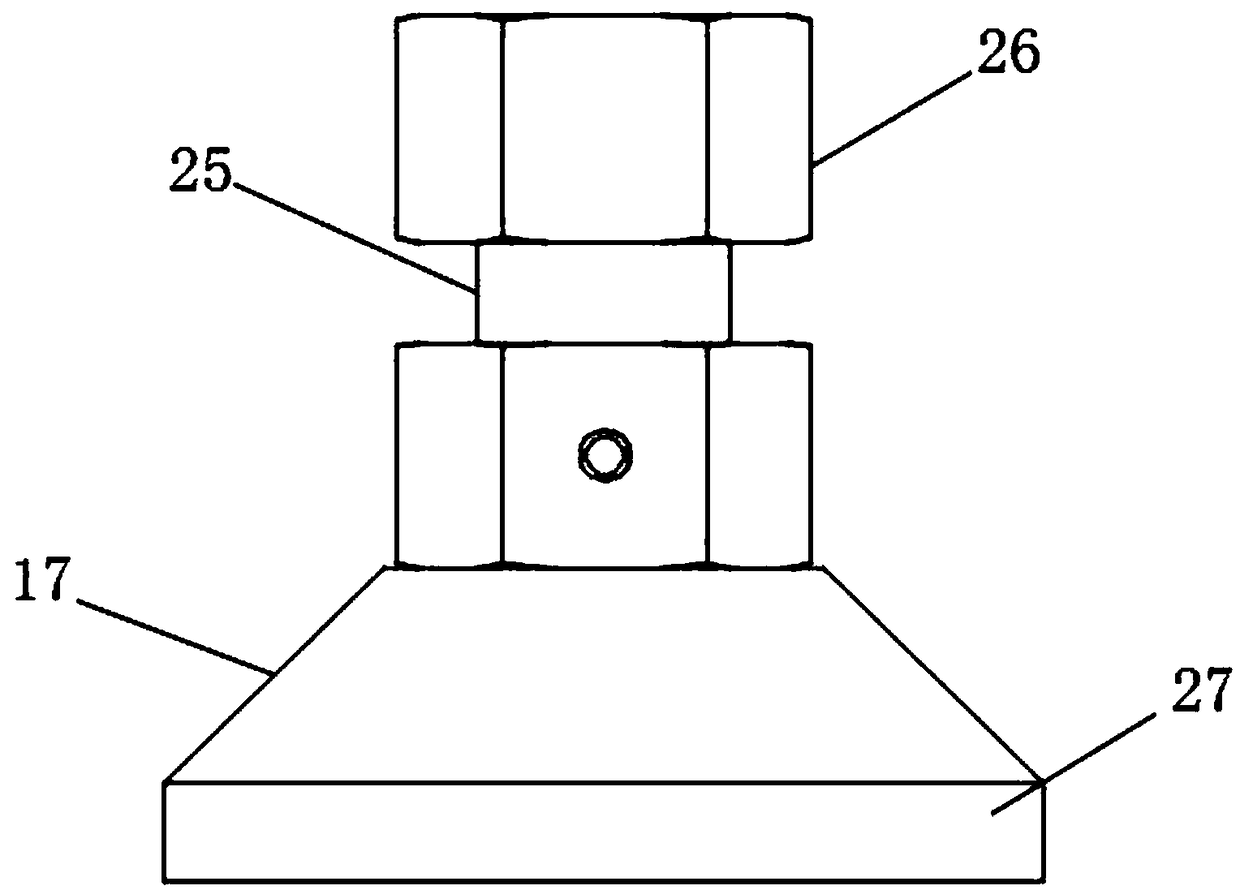

Industrial cleaning brush roller punching device

ActiveCN109730439AReduce the vibration effectGuaranteed punching accuracyBrush bodiesEngineeringHydraulic cylinder

The invention relates to the technical field of brush roller punching devices and discloses an industrial cleaning brush roller punching device comprising a base; the upper surface of the base is fixedly provided with a mounting seat; the upper surface of the mounting seat is provided with two symmetric spring clamping devices; the left side surface of the mounting seat is fixedly provided with amounting plate; the upper surface of the base is fixedly provided with a fixed plate; the upper surface of the base is fixedly provided with a fixed seat; the left side surface of the fixed seat is fixedly provided with two symmetric air cylinders; a pressing plate is fixedly mounted between the output ends of the two air cylinders; the upper surface of the base is fixedly provided with two symmetric support frames; a top cover is fixedly mounted between the tops of the two support frames; the bottom surface of the top cover is fixedly provided with two symmetric hydraulic cylinders; a connecting plate is fixedly mounted between the output ends of the two hydraulic cylinders; and the bottom surface of the connecting plate is provided with uniformly distributed punches. The industrial cleaning brush roller punching device is simple in structure, and the position of a roller body can be regulated without unscrewing a bolt.

Owner:安徽琼钰刷业有限公司

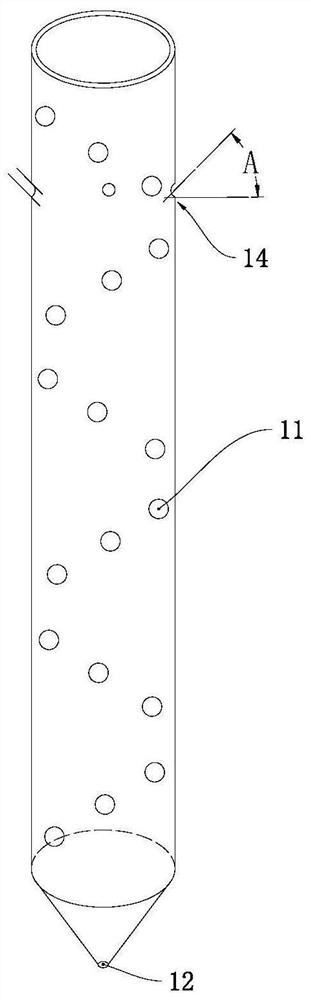

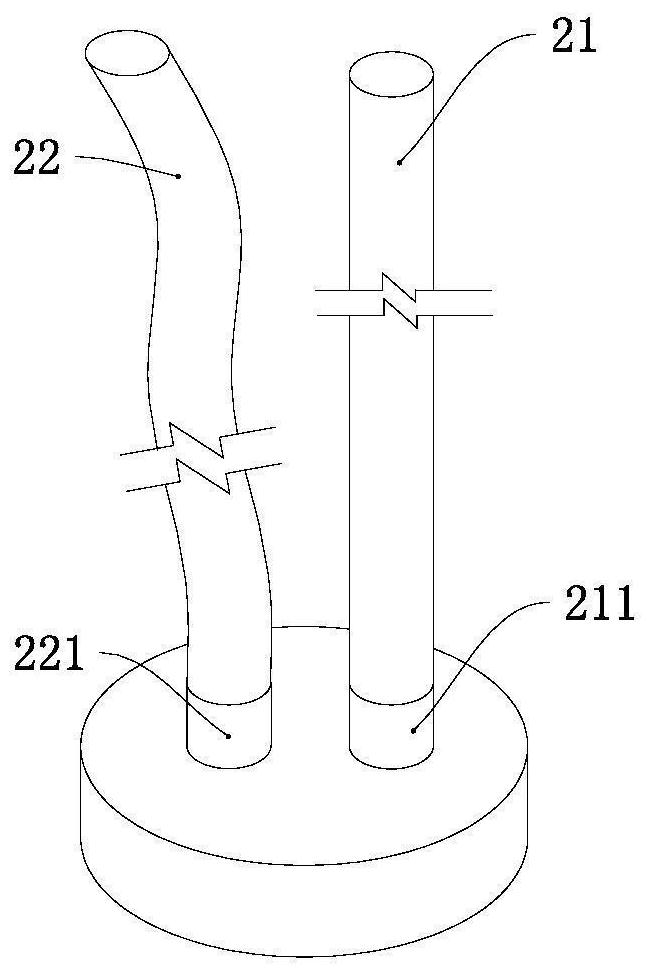

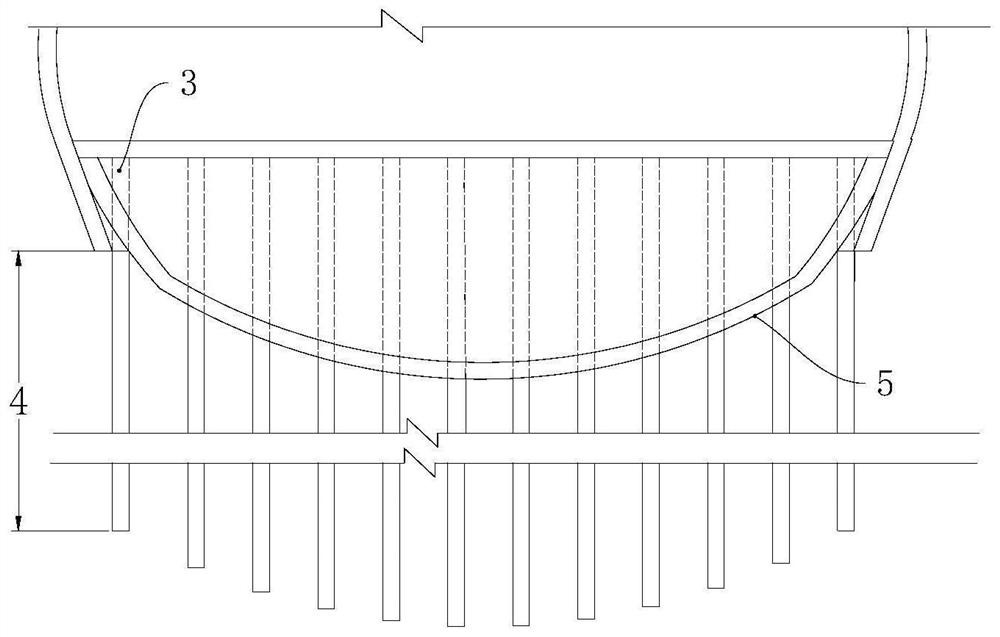

Tunnel inverted arch foundation reinforcing assembly and construction method

ActiveCN111676947ASimple structureReasonable designSoil preservationArchitectural engineeringExhaust pipe

The invention discloses a tunnel inverted arch foundation reinforcing assembly and a construction method. The reinforcing assembly comprises multiple steel flower tubes and a steel cover. The multiplesteel flower tubes are sequentially and fixedly connected in the vertical direction. Multiple grouting holes are formed in the tube walls of the multiple flower steel tubes. The steel cover is arranged at the top end of the topmost steel flower tube in the vertical direction. A first through hole and a second through hole are formed in the steel cover. The upper ends of the first through hole andthe second through hole are each provided with a detachable grouting steel tube and an exhaust grouting hose. The construction method comprises the steps of drilling, link-by-link connection, steel flower tube discharging in place, installing of steel caps, grouting tubes and exhaust tubes, grouting reinforcing, disassembling of grouting steel tubes, excavating inverted arching and supporting structure constructing. According to the reinforcing assembly and construction method for reinforcing a foundation before inverted arch excavation, the defect that a drill is placed at an arc inverted arch contour line due to the fact that drilling is performed after inverted arch excavation is avoided, drilling operation is greatly facilitated, and the drilling efficiency and the drilling quality are improved.

Owner:CHINA RAILWAY DESIGN GRP CO LTD +1

Processing equipment and processing method for water level indicator mica sheet assembly

InactiveCN112476791AEnsure stabilitySolve the technical problems of instability and low machining accuracyRevolution surface grinding machinesWorking accessoriesTool bitPunching

The invention discloses processing equipment and a processing method for a water level indicator mica sheet assembly. The processing equipment comprises a workbench, wherein a supporting plate is fixedly installed on the upper surface of the workbench, a strip-shaped through groove is formed in the supporting plate, a first supporting frame is fixedly installed on the workbench, a sliding plate ismovably installed on one side of the first supporting frame, a pushing block is fixedly installed at the bottom of the sliding plate, a clamping mechanism is fixedly installed on the workbench, a punching air cylinder is installed at the top of a third supporting frame, a punching tool bit is fixedly installed at the bottom end of an output rod of the punching air cylinder, and a feeding mechanism and a grinding mechanism are fixedly installed on the upper surface of the workbench. The mica sheet assembly can be driven by the feeding mechanism to move above the supporting plate, automatic feeding can be achieved, and the labor intensity is reduced; and the punching tool bit is guided through semi-circular through holes of semi-circular clamping blocks, the stability of the punching tool bit is guaranteed, and therefore the punching precision and the polishing effect are guaranteed.

Owner:安徽富航电子科技发展有限公司

Tire mold automatic punching device

ActiveCN113246212BRapid positioningMeet the positioning needsMetal working apparatusRolling chassisAutonomation

The invention discloses an automatic punching device for a tire mold, which relates to the technical field of punching devices and includes a workbench, a positioning mechanism, a rotation mechanism, a linkage mechanism, a collision mechanism and a punching mechanism. The rotation mechanism is installed at the bottom of the workbench , the workbench is provided with a circular groove, the positioning mechanism is installed on the rotating mechanism and located in the circular groove, the positioning mechanism includes a base plate, a chassis, a driving assembly and three driven assemblies, and the base plate is installed on the base plate and a cavity for accommodating three driven components is formed between the two. Each of the active components is provided with a limit component connected thereto. The present invention can realize rapid positioning of the tire mold and satisfy the A variety of tire molds of different sizes require positioning, and the degree of automation is high, which improves production efficiency and product quality; and can complete multi-directional and multi-angle drilling operations for tire molds, further improving the overall processing efficiency and practical performance.

Owner:山东新豪克轮胎有限公司

Multifunctional bending machine

InactiveCN107552616AAvoid the deficiency of low punching precisionGuaranteed punching accuracyPerforating toolsHydraulic cylinderPunching

The invention provides a multifunctional bending machine, which includes a frame, a first bolt, a hydraulic cylinder, a tool holder, a pressing device, an upper die, a special die, a general die, a workbench, a second bolt, a first press The clamping plate, the third bolt, the second clamping plate and the supporting device, the hydraulic cylinder is fixed on the frame by the first bolt, the knife rest is fixed on the piston rod of the hydraulic cylinder by the bolt, and the upper die is fixed by the clamping device Under the tool holder, the general mold is installed on the workbench, the special mold is installed in the top T-slot above the general mold through the second bolt and the first pressing plate, and the supporting device is installed through the third bolt and the second pressing plate In the side T-slot on the side of the universal mold. The present invention can complete bending, shearing and punching processing on the same machine tool by replacing the special mold on the general mold, realizes multiple functions of one machine, and greatly saves equipment procurement cost. The invention has simple structure and better economic benefits.

Owner:ANHUI YAWEI MACHINE TOOL MFG

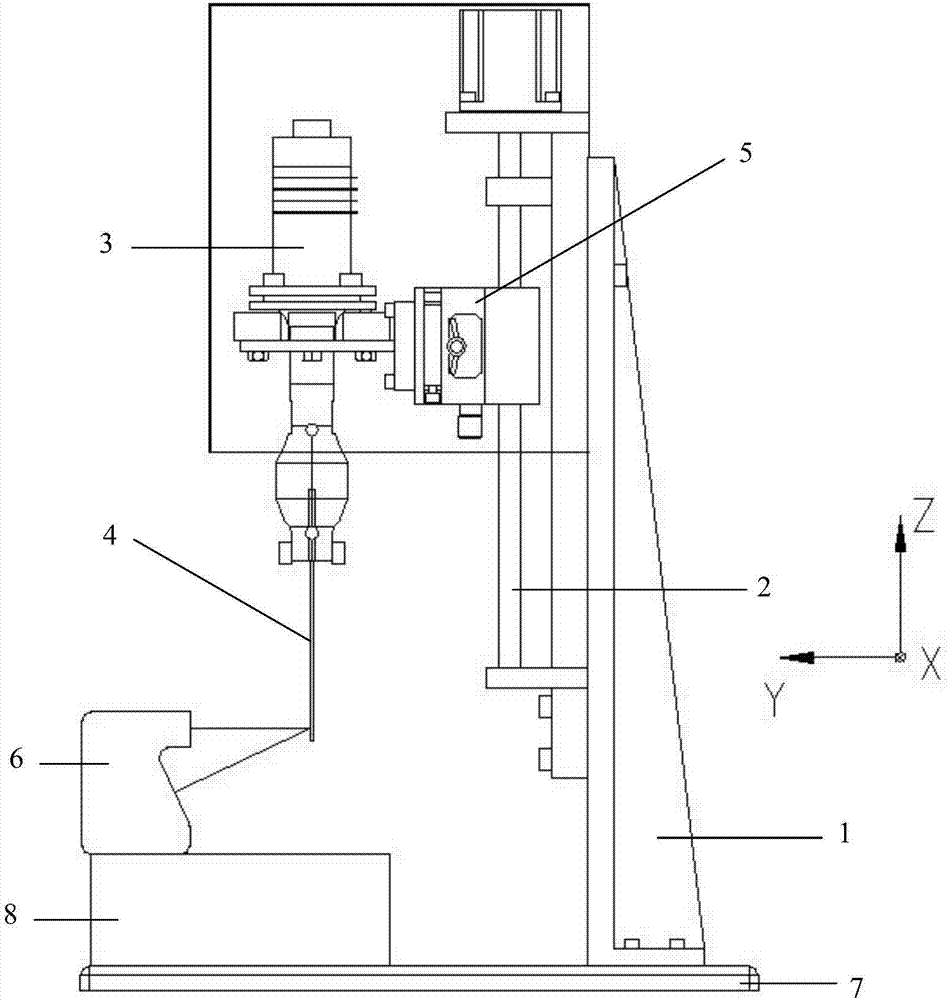

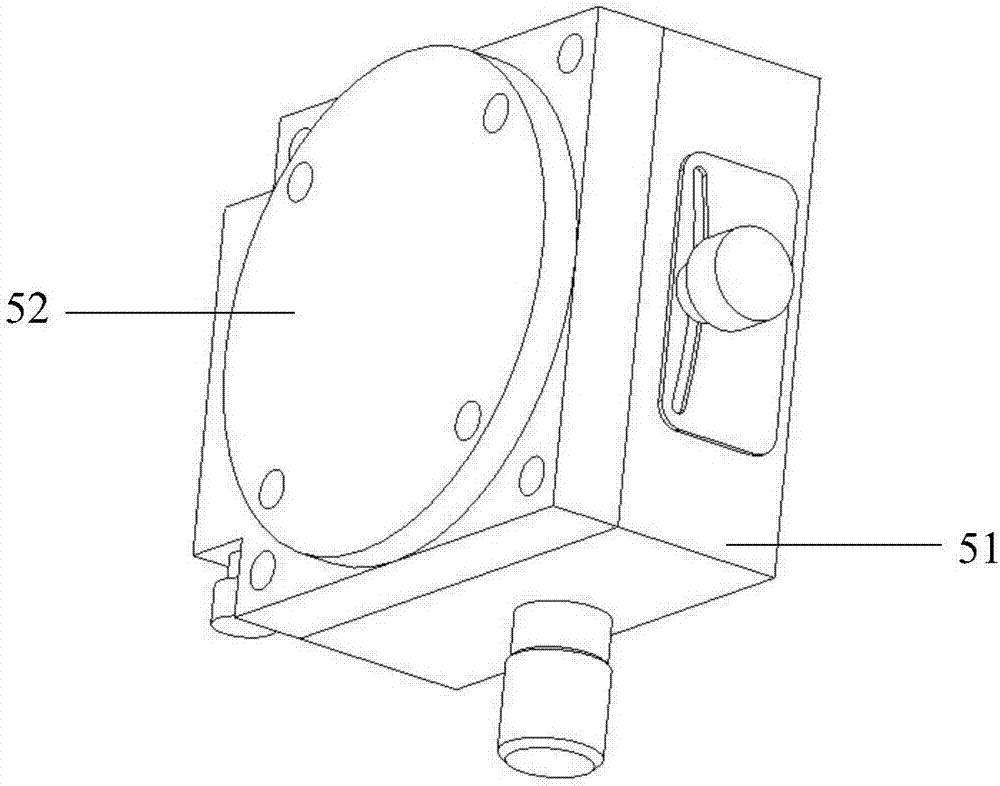

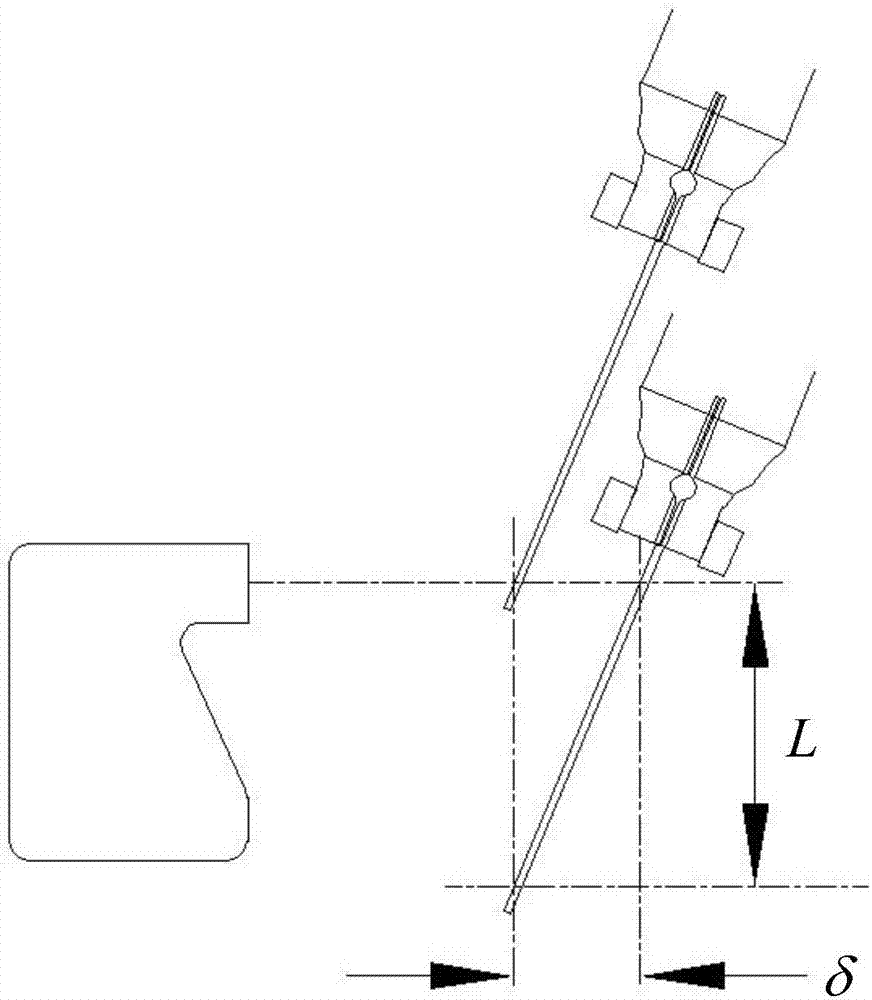

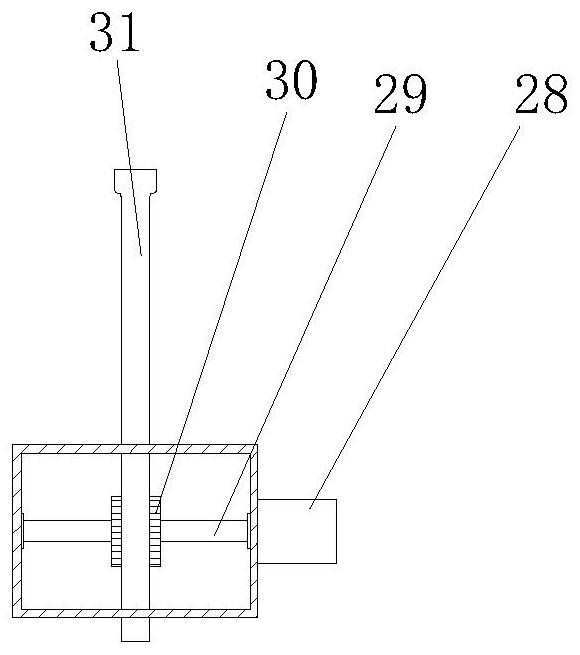

Precise ultrasonic punch and tool head angle adjusting method thereof

PendingCN107511938AGuaranteed punching accuracyPlay the role of protecting the tool headWorking accessoriesFine working devicesEngineeringUltrasonic vibration

The invention discloses a precise ultrasonic punch and a tool head angle adjusting method thereof. The precise ultrasonic punch comprises a frame, a guide rail, a slide block, an ultrasonic vibration system, a tool head, a feeding system, an angle adjusting device and a displacement sensor; the angle adjusting device comprises an X-axle angle micropositioner and a Y-axle angle micropositioner; the ultrasonic vibration system is mounted on the Y-axle angle micropositioner; the angle of the ultrasonic vibration system and the angle of a tool head can be adjusted through the angle adjusting device; the displacement sensor is mounted on the frame for detecting the difference of two measured values of the displacement sensors before and after movement of the tool head and the feeding quantity of the tool head along the guide rail; and the angle of the tool head is adjusted through the angle adjusting device according to the difference of the two measured values and the feeding quantity. The precise ultrasonic punch has the following advantages: the tool head can be precisely adjusted, so that the axis of the tool head is parallel to the guide rail, the punching precision is effectively guaranteed, and the effect of protecting the tool head is achieved.

Owner:HUAQIAO UNIVERSITY

Multi-plane punching die

The invention relates to part punches, in particular to a multi-plane punching die. The multi-plane punching die comprises an upper die mechanism and a lower die mechanism. The lower die mechanism isarranged below the upper die mechanism; the upper die mechanism is mainly composed of an upper die plate, a fixing sleeve, a convex die, an unloading plate and bevel wedges, wherein the convex die isconnected to the fixing sleeve; the unloading plate is slidably connected to the lower end of the convex die; and the bevel wedges are arranged on both sides of the lower end of the upper die plate. The lower die mechanism is mainly composed of a lower die plate, a reinforcing plate, stop blocks, a concave die, fixing seats, bevel hole convex dies and positioning pins, wherein the reinforcing plate is arranged on the lower die plate; the stop blocks are fixedly connected to both sides of the upper end face of the reinforcing plate; the concave die is connected to the upper end face of the reinforcing plate; the fixing seats are arranged on both sides of the concave die; the bevel hole convex dies are arranged on the upper portions of the fixing seats; and the positioning pins are arrangedon the lower portions of the fixing seats. With adoption of the structure, multiple different planes can be punched at the same time; the punching precision is ensured; the punching procedure is simplified; the production efficiency is improved; and the production cost is reduced.

Owner:丹阳市景顺塑料制品有限公司

Automatic abrasive paper punching and cutting machine

The invention discloses an automatic abrasive paper punching and cutting machine which comprises a punching and cutting main machine, a paper receiving table, a base, a mounting hole, a driving component, a sliding strip feeding frame, a rolling shaft, a fixing frame, a receiving channel, a receiving rod, a square groove, a rolling and unrolling rack, a deviation-rectifying shaft, a deviation-rectifying frame, a strengthening rib, a transmission roller, a footstand, a supporting column, a limiting block, a sliding groove, an inclined plate, a supporting shaft, a conveying roller, a conveying belt, a stud, a nut and a non-slip washer. One side of the driving component is provided with the sliding strip feeding frame, one side of the transmission roller is provided with the deviation-rectifying frame, one side of the deviation-rectifying frame is provided with the rolling and unrolling rack, the outside of the rolling and unrolling rack is provided with the square groove, and the receiving rod is arranged below the rolling and unrolling rack. The invention has the advantages of the simple structure, convenient assembling, reliable action, long service life and the like; and the deviation-rectifying frame is arranged and arranged in front of the rolling and unrolling rack, so that deviation rectifying is carried out on products in front of the punching and cutting device, the punching accuracy of the products, and the processing precision of the products is improved.

Owner:YANCHENG HUASEN MACHINERY

Punching auxiliary machining device for automobile aluminum alloy seat framework parts

PendingCN114850539AAvoid offsetGuaranteed punching accuracyAutomatic control devicesFeeding apparatusMachiningHydraulic pressure

The invention discloses a punching auxiliary machining device for automobile aluminum alloy seat framework parts, and relates to the technical field of automobiles. The punching auxiliary machining device for the automobile aluminum alloy seat framework parts comprises a closed box, a driving mechanism, a clamping mechanism, an overturning mechanism and a slag blowing mechanism, a hydraulic oil tank is fixedly installed on the inner wall of the closed box, punching equipment and a machine box are arranged in the closed box, and the punching equipment is located below the machine box. According to the automobile aluminum alloy seat framework part punching auxiliary machining device, the plate fixing frame can clamp and fix the two sides of a seat framework, the seat framework is prevented from deviating in the punching process, the punching precision of punching equipment is ensured, the bottom of the seat framework can be punched, and the punching efficiency is improved. The seat framework does not need to be manually loosened and then turned over and fixed, and the punching equipment can move front and back, left and right and up and down, so that the punching equipment can punch different positions of the seat framework.

Owner:湖州龙瑞电子科技有限公司

High-strength production equipment for pulling plate of transformer

InactiveCN112475350AGuaranteed punching accuracyHigh speed rotationDriving apparatusBoring/drilling componentsDrill bitLeather belt

The invention discloses high-strength production equipment for a pulling plate of a transformer. The high-strength production equipment for the pulling plate of the transformer comprises a rack and asupporting arm, the supporting arm is installed on the top side of the rack, a first hydraulic rod is installed at the top of the supporting arm, the telescopic end, penetrating through the top of thesupporting arm, of the first hydraulic rod is provided with a lifting table, and a plurality of supporting plates are vertically installed on one side of the lifting table. The first hydraulic rod onthe supporting arm extends to drive the lifting table to descend along a side frame, meanwhile, a servo motor works, a main belt wheel rotates, a rotating shaft is driven to rotate on a shaft seat through transmission of a belt and a driven belt wheel, and then high-speed rotation of a drill bit is achieved; and continuous descending is carried out until a lifting cylinder is firstly in contact with the top side of the pulling plate, continuous descending is carried out at the same time, a movable rod moves upwards in a mounting groove of a sleeve, compressing is carried out on a spring, thereactive force of the spring carries out limitation on the pulling plate through the lifting cylinder while the spring plays a role in buffering, and therefore it is guaranteed that during punching, the phenomenon of displacement of the pulling plate does not occur, and the punching precision is guaranteed.

Owner:WUXI PUTIAN IRON CORE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com