Multifunctional bending machine

A bending machine, multi-functional technology, applied in the field of bending machines, can solve the problems of increasing production costs and equipment procurement costs, single bending processing, difficult shearing, punching processing, etc., to save equipment procurement costs, guarantee The effect of machining precision and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below with reference to the accompanying drawings.

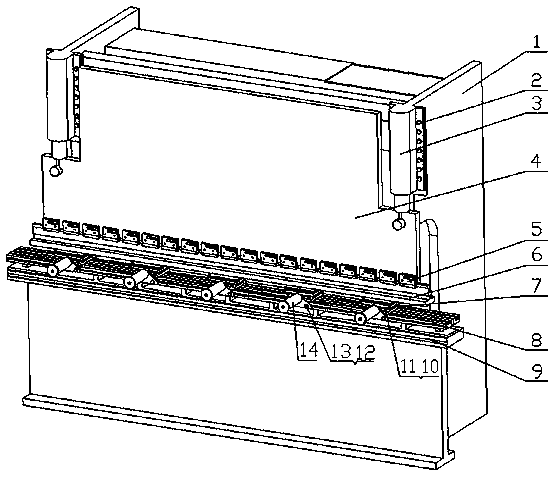

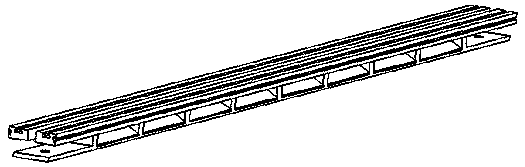

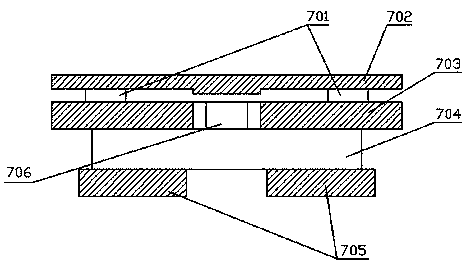

[0016] like figure 1 It is a schematic diagram of the structure of the present invention, a multifunctional bending machine, including a frame 1, a first bolt 2, a hydraulic cylinder 3, a tool rest 4, a pressing device 5, an upper die 6, a special die 7, and a general die 8 , worktable 9, second bolt 10, first pressing plate 11, third bolt 12, second pressing plate 13 and support device 14, the hydraulic cylinder 3 is fixed to the frame 1 through the first bolt 2, the knife The frame 4 is fixed on the piston rod of the hydraulic cylinder 3 by bolts, the upper die 6 is fixed under the tool holder 4 by the pressing device 5, the general die 8 is installed on the worktable 9, and the special die 7 is fixed by the second bolt 10 and the first. A pressing plate 11 is installed in the top T-slot above the universal die 8 , and the support device 14 is installed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com