High-strength production equipment for pulling plate of transformer

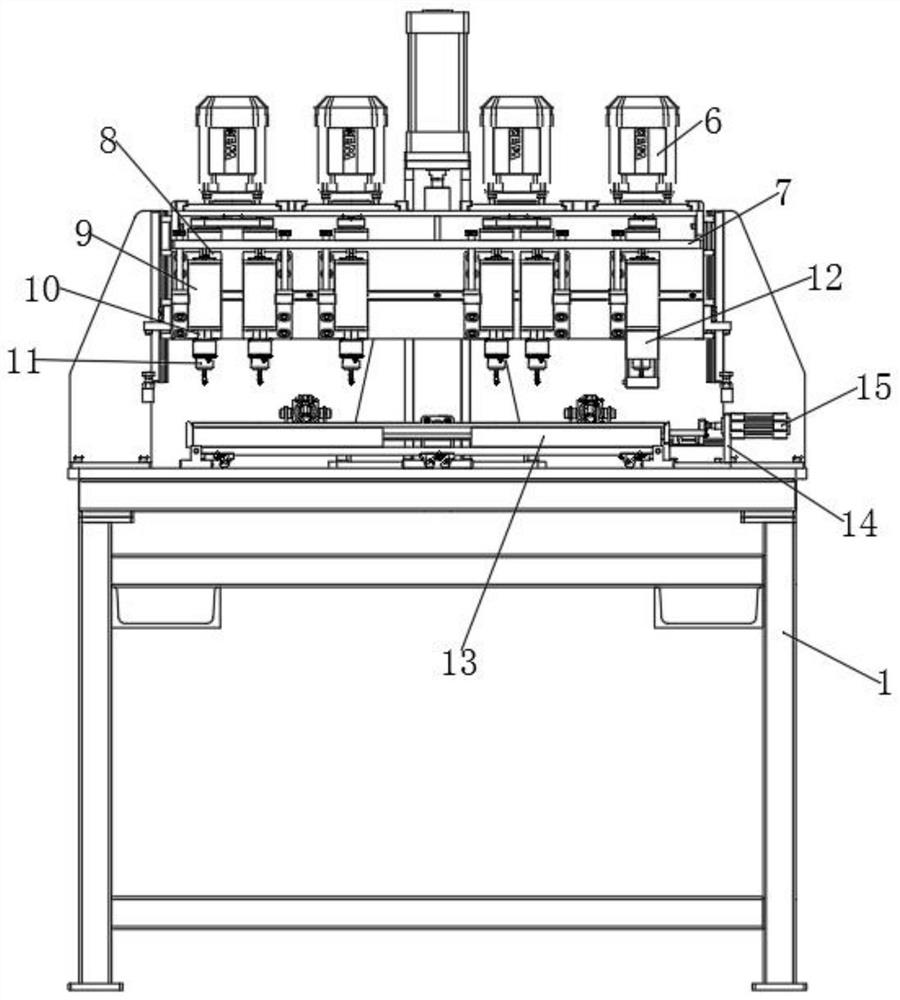

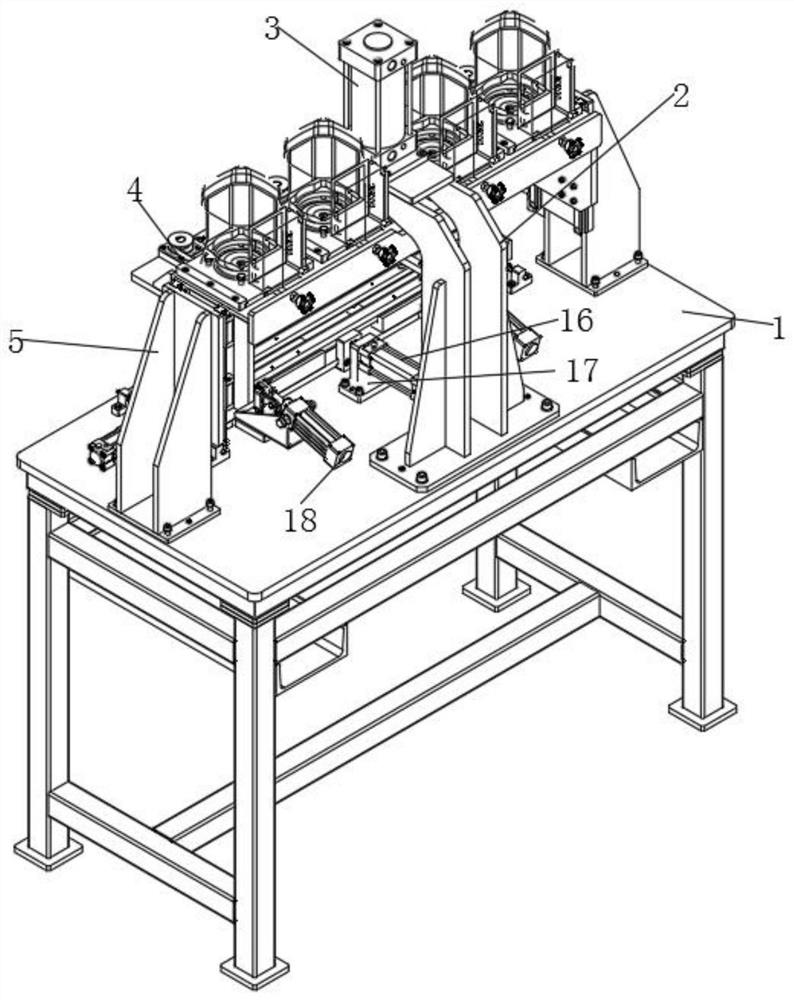

A kind of production equipment and high-strength technology, applied in the field of transformer processing, can solve the problems of drilling position deviation, pulling plate displacement, temperature rise, etc., and achieve the effect of ensuring the drilling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

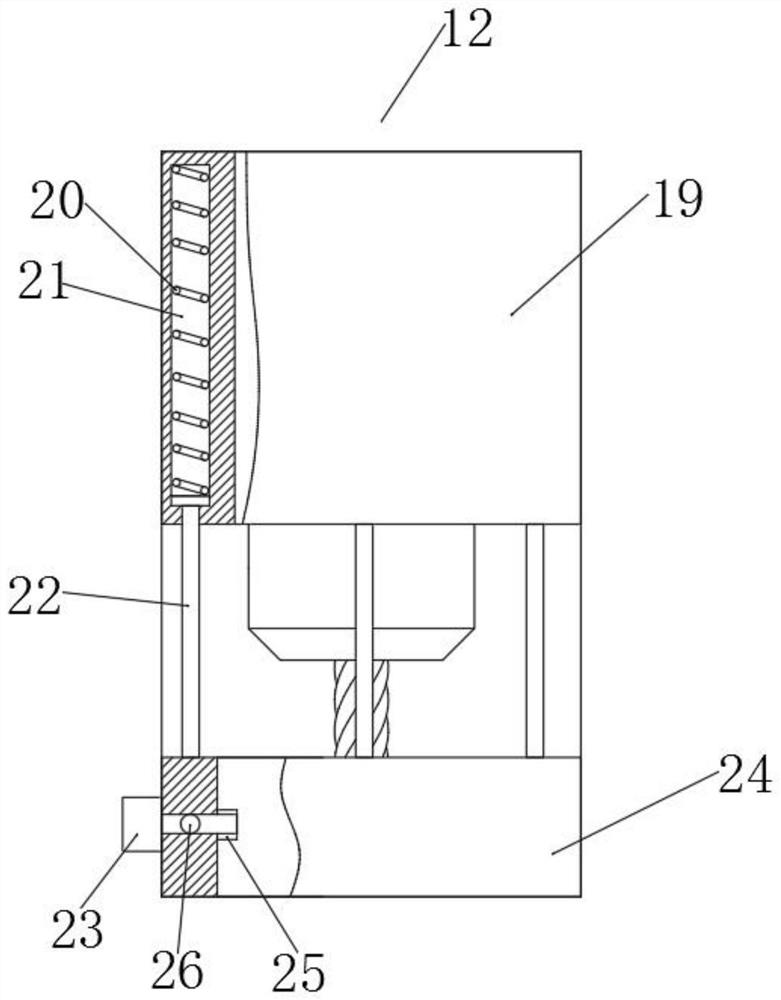

[0033] As an embodiment of the present invention, several installation grooves 21 are vertically opened inside the sleeve 19, and a spring 20 is installed inside the installation groove 21, and the spring 20 is connected with the top end of the movable rod 22, and the bottom end of the movable rod 22 is connected with the lifting The cylinder 24 is connected, and the elevating cylinder 24 first contacts with the top side of the pull plate, and at the same time continues to descend, and the movable rod 22 moves up in the installation groove 21 of the sleeve 19, compresses the spring 20, and plays a buffering role.

[0034] As an embodiment of the present invention, the external joint 23 is connected to the external water pump through a conduit, and the water pump is connected to the water tank, and the water pump transports the water in the water tank to the external joint 23 through the conduit, and then to the nozzle 25 through the internal channel 26 squirt.

[0035] As an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com