Punching auxiliary machining device for automobile aluminum alloy seat framework parts

A seat frame and auxiliary processing technology, which is applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of easy deviation of the workpiece, cumbersome cleaning, and inability to punch holes, so as to improve portability and improve Drilling accuracy, the effect of ensuring the drilling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

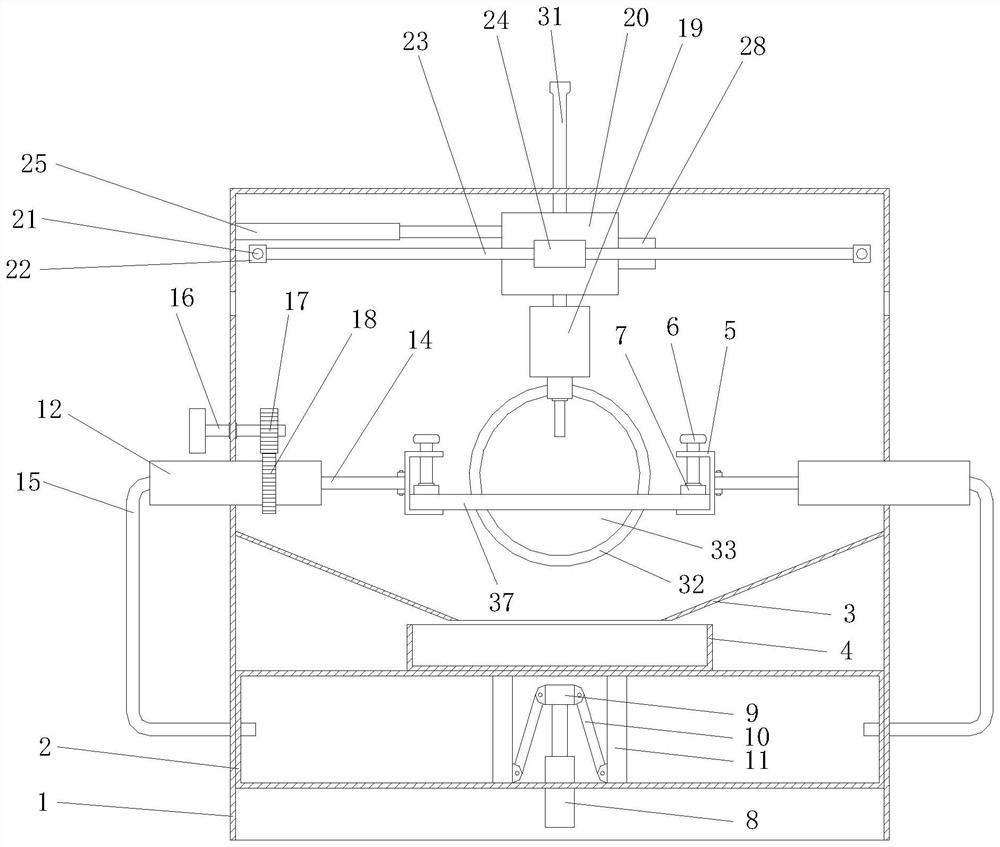

[0026] see Figure 1-6 , The present invention provides a technical solution: an auxiliary processing device for punching aluminum alloy seat frame parts of an automobile, comprising a closed box 1, a driving mechanism, a clamping mechanism, a turning mechanism and a slag blowing mechanism, and the inner wall of the closed box 1 is fixedly installed There is a hydraulic oil tank 2, a punching device 19 and a casing 20 are arranged inside the closed box 1, the punching device 19 is located below the casing 20, a seat frame 37 is arranged inside the closed box 1, and the driving mechanism is arranged in the closed box. 1, the driving mechanism can drive the punching device 19 to move up and down, left and right, front and rear, the clamping mechanism is provided on the closed box 1 and the hydraulic oil tank 2, the clamping mechanism can clamp and fix the seat frame 37, and the overturning mechanism is provided On the closed box 1 and the clamping mechanism, the turning mechanis...

Embodiment 2

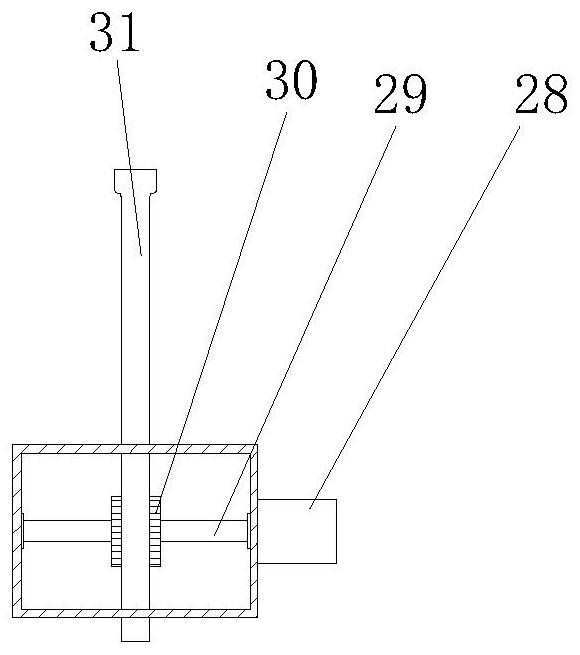

[0028] see Figure 1-6, On the basis of Embodiment 1, the drive mechanism includes a guide frame 21, a guide block A22, a guide rod 23, a guide block C24, an electric telescopic rod B25, a guide block B26, an electric telescopic rod C27, a motor A28, a rotating shaft 29, a rotating The gear 30 and the rack 31, the guide frame 21 are fixedly installed on the inner wall of the front and rear sides of the closed box 1, the guide block A22 is slidably installed on the outer wall of the guide frame 21, the guide block B26 is slidably installed on the outer wall of the guide frame 21, and the electric telescopic rod C27 It is fixedly installed on the front side of the guide block B26, the free end of the electric telescopic rod C27 is fixedly installed with the rear outer wall of the casing 20, the guide rod 23 is fixedly installed between the two guide blocks A22, and the guide block C24 is slidably installed on the guide rod 23, the box 20 is fixedly installed between the two guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com