Multi-plane punching die

A punching and die technology, applied in the field of multiple plane punching die, can solve the problems of cumbersome, not well guaranteed hole position accuracy, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

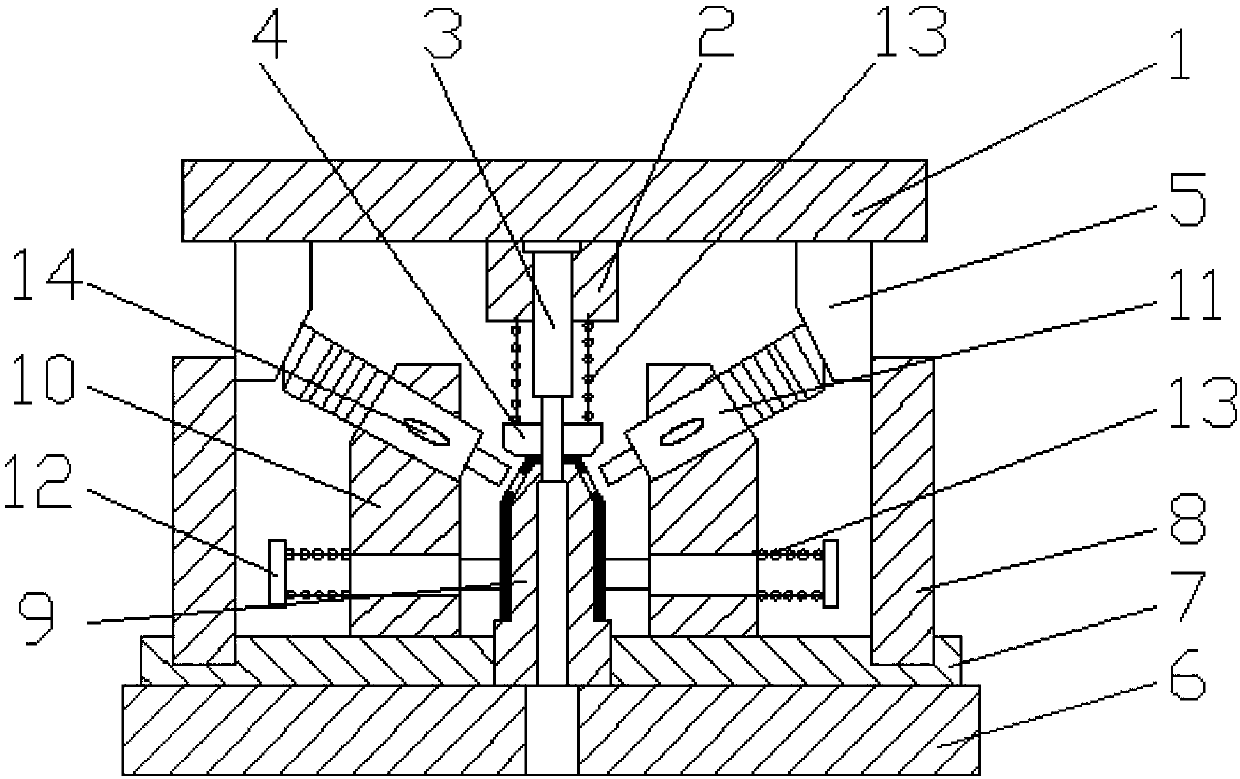

[0012] like figure 1 Shown is a plurality of plane punching dies, mainly composed of an upper mold mechanism and a lower mold mechanism; the lower mold mechanism is arranged below the upper mold mechanism; 3. The unloading plate 4 and the inclined wedge 5 are composed; the fixed sleeve 2 is set under the upper template 1, the punch 3 is connected to the fixed sleeve 2, the unloading plate 4 is slidably connected to the lower end of the punch 3, and the inclined wedge 5 It is arranged on both sides of the lower end surface of the upper template 1; the lower mold mechanism is mainly composed of the lower template 6, the reinforcement plate 7, the stopper 8, the die 9, the fixing seat 10, the inclined hole punch 11 and the positioning pin 12; the reinforcement plate 7 is set On the lower template 6, the stoppers 8 are fixedly connected to both sides of the upper end surface of the reinforcement plate 7, the die 9 is connected to the upper end surface of the reinforcement plate 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com